How to change the stabilizer on a VAZ 2107

Part - anti-roll bar for VAZ 2105, 2107 cars is designed to reduce vehicle roll when cornering. It is an elastic steel rod mounted on brackets with rubber cushions to the front arms and the lower parts of the front side members.

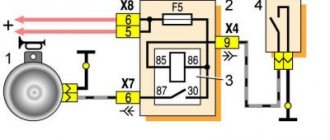

Main elements of the anti-roll bar

Notes and additions

Most often, rubber stabilizer pads fail. It is recommended to check and change them every 15,000 km.

On used cars, the attachment points of the stabilizer brackets to the side members often become rotten. For preventive purposes, it is recommended to periodically treat these places on the outside with bitumen mastic and spray the spars inside with a mixture of Movil and Pussala. For advanced cases, there are a couple of methods for repairing and restoring damaged areas (See “Restoring stabilizer mounts 2105, 2107”).

A stabilizer bent after an impact must be replaced, as it will tear out the fasteners.

— Knowing the catalog number of the stabilizer parts, you can easily purchase in the store exactly the part that needs to be replaced.

More articles on parts of VAZ 2105, 2107 cars

— Parts of the lower arm of the front suspension of VAZ 2105, 2107 cars

— Parts of the upper arm of the front suspension of VAZ 2105, 2107 cars

— Parts for fastening the shock absorber of the front suspension of VAZ 2105, 2107 cars

The compression of the springs on the left and right sides of the front suspension should be equal. Otherwise, the twisted bar, when straightened, may cause injury.

It is more convenient to change the pillows when the car is on wheels.

1. Using a 13mm wrench, unscrew the two nuts securing the stabilizer clip to the lower arm.

Before removing, mark the top of the bracket so that it can be reinstalled correctly.

2. Using a mounting spatula, press out the end of the rod and install a new pillow, having first moistened its hole with a soap solution.

We install the pillow so that its protrusion fits into the hole in the bracket.

If the stabilizer bar is deformed or if there is severe wear from contact with the pads, it should be replaced. To do this, remove the engine mudguard and the mounting brackets for the airbags.

3. Using a “8” head, unscrew the 12 screws securing the mudguard.

Remove the brackets securing the ends of the rod to the lower suspension arms.

4. Using a “13” socket, unscrew two nuts securing the two rod brackets to the side members from the bottom of the engine compartment

5. Remove the rod with mounting brackets

Install the stabilizer bar in the reverse order.

If the rubber bushings on the stabilizer bar of VAZ 2101-2107 cars are worn out enough, the car begins to feel not very stable on the road, the front end becomes loose and you have to catch the car on the highway at high speed.

The elastic bands are changed quite simply and in most cases they are what they buy, and the bar remains in place. But if the structure itself is damaged, it changes completely.

To perform this repair, you will need the tool shown in the photo below:

To begin this procedure, the first step is to apply a penetrating lubricant to all threaded connections that secure this structure, otherwise the bolts may break off when unscrewing, which happens quite often.

When several minutes have passed after application, you can try to unscrew the bolts and nuts, starting from either side, first unscrewing the side fasteners (clamps), which are shown in the picture below:

Then you can proceed to the central mounts, which are also located on both sides of the front of the car, on the right and left:

READ How to install hay day on a computer even a child can do it

When everything is unscrewed on both sides, the VAZ 2101-2107 stabilizer bar can be removed without any problems.

Installation is carried out in reverse order. The price of a new bar is about 500 rubles, depending on the place of purchase, of course!

Source

What are stabilizer bars used for?

To understand what the stabilizer link affects, you need to understand what function the stabilizer itself performs. Its purpose lies in its very name - car stabilization. When making turns, a centrifugal force begins to act on the car, which creates a certain roll, that is, tilts the car relative to the horizon. At such moments, the car’s suspension experiences heavy loads. Moreover, these loads are distributed unevenly: the outer side of the suspension when turning is loaded much more than the inner one. This is where the stabilizer comes into play. It distributes these loads on both sides so that they are loaded evenly.

This is what the front suspension stabilizer link looks like:

Car front stabilizer strut

The stabilizer strut (rod) serves as an element of the kinematic connection between the car body and the suspension, that is, it provides movable fixation of the stabilizer. How many stabilizer links are there in the front suspension? As a rule - 2 (on the left and right axle shaft).

Principle of operation

In order to understand the principle of operation of this suspension element, it is necessary to refer to its design. On the vast majority of cars, the stabilizer link is a rod measuring from 5 to 25 cm at the ends of which there are hinged fasteners (on some models the struts are made with hingeless fasteners).

If you understand the design of the rack and its purpose, the principle of operation of this element becomes obvious. With its movement, the rod ensures limited mobility of the connection between the stabilizer and the remaining elements of the suspension structure. The rods work together with the stabilizer: due to their design, they either press or hang the wheel. This reduces the vehicle's roll angle. That's what a stabilizer link is for.

The length of the element ranges from 5 to 25 cm, depending on the type of car and its suspension.

Please note that the rack design is not one-piece. The hinge is fastened by welding, and a so-called “neck” is formed at the fastening point. This trick is necessary so that when a critical load is placed on the rack, the location of its fracture is known, otherwise the rack could damage the bottom.

Purpose, design and principles of operation of the VAZ 2107 stabilizer

It has already been written above that the SPU is one of the important parts of the car. But why? The answer is simple - thanks to it, driving improves significantly, becoming more comfortable. This device makes it possible to keep the chassis tilt under control without increasing the pressure on the camber of the rear wheels.

The increased control over the vehicle on sharp turns is especially noticeable.

Thanks to the stabilizer, it will be possible to enter such turns at higher speeds without the risk of capsizing.

The roll bar SPU looks like a C-shaped hose that is installed next to the axle. The stabilizer is mounted on brackets with rubber bushings inside.

It is worth noting that the VAZ 2107 stabilizer bushing is the weakest point in the design and breaks most often.

The stabilizer works on the principle of distributing the load between two suspensions.

It works relatively simply - when making a sharp turn, the car can roll. Stabilizer, since one wheel lowers and the other, accordingly, rises. The stabilizer prevents this from happening by twisting the rod and raising the lowered wheel and lowering the raised one. Thanks to this, the car is leveled.

Malfunctions of the stabilizer struts

Malfunctions can be identified by knowing the symptoms and signs of malfunction. If problems occur in the operation of the stabilizer struts, the following symptoms appear:

- There is a characteristic knocking noise when driving on rough roads. This symptom occurs on machines that have racks with ball joints. For example, the stabilizer knocks when moving over a speed bump (an artificially created unevenness in the road to reduce speed).

- While driving on a flat road, the car pulls to the left and then to the right.

- During a normal turn, the car rolls (tilts) more than it was before.

- There is a lateral swaying of the car body when driving on a flat road.

Causes of breakdowns of stabilizer struts

The most vulnerable element in this assembly is the hinge joints. The reasons may be the following:

- The boot has ruptured, causing dust to get onto the lubricant and into the joint itself.

- The ball pin race has worn out. In this case, the ball pin dangles in the seat.

Repairing racks is a complex process. For this you need good factory equipment. You can simply replace the worn part, ball pin or bushing. The cost of such work is high. Therefore, it is better to buy new stabilizers. It is not necessary to buy original ones, you can buy regular ones, they also work well.

Source

Diagnostics

A breakdown can occur for a variety of reasons, so it is impossible to determine the exact time of full operation without breakdowns. Basically it all depends on the operating conditions. For example, if you often drive off-road, the stabilizer will break down often.

Basically, the SPU is checked during annual maintenance, but no one bothers you to do it yourself at any time.

First you need to remove the wheel. After this, use the steering wheel to make a maximum turn in any direction and shake the “bare” stand from side to side with your hand, grasping the middle third. If there are faults, looseness will be noticeable.

Signs of a broken rear stabilizer

The most common signs of failure are:

How should the stabilizer be positioned?

A correctly installed SPU should twist when the wheels turn.

Therefore, on passenger cars it is strictly forbidden to weld to the frame, since there must always be an intermediate link between it and the wheel. For example, in the VAZ 2107 bushings act as such a link. It is not recommended to use a stabilizer without them.

Causes of creaking stabilizer bushings

Drivers most often complain about bushings creaking either in cold or dry weather. But these are not the main factors and each driver may have his own reasons for this problem. They are individual for everyone. Main reasons:

Before replacing the anti-roll bar, you need to figure out what the problem is. Most often you just need to replace the rubber bands.

Why does the stabilizer bushing squeeze out?

In fact, the bushing is quite gentle to use. It can wear out pretty quickly. This mainly happens in winter. In cold weather, the bushing freezes, which can cause cracks to appear on it. Various reagents that are used to sprinkle roads during icy conditions can also play a role in this.

If the driver did not notice the problem in time, the cracks continue to grow. Because of this, the bushing begins to lose its elasticity. And so, at the next turn, it can simply be squeezed out of the eyelet. It is no longer possible to return it back - it is too worn out and will not be able to perform its direct functions.

READ How to install Windows 10 on a gpt disk via BIOS

After this, when entering a turn, the motorist may hear a creaking and grinding sound. The vehicle's handling will also decrease.

About double stabilizers

As the name suggests, there are two rods in this stabilizer. But such a device is installed only on the front wheels. Basically there are no fundamental differences.

Thanks to this SPU device, the stiffness of the suspension will increase significantly, which on the one hand is good, but on the other hand, some problems may arise. The fact is that on the classic VAZ 2107 the two front wheels operate independently of each other - that is, if the left front wheel lifts, the right one does not. But due to the installation of a double stabilizer, everything will change - the suspension will become semi-independent and the steering will become much stiffer, and the traction will become worse.

Therefore, before purchasing and installing a double SPU, you need to think carefully - either comfortable driving and good cross-country ability, or no roll.

Benefits of timely replacement

Replacing bushings is a simple process that any driver can handle. As they say - “if there is a desire.” If it is not there, it is better to contact a car service center, where you will be provided with professional assistance.

Thanks to the timely replacement of worn bushings, the anti-roll bar of the VAZ 2107 can last longer.

Thanks to the new bushings, driving on roads, regardless of whether they are of high quality or not, will become much more comfortable and safer.

Solution

Many beginners may experience problems or difficulties when replacing bushings. This section of the article will help you solve them.

When to replace transverse stabilizer bushings

SPU bushings are replaced immediately after wear is detected. If this is not done and you continue to drive with worn bushings, then irreparable problems may soon appear and then you will have to replace the stabilizer completely.

Installation materials and tools

In order to successfully change rubber bands you will need:

Sequence of operations for replacing rear stabilizer bushings on a VAZ 2107

Having prepared everything you need, you can begin the repair:

Video of replacing stabilizer bushings on a VAZ 2107. Useful video:

Let's summarize - the stabilizer for the classic VAZ 2107 is an extremely controversial tuning element. On the one hand, it increases the stability of the car, but on the other hand, it reduces cross-country ability and driving comfort. However, it has one undoubted advantage - ease of maintenance. Even a novice car enthusiast can cope with this. After all, the only part of the SPU that is subject to rapid wear is the bushings, replacing which will not be a problem for a person who has at least once held a wrench with a mounting blade in his hands.

Source

Front stabilizer VAZ 2107: purpose, repair, modernization

When maneuvering and making sharp turns in a car like the VAZ 2107, a roll occurs, which the stabilizer fights. Structurally, the front stabilizer of the VAZ 2107 is a steel rod (rod) of the appropriate shape, which is attached to the car’s suspension in four places. These places include the side members, as well as the lower suspension arms of the seven. Why the unit in question is needed and how its maintenance is performed, we will find out in detail.

Types of stabilizer struts

Firstly, the stabilizer struts are divided into front and rear, depending on the axles on which they are located. Stabilizers are not always available on the rear axles of cars, while almost all modern cars are equipped with front stabilizers.

Secondly, a distinction is made between active and passive stabilization systems. If in the case of a passive stabilizer everything is clear (classic all-metal construction with constant rigidity), then in the case of an active stabilizer everything is a little more interesting.

Modern technologies allow you to change the rigidity of stabilization depending on the type of road surface and driving speed (maximum rigidity for cornering at high speeds, medium – on dirt roads, when driving off-road, the stabilizer can be turned off altogether). There are several ways to achieve different hardness:

- the use of hydraulic cylinders instead of racks;

- use of active drive;

- and the use of hydraulic cylinders instead of bushings.

Stabilizer link elements

Purpose and design of the VAZ 2107 stabilizer

The design of the front suspension of cars of the VAZ 2101-07 family uses a front stabilizer, the task of which is to distribute the load as efficiently as possible. This is the load that the suspension of a domestic car experiences when turning and performing maneuvers on the road. Due to the presence of a stabilizer, the occurrence of a roll is eliminated, and the car is kept in a horizontal position. If you remove the front stabilizer, the driver will immediately feel how much the car will shift to one side during sharp turns or maneuvers. Moreover, the rolls are so large that the vehicle can tip over.

Structurally, the part of the suspension of the VAZ 2107 car under consideration consists of a long rod, which has the shape of the letter U. The rod is made of special steel, which has increased elasticity.

This is interesting! Springs for cars are made from similar steel, which have high strength, memory, and resistance to deformation.

The part in question is fixed using a bracket with a rubber bushing. The ends of the bar are secured to the lower control arms, and the middle area is secured to the front of the body. During operation, depending on the mileage and driving habits of the car, wear occurs on the rubber bushings or stabilizer pads. When they wear out, they need to be replaced. However, first let’s look at the design of the unit in question:

READ How to install psp emulator on xbox 360 freeboot

Bushings made of rubber material are needed to soften the connection of steel parts. The stabilizer is attached in 4 places, but there are 6 brackets for fixation in its design.

The bar is activated only when the body shifts when turning or maneuvering. When driving in a straight line, the device is practically inactive. When maneuvering, one end of the device bends upward and the other downward, which leads to balancing stability. The harsher the driving style, the faster the rubber bushings of the front stabilizer on the VAZ 2107 will wear out.

Stub maintenance

The part in question rarely fails, however, as soon as the vehicle becomes unstable on the road, it is time to make repairs. When operating a classic, several types of malfunctions of the VAZ-2107 anti-roll bar bar occur. Some of these malfunctions include:

Servicing the SPU is a simple process that includes replacing the rubber bushings. To change them, you will need to dismantle the part, remove the worn rubber bands, and replace them.

It is important! It is recommended to change all rubber seals of the stabilizer so that you do not have to replace it again after a short period of time.

Most often, rubber seals have to be replaced, and cases of stud breakage rarely occur. Usually the result of a breakage is extreme driving, so in order to prolong the life of the studs, it is advisable to drive moderately. Identifying a device malfunction is quite simple. If a roll occurs on sharp turns, accompanied by the formation of loud sounds, this means that the end of the rod has become free and is now in contact with the metal of the lever.

Changing classic stabilizer bushings

We recommend inspecting the bushings every 30–50 thousand km. However, parts can last 100 thousand or more if you drive moderately and do not overload the suspension. You can detect wear visually, but to do this you should look under the front end. The presence of cracks in the rubber bands, as well as visible gaps between them and the bar, indicate that the bushings need to be replaced. The more wear the rubber bands have, the higher the chance of hearing unpleasant knocks in the suspension and experiencing a deterioration in the car's handling. To restore the original controllability and control confidence, you will need to replace the VAZ 2107 stabilizer bushings.

To replace the rubber bands, you will need to completely remove the bar from the suspension. It is recommended to carry out work on replacing the device directly from the inspection hole or by placing the car on an overpass. The algorithm for replacing stabilizer bushings is as follows:

At this point, the replacement process is considered complete, and all that remains is to lower the front part and test the unit in action.

Checking the wear of the stabilizer links

There are certain “symptoms” by which a car owner can understand that it is time to change the stabilizer struts. These include:

- the car goes off course with free steering (if you take your hands off the wheel), but this can also indicate other malfunctions of the car;

- characteristic knocking noise when driving over rough terrain and when turning;

- the right or left side of the car is higher than the other (roll when parking or driving straight);

- swaying when starting to move (starting), braking (slowing down) or making turns;

- significant deterioration in vehicle controllability.

There are several ways to check the wear of the front stabilizer links to ensure their suitability:

- you need to turn the wheels all the way, grab the stabilizer link with your hand and try to loosen it from side to side. If at the same time a knock is heard or the rack gives in, this is a signal of its malfunction (the presence of play is unacceptable!);

- An almost similar check can be performed in a special pit by holding the stabilizer itself.

If it wobbles or knocks when moving, this is another signal of a breakdown. Also, the last two methods can be used to check the serviceability of the racks immediately after replacing them.

Replacing racks

Many people ask the question: is it possible to drive without a front strut stabilizer? When driving this way, an uneven load on the elements of the car occurs, as well as a deterioration or even complete loss of controllability (excessive controllability may occur, etc.), roll when turning will increase, the car will become less stable, therefore experts strongly advise replacing the struts on time and according to regulations, if their presence is provided for by the design of the car. It is recommended to replace the bushings and struts of the front stabilizer together.