Causes: fuse, relay, connector

The pump power circuit includes many elements: closed relay contacts 5, fuse 3 (15 A), “+” wire, “pump-to-ground” wire. The most “difficult” defect is a short circuit of the “+” wire to ground. By the way, the cord itself is laid on metal, so such a defect cannot be ruled out.

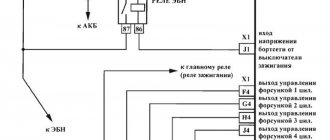

Mounting block for dashboard

Both the relay and the fuse are located in a block located under the dashboard on the right. A fuse can blow in two cases:

- The “+” cord makes contact with ground;

- The motor resistance decreases due to overheating.

The first defect may be “floating”, and then it will be difficult to identify. But before calling an electrician, try checking everything else:

- Relay 5 should click twice: when the ignition is turned on and after 1.5 s. If this does not happen, replace the relay;

- Check fuse 3. If it is blown, you need to look for the cause.

Consider the situation: the relay is working, but the fuse is blown. Then we do this: disconnect the pump connector, install a new fuse and measure the voltage at the terminals. Details are below.

Connectors under the hatch, disconnecting them

You need to remove the hatch under the rear seat: two screws are unscrewed with a Phillips screwdriver. Next you need to disconnect the connector on the module, and then move on to the block under the dashboard.

First, turn off the fuel pump!

Replace the fuse. Let's move on to the fuel pump: connect the probe (zero cord) to any of the mounting studs. Voltage should appear on the “gray” wire when the ignition is turned on. And also check the potential difference between the “gray” and “black” wires - it should be equal to 12 volts, and also at the moment the ignition is turned on. Wiring:

- The two outer cords are the FLS sensor;

- “Black” – minus power supply;

- "Grey" is a plus.

The "black wire" sometimes loses contact with ground. At the last step, we checked exactly this version.

There are reviews from owners that say: the fuel pump on a VAZ-2112 does not work if the electric motor is working properly and there is voltage in the connector. This happens when the contacts of the internal terminal block oxidize (see photo).

Internal connector - yellow

Getting to the connector on the motor is not easy - you need to remove the fuel pump module by unscrewing 8 nuts around the perimeter.

Diagnosing the fuel pump

Safety precautions

Before unscrewing the nuts, you need to disconnect the two hoses. But first try starting the engine. The power supply to the fuel pump is not connected.

Please note - the power is turned off here!

Everything is ready for dismantling if:

- External connector is disabled;

- It is impossible to start the engine, although the on-board network is not de-energized;

- It is better if the tank is filled less than 50%!

You need to unscrew two fittings from the module cover (top photo). Then use a socket wrench to unscrew the nuts from the studs and remove the retaining ring.

There is very little left to the internal connector

Having gained access to the internal connector, you need to clean its contacts. Assembly is carried out in reverse order. Good luck!

Oxidation of the terminals of the internal connector is a typical disease of the VAZ-2112 fuel pump, and only one of the contacts does not work. The “+” terminal is more often oxidized.

Removing the pumping unit

Before starting work, you must disconnect the terminal from the battery. This will prevent damage to electrical equipment. In addition, replacing the fuel pump may cause a fire.

Let's prepare tools and materials. To remove the VAZ-2110 fuel pump, you need the following:

- Screwdriver.

- 10mm socket wrench.

- Collar.

- Open-end wrench 13.

- Rags.

The device itself is located under the rear seat cushion. To get to the installation location of the fuel pump 2110, you need to remove the seat. Under the casing we find a hatch. We unscrew the hatch. Disconnect the electrical drive connector.

Using an open-end wrench, unscrew the tips of the fuel pipes. We pull off the pipes. Using a spanner, unscrew the 8 nuts around the perimeter of the clamping ring. Release the flange.

There is a gasket under the pressure ring of the fuel pump 2110. The gasket is removed. It is better to change worn tires.

Then we raise the VAZ fuel pump together with the float. Gasoline will leak from the body. To avoid staining the interior, place a rag. There will be up to 1 liter of gasoline left in the old building. Drain it into the tank.

Assembly is carried out in reverse order. There is an arrow on the top of the cover. It should point towards the trunk. This is the correct pump position.

When replacing, do not forget to remove the float and level sensor.

These spare parts are installed on the new structure.

All operations, including preparation, will take less than an hour. After replacement, perform a test. Start the engine. Finally, you should check the fuel pump, make sure the connections are tight and there are no leaks.

Advantages of injection models

The main function of the pump is to supply fuel to the combustion chamber. It must meet certain requirements. The main criterion is pressure.

The pumps for injection and carburetor engines are different. Thanks to the engine with direct fuel injection, there is no need for preliminary preparation of the combustible mixture. As you know, the carburetor is the weak link. Difficult adjustments, clogged jets, difficult starting in cold weather create inconvenience for owners of classic VAZ brands.

Tens and VAZ-2112 internal combustion engines have significant advantages. Let us note the advantages of injection units:

- support for environmental standards;

- direct injection into the combustion chamber;

- fuel economy;

- system reliability;

- increased engine power;

- starting a cold unit without warming up;

- dispensing a portion of the mixture;

- The fuel module is controlled electronically.

Unfortunately, the injector has a number of disadvantages. Maintenance and repairs have to be carried out at a service station. It also requires qualified personnel and a computer to determine the malfunction of electronic components. Let us point out other disadvantages:

- design complexity;

- high requirements for the octane number of gasoline;

- complex diagnostics and repairs;

- expensive spare parts and equipment.

How do fuel pump breakdowns manifest themselves?

We will not consider a broken relay or a blown fuse as a serious reason. Sometimes the relay itself is enough to be removed and inserted into place, and the system will work; the contacts are simply oxidized, and the fuse needs to be tested with a tester and, if necessary, replaced with a similar one.

A much less pleasant situation is when the coarse filter, which is located in the fuel module along with the pump, becomes clogged. The symptoms of a breakdown are floating, so it’s quite difficult to immediately understand what needs to be done. The first signs of a clogged coarse filter:

- reduction in engine power;

- lack of traction at high speeds;

- Unstable engine operation at low and idle speeds;

- Difficulty starting the engine.

Signs of a fuel pump malfunction

Using these signs, you can determine that the fuel pump is not pumping.

- The most common sign of a faulty fuel pump is that the car drives intermittently. While driving, the car begins to sharply slow down and then accelerate. Uniform movement of the vehicle is ensured by a continuous supply of fuel.

- The second most common symptom is floating engine speed at idle. This way you can determine if the fuel pump is faulty before you start driving.

- The engine starts with difficulty or does not start at all. Quite often this happens because the fuel pump has completely failed. The symptom is not the most common, since the reason that the engine does not start may lie in a variety of malfunctions.

- The car's dynamics deteriorate. When you press the gas pedal all the way to the floor, the car jerks or does not respond at all to moving the pedal. In this case, the fault may lie not in the pedal, but in the fuel pump.

We recommend: Replacing silent blocks by professionals - quality guarantee

Do not forget that all the signs listed above are not one hundred percent. Such malfunctions can be caused by failure of various other engine parts. The engine speed may well fluctuate due to a malfunction of the mass air flow sensor or throttle position sensor.

Such malfunctions most often occur due to low quality fuel or uncleaned injectors.

Model selection

It is best to install an imported fuel pump on the VAZ 2110 injector, capable of delivering a performance of up to 7 atm. It will not only last much longer, but will also ensure better and longer operation of the injector and improve the quality of the mixture at the outlet of the nozzle.

You should know that Bosch fuel pumps usually differ only in length, location of terminal connectors, and sometimes in the diameter of the housing. Therefore, it is advisable to either go shopping with an old device, or make some minor modifications at home.

Bosch fuel pump

To avoid buying a fake, keep in mind that any Bosch gas pump is packaged in very durable packaging. The bag contains purified gasoline in which the device is immersed. If you smell it, it means the seal is broken, corrosion may begin inside the pump, it’s better not to buy one.

You can get acquainted with the malfunctions of the VAZ 2110 fuel pump here: https://vazweb.ru/desyatka/pitanie/toplivnyj-nasos.html

It is necessary that the gasoline level is no more than half the volume of the tank. Next we proceed like this:

- Disconnect the negative battery;

- Removing the back seat;

- Remove the cover from the hatch;

- Disconnect the electrical connector;

- We remove the fuel supply pipe by unscrewing the fitting;

- We do the same with the drain pipe;

- Remove the clamping ring (it is secured with nuts 7);

- Carefully remove the float from the hole in the tank, remove the electric fuel pump along with the fuel level sensor;

- Using a screwdriver, disconnect the fuel level sensor;

- We remove the clamps and remove the fuel pump itself from the guides;

- Reinstalling a new Bosch pump is simple and straightforward.

You just need to consider a few points:

- If you installed not a new, but a refurbished pump on a VAZ injector, lubricate the centering bushings (WD-40 grease is usually used);

- The fuel pump with a fuel sensor is installed in the tank so that the arrow on the flange faces the rear of the car;

- Be sure to check that all o-rings are intact, but it is best to replace them with new ones.

After replacement, start the engine and check what pressure the fuel supply system produces and whether there are any leaks.

Purpose and principle of operation of the fuel pump

The fuel pump is designed to pump fuel from one point to another. In a car, the role of the first point is played by a fuel reservoir - the tank, and the second - by the engine, where the pumping takes place. This process occurs at a certain pressure, which is maintained by the pump reducer, which is a very important point.

Fuel pump diagram

Fuel pumps are divided into 2 types according to the type of drive: electric and mechanical. Inside the first there is an electric motor with a mini-pump, which operates from the mains and uninterruptedly pumps fuel into the engine. The second type is becoming increasingly rare, as it is installed on carburetor cars, and operates due to the reciprocating movement of the lever.

Fuel pump diagram

VAZ 2110 fuel pump, carburetor engine, VAZ 2110 fuel pump injector

Do-it-yourself wheel alignment: step-by-step instructions

A VAZ 2110 whose gas pump acts as a gasoline supercharger is unlikely to be able to move independently without this small but very important unit. Let’s say right away that the fuel pump of the carburetor “ten” is mechanical, and the VAZ 2110 injector has an electric fuel pump

Today we’ll talk about both in detail.

So, a mechanical fuel pump for a VAZ 2110 carburetor engine is installed between the valve cover and the ignition distributor, in the engine compartment. Actually, this arrangement allows you to receive reciprocating torque from the shaft, which goes from the camshaft to the ignition distributor. Thanks to the eccentric on this shaft, movements through the rod are transmitted to the fuel pumping lever. The lever itself, in a reciprocating motion, sucks in fuel through a membrane. By the way, this pump, like all pumps starting from the VAZ-2101 model, has a manual fuel pumping lever. This is quite convenient, as it allows you to quickly check the operation of the mechanism literally with your bare hands. Photo of the VAZ 2110 mechanical pump itself is below.

This is what a mechanical pump looks like in cross-section, look at the schematic drawing.

The VAZ-2110 mechanical fuel pump consists of the following elements -

- 1 – discharge pipe

- 2 – filter

- 3 – body

- 4 – suction pipe

- 5 – fuel pump cover

- 6 – suction valve

- 7 – rod

- 8 – manual fuel pumping lever

- 9 – spring

- 10 – cam

- 11 – balancer

- 12 – mechanical fuel pumping lever

- 13 – lower cover of the fuel pump

- 14 – internal spacer

- 15 – external spacer

- 16 – discharge valve

Removing and installing a VAZ 2110 mechanical pump does not cause much difficulty. It is enough to remove the air filter, loosen the clamps of the incoming and outgoing fuel line hoses, remove these hoses, then unscrew the two nuts securing the pump itself and you can remove the mechanism from the two studs on which the fuel pump hangs. During installation, it is advisable to replace the gaskets that are on the thermal insulation insert.

Causes of malfunctioning fuel pump

Fuel pumps are different. It all depends on the specific brand of car and the characteristics of the pump itself.

Knowing the causes of problems in the vehicle’s fuel system is a necessary condition for its successful repair. Problems may arise for the following reasons:

- Wiring problems: Wires have become dirty, rusted, or melted. As a result, the electric voltage decreases and fuel pumping becomes more difficult.

- Debris and dust getting into the gas tank. Rust in the tank. As a result, the fuel becomes unclean and causes problems. Poor quality fuel also pollutes the gas tank.

- Filter dirty. Fuel pressure decreases and the functions of the device are weakened.

- Driving with an empty tank. This leads to a decrease in pressure and overheating. It dries out and becomes damaged.

To effectively treat a living organism, it is important to know not only the symptoms, but also the causes of the disease. It’s the same with the operation of car systems: you need to find out the causes of problems in the operation of the fuel pump

The gasoline pump is one of the key elements of the automobile fuel complex. It is responsible for transferring fuel under pressure to the injectors (when the car uses a system in which fuel is injected) or to the carburetor. Like other parts of the car, the pump may stop working properly.

The device can be mechanical or electrical. It all depends on its functional characteristics and structure.

How to check functionality

This is easy to do at home. First you need to remove the pump and place it in a vice. Then connect a hose to each branch pipe. One hose must be directed into an empty container, and the other into a container with gasoline. The mechanism must be pumped by hand. If the fuel moves from hose to hose, then you can be happy. This means everything is fine. If this does not happen, then most likely the part needs to be replaced.

Knowledge of the operation of all vehicle systems and experience in troubleshooting them will help save money and provide invaluable assistance in the event of a breakdown far from populated areas.

BOSCH fuel pump VAZ 2110 – pros and cons

Among manufacturers of automotive electrical equipment, the most reputable is BOSCH. The combination of affordable prices and good quality allowed this brand to conquer the shelves in every auto goods store. However, counterfeit manufacturers do not sleep and have flooded the market with their products of worse quality.

How to choose a Bosch fuel pump of original quality for a VAZ 2110

Despite the high-tech equipment of factories with counterfeit activities, it is possible for the buyer to identify original products from counterfeits. This guarantees the car owner that the service life declared by the manufacturer for the Bosch fuel pump for the VAZ 2110 will be observed.

A fake is identified by the following criteria:

- the corners on the packaging stickers are sharp, not oval like on the original;

- typos and errors in the text of the accompanying documentation;

- the pump is packed in a vacuum plastic bag without oil;

- the date of manufacture and shift number may be poorly printed on the case or missing.

Helpful information! The price difference between the original and the replica can be 2-3 times the cost. As a result, “enterprising” sellers can replace the original with a fake, because it is impossible to visually distinguish spare parts without knowledge.

Bosch fuel pump performance and characteristics

The manufacturer BOSCH produces a pump for each fuel system with certain pressure parameters. It is not necessary that the pressure strictly correspond to the performance characteristics. The main thing is that it should not be less, otherwise it will not be enough for the normal operation of the fuel system. As for the excessive pressure, in this case the return line helps out by returning the fuel to the tank.

For example, if there was a fuel pump from a VAZ 2110 (3.5 bar), then installing an analogue with parameters of 4.0 bar will not make things worse, but vice versa. Fuel economy may increase, since the spraying in the ramp will be of better quality.

If you are going to repair a VAZ 2110 fuel pump (injector) yourself, then you should purchase an electric motor with number 0580453453. In addition to the Togliatti family, a part with this code is installed on some RENAULT models.

Table 1. Characteristics of the fuel pump for VAZ 2010-12

| Options | Indicators |

| Manufacturer code | 0580453453(BOSCH) |

| Type | submersible |

| Productivity (hp) | 60 |

| Revolutions per minute | 5600 |

| Pressure maximum (kPA) | 650 |

| Minimum pressure (kPA) | 450 |

| System pressure max. (kPA) | 350 |

| System pressure min. (kPA) | 100 |

| Current consumption (A) | 5 |

| Voltage (V) | 6-13 |

| Diameter (mm) | 38 |

| Length (mm) | 111,4 |

| Cost, rub) | 2 800 |

Many car owners of the “tenth” family do not have the desire to immediately purchase a Bosch fuel pump for their VAZ 2110 (8-valve injector), since its cost of over 2,500 rubles significantly impacts the personal budget. However, having experienced failure after installing a fake, you can hear an objective assessment from the first person, which has its pros and cons.

Table 2. Advantages and disadvantages of the BOSCH 0580453453 fuel pump

| Advantages | Flaws |

| Durability | High price |

| High quality | |

| Easy to install | |

| Adds dynamism to the car | |

| Stable pressure | |

| Warranty at point of sale | |

| Suitable for all VAZ models |

Turning to the site with reviews, it turned out that many attribute such a disadvantage as a high degree of fakes. But this is hardly worth adding to the cons section.

How to check and replace the fuel pump relay

If the electric fuel pump does not show signs of life when the ignition is turned on, this does not mean that it has burned out. The cause of the breakdown may also be the “relay”. The simplest method of checking the fuel pump relay is by ear - it should click when the ignition is turned on. If you don’t hear a click, then most likely the relay is faulty.

However, everything is not so simple - the breakdown can be “tricky”, for example, the car does not start the first time. The cause of the breakdown may be burnt relay contacts.

In this case, checking the functionality of the pump is very simple:

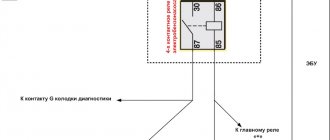

- Remove the protective cover that hides the fuse and relay block.

- Unscrew the fastenings of the block and remove it; it will remain attached to the wires.

- Pull the relay out of the block and place a jumper between 2 opposite contacts, so we will supply power directly to the fuel pump.

- If the electric motor of the fuel pump begins to make noise with this connection, it means that most likely the fuel pump itself is working, and the fault lies in the relay. In this case, replace the relay.

Fuel pump relay and fuse

As soon as the ignition is turned on, the pump motor starts working - this is indicated by a characteristic sound. Complete silence indicates a breakdown.

Thus, the relay protects the circuit from high inrush currents, sometimes reaching 80 or even 300 amperes. The operating principle of this element is as follows: voltage is supplied to an electromagnetic coil, which attracts the armature and closes the contacts.

The relay in question can withstand 30 amperes. Exceeding the specified indicator disables the element (its winding may burn out).

To detect a relay in an injection machine, no pinout is needed - the unit is located in the cabin, under the instrument panel. Remove the housing (unscrew the 2 screws) and you will see three elements. The one you are looking for is exactly in the center.

The location of the fuel pump fuse is to the left of the relay. By the way, it is also capable of burning out, and therefore the test begins with it. Do this:

- pull out the fuse and inspect;

- make sure the block is not broken;

- replace if necessary.

Sometimes the fuse blows right away. This means that the wiring is shorted (the insulation can be corroded by oil, or it can fray due to vibration). If there is no pinout, the required cores are found with a tester.

Also, the fuse-link burns out when the pump motor itself short-circuits.

When should you check your fuel pump?

It is necessary to check all potentially faulty components one by one, and the fuel pump first.

Problems when starting and running the engine are not always associated with the fuel pump. Sometimes the signs of a fuel pump breakdown are the same as those of a faulty fuel pressure regulator , injectors or jets, spark plugs and high-voltage wiring. Even experienced specialists who know by heart all the signs of a “dying” pump cannot unambiguously determine the type and cause of the breakdown the first time, and it is necessary to check all potentially faulty components one by one. In this case, the fuel pump is usually checked first. In this case, there are two types of malfunction - the fuel pump does not work at all or does not produce the required pressure. In the first case, the malfunction can be recognized by ear, since it should start when the ignition is turned on. In the second case, you need to know how to check the pressure of the fuel pump. Here you need to use a special pressure gauge. We list the main symptoms of a fuel pump malfunction:

- the engine does not start;

- the engine is unstable;

- the engine lacks traction during sharp acceleration;

- The engine lacks traction at low speeds.

We recommend: Is it possible to mix antifreeze with antifreeze?

Where is the Fuel Pump Relay for VAZ 2110 Injector ~ AUTOINTERLINE.RU

For what reasons can you not pump out a gasoline pump

on VAZ-2110

The smooth operation of the VAZ-2110 car directly depends on the fuel system. If it is not properly maintained, it will fail very quickly. Therefore, when the car does not start in the morning, there is a problem in the fuel supply system. In most cases, this is due to the condition of the gasoline pump. The main role of the gasoline pump. fuel supply and pressure maintenance.

THIS IS INTERESTING: Fuel sensor VAZ 2110

Gasoline pump diagnostics

If the fuel tank is full, the battery is in good condition, the spark plugs are dry and sparking, and the starter turns the engine, then the cause is the gasoline pump. The most common reason is that there is no power being supplied to the petrol pump after the ignition is turned on. The same is true when the car is moving, when power is lost and the engine begins to stall. Another important nuance is the supply of the required amount of fuel.

The pump can be operational, create noise and noise, that is, a power source, but does not create the required pressure.

The pressure in the fuel system with a working gasoline pump of more than 3 bar is considered normal. This pressure is collected in the fuel rail and corresponds to 300 kPa. To check the condition, you need to take a pressure gauge and measure the pressure in the fuel rail, taking into account those indicators that are considered normal for each individual model.

For a VAZ-2110 with an injector, the pressure at the moment the ignition is turned on should show at least three atmospheres, at idle speed. 2.5, and when you press the accelerator pedal. from 2.5 to 3 atmospheres. This method allows you to accurately determine:

- The pressure regulator output is faulty.

- Faulty fuel pump or reduced efficiency due to wear.

- The filter or mesh is heavily soiled.

A decrease in pressure leads to the fact that the engine does not start or does not start with difficulty, begins to touch, and failures occur during operation. If the pump is faulty, then the coarse screen of the gasoline pump may be clogged.

In this situation there is no need to change the entire block, you can clean the mesh or place a new one. If you suspect that the gas pump is not receiving power, you will need to turn the ignition on and listen. When the gasoline pump is running, you should hear a slight noise or hum.

And if you don't hear anything, then there is a problem with the operation of the gasoline pump or the wiring to it.

RELAY

AND FUSE FOR PETROL PUMP VAZ 2110

, 2111, 2112 LADA. FUEL PUMP DOES NOT WORK.

Direct fuel pump VAZ 2110

Since the fuel pump

I had a glitch, sometimes it turned on, sometimes it didn’t, especially in the mornings, so I decided to put it in temporary mode

The main list of reasons why the fuel pump

cannot be pumped on a VAZ-2110 car, these include:

- Fuse failure;

- non-working relay;

- engine breakdown;

- oxidation of contacts in the wiring leading to the gasoline pump;

- breakdown of the gasoline pump.

wiring

In almost all models, the automotive wiring for the gasoline pump consists of three wires: “plus”, “negative” and a wire for determining the amount of fuel in the tank. If the gas pump stops shaking, the electrical wiring may be damaged. You can check the power using a 12-watt lamp, supplied from the external connector of the gasoline pump. When the ignition is turned on, the lamp should light up. If not, then somewhere outside the circuit it will break.

To check the external wiring, you must, in turn, connect the plus and minus contacts removed from the fuel pump power connector. It is necessary to close the “negative” contact with the ground, after which the light will light up when the ignition is turned on.

Placing a contact on a relay in which the lamp does not light may indicate a wiring fault in the range from the relay to the gasoline pump.

electric motor

If searching for the problem in the fuel rail and wiring does not yield results, you need to check the gasoline pump motor. It is responsible for circulating fluid inside the fuel pump. When checking, it is necessary to take into account that after a certain time interval the terminals on the gasoline pump may be oxidized and there will be no power. This also often causes the gasoline pump to fail. This means the motor is likely running, but the terminals need to be cleaned and tightened.

If everything has been checked, but the fuel pump does not work - article numbers

In general, the pump article number for VAZ-2112 engines looks like this: 21102-1139009-XX. Instead of the letters XX there are numbers, for example 02 or 03. They indicate the manufacturer. So, modules from different factories are not interchangeable! The resistance of the FLS resistor is different in them. However, when replacing the FLS sensor, you can borrow it from the “old” module. That's what they usually do.

Until April 2002, article numbers of the type 2112-1139009 were used.

Almost every module available for purchase contains a built-in pressure regulator. There are also exceptions - KSZC-A243, for example. The meaning is as follows:

- All internal combustion engines with a volume of 1.5 liters are equipped with a ramp with an “external” regulator (2112-1160010);

- The 21124 or 21114 motor requires a built-in regulator.

In conjunction with 1.5 liter engines, you can use any module – both with and without a built-in regulator.

Designations of analogues

- 21102-062213.0XX – instead of the letters XX there will be a plant designation (07, 13, etc.);

- KSZC-A233 or A243 – KSZC brand. No pressure regulator .

Fuel pump VAZ 2110 injector, fault diagnosis

The fuel pump for Lada-110 is the heart of your car; when the pressure supplied to the fuel injector drops, the car’s power is inevitably lost, the car periodically stalls at idle or has difficulty starting. In this case, most likely, the fuel pump mesh is clogged and repairs should begin with replacing it.

Diagnostics of the fuel pump VAZ 2110

By measuring the pressure in the fuel rail with a pressure gauge, you can also speak with a high degree of probability about the causes of the malfunction. So, a clogged filter will cause a low pressure reading at the output of the regulator, and high values hint at problems directly in the regulator itself.

Normal pressure on the injector from the Lada-110 fuel pump depending on the engine type, ranges:

If you have insufficient skills in measuring pressure, you can very tentatively conclude that the VAZ 2110 fuel pump is working properly, having pumped gasoline into the container through the main fuel supply hose. A working fuel pump will pump at least 1.5 liters in a minute. gasoline.

Replacing the fuel pump

If on a VAZ 2110 the fuel pump does not turn on at all, then you should first pay attention to the electrical power supply circuit according to which the VAZ 2110 fuel pump operates, namely:

- serviceability of the fuse in the fuel pump circuit;

- sticking of the fuel pump relay contacts;

- presence of voltage on the terminal block by turning off the “tens” fuel pump and connecting an ordinary 12 V test light to the corresponding power connectors;

- burnout of the electric pump motor windings.

Master node of the system

The VAZ-2110 fuel pump is equipped with an electric drive. Its body is lowered into the fuel tank. Gasoline is both a pumpable fuel and a coolant. It should be remembered that traveling with an empty tank is fraught with overheating of the VAZ-2110 injector fuel pump.

This electrical device is an independent unit. Accordingly, its operation does not depend on the state of other mechanisms. A necessary condition for rotating the VAZ-2110 fuel pump rotor is maintaining normal voltage on the on-board network.

The voltage comes through the ignition switch. When the key is moved to position 1, the circuit is closed to turn on the drive. The VAZ fuel pump fills the fuel rail. The engine is ready to start.

If symptoms of poor fuel system performance occur, the pump should be checked. We list the signs that make it possible to replace the VAZ-2110 fuel pump:

- the car is malfunctioning;

- accelerates poorly;

- twitches while driving;

- won't start at all

- gasoline does not flow to the ramp.

First of all, a hearing test is performed. After turning the ignition key to position No. 1, there should be a noise under the rear seat. The sound lasts for a couple of seconds. This means that the pump has pumped up the required pressure.

What kind of fuel pumps are installed on VAZ 2110/2112 cars

The fuel pump is considered the most important element of the fuel system of any car. So, depending on what type of engine the VAZ 2110/2112 model is equipped with, the choice of fuel pump will also depend. An electric pump is installed on injection cars, and a mechanical one on carburetor cars.

The family is equipped with fuel pumps produced by AvtoVAZ. However, these units do not have a high service life and reliability, so often car owners do not wait until the fuel pump fails and replace it.

Installed at the factory on every VAZ 2110/2112 model

Most often, fuel pumps (Russia) and “Bosch” (Germany) are chosen for replacement. Their quality and durability have been known for a long time, although their cost is several times higher than the price of AvtoVAZ gasoline pumps.

The German manufacturer ensures the quality and durability of the products

It’s worth mentioning separately about the location of the fuel pump in the VAZ 2110/2112: the device is not located under the hood. To achieve maximum optimization of the fuel pump, manufacturers install it directly into the fuel tank. That is, to get to the pump, you will need to fold back the cushion in the back seat of the car and open the hatch hidden under the carpet.

The fuel tank and fuel pump are located under the seat cushion.

Features of the injection power system

The tasks of fuel pumps in carburetor and injection engines are somewhat different. If for a carburetor engine it is important to simply supply gasoline to the carburetor, then for an injection system this is not enough. The fuel pump must not only pump fuel from the tank to the ramp, but also create a certain pressure, without which the engine simply will not start.

Access to the fuel pump in injection cars is also complicated by the fact that in cars of recent years of production it is mounted together with a fuel receiver and a coarse filter directly in the gas tank. This complicates the diagnosis, repair and maintenance of the entire fuel module, but simplifies the design of the pump, since the gasoline itself lubricates and cools it. But this is precisely what often leads to unit breakdowns.

When is it necessary to replace the mesh on the fuel pump?

The condition of the unit can be judged by its performance and the pressure developed. To do this, you need to connect a pressure gauge to the fuel system through a special adapter. This diagnosis is done at a service station. It’s easier to diagnose a fuel pump at home like this:

- The ignition is turned on, but the VAZ fuel pump does not work, there is no characteristic hum or makes a loud noise, which entails an overload of the unit and shortens its service life.

- The pump performance decreases, which is clearly visible when driving at third and fourth speeds on a flat road. The car does not respond when the driver presses the gas pedal.

- If a VAZ 2112 car “spontaneously” slows down while driving. This most likely indicates that there is a problem with the fuel supply to the gas tank.

- The reasons may be: clogged coarse or fine filters. The fine filter must be replaced, and the coarse filter (mesh) can be washed. But this will only give a temporary effect; after a short period of time, you will still need to replace the fuel pump grid on the VAZ 2112. Any car owner can purchase it at a car store without any problems. The price of the part is small, the DIY process will take a little time, but the reliability of the gas pump will increase for a long time.

How to clean the fuel pump screen

To work you will need:

- Compressor.

- Fuel pump seal.

- Gaskets for fuel line fittings.

To clean the coarse filter, as the instructions indicate, you need to remove the fuel pump from the tank. This is done in this way:

- The car is de-energized.

- The cushion is removed from the rear seat.

- The screws are unscrewed and the hatch cover is removed.

- The electrical connector is disconnected.

- The fitting on the tube through which fuel is supplied is disconnected.

- The tube is pulled to the side.

- Similarly, the fitting is disconnected and the drain pipe pipe is moved to the side.

- The pressure ring is removed.

- The fuel pump is lifted, the float is removed from the tank opening and the fuel pump is removed simultaneously with the fuel level sensor.

- At the bottom of the fuel pump there is a mesh, which is a coarse filter. The general view of the mesh is shown in the photo.

General view of the VAZ 2112 fuel pump grid

Contamination of the mesh is not always detected by eye. Very small particles are often translucent and the filter appears clean.

https://youtube.com/watch?v=IEqEQgPaywE

So:

- Using the same detergent and a brush with fine bristles (or a toothbrush), the mesh is washed well.

- Blown with compressed air from a compressor. In the absence of the latter, you need to give the filter time to dry, you need to make sure that dirt and dust do not get in.

- After the mesh has completely dried, the fuel pump can be assembled.

- The VAZ 2112 fuel pump is assembled in the reverse order of its disassembly.

- The car starts, the quality of the operations performed to eliminate defects is checked.

How to correctly replace the fuel pump mesh on a VAZ 21124 can be clearly seen in the video. If on a VAZ 2112 car the fuel pump mesh is replaced regularly and correctly, then major problems with the supply of fuel from the tank to the engine can be significantly reduced.

How to check the operation of the fuel pump?

First, you should check the fuse. To do this, check the instructions for its location. Next, you should check the voltage at the pump. Before doing this, be sure to check if everything is in order with the battery. The voltage at the fuel pump terminal must be checked using a multimeter or tester. The instruction manual always indicates the required voltage.

Using a tester, check the voltage supply to the fuse. Often this is where the electrical circuit breaks.

If the search does not yield results, then the voltage should be checked on the contacts themselves. All contacts must be in place and connected to ground. A broken contact or its oxidation leads to failure of the fuel pump system. If no broken contacts are detected, but the voltage drops by more than 1 volt, then the problem is in the wiring or oxidation of the contacts. There should be no short circuit in the wiring.

If, after checking the voltage, contacts and fuse, you do not find any problems, then the problem lies in the fuel pump itself. In this case, the fuel pump will most likely require replacement. In practice, it most often turns out that replacement is a last resort. First, you should try to restore and test the fuel pump again.

Before you check the fuel pump, you need to remember that, as mentioned above, pressure is the most important characteristic of the fuel pump, so it is worth measuring its level.

How to check the pressure in the fuel rail?

You will need a pressure gauge that measures pressure in the range from 7 to 10 atmospheres. If you choose a pressure gauge with a large margin, you risk getting less accurate measurement results. Specialized stores sell a kit for measuring pressure, but you can also design your own device.

If you want to assemble the device yourself, you will also need a hose with an internal diameter of 9 millimeters. You will also need plumbing tow, with which you can seal the connection between the pressure gauge and the tube. All parts are connected and tightened using a clamp. You will also need a car spool. Next you need to perform a series of actions:

- Place the car on a level surface that is prevented from rolling, turn off the ignition and open the hood.

- Check that the injection nozzles have access to the fuel rail.

- Find the fuel pressure plug and remove it. Then you should unscrew the nipple using the spool.

- Prepare an empty container (a regular bucket will do) and a clean rag. This is necessary to collect residual fuel, which under pressure can splash out in different directions. Therefore, take care of the safety of your skin (especially your face and eyes).

- Connect the device to the fitting and begin checking the mechanism.

We recommend: Procedure for adjusting valves on a VAZ 2107 carburetor

Checking the pressure in the fuel rail should occur in four operating modes of the power unit:

- when the ignition is on;

- at idle engine speed;

- code the fuel pressure regulator tube is reset;

- when the drain tube is compressed.

Fuel rail pressure measurement results

The results may vary slightly for different car models, but in general they should be as follows:

- when the ignition is turned on, the pressure must be at least 3 atmospheres,

- at idle engine speed - at least 2.5 atmospheres,

- when the pressure regulator tube is reset - at least 3.3 atmospheres,

- when squeezing the drain tube - at least 7 atmospheres.

Fuel rail pressure fluctuates slightly during preparation. When you press the pedal, it suddenly takes on a value of 3 atmospheres; when you release the pedal, it drops to 2.5 atmospheres. When fuel enters the fuel system, turn off the ignition and begin observing the pressure gauge. The pressure in this case should drop to 0.7 bar and remain unchanged.

If the pressure drops to zero, there may be a problem with the fuel pressure regulator. In this case, the regulator must be replaced immediately. The cause could also be the fuel pump check valve.

It is necessary to observe the behavior of the pressure gauge even at 3,000 engine speeds. A drop in pressure will indicate a faulty fuel pump. Sometimes the fuel pump cannot reach the required pressure for a long time. In this case, the problem lies in a clogged fuel filter, which needs to be replaced, or in a dirty fuel pump mesh (read more about where the fuel filter is located).

If the above methods do not reveal a malfunction of the fuel pump, you will have to diagnose other units (DPZD, IAC, mass air flow sensor, compression in the engine and some other indicators and parts).

New fuel pump VAZ 2110, manufacturer's choice (Bosch)

Undoubtedly, the advantage of the domestic automobile industry is a rich variety of cheap replacement parts. However, among about two dozen manufacturers of fuel pumps, it is recommended to buy a VAZ 2110 Bosch fuel pump, which is characterized by high performance and technical performance.

Bosch fuel pump

The price of a fuel pump for the 2110 series from Bosch will vary from 1,200 rubles and more. When buying an analogue that is too cheap, there is a high risk of encountering a low-quality fake. Therefore, it is advisable to buy in stores representing an official Bosch dealer.

In addition, pay attention to the tightness of the original packaging and the absence of gasoline odors. For the VAZ 2110, the Bosch fuel pump is sold in tightly sealed transparent plastic packaging with the addition of pure gasoline to prevent drying out of the injectors and corrosion, which is susceptible to the body, as well as the valve of the VAZ 2110 Bosch fuel pump

Replacing the fuel pump VAZ 2110

In order to replace an old fuel pump due to its depletion, failure of the float sensor, valves, uncharacteristic noise during operation, or if it is necessary to replace a dirty mesh, it is recommended to adhere to the following fairly simple algorithm.

- 1. Disconnect the negative terminal of the battery;

- 2. Relieve the residual pressure in the fuel rail using a special fitting;

- 3. The “tens” fuel pump is located under the rear seat of the car. We recline the seat and unscrew the protective cover;

- 4. Disconnect the electrical terminal block of the pump, unscrew the fuel supply and drain lines. The rubber gaskets for the tips of the lines should be replaced;

- 5. On a VAZ 2112, the fuel pump is held in place by eight bolts on an o-ring with a lining;

- 6. All you have to do is remove the old fuel pump and install the new one according to the indicating arrow on the product body.

Possible causes of fuel pump malfunction

Mechanical fuel pump disassembled

A mechanical fuel pump may fail for the following reasons:

- If the integrity of the diaphragm is damaged.

- After dirt accumulates under the valves.

- When the filter is clogged.

- When the spring loses its elasticity.

- If the seal of the housing is broken.

- Due to natural wear and tear of parts during operation.

The electric fuel pump of a modern car is quite reliable. Malfunctions in it arise only due to the influence of certain factors, among which the most common are the following:

Burnt contacts inside the fuel pump

1. Faulty wiring in the form of dirty, rusty, melted or damaged wires in the fuel complex interferes with the operation of the device and also limits the required current parameters, making it difficult to pump fuel.

2. Debris and foreign impurities in the fuel tank in the form of rust, dirt, water, mechanical particles that penetrate the fuel pump and cause its breakdown.

Clogged fuel pump filter

3. A clogged fuel filter with debris from the tank contributes to a sharp decrease in the pressure created by the pump and a deterioration in its operating parameters.

Melted fuel pump turbine

4. Driving a car for a long time with a small amount of fuel, during which the pump is not immersed, experiences significant overheating, quickly consumes internal lubricant and fails.

5. Natural wear of the rubbing parts of the pump.

Problems with the operation of the vacuum type device

The vacuum pump may malfunction. This can happen for several reasons:

| Problems | Causes | Solution |

| Insufficient vacuum | Insufficient oil level | Add oil to the required level |

| The oil has become dirty | Dirty engine. The higher the alkali content in the oil, the faster the engine cleans and the oil turns black. | Replace the oil with clean oil. If the alkali content is high, replacement is required after 5,000 kilometers. |

| The oil fill hole is clogged | Small particles on the surface of the lid | Clean the inlet and rinse the filter |

| The integrity of the hoses is compromised | Wear, mechanical damage, hose connection failure | Check hoses and their connections |

| Insufficient pump power | Loss of voltage from the generator to the pump due to unsuccessful implementation of standard wiring, insufficient device size | Replace the wiring or purchase a new part of the required power |

| Oil started leaking | The integrity of the oil container is damaged | Replace container |

| The cover of the hole for draining the oil does not fit well or the rubber ring has become unusable | The thread of the cover is torn off, the ring is worn out | Replace the cover and replace the gasket |

| Oil splashes | Permissible oil level exceeded | Drain some of the oil to the desired level |

| The pressure at the air evacuation fitting has been exceeded | Insufficient pump power | Install a more powerful pump |

| The pump is hard to start | The temperature has become too low | The device must be turned on and off several times in a row or the oil must be heated |

| Breakdowns in the electrical part of the pump | Voltage surges, short circuit | Check and eliminate breakdowns |

| Garbage has accumulated inside | Dirt in the gas tank | Examine the contents and remove the blockage, clean the gas tank |