How important is the ball joint?

The ball joint requires special attention; this is one of many reasons that will once and for all force a person who believes that he controls everything to observe the speed limit and pay due attention to his car.

To replace the pivot device

One main suspension element came, which is called a ball joint. When it wears out to a critical point, serious problems arise in some car models. Read on to find out how to determine if a ball joint is faulty.

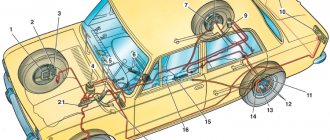

The ball joint is the assembly that connects the hub

on the steering wheel and the suspension arm. Its task is to provide the ability to rotate the hub with the initial position of the wheel horizontally during vertical movement.

The design of the ball joint is very simple

. It is a cone-shaped finger with a mushroom-shaped or spherical tip, which is capable of rotating and, at the same time, swinging at angles in the support body. The housing is pressed onto the lever or bolted. In this case, the ball joint is usually changed along with the suspension arm.

In modern newly introduced units, a non-dismountable design is mainly used. In it, after installing the finger, the body tends to roll. Plastic or other types of inserts are placed between the body and the finger. They work like a sliding bearing and provide rotation with little effort. For domestic, older car models, other ball joints are also supplied, which are called collapsible. Backlashes in them are eliminated by tightening the cover.

Purpose and design of ball joints

A ball joint is a joint that is one of the fundamental parts of the front suspension of a car. In a car's design, these elements are designed to allow the front wheels to move left and right. The hinge is subject to heavy loads, so it has a short service life, which means it needs to be replaced often.

Ball joints on domestic cars began to be used relatively recently, and before that the ability to move the front wheels in a horizontal plane was realized through king pins. The pivots need frequent lubrication, and the slightest lack of lubrication reduces the mobility of the joints, which means the controllability of the vehicle deteriorates. In the design of the VAZ-2107 car, kingpins are not used, but instead, ball joints are used, which are structurally simpler and 10 times smaller.

The design of the ball joint is as follows:

- Body or base.

- The ball pin is a movable element of the part.

- Boot or protective cover - prevents water and dust from penetrating into the connection.

- Plastic liner inside the case. It is located between the ball part of the pin and the base of the part.

To ensure the mobility of the finger inside the housing, a lubricant is used, which not only improves the mobility of the part, but also protects the internal parts from corrosion and increases service life. The front suspension of the VAZ 2107 has two ball joints per wheel. These are upper and lower devices that differ in design. The upper devices have a poured design inside the housing, and the lower ones consist of metal-ceramic liners. This was done for a reason, but for the reason that the upper and lower ball joints experience different degrees of load.

Causes of ball joint failure

During operation, these supports experience severe loads. Depending on the location of their installation and the design of the suspension, the supports carry most of the total weight of the car, and also withstand constant systematic impacts when driving on uneven roads.

The main reason is disruption of proper operation

The ball joint wears out the contacting surfaces, which leads to an increased gap in the gap from the body to the pin. As a result, the finger begins not only to rotate, but also to dangle in the body.

If the wear is too severe, the loads on the support may cause the pin to break out of the housing. As a consequence of all this, it turns out that the support is not able to hold the wheel, and the car collapses onto the asphalt.

An increase in the gap occurs due to the following factors:

Here are a few main signs of wear on ball joints:

Symptoms of malfunction

| Symptoms of ball failure | Description of symptoms and causes |

| Wheel knocking while driving | Extraneous sounds will appear at any speed and are clearly noticeable when hitting an uneven surface, a hole, etc. It is both one-time and recurring in nature. |

| Changing wheel alignment | The wheel with a faulty ball joint suffers the most. Increased tire wear at the edges is possible. |

| The car swerves along the road | There is play in the ball joint, which causes the wheel to wobble when driving. |

| Creaks during maneuvers | Creaks can come from the steering wheel or rear wheels; you should listen specifically to the front ones during maneuvers. |

| Changing the braking trajectory | The car will drift in the direction with the faulty ball joint. |

Causes of ball joint failure

The ball joint fails due to mechanical damage. There are a number of factors that can speed up this process:

Anther rupture. To extend the life of the ball joint, boots are used to prevent water, sand and other debris from entering the mechanism. From time to time it is necessary to check the safety of the boot and make sure that there is no mechanical damage on it. Since the boot is made of rubber, it is especially susceptible to wear during the hot season and at low temperatures. If a crack forms on the boot, it must be urgently replaced to avoid small particles and moisture getting into the ball joint;

The ball joint is one of the key elements of the suspension, and it requires the driver's attention. If severe wear is not noticed in time, this can lead to a dangerous accident.

( 412 votes, average: 4.57 out of 5)

Related Posts

Oil pressure stays on for a long time when starting the engine

What is car clearance and how to measure it

How to determine whether a ball joint is faulty

The condition of the supports, unfortunately, cannot always be determined by stands designed for diagnosing suspension units. You can assess their condition using the usual old methods - by touch and hearing.

Method No. 1

When a hearing test takes place, you need to rock the car and listen to what exactly is knocking in it.

Method No. 2

In order to avoid diagnostic errors, with the brake pedal depressed all the way (to eliminate bearing play), the wheel must be rocked by hand. To do this, you need to grab it at the highest and lowest points. If play is still felt, then know that there is a gap in the support and it needs to be replaced. But to determine the amount of wear, it would be better to use the most accurate devices and tools.

In the classic VAZ car model there is a special control hole located in the design of the lower ball joint. To diagnose it, use a caliper or depth gauge to measure the distance between the end of the ball pin and the outer surface of the body through this control hole under load. For VAZ cars the figure will be no more than 11.8 millimeters (for original supports).

The play in the upper support can be measured with a specialized device with an indicator. The play should not be higher than 0.8 millimeters.

If you do not have specialized tools or devices at hand, you can place your palm on the body of the ball joint so that you simultaneously touch the body and your finger. Ask your partner to rock the wheel. If there is play, then, as a rule, it is felt.

Methods for diagnosing ball joints

To do this you need a pit or a lift. After hanging the wheels, insert a pry bar between the suspension arm and the steering knuckle. We are trying to shake up these two parts of the suspension and chassis. I told you how to properly diagnose all elements of the front suspension yourself in a previous article. If play is visible, even if it is not large, this is a sign of wear on the ball joint liner. The video shows how to do this.

The second method is to measure the gap between the ball and the inner joint liner. This method allows if the design has a hole in the lower part of the body.

For example, on a VAZ classic, there is a hole in the lower ball joints with a threaded plug. To diagnose, you should unscrew it and use a caliper with a bore gauge to measure the distance from the edge of the body to the ball. It should be no more than 11.8 millimeters.

Ball joint repair

There are several repair methods. Often, the ball joint is replaced with a new one. Replacing a support along with a lever on most foreign cars is a very expensive pleasure, since the price of one lever is not a small amount, and there are also cars that have complex multi-link suspensions (up to 5 on one side only). The cost of the work performed will also be quite high for the lower lever, and twice as much for the upper one. Therefore, the services of restorers who repair even those supports that are replaced in the assembly with a lever are in great demand.

What is a ball joint in a car

As noted, a ball joint is a part that connects the wheel hub to the suspension arm. Often, we are talking about steered wheels, i.e. The unit is widely used in the front suspension. The use of ball joints made it possible to eliminate the movement of wheels in the vertical plane and maintain mobility in the horizontal plane.

The most common suspension options include a design where the wheels have one support each, i.e. there are only two of them. But in some cars, in particular in SUVs, it is more advisable to use two per wheel: upper and lower.

It should be noted that some cars are equipped not only with front, but also with rear independent suspension, including a multi-link system. But such options are rare. It is worth noting that an increase in the number of ball joints undoubtedly complicates the diagnosis and the final cost of repair, but at the same time ensures longer operation, increasing reliability and reducing the likelihood of failure.

What is the lifespan of the ball joint?

The service life of a ball joint mainly depends on several factors; it can range from 15 to 120 thousand kilometers.

Even a small crack in the boot will sharply shorten the life of the ball joint. This can cause water, dirt and sand to enter the joint. To prevent damage to the ball joint, it is necessary to observe the condition of the protective rubber boot. It is best to do this on an overpass.

In order for ball joints to last longer, you should drive more carefully on broken roads, and also replace damaged boots in a timely manner.

Source

How to check a ball joint

The question of how to check a ball joint can be of concern both when symptoms of its malfunction appear, and even when purchasing a new one. There are three main methods for checking serviceability - without hanging the wheels, with jacking up the car and using a lift on which the car is lifted (usually used in a car service center). The check also depends on the type of ball joint - single-link (another name for MacPherson strut suspension) and multi-link. In addition, there are lower and upper supports. Despite the diversity, the testing methods are largely similar and are available to almost any car owner who has basic skills in performing car repair work.

Ball joint testing methods

There are 3 main methods that allow the car owner to check the condition of the car's ball joint. The first and simplest is without removing the wheels or even jacking up the car. The second is using a jack (you need to hang the wheels one at a time). The third is using a lift. This method is only available in a service station, but this diagnostic method gives the most accurate answer to the question about the condition of the car’s ball joint. Also, testing methods differ depending on what type the ball is - single-lever or multi-lever. So let’s look in more detail at the serviceability of a ball without a lift, focusing only on the knock, play and degree of wear by the way the ball dangles in the body.

Types of ball joints

The choice of testing method depends on the type of ball joints used in the vehicle. As stated above, they are of two types, namely:

Replacement of VAZ 2110 support

The support has been purchased, the tool has been assembled, and you can start replacing it. The whole job will take no more than half an hour. To replace the support, select a flat area and place the wheel chock under the diagonally opposite rear wheel. After this, we tear off the front wheel mounting bolts, after which you can hang the car on a jack. Remove the wheel and unscrew the ball joint pin nut with a 19mm wrench.

Now we install the puller and press the support pin out of the axle. If there is no puller, then it is better not to tighten the nut all the way, but just loosen it. In this case, you will have to pound with a hammer and press out the finger using a pry bar.

After the pin is freed, unscrew the ball joint housing with a 17mm wrench and dismantle it. Actually, that's all. You have the old support in your hands, leave it alone, install the new support in the reverse order, and be sure to check the quality of the tightening of the nuts 200-250 kilometers after installation. Now carefully drive around deep holes, and good luck on the roads!

How to check a ball joint without a lift

Next, we will consider in order the algorithm for searching for wear of ball joints of various types, although often the methods for checking them are largely similar, accordingly, they can be used for different types of ball joints.

How to check the upper ball joint on a car

To check the serviceability of the upper multi-link ball joint, you must follow the following algorithm (it will make it possible to check the play):

Checking the upper ball

If there is play in the upper hinge on the support, then during the described check it will be clearly felt. You may also hear clicks or squeaks coming from the ball joint. However, often such a check is only suitable in case of significant wear; at the initial stage, such an algorithm may not produce results.

Therefore, it is better to use a jack to check. The algorithm will be the same, but the difference will be that you need to swing not only the upper part of the wheel, but also the lower and side ones. Specifically, you can grab the top of the wheel with one hand and the bottom with the other. Next, swing the wheel in a vertical plane . A similar check can be performed by grasping the left side of the wheel with one hand and the right side with the other. In this case, the wheel must be rocked in a horizontal plane . If there is play and “unhealthy” creaking sounds, then it is necessary to replace the support with a new one. These simple steps will help you check the ball joints without removing them and without a lift.

Ball joints from various manufacturers

First of all, it should be said that the ball joint is a very important part. During operation, it is subjected to severe shock loads, so the technical requirements for it are very high. There are very few enterprises capable of meeting these requirements. Let's list the most popular companies.

Ball joints "Track"

Track supports are very popular among VAZ 2107 owners.

The Track ball joint has an optimal combination of quality and price

The reason is simple: these supports are good value for money. Here are the main features of Track ball joints:

- the ball rod in all Track supports is manufactured using cold heading technology, after which it is subjected to heat treatment;

- the ball on the “Track” support rod is always carefully processed, surface roughness class - 10;

- threads on the ball rod are applied only by rolling;

- liners on the “Track” supports are made of a special wear-resistant polymer, which significantly extends the service life of the supports;

- the bearings in the “Track” supports are made of cermets and are thoroughly lubricated, so there are no problems with the sliding of the ball rods;

- The body of the “Track” support is obtained by cold stamping. Then its parts are fastened to each other using spot welding, and between the fastened halves of the body there is always a layer of industrial sealant;

- The support boot is very durable, and what is especially important for our country, is frost-resistant. Due to this, the service life of the boot almost always exceeds the service life of the support itself;

- The body of the Track support is coated with a special coating that reliably protects the support from corrosion.

The manufacturer claims that the Track supports are guaranteed to cover 40 thousand km, and the actual mileage of the supports can reach 100 thousand km or more. The cost of a set of four “Track Champion” supports starts from 1,500 rubles.

Ball joints "Cedar"

In the Kedr ball joints, which are the second most popular among VAZ 2107 owners after the Trek, the manufacturer has implemented several technical innovations that should definitely be mentioned.

Kedr ball joints are always carefully checked using special equipment

These are the features:

- All Kedr ball joints are equipped with a compensator. The manufacturer claims that this part allows you to increase the service life of the support by 30%;

- all “Kedr” support bodies are protected with a special cataphoresis coating, which has increased adhesive properties;

- Before applying the cataphoresis coating, the support bodies are subjected to shot blasting, which guarantees the complete absence of surface defects and dirt on the surface of these parts;

- The material for the liners of all Kedr supports is graphite-filled polyamide. This material is able to halve the friction in the support and thereby increase the service life of the part;

- The anthers on the Kedr supports are made of rubber used in the aviation industry. Rubber has increased oil and gasoline resistance, and is practically immune to sudden temperature changes;

- the rod of the ball joints “Kedr” is coated with a special material “Nilbor-20”, which several times increases the anti-friction characteristics of the rod and reliably protects it from corrosion;

- All Kedr ball rods are monitored using ultrasound for internal defects. Thus, the possibility of marriage is practically excluded.

The manufacturer provides a 18-month warranty on “Kedr” supports (for comparison: the “Trek” supports have a 12-month warranty). The guaranteed mileage of the supports is 40 thousand km. The cost of a set of four “Cedar” supports on the market starts from 1,400 rubles.

Ball joints "Belmag"

It has become not so easy to find Belmag ball joints on the shelves of auto stores.

Finding Belmag supports on the shelves is becoming increasingly difficult

Nevertheless, they are in demand among car owners. Here are some features of these parts:

- Ball rods on Belmag supports are produced using volumetric cold stamping. Subsequently, they are subjected to heat treatment, which exactly meets the requirements;

- blanks for the production of ball rods are provided. It is this manufacturer that supplies rods for AvtoVAZ (in fact, it is their only supplier);

- all workpieces received from are not subjected to eddy current testing, which makes it possible to identify all internal metal defects and obtain a complete picture of the structure of the part;

- each support hinge is capable of withstanding a load of 2.5 tons, this is almost twice the mass of the VAZ 2107, and almost eight times the shock loads acting on the support when driving;

- Each Belmag ball joint has an individual number consisting of six digits. In addition, each support has a hologram, which allows you to further protect the product from counterfeiting.

The cost of a set of four Belmag supports starts from 1,200 rubles.

Ball joints LEMFORDER

The German company LEMFORDER is a recognized global manufacturer of high-quality ball joints. Unfortunately, it is not possible to tell anything specific about the features of production and the technologies used. The Germans simply do not disclose this information, citing trade secrets. On the official website of LEMFORDER you can only read assurances that their supports are of the highest quality, and the most modern technologies are used in their production.

German LEMFORDER ball joints cost twice as much as domestic ones

Practice shows that the Germans tell the truth. The vast majority of VAZ 2107 owners claim the high reliability of LEMFORDER supports (and an equally high price, which, frankly, bites). The cost of a set of 4 LEMFORDER supports for a VAZ 2107 starts from 3 thousand rubles. The warranty period is 2 years.

How to check the serviceability of the lower ball joint

You can check the lower balls in the same way as in the case of the upper ones, but the result will be much more effective if you use a pry bar and install the machine on an overpass or lift. It is necessary to insert the assembly between the trunnion and the lever to unload the ball joint and check the possibility of its movement. The following test methods are suitable for testing a single lever system.

Checking lower ball joints on a lift

Checking the ball video instructions

So, to check the lower ball in a single-link suspension system, you need to use a jack and a pry bar. It is advisable to drive the car onto an overpass (inspection hole) or onto a lift so that it is more convenient to carry out diagnostics. The verification algorithm in this case will be as follows:

Checking the lower ball joint on a machine without a lift

The method of checking a ball joint without a lift can be carried out using an additional support, like a stump, capable of supporting the weight of a car or a similar structure.

So, first you need to jack up the wheel under test, then place a stop under the ball joint in such a way as to load the ball joint. If it is in relative order, then the car wheel will remain suspended and will rotate freely, without making any extraneous knocking sounds. If you feel a beating and knocking noise when the wheel rotates , it means that the ball joint has failed and must be replaced.

Required tools and materials for DIY replacement

The table below shows the tools and materials that need to be prepared before replacing the ball joint on a VAZ 2107.

Table - Tools and materials required to replace ball joints

| Name | Note |

| Puller | Special for VAZ 2107 ball joints or universal, for example, fork type. In extreme cases, you can do without a puller by using a hammer |

| Metal brush and rags | For cleaning surfaces and fastenings |

| Penetrating lubricant | For example, WD-40 |

| Key | "at 7", "at 22" |

| Grease | Graphite, ShRB-4, Litol-24 or special for ball joints |

| adjustable wrench | Lasting |

| Hammer | Medium size for easy removal of ball joints |

| Scrap | Can be replaced with a mount |

| Jack | To lift the car |

| Balloon wrench | For removing and installing wheels |

Fork type puller

Checking the ball joint boot

When checking the condition of the ball joint, you must pay attention to its boot. It is made of rubber and its task is to prevent moisture, dust and various debris from the road from entering the joint during operation of the machine. The boot, by and large, is a consumable item and must be periodically replaced. As a result of temperature changes (including in winter), mechanical influences, damage and simply the aging process, first small and then increasingly enlarged cracks may appear on its rubber body, through which dust, sand and other small debris will get inside the ball joint . This mixture will act as an abrasive, gradually breaking down metal surfaces and washing away lubricant.

Therefore, when performing an inspection, you should always pay attention to the condition of the boot, the presence of debris and lubricant in it. If it is damaged, it must be replaced with a new one, since the use of a torn boot leads to a sharp decrease in the overall service life of the ball. And when replacing the boot with a new one, you need to remember to fill it with lubricant (Litolom, ShRB-4 or their analogues).

There is another non-standard method of checking the ball, in particular due to damage to the boot. In particular, the method is suitable for testing on machines in which the ball is positioned vertically with its finger up, that is, if water gets inside, it remains inside like in a vessel, and it enters from above through the oil seal. So, on machines where it is difficult to dismantle and generally get to the support, you can take a regular medical syringe with a needle and pour a little liquid oil into it (2...3 cubes). Next, you need to pierce the boot at the top with a syringe needle and pour the existing oil inside. After this, compare the nature of the old knock and the knock after adding oil. If a difference appears, it means that the ball has failed and it is advisable to replace it. As for the hole from the needle, water will not get inside through it, so the car owner can be calm about this.

Ball joint life 2110

Replacing the VAZ 2110 ball joint, oddly enough, becomes relevant only after 150-200 thousand mileage. Not 15-20, but precisely 150 thousand. That's how long a quality support for ten goes. Another thing is that buying one is not so easy. The supports are falling like leaves in October, and the producers are multiplying. Therefore, choosing a human support becomes increasingly difficult. But it is possible. To do this, you need, without paying attention to the boxes and colored packaging, just carefully examine the support, and the scorched part will show itself.

After 150,000 km on the “ten” you need to think about replacing the ball joint

To buy the right support, you need to conduct a detailed inspection and do several tests right at the point of sale:

- Anther quality. No matter what they say on the packaging, the boot should be rubber, elastic and remain that way for a long time. If it still shows microcracks in the store and its design is primitive, one cannot expect good things from such a support. The boot must have a metal ring filled with rubber on the finger side and a clip for shrinking onto the body.

- The finger must have a high class of machining accuracy and in no case should show traces of machining on a lathe. 80% of all supports have just such fingers, which simply gnaw out the liner after 10 thousand km due to poor quality treatment of the ball surface. The thread on the finger should be rolled, not threaded, the finger itself should be forged, no paint should be used.

- The body must be made of hardened steel halves. The three welding points should be clearly visible, the lower half should be cylindrical, without a cone, and a grease nipple can be screwed into the lid.

- The finger can be turned with difficulty, but must be turned by hand. Moreover, it turns without jerking, evenly. If your finger is standing like a stake, this is not a support that will last long. There is a possibility that it will simply tear out part of the lever.

Once again, we emphasize that the price and brand do not matter, because Tracks and Crafts can be made in a garage around the corner, and the hologram and packaging also say little

Checking the new ball joint

Many new car parts, even from the factory, are not as high quality as the car enthusiast would like. This is especially true for budget spare parts from little-known Chinese and other brands. This is also true for new ball joints. Therefore, before purchasing a spare part, it makes sense to check its condition by visual inspection. By the way, a similar check can be performed if for some reason the car owner dismantled the problematic ball joint. As for repairs, modern ball joints are non-repairable, but old parts for Moskvich or VAZ classics were often made with the ability to replace the polymer liner, that is, with the possibility of restoration.

The simplest method for checking a removed or new ball joint is to turn the ball pin down. If in this case the upper (when turning over, respectively, the lower) end of the pin sank down under its own weight (and even more so if it simply fell out of the seat), then such a ball is obviously faulty and must be replaced. Even if there is no big play in it yet, it is only a matter of time. Likewise, it makes sense to jerk the ball pin from side to side in its seat. Not only should there be no play, but the movement itself should be with little effort!

Another sign of low-quality (mainly Chinese) ball joints is the presence of a grease trap or a place for it. Original high-quality supports should not have grease fittings (roughly speaking, it is believed that grease fittings are a thing of the past). For reference, a grease fitting is the old name for a grease fitting. The name comes from the word grease, as lubricating oils were previously called. Accordingly, a grease gun is a device for supplying lubricant.

Also, on a new ball joint, it is necessary to inspect the integrity of the boot. Not only should it not be damaged (even small cracks), but there should also be plenty of lubricant underneath it. Otherwise, it is better for the car owner to fill the boot with lubricant himself before installing it on the car.

Conclusion

It is best to check the functionality of the ball joint on a lift, but you can easily do it yourself using a jack and a pry bar. Also don't forget to check the boot. The main thing is to carry out the check in a timely manner in order to replace the ball joint at a stage when it does not yet threaten the safety of the driver and passengers when the car is moving!

Source

Removing and installing a ball joint on model 2110

Maintenance

Replacing a ball joint begins with preparing the necessary tools: a special puller, a socket or socket wrench for “17” and “19”, a balloon wrench, a mounting blade or a pry bar. Start the repair by checking the ignition is turned off and the condition of the handbrake lever - it must be tightened. For safety, place chocks under the wheels.

Loosen the wheel bolts on the wheel being repaired. Raise the car using a jack. Remove the wheel. Then, using a “19” wrench, unscrew the ball pin mounting nut, move the steering knuckle to the side, install the puller and uncompress the ball pin. Then use the pry bar to move the suspension arm down. The VAZ ball joint can be easily removed.

If there is no puller, unscrew the ball stud mounting nut only halfway. Then, pulling back the pin bracket with a pry bar, carefully strike the fastening element with a hammer, gradually unpressing the pin. After this, using a key set to “17”, unscrew the fasteners securing the ball joint to the steering knuckle and remove it. These bolts have spring and flat washers, which must also be removed and cleaned.

If you want to finally verify that the unit is faulty, clamp it in a vice to check the radial and axial play of the ball pin. If the finger can be moved fairly easily by hand, the support needs to be replaced. Each VAZ ball joint has a protective cover - boot. Before installation, be sure to clean it from dirt and inspect it. If the protective cover is torn, it must be replaced with a new one.

Before installing the boot, be sure to fill it halfway with lithol or grease. For reliability, seal the installed boot with a special sealant. Bolt the new assembly to the steering knuckle, then, pressing the lower suspension arm down, insert the ball pin into the eye and secure it with a nut. When the Lada is suspended on the jack, do not tighten the nuts and bolts completely.

Remove the car from the jack, rock it from side to side several times with force, then finally tighten: the ball joint nut with a force of 65-95 N.m (6.5-9.5 kgf/m), the bolts securing the ball joint to steering knuckle with a force of 50-65 N.m (5-6.5 kgf/m). After a run of 100 km, it is recommended to check the tightening torque of nuts and bolts.

Signs of wear or malfunction of the car's front suspension ball joint

Ball joints are an important component of the suspension of almost all modern cars. They are a spherical hinge located in the body and protected by a rubber boot. Functionally, ball joints resemble human hip joints and serve as one of the main moving fulcrum points through which the suspension arms are connected to the steering knuckles. Ball joints allow the front wheels and suspension components to move forward and backward, up and down, and when the wheels turn. Typically, some symptoms that indicate wear and malfunction of the ball joint are listed below.

Clunking sound in the front suspension

One of the most common symptoms of bad front suspension ball joints is a clunking sound from the front of the car. As the hinges wear, play occurs, which leads to clanging and grinding noises when moving suspension parts. Clunking and knocking noises may occur when driving on uneven roads, when accelerating or braking hard, or when turning corners. Typically, as it wears, the sound gets louder until the joint completely fails or breaks.

Strong vibration in the front of the car

Another symptom of bad ball joints is intense vibration in the front of the car. Worn joints move freely in the supports, which leads to vibration when the car moves. The vibration usually comes from a faulty joint on the right or left side of the car. Sometimes it can be transmitted to the steering wheel. The cause of these symptoms may be a torn boot; as a result, sand and dirt get inside the hinge, which contributes to its rapid wear and increasing the gaps between the body and the pin.

Causes of ball failure

There are a number of typical reasons why a ball joint becomes unusable. Among them:

Natural wear and tear. On average, a ball joint can last from 20 to 150 thousand kilometers. However, if the part is of more or less high quality, then problems with it may begin after about 100 thousand kilometers of the car. Wear is influenced by many factors - the quality of the part, operating conditions, care of the part, the presence of lubrication, the integrity of the boot, driving at high speed on uneven roads, sudden temperature changes, off-road driving, and so on.

- Torn boot. This part of the ball joint, roughly speaking, is considered a consumable item, so it is advisable for the car owner to periodically monitor its condition, in particular, its integrity. If the boot is damaged, then moisture, sand, dirt, and small debris will probably get inside the ball joint while driving. All these elements will form an abrasive material that will naturally wear out the insides of the support. Therefore, torn anthers must be replaced in a timely manner using the appropriate lubricant.

- Increased loads. This primarily applies to driving a car at high speed on uneven roads. In such conditions, impacts occur on various suspension elements, including the ball joint. Naturally, this leads to wear and damage. Another situation is overloading a vehicle, that is, transporting cargo with the maximum permissible weight or even exceeding the permissible weight. A particularly difficult option is driving fast on a rough road with a significantly loaded car.

Lubrication production. It is removed from the ball for natural reasons - drying out, evaporation. As mentioned above, if the boot is damaged, the lubricant can be removed very quickly due to natural causes, which will lead to increased wear of the ball joint. Accordingly, it is useful to periodically add lubricant to the ball, including when installing a new unit, since manufacturers often do not leave as much lubricant on new bearings as required by the automaker’s instructions. There are special devices for adding lubricant to the ball. And as a lubricant you can use lithium greases (for example, “Litol”), ShRB-4 and others.

Remember that the causes of ball joint failures do not appear overnight. The only exception may be an initially defective part (for example, with a crack in the body), but the likelihood of this is quite low. Therefore, it is necessary to diagnose the ball at the initial stage of failure. And when buying, it’s also better not to skimp and pay a little more, because the more expensive the part, the more wear-resistant it will be (in most cases). Their main difference is the quality of the material, the type and amount of lubricant used, as well as tensile strength.

Pull the car to the right or left

Another sign of worn ball joints is when the vehicle pulls to the side. Steering is an arbitrary displacement of the car from straight-line movement to the left or right. When the ball joints are in good condition and the wheel alignment angles are within acceptable values, the steering wheel is level and ensures straight movement. Wear on the ball joints causes the car to shift to one side, forcing the driver to constantly steer.

Usually, the wheel does not pull out right away; at first the suspension will knock and make noise, and if you do not pay enough attention to this, the hinge pin may fly out of the body and the wheel will turn to the side. At high speeds this can lead to a serious accident.

Since ball joints are an important component of any vehicle's suspension, when they wear out or fail, the overall handling and ride quality of the vehicle will deteriorate. Therefore, if you suspect that your vehicle's ball joints are highly worn and need to be replaced, you should have your vehicle's suspension diagnosed. It is better to entrust it to a qualified specialist who will determine how to eliminate this malfunction and replace worn parts if necessary.

Source