This is the element

When operating a vehicle, the timing chain is stretched. This is due to an increase in the pitch between the links. The elongation of the chain on the VAZ 2107 must be controlled by checking the possibility of its tension. In this case, auto mechanics advise paying attention to the phases. If the mark of the timing gear sprocket coincides with the mark of the bearing housing, when this indicator on the crankshaft pulley is located 10 mm below the mark on the front cover of the engine, you will need to change the timing chain yourself. This work is also carried out when the bushings are chipped and there are cracks in the brushes. Replacement of the VAZ 2107 chain tensioner shoe is carried out when defects in this part are identified.

What is the risk of a circuit malfunction?

Due to the increase in the chain pitch of the VAZ 2107 engine, the injector operates unevenly at idle. This is explained by the fact that each link wears out differently. In some cases, the guide rail, stop pin, or corner of the shoe may break off. Replacing the VAZ 2107 timing chain is carried out taking into account these nuances.

If you jump several teeth, the car engine may stall or fail. To prevent such consequences, auto mechanics recommend adjusting the tensioner more carefully and more often. Sometimes the chain tensioner shoe is replaced.

Before installing the VAZ 2107 timing chain with your own hands, it is recommended to carefully inspect it. Links and bushings must be hardened. If raw metal is detected, this spare part will not be installed. You can check the tensioner by hand. If the deflection is 7-10 mm, it is considered new and suitable for use. The original products of this type are the products of the manufacturer Sachs.

Replacing the VAZ 2107 timing chain tensioner is done with your own hands, taking into account the length of the main part. If necessary, install the tensioner shoe. When choosing this product, you should remember the following nuance:

- 2101 and 21011 have 114 links;

- 2103 and 2106 have 116 links.

Chains are distinguished as follows: when they are stretched, the outermost links on the right and left are studied. If the links are located equally, outside or inside, then the chain consists of 116 elements. With different links, their number is 114.

Operation, maintenance, replacement and repair of the chain tensioner in a VAZ 2106 car

The camshaft drive mechanism on the “six” operates using a chain-type transmission. However, the device is imperfect and requires periodic tightening. The required degree of tension is achieved with the help of a tensioner, which, with its front protrusion, rests against the VAZ 2106 chain tensioner shoe, which creates the necessary conditions for this.

You need to know that the chain tensioner is a component of the gas distribution mechanism of a car, which is constantly exposed to friction, which negatively affects the degree of wear of the associated parts. As a result, such a VAZ 2106 timing chain tensioner should be made only from high-quality materials, which are used mainly in factory production.

Of course, the price of the “six” chain tensioner, which is used during factory assembly, is slightly higher than analogues offered for sale by auto parts stores, but you should know that here the experiment with replacing the part with a cheaper one is very dangerous, and calls into question the reliability of the gas distribution mechanism in in general.

At the same time, you can see how the chain tensioner shoe and other components of this unit work. If the product cannot provide the correct tension of the chain drive when changing the position of the cap-shaped nut or does not function as a chain clamp in a tensioned position, it must be repaired, and if this is not possible, replaced.

Basic methods for replacing parts

Experienced auto mechanics know how to install a chain on a VAZ 2107. They distinguish 2 methods.

- Incorrect and unreliable, but fast. This method does not require the car owner to have special knowledge about the operation of engines. It provides for independent dismantling of the valve cover. To do this, you will need to disconnect the circuit installed on the motor. Do the same with a new part. Next, the two chains are connected into one. With a crooked starter, the new part is rotated until it passes completely through the engine. They are then connected and tightened. Please note that the lower sprocket is not replaceable. It is also impossible to replace the VAZ 2107 chain tensioner shoe.

- Correct. This method involves partial disassembly of the engine, including the removal of the front shield, radiator and other parts. In this case, you can install a new last sprocket. It is also possible to replace the VAZ chain tensioner shoe.

To install the VAZ 2107 timing chain, you will need the following equipment: keys, vice, pencil (chalk), ruler.

The master removes the chain

The first step of the second method is to drain the coolant from the system. It is recommended to remove the hood cover. After loosening and removing the generator belt from the engine, the cylinder head cover is dismantled. If necessary, the tensioner is replaced. To do this, you will need to align the marks on the crankshaft and the camshaft sprocket. Next, the nut is unscrewed and the pulley is removed. In this case, you will need to dismantle the radiator. If you bend the lock washer, you can unscrew and remove the sprocket from the camshaft.

Replacing the chain involves dismantling the front motor shield. You need to remember the 3 bolts from the bottom, they secure the pallet. After removing the cover, it is recommended to mark the position of the sprocket of the additional elements. This step eliminates serious ignition adjustment, which is performed after installing a new circuit on the VAZ 2107.

When installing new sprockets, the old ones must be removed. Replacing the VAZ chain tensioner shoe involves similar actions. When purchasing this part, great attention should be paid to its quality.

Replacing the timing chain of a VAZ 2107 requires installation work, and the location of the marks is taken into account. If you do not pay attention to them, the piston will meet the valves, resulting in the need for a major engine overhaul.

Required tools:

- keys from the standard set;

- universal pulley clamp;

- special key for “36”;

- empty, clean container for draining antifreeze.

Replacing the timing chain on a VAZ 2106 as well as a damper, tensioner shoe, and sprockets

- Remove the air filter housing from the carburetor.

How to replace the timing chain on a VAZ 2106 with your own hands

- Unscrew 3 nuts with a “10” wrench, and 4 nuts with a “8” wrench. All actions must be performed carefully so that nothing falls on the carburetor. If this is neglected, it will be necessary to remove this unit, possibly the intake manifold.

Do-it-yourself replacement of the timing chain on a VAZ 2106

- Remove the distributor cap and remove the pipe used to supply fuel.

- Using a “10” wrench, remove the 8 nuts securing the valve cover and remove the washers with plates.

- Disconnect the choke cable and throttle valve drive.

- Remove the valve cover with gasket (ideally it is better to replace it).

Changing the timing chain on a VAZ 2106

- Remove the protection from below, drain the antifreeze into the container that was prepared initially.

- Using a wrench set to “19”, loosen the generator mounting nut.

- Loosen the clamp of the lower water pump pipe and remove it.

How to replace the timing chain on a VAZ 2106, stabilizer, tensioner shoe, and sprockets on your own

- Turn off the power to the fan, as well as the power to the temperature sensor on the radiator.

- Remove the radiator with pipes and thermostat.

- Loosen the generator chain tensioner nut. Use a pry bar to move it forward.

Read more: Modification of the cooling system of the Lada Kalina

Replacing the timing chain on a VAZ 2106 with your own hands

- Disconnect the VAZ 2106 alternator belt.

- Using the “36” key, turn the crankshaft by the pulley until the marks of the cover and pulley, the sprocket and the casting in the camshaft bed coincide.

Timing chain VAZ 2106

Also check out

Timing chain VAZ 2106

- Unscrew the “36” nut securing the crankshaft pulley. Use a special key to lock the pulley and unscrew it. If there is no special key, you need to engage fifth gear, depress the brake pedal, and unscrew it using the key.

Replacing the timing chain on a VAZ 2106, as well as a damper, tensioner shoe, and sprockets

- Remove the pulley. Unscrew 6 bolts and 3 nuts with a “10” wrench, then 3 more bolts of the camshaft drive cover, remove the cover.

We change the timing chain on a VAZ 2106 damper, tensioner shoe, and sprockets with our own hands

- Unscrew the 2 nuts securing the chain tensioner and remove it.

The photos show an automatic tensioner.

- Loosen the bolt that secures the camshaft sprocket, after which you can remove it. The position for centering is worth remembering, or better yet, marking.

In the photo you can see the result.

- A fuse to prevent the circuit from jumping.

- Fastening the timing chain tensioner shoe.

- Crankshaft sprocket.

- Using a “10” key, disconnect the fuse, the tensioner mount, and the bolt that secures the auxiliary drive sprocket.

Replacing the timing chain on a VAZ 2106 at home

- Remove the sprockets and old timing chain. The crankshaft key and the casting on the cylinder block must match.

- Install new sprockets, crankshaft and auxiliary units to the drive. Install a carefully lubricated new chain.

- To prevent the chain from falling down, you need to place some kind of tool under it.

Changing the timing chain of a VAZ 2106 at home - The sprocket is installed in the chain so that the descending branch of the chain is tensioned and all its marks coincide. Next you need to turn the camshaft from right to left and go back behind the crankshaft. Thanks to these actions, the chain is tensioned, and you can check the correct installation of the marks. If the marks do not match, you need to throw the chain over the tooth and then repeat the procedure.

- Return the tensioner to its place and activate it. Tighten all mounting bolts and secure them. Turn the crankshaft 2 turns, make sure that the marks match and that the valves and pistons do not collide.

- Lubricate the crankshaft cover gasket with sealant and install it in place.

- Place the pulley, make sure that the marks match, and tighten it.

- Unscrew the distributor nut to “13”, remove the distributor itself, turn the slider to the contact of the 4th cylinder.

- Return the distributor to its place.

- To complete the procedure for installing a new VAZ 2106 timing chain, be sure to turn on the ignition.

- Reassemble in reverse order and add antifreeze.

- At this point, the replacement of the timing chain on the VAZ 2106 can be considered complete.

Replacing the timing chain on a VAZ 2107

The gas distribution mechanism in an internal combustion engine is an important part, without which driving is impossible. It is the timing belt that is responsible for supplying the fuel-air mixture to the cylinders and removing exhaust gases, that is, this is the basis for the operation of the internal combustion engine in any car. The movement of the valves responsible for the intake and exhaust of the mixture is controlled by the camshaft. There is one in 8-valve power units and two in 16-valve ones. The camshafts are driven by a belt or chain drive. The oil pump and other engine mechanisms operate from the same drive.

Chain tensioner malfunctions

The chain tensioner of the VAZ 2106 car is part of the engine gas distribution mechanism. As a result, it is in constant motion, under the influence of friction forces. This, in turn, has a very negative effect on its wear. Therefore, many owners of the “sixth” VAZ model prefer to install a factory timing part, since it is much stronger and of better quality, and lasts, on average, twice as long as the imported prototype.

Of course, the price of a factory part will be slightly higher than that of other analogues, but at the same time, the well-coordinated operation of the engine will not be in doubt. Indeed, in the case when the chain tensioner stops working, due to wear of the rubbing part, the cylinders work unevenly, and the engine begins to trip, and may even jam.

If the timing chain wears out very quickly, then the problem is clearly not in its quality, but in the location of the shoe. If it gives the wrong tension, the part will either constantly fall off or frequently tear. Therefore, this element must be monitored very carefully.

Possible faults

In the family of cars of the Volzhsky Automobile Plant, which are called “classics”, the timing drive is made in a chain version. The service life of a good double-row chain is longer than any belt, and the chain is better protected from any external influences while being inside the engine block. Instant stretching of the chain is excluded; moreover, the chain, unlike the belt, will not slip when the engine is suddenly revved up. The downside: noise and some cumbersomeness are not so noticeable when operating the VAZ-2107.

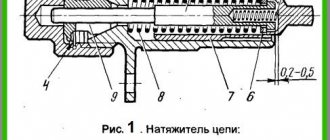

Tensioner diagram: 1 — camshaft sprocket; 2 - timing chain; 3 — chain damper; 4 — auxiliary drive sprocket; 5 — crankshaft sprocket; 6 — tensioner shoe; 7 — hydraulic chain tensioner; 8 - oil line fitting

Unfortunately, the chain also does not last forever. It also stretches - only not immediately, but gradually, as a result of the metal fingers working against the gear teeth.

Signs that the chain has stretched and you need to diagnose the degree of its serviceability are the following:

- extraneous knocking and clanking when the engine is running;

- severe stretching and metal wear can lead to irregular valve timing, increased fuel consumption and other malfunctions.

If the chain has only slightly stretched, you can compensate for the sag by increasing the pressure with the tensioner shoe. When the limit of adjustments has been exhausted, only replacing the chain can help.

Chain stretch even of a few millimeters is noticeable to the eye

In order to better understand when you can get by with little blood and when to change the chain, the manufacturer has established the approximate resource for normal operation of the timing drive, which on the “seven” is 60 thousand kilometers. When used beyond the specified period, there is a risk of not just stretching, but the teeth jumping during operation, or the unit breaking.

Jumping the chain by one or two gear teeth leads to a violation of the valve timing, which will affect malfunctions even at idle speed, not to mention operation under load.

An open circuit leads to the disappearance of synchronization between the revolutions of the crankshaft and camshaft. As a result, the pistons, by inertia, hit the valves open inside the cylinder, deform themselves and deform them. The pistons of the “seven” engine have special grooves that protect the valves from bending. But if the engine has undergone a major overhaul with the replacement of the cylinder-piston group, the pistons may well not have recesses, then the risk of serious damage increases. Monitor the drive chain and change it on time.

Symptoms of mechanism malfunction

The first signs that the engine chain tensioner or the chain itself is faulty are:

- A sudden stop in the vehicle's movement while the engine is running, and a significant increase in the speed of rotation of the crankshaft, with the same throttle position.

- Instant engine blocking (wedge), accompanied by a characteristic sound.

The causes of such breakdowns can also be factory defects, such as:

- A weak collet-type clamp that cannot lock the rod in one position, preventing the tensioner from working correctly.

- Deformed shape of one of the planes of the product.

- Damper spring faulty.

- Defective threaded connections of installation fasteners.

Replacing the timing chain

The owners of the VAZ-2107 became the heirs of the Soviet school of automotive engineering. It was believed that a significant part of the repair work should be within the capabilities of the vehicle owner. The Zhiguli engine of the 7th model has almost no components and assemblies that require adjustment using special equipment, for example, computer diagnostic systems. A driver who has the skills to use hand tools can easily replace the timing belt on his own. There are two ways to perform this operation.

It is important! The fuel injection system on the VAZ 2107 can be injection or carburetor. It does not affect the process of replacing the timing belt assembly. The new chain is installed in the same way on both the injector and the carburetor.

Fast way

It is worth mentioning right away that this method does not guarantee long-term proper operation of the engine. Use it at your own risk! Sometimes a quick timing chain replacement is justified if you have a new part with you and you discover a critical chain failure. It's dangerous to go any further. In this case, quickly replacing the chain will lead to less risk than continuing to drive with the old one. This is done only in order to reach the house or the nearest service station, where more time can be spent on correctly installing the transmission mechanism. The sequence of actions for quick dismantling is as follows:

- After opening the hood, you need to remove the cylinder head cover. A view of the camshaft with driven gear will open.

- Remove the connecting pin and disconnect the prepared new chain. The same operation must be done with the old chain.

- Connect the new chain to one end of the old one.

- Holding and tightening the free end of the old chain, use a special wrench to turn the crankshaft until the new chain takes the place of the old one.

- After this, it is enough to connect and rivet the new chain. This will not be easy to do, since it will be pulled by the unrestricted tensioner shoe, which cannot be reached without removing the engine cover.

Timing chain tension for VAZ 2106

One of the main reasons for the occurrence of malfunctions in the tensioner unit is considered to be the characteristic knock of the chain drive from the front section of the over-valve casing, where the VAZ 2106 chain tensioner sprocket is located, mounted on the camshaft axis. Creating a certain degree of tension in the chain drive and then installing the chain tensioner is not very difficult, even for a novice car enthusiast. So:

- Remove the air purification filter element with the housing and the over-valve casing.

- We begin this type of repair of the chain tensioner, for which we unscrew the tensioner not completely, video instructions for dismantling which are on the Internet.

- Using the starter handle or another method, we make 2-3 circular rotations of the crankshaft, after which the chain drive is engaged.

- We check the tension of the chain drive by pressing on its links.

- If the timing chain has received sufficient tension, you need to tighten the timing chain tensioner tightly and reassemble the attachment in the reverse order.

Useful notes

If you have a “seven” with a carburetor, then after replacing the timing chain you need to adjust the ignition, because the drive sprocket of the ignition distributor-distributor (in common parlance, distributor) was also removed from its seat. Injection models do not require such adjustment.

The carburetor in VAZ 2106-2107 cars is characterized by stable operation and rarely fails. However, even this unit may need repairs. Details of the procedure are outlined here: https://vazweb.ru/desyatka/dvigatel/remont-karbyuratora-vaz-2107.html

Soviet and early Russian cars of the classic family were traditionally equipped with double-row timing chains. This provided increased reliability due to the fact that the break of one link did not provoke an instant collision of the piston with the valve in the open position. The disadvantage was the increased weight. In order to save money and simplify the design, the chain began to be made single-row. The resource of a double chain reaches 100 - 120 thousand kilometers, while a single chain is half as much. Some car owners are returning a double-row chain to their power units. True, for this you will also have to replace all the gears that mesh with the chain. Today, a set of such parts is quite difficult to find, so get ready for search work if you want to increase the reliability of the timing mechanism.

A double-row timing chain has a much longer life, but choosing a set of parts for its installation is much more difficult

The timing chain is a transmission mechanism, the condition of which the car owner must monitor especially carefully. It is not without reason that experienced drivers advise listening to their car. Extraneous noise with jingling notes is a sure sign that it’s time to open at least the cylinder head cover, crank the crankshaft and inspect the chain, at least externally. If there are alarming signs, the chain will need to be removed and replaced. Confidence, accuracy and these instructions will help you save a considerable amount of money, because replacing a chain or belt on a “classic” costs about 2,000 rubles in the country.

Alternative replacement

Recently, many VAZ 2106 owners have been replacing the standard timing chain tensioner with a more modern automatic one. It, unlike the old mechanism driven by friction, begins to work under the influence of oil pressure inside the engine’s lubrication system.

With this system, the chain tensioner operates smoothly and the mechanism does not require manual tensioning. The only thing that can happen to it is a break at the point of wear. Of course, this will happen very rarely.

The price for an automatic chain tensioner is slightly higher than for an ordinary shoe-type one, but it justifies the investment due to the subsequent savings. So, it’s better to spend money once than to subsequently spend a large amount of money and time on replacing a chain, which will break several times more often than on a similar system.

The part is removed in the following sequence:

See:

- Remove the air filter housing.

- We remove the carburetor (first you need to cover the diffuser wells with a clean, dry rag).

- We unscrew the eight bolts of the cylinder head cover and we remove it.

- We then turn the camshaft sprocket until its mark aligns with the flow on the camshaft housing, which acts as a mark.

- We reject the chain tensioner nut (not completely, you just need to loosen it).

- Using a long screwdriver, press the tensioner

, loosening the chain. - Tighten the tensioner union nut while continuing to hold the screwdriver.

- We hook the chain support with a wire hook to the access hole on its body.

- We unscrew the screws securing our part.

- Remove the tensioner from the engine by pulling it out with the hook.

During a complete break, the VAZ 2106 chain cooler, the price of which is 200-450 rubles, often falls. In this case, it is pulled out with a long wire hook or tweezers. If this removal is not possible, the engine sump must be removed.

Before installing the element, make sure that the markings of the old and new parts match. Installation of the depressor is carried out in the following order:

- In the reverse order of removal, install the new part in place of the old one.

- We adjust the tension of the camshaft drive chain. To do this, loosen the union nut used in its design. At the same time, we observe the degree of movement of his shoes. If the shoe does not move, do not hit the nut too hard. Therefore, we release the plunger of this assembly. Then turn the engine crankshaft (clockwise) until the resistance turns on the side (1-2 full turns is enough). Tighten the tensioner nut.

- We control the coincidence of the marks located on the camshaft sprocket and on the VAZ 2106 engine pulley.

- Install the cylinder head cover. Before installation, if necessary, inspect and change the cover lining.

- Then attach the carburetor (be sure to observe the tightening torques of the mounting nuts to avoid deformation of its middle part).

- Install the air filter.

Purpose and design of the VAZ 2107 timing chain damper

The damper dampens jerks and vibrations of the timing chain, which usually occur when the engine starts. An increase in the vibration amplitude of the chain can lead to its breaking off the crankshaft guide gears and timing shaft. Moreover, the chain can break at the most inopportune moment.

Typically, a timing chain break occurs at the moment when the crankshaft begins to rotate at maximum speed. It happens instantly. Therefore, the driver is physically unable to quickly react to the situation and turn off the engine. A broken timing chain leads to serious engine damage. First of all, the valves fail - both inlet and outlet.

Then the cylinders fail. After all this, it is almost impossible to restore the engine. Car owners in such situations usually sell the car for spare parts. Therefore, the timing chain guide is the most important part, the performance of which must be constantly monitored.

Timing chain stabilizer device for VAZ 2107

The VAZ 2107 timing chain guide is a regular plate made of high-quality carbon steel with two mounting holes.

The second element of the timing chain calming system is the hydraulic chain tensioner shoe. It is located under the timing cover next to the damper. The surface of the shoe in contact with the chain is coated with a durable polymer material.

To provide access to the chain guide, you must:

- unscrew the timing cover;

- Slightly loosen the chain tension roller.

Without this, it will not be possible to remove the sedative.

The principle of operation of the VAZ 2107 timing chain guide

When the VAZ 2107 engine starts, the timing shaft and crankshaft begin to rotate. This does not always happen synchronously. The fact is that these shafts have toothed sprockets that are connected by a timing chain. This chain can wear out and become sagging over time. In addition, sometimes the teeth on the guide sprockets break, and the chain sag increases. As a result, when the engine starts, the timing shaft begins to rotate only after the crankshaft has already turned a third of a revolution. Due to such desynchronization, the timing chain begins to sag even more and can fly off its sprockets. To prevent this from happening, the chain calming system begins to work, consisting of a tensioner shoe and the damper itself.

The tensioner shoe is connected to an oil line, on the fitting of which an oil pressure sensor is installed. When the timing chain begins to sag too much, this sensor detects a sharp drop in lubricant pressure. An additional portion of oil is pumped into the oil line, under the pressure of which the tension shoe moves out of its fitting and sharply presses on the slack timing chain, preventing it from flying off the sprockets. Since the shoe presses very sharply and strongly, the chain begins to oscillate strongly under its influence, and the vibrations do not occur under the shoe, but on the opposite side of the chain. The chain damper is designed to dampen these vibrations.

The damper is just a strong metal plate on which the timing chain hits when the tension shoe is triggered. It has no moving parts. However, without a damper, the teeth on the sprockets and timing chain links will wear out much faster, which in turn can lead to serious engine damage.

How to properly tension the chain?

Replacing the timing chain on a VAZ 2107

In the case when the VAZ 2106 timing chain does not require replacement, adjusting its tension turns out to be a fairly simple operation.

In the car's operating manual, the manufacturer claims that it can be done even without removing the cylinder head cover. However, to control the process and achieve the best result, it is better to do this too.

Adjustment procedure:

- Remove the cylinder head cover.

- Remove the air filter.

- Make sure that adjustment is necessary by visually checking the tension.

- Unscrew the cap nut on the plunger tensioner (0.5-2 turns is enough). The tensioner shoe should move (controlled visually). If no movement is noted, the plunger should be released. To do this, unscrew the nut completely and remove the plunger.

- Rotate the crankshaft 1-1.5 turns (stop rotation at the moment of maximum resistance to movement; rolling back in the opposite direction is not allowed).

- Check the tension again and tighten the cap nut.

- Install previously removed components and parts.

Replacing timing parts will require much more effort and time. You can entrust this to car service specialists, but a car enthusiast can handle this task on his own.

Signs of a malfunction of the VAZ 2107 chain damper

Typical signs of a breakdown of the VAZ 2107 timing chain guide include:

- A characteristic loud grinding noise and knocks coming from under the timing cover. These sounds are loudest immediately after starting the engine, especially if it is cold. The loudness of the grinding noise is determined by the amount of slack in the chain - the more slack the chain is, the louder the sound will be.

- Power failures during engine operation. They are most clearly noticeable when starting a cold engine. A worn-out damper cannot dampen chain vibrations in a timely manner, which leads to a mismatch in the rotation phases of the crankshaft and the timing shaft. As a result, the synchronous operation of the cylinders is disrupted. The engine begins to respond inadequately to pressing the accelerator pedal, and failures appear in its operation.

When is it time to change the chain?

Replacement or adjustment of the chain is necessary if the following symptoms are present.

- Loud knocks and grinding noises in the hood area after starting the engine. As the crankshaft speed increases, the noise frequency also increases.

- Fuel consumption cannot be called economical if the cylinder block is not operating properly. The increase in consumption occurs by a third or even two times.

- Gaps form in the engine's power output, which can be noticed both at idle and when accelerating.

- The vehicle's reaction to activating the gas pedal is not good enough; the reaction may be delayed by a couple of seconds.

The presence of these signs indicates the need to remove the chain and examine the degree of its wear. Excessive wear requires replacing the chain, but if signs of wear are insignificant, it is enough to tighten it.

Be sure to read our specialist's detailed article, which talks about replacing the timing chain.

We also recommend that you carefully study our expert’s article, in which he talks in detail about replacing the timing belt.

Reasons for failure of the VAZ 2107 chain guide

Like any other part, the VAZ 2107 chain guide can fail. This may happen for the following reasons:

- Loosening the mounting bolts. The mechanical load on the damper is constantly changing. Under the influence of continuous impacts from the chain, the mounting bolts gradually weaken. As a result, the damper becomes looser even more, and eventually the bolts break.

Wear level study

Visually, no driver will be able to distinguish an old chain from a new one, but there are two ways based on measurements and comparisons.

- Place a 20cm piece of old chain horizontally and turn it in your hand so that the pins are perpendicular to the floor. Examine the chain overhang angle. If the deviation of the hanging edge from the horizontal is 10-20 degrees, there is no cause for concern. If this parameter exceeds 45 degrees, replacing the chain is a mandatory measure.

- The second method can be considered more accurate, but its implementation requires a caliper. Select 18 pins or 8 links anywhere on the chain. Use a caliper to determine the length between the first and last element on the selected segment. Repeat the measurements two more times, but in other random areas. Exceeding the length by more than 122.6 mm in one of the areas you measured indicates that the chain needs to be replaced or tightened.

Replacing the VAZ 2107 timing chain guide

To replace the damper you will need:

- a new timing chain guide for the VAZ 2107 (today it costs about 500 rubles);

- a piece of steel wire with a diameter of 1.5 mm and a length of 20 cm;

- set of open-end wrenches;

- set of socket wrenches with a crank;

- flat blade screwdriver.

Sequence of work

Work on replacing the VAZ 2107 chain guide is carried out in the following order.

- The air filter is removed. To do this, use a 12-mm open-end wrench to unscrew the five filter mounting bolts. It is impossible to get to the damper without dismantling the filter.

- Use a 13mm socket with a ratchet to unscrew the fastenings of the cylinder block cover. The cover is removed.

- Using a 13mm spanner, slightly loosen the special cap nut securing the chain tensioner to the timing belt.

Instructions for disassembling the mechanism

The first thing to do is remove the engine valve cover. Here you can see some signs of wear, for example, a chain dangling on the camshaft gear or a torn damper (or rather, its absence). It even happens that in the place where it stood, the chain selected a groove in the material of the head itself. For convenience, it is better to immediately align the round mark on the camshaft drive gear with the protrusion on its bed.

This is done by rotating the crankshaft with a 38mm wrench. For further disassembly, it is better to remove the radiator, first draining the antifreeze from it. There are craftsmen who replace the VAZ 2106 chain without removing the radiator, but this makes access to the timing mechanism very difficult, which will take up extra time. It is better to spend it on dismantling and installing the radiator, creating conditions for normal operation.

Once access to the front of the engine is open, you need to loosen and remove the generator drive belt. Then, using a 38mm wrench, loosen the pulley nut in this way: engage 4th gear, and ask an assistant to press the brake, and then unscrew the ratchet. This method will save you from the need to insert various pieces of hardware into the engine to stop the rotation of the crankshaft. Further disassembly is carried out according to this scheme.

- Remove the pulley from the crankshaft, clean the turnkey bolts on the 10th front cover of the cylinder block from dirt, and unscrew them. Three of them are located at the bottom and connect the cover to the oil pan. Remove it, clean off any remaining gasket, as well as the mating flange on the cylinder block.

Replacing the timing chain of a VAZ 2106

- Unlock the bolts of the two gears, loosen them and unscrew them. Remove these gears, then use a 10mm wrench to unscrew the travel stop (located to the left of the crankshaft axis), and then remove the old chain. The crankshaft gear is removed last; be careful not to lose the key.

- Use a 13mm wrench to loosen the chain tensioner nut, use a pry bar to gently press the chain tensioner shoe so that the plunger goes in, and then tighten the nut again. This is done because previously the chain tension was greater; the tensioner will not allow you to install a new one.

- Replacing the chain tensioner consists of unscrewing its working part (shoe) and replacing it with a new one, which is done in the next step.

- The chain damper is replaced in the same way. You need to unscrew 2 bolts with a 10mm wrench, remove the old element, and install a new one in its place and screw it on.

This photo report shows how to replace the timing chain of VAZ 2106, 2107 cars. Also, this method is suitable for all VAZ (Classic) car models, except for the VAZ 2105 engine, since it uses a belt drive.

Read more: How to properly bleed the brakes on a VAZ 2107 and other classic models: replacing the fluid, bleeding procedure, instructions with photos and videos

To drive the VAZ 2106/2107, a double-row roller chain is used. It transmits force from a sprocket mounted on the crankshaft to another sprocket mounted on the end of the camshaft.

The chain is a structure that develops large inertia, so a chain drive requires vibration damping.

Even a well-tensioned chain retains the property of “playing” in those places where there are no sprockets or tensioners.

The chain has virtually zero ability to stretch and compress, and fairly limited flexibility. Therefore, in order to provide it with constant tension while working in its place at any speed, it has to be literally shackled, using a system of tensioners and dampers.

This problem on the VAZ 2106/2107 is solved by a damper - an additional spring-loaded clamping bar. They have a steel frame covered with a layer of durable rubber. Tensioners and dampers dampen vibration and noise quite effectively. The chain is prevented from falling off by a stop pin that is screwed into the block or cylinder head. During normal operation the chain does not touch it.

The performance and durability of the timing chain drive depends on the material and quality of heat treatment of the chain and sprockets themselves. Manufacturing accuracy and cleanliness of working surfaces are of great importance. The main advantage of a timing chain drive is its long service life.

On engines of the VAZ family, the chain life is from 100 to 200 thousand kilometers. If high-quality materials were used in the manufacture of components, and proper tension and abundant lubrication of the drive were ensured during operation, then the chain will last no less than the engine itself. A broken circuit is a rare occurrence.

The deterioration of its condition can be monitored by increased noise when the engine is running.

For engines 2101 and 21011, where the block is lower, the number of chain links is 114, and for 2103/2106 the number of links is 116.

Replacing the timing chain on a VAZ is necessary when its critical wear has occurred, its service life has been exhausted, and tightening it with all sorts of “cunning” methods no longer gives results. These methods include:

- increasing the length of the working part of the tensioner by pressing on a piece of tube of a suitable diameter;

- “addition” of an additional bracket to the shoe and other “bullying” of the engine.

An extended timing chain no longer ensures accurate valve timing, which negatively affects engine performance.

In addition, she wears out the shoe and constantly “beats the head off” the pacifier. In addition, engine noise increases, fuel consumption increases and engine starting becomes worse.

It is also worth saying that the chain sometimes breaks with all that it entails.

- To remove the timing chain, you do not need to remove the crankshaft sprocket!

- For work we will need: keys “10”, “13”, “17”, a special wrench for the crankshaft pulley nut (or a “36” head), a screwdriver, a mounting blade, a hammer, and a bit.

- After removing the sprocket, do not turn the drive shaft, because this may disrupt the initial ignition setting!

- The original timing chain number is 2103-1006040, the average price is 380 rubles.

- Analogues:

- Fenox PC2103C3 — 519 rub.

- Kraft KT 017736 — 620 rub.

The original number of the timing chain tensioner is 2101-1006060, the average price is 364 rubles.

Analogues:

- TSN 671 — 254 rub.

- Riginal RG2101-1006060 — 230 rub.

- Trialli MT 151 — 407 rub.

Replacement frequency: every 200 thousand km.

First, remove the block head cover.

Now we turn the crankshaft until the mark on the camshaft sprocket aligns with the mark on the housing.

The mark on the crankshaft will also need to line up with the mark on the camshaft cover.

Next, bend the lock washer of the camshaft sprocket bolt. Then we engage fourth gear and put the car on the handbrake.

Then loosen the camshaft sprocket bolt.

Using a 10mm spanner, unscrew the two nuts of the studs connecting the parts of the casing. Using a 10mm socket with an extension, unscrew the bolt securing the upper casing to the bracket. We remove the casing. Using the “10” wrench, unscrew the “propeller”.

Using a 10mm wrench, unscrew the three nuts and six bolts securing the camshaft drive cover to the cylinder block.

Remove the camshaft drive cover.

Using a 17mm wrench, unscrew the bolt securing the tensioner shoe...

Using a chisel, bend the edge of the lock washer on the oil pump drive sprocket bolt.

Using a 17mm wrench, unscrew the bolt securing the oil pump drive sprocket.

We remove the star. We take out the camshaft drive chain. Then, lifting the chain, remove the camshaft sprocket.

Using a 10mm wrench, unscrew the chain limiting pin and remove it.

Before installing the chain, align the mark on the crankshaft sprocket with the mark on the cylinder block.

Using a 13mm socket, loosen the cap nut of the chain tensioner. Turn the crankshaft clockwise one and a half to two turns. In this case, the tensioner spring, acting on the tensioner shoe, will automatically adjust the chain tension. Tighten the tensioner cap nut.