The tenth family of the Tolyatti auto giant was equipped with injection engines. The first releases of cars were with 8-valve heads, and subsequent ones with 16-valve heads. Both engines were equipped with electronic control units (hereinafter referred to as ECU). The main controller collects readings from several sensors and adjusts the balanced operation of the engine (hereinafter referred to as the internal combustion engine). The temperature sensor on the VAZ 2110 is also responsible for interacting with the computer, and if it malfunctions, the “Check Engine” signal lights up, which in English means “Check the engine.” Next, we will tell you where the temperature sensor is located on the VAZ 2110, how to check and change it.

Attention! The injection "tens" have 2 coolant sensors. One for the arrow on the dashboard, and the second for exchanging data with the ECU and turning on the radiator fan. It's called DTOZH. The article is dedicated to him.

Principle of operation

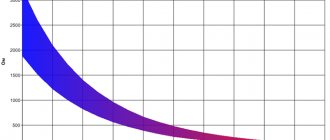

The mechanism of action of the temperature sensor on the VAZ 2110–2112 family is based on changing resistance parameters depending on the ambient temperature t°C. In essence, we have before us an electronic resistor with a negative temperature coefficient. That is, the lower the t°C, the higher the resistance of the device, and vice versa.

Table 1. Operating temperatures and parameters of DTOZH

| Temperature, t°C | Resistance, Ohm |

| 100 | 177 |

| 40 | 1459 |

| 25 | 2796 |

| 0 | 9420 |

| −20 | 28680 |

| −40 | 100700 |

The presented values can be used to check the sensor with a tester. More on this below.

What function does DTOZH perform in the ECU system?

There is no damper (choke) on injection machines. Now the fuel is enriched or leaned by the control unit using the t°C values coming from the DTOZH. In addition, the main controller monitors the operating temperature of the engine and gives a command to turn on the fan if it overheats.

Car repair and maintenance

General information about the engine temperature sensor

The engine temperature sensor (ETS), or as it is more often called, the coolant temperature sensor (ETS), is an engine temperature recorder and is a thermistor, i.e. a resistor whose resistance changes significantly even with a slight change in temperature. The sensitive elements of such sensors are substances that can change some property or parameter (usually electrical resistance) when heated or cooled.

The sensor is screwed into the flow pipe of the engine cooling system and its sensitive element is constantly in the coolant flow. At low engine temperatures, the sensor has a high resistance (about 100 kOhm at -40 °C), and at high temperatures it has a low resistance (10...30 Ohms at 130 °C).

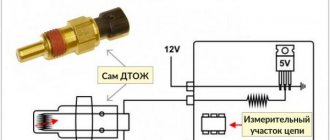

The electronic engine control unit (engine ECU) supplies a stabilized voltage of 5 V to the sensor through a resistance of a certain value and, using a divider, measures the drop in this voltage across the sensor. The voltage drop will be significant when the engine is cold and small when the engine is warm. Based on the measured voltage drop across the sensor, the control unit uses a program to determine the temperature of the coolant and engine. This temperature affects the operation of most systems controlled by electronic automation.

For example, the composition of the air-fuel mixture (TV-mixture) is adjusted based on the engine temperature: for a cold engine the mixture should be enriched, for a warm engine it should be lean. The ignition timing is also adjusted according to engine temperature.

Temperature sensor malfunctions

An open (poor connection) in the coolant temperature sensor circuit is interpreted by the engine electronic control unit (ECU) as low engine temperature. In this case, the TV mixture becomes excessively enriched, and the engine begins to operate uneconomically and pollutes the environment. The fault recorder (in the memory of the engine ECU) will record the code “Engine running on a rich TV mixture.”

A short circuit or malfunction of the coolant temperature sensor is interpreted by the ECU as engine overheating. The fuel injection system will form an over-lean fuel mixture, and engine operation will become unstable. The fault code “Engine operation on a lean TV mixture” will be recorded in the memory of the engine ECU recorder.

The coolant temperature sensor should be checked in the following cases:

- when corresponding codes are detected in the fault recorder;

- when starting is difficult, unstable operation or engine stops at idle;

- with increased fuel consumption, detonation or increased concentration of carbon monoxide CO in the exhaust gases;

- when the “engine overheating” warning light does not go out (if equipped).

Checking engine cooling system components

Before checking the coolant temperature sensor, you should ensure that the engine cooling system is working properly.

The cooling system must be properly filled with coolant. The radiator and expansion tank must be filled to normal levels. It should be remembered that the cap on the radiator or expander can only be removed when the engine is cool, otherwise coolant with an operating temperature of more than 100 ° C may splash out under vapor pressure and cause burns. For normal operation of the sensor, its working part must be constantly in the coolant flow.

The radiator cap must be sealed, otherwise air pockets may form in the cooling system and the temperature sensor readings will be incorrect. The type of coolant must comply with the manufacturer's recommendations. The fan must work properly to prevent the engine from overheating. If a thermostat or electrical contact thermal switch is installed in the cooling system, then you need to make sure that they are working.

Diagnostics of DTOZH using a multimeter and contact pyrometer

Using a multimeter, check the resistance of the thermistor in the coolant temperature sensor disconnected from the harness. The sensor output voltage is checked with the harness connected. Both of these parameters must be within specification.

Directly with the car engine running, the temperature of the sensor being tested can be monitored using a contact pyrometer. A pyrometer is a device for contact or non-contact (remote) measurement of the temperature of an object (Fig. below). If the temperature sensor is normal and the corresponding fault code is stored in the engine ECU memory, then most likely there is a problem with the connecting harness. The wiring between the sensor and the engine ECU is checked according to the manufacturer's methods and diagnostic cards.

A faulty sensor will not meet standard parameters and must be replaced as it cannot be repaired. The nominal (operating) coolant temperature varies depending on engine models. On some models, the thermostat opens at a temperature of 82 °C, on others - at 90 °C and above. Before replacing the sensor, ensure that the engine is operating within specification temperature.

In homemade conditions, checking a temperature sensor using a multimeter can be done by immersing the sensor alternately in hot and cold liquid (for example, water). The sensor's thermistor must respond to changes in temperature by changing its resistance, which can be determined by reading the ohmmeter in a multimeter. Of course, such a test only approximately diagnoses the correct operation of the sensor and compliance of the thermistor resistance parameters with specifications.

Diagnostics of the temperature sensor using a scanner

The scanner connected to the on-board diagnostic connector displays the current coolant temperature values. Measuring the current (temperature-varying) sensor resistance value is not required, since the scanner automatically compares these values with the specified sensor voltage and temperature values.

Causes and symptoms of malfunction

Service workshop technicians say that in 90% of cases, the breakdown of the temperature sensor on a VAZ and other brands of cars occurs due to natural causes. Most often, a break in the internal contacts of the resistor occurs. As a result, the DTOZh sends incorrect parameters to the ECU, for example, engine starting t° within 0 °C. The control unit considers the engine cold and gives a command to another sensor - the mass air flow sensor - to reduce the air supply, that is, to enrich the mixture. Therefore, a warmed-up engine begins to work strangely, “excitedly” with failures. Here are 3 more most common reasons for the incorrect operation of the DTOZH:

- The seal of the sensor housing is broken.

- There was a break in the electrical wires.

- The power supply has fallen off.

In the above cases, the ECU does not see the DTS system, so it attracts the driver’s attention with a “Check Engine” signal on the dashboard. In this case, the operation of the car becomes unusual:

- the engine starts with difficulty and tends to stall;

- the speed fluctuates even on a warm engine;

- strong detonation is felt;

- the former power is lost.

In addition, fuel consumption increases, and dark smoke comes out of the exhaust pipe. It is necessary to make a diagnosis. To do this, you can go to a car service center, or install a special application on your smartphone and buy a Bluetooth adapter.

Why do you need DTOZH

It should be noted that the sensor and coolant temperature indicator on the VAZ 2110 work together. Some people get confused, considering the sensor and pointer to be the same device.

DTOZH is a semiconductor resistor that has a negative temperature coefficient. It is mounted in the engine cooling system directly on the thermostat housing. The resistance indicator directly depends on the current temperature. If the temperature is high, the resistance is low, or vice versa.

The signal from the DTOZH is sent to the electronic control unit, and the ECU, in turn, adjusts the supply of the air-fuel mixture to the engine cylinders. If the engine has not yet reached the optimum temperature, the air-fuel mixture is supplied richer.

If the sensor malfunctions, the ECU displays incorrect temperature readings, which causes the engine to stop functioning normally and often overheats. Therefore, if you encounter a breakdown of the DTOZ, be sure to replace it as soon as possible.

Where is DTOZH located?

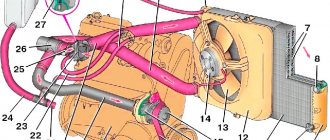

All front-wheel drive VAZ cars received a transverse internal combustion engine. If you look down, between the cylinder head and the air filter housing, you can see the location of the DTOZH. It is built into the coolant flange pipe and looks in the direction of travel, that is, towards the radiator. A block with two wires fits into it. (A little lower, directly in the block, there is another coolant temperature sensor. Thanks to it, we can see the t°C level on the dashboard. 1 white-green wire goes to the device).

Checking the sensor yourself

As you can already understand from the above, the temperature sensor transmits the level of heating of the coolant to the dashboard to the driver, so that the driver can independently visually assess its condition.

And in order to diagnose it, you need to do the following:

- We start the car in advance, let it idle until the needle shows the maximum operating temperature, that is, 90-98 degrees.

- Next, you need to disconnect the contacts and look at what the arrow on the instrument panel will indicate.

In this case, there may be two types of further course of events.

- The arrow remained motionless and does not react in any way to what is happening - the reason lies in the wiring or in the sensor itself. It is necessary to check the wires themselves for integrity, and only then proceed directly to the sensor.

- The arrow goes to “zero” - in this case it is necessary to check the fuse. If the fuse in the block is intact, and when the contact closes to ground, the arrow begins to jump, the temperature sensor does not work.

Checking with a multimeter

Checking the operation of the coolant temperature sensor with a multimeter

Before you start testing in multimeter mode, you need to prepare a container that will be able to withstand a temperature of 100 degrees, a water thermometer and a boiler, with which we will heat the prepared antifreeze for testing the sensor.

- On the multimeter, set the values to ohmmeter test mode.

- Next, we attach the probes to the body and to the sensor contacts.

- We put the sensor in a container with antifreeze and slowly begin to heat it.

We compare the data you receive with the results of a fully functional device. And if they are lower or higher than these readings, then the sensor can be considered faulty.

Thermometer and multimeter readings with resistance test mode.

| Temperature, C | Resistance, Ohm |

| 30 | 1350-1880 |

| 50 | 585-820 |

| 70 | 280-390 |

| 90 | 155-196 |

| 110 | 87-109 |

This method makes it very easy to check both new and used sensors.

Which sensor to choose

Independent automotive industry experts and service workshop specialists are of the opinion that it is better to buy original spare parts or branded analogues. The latter are selected according to codes in special combination programs. The coolant temperature sensor, VAZ 2110–2112 family, has serial number 21120–3851010–00. Sometimes at the end, instead of 00, you can see: 01, 02, 03. This indicates that the device was made at one of the related AvtoVAZ enterprises.

Table 2. Price of the original DTOZH and its foreign analogues

| Manufacturer | Number | Amount, rub. |

| GM AvtoVAZ | 21120–3851010–00 | 250 |

| AvtoVAZ | 21120–3851010–82 | 165 |

| Magneti marelli | 1719 16011 150 | 355 |

| Hella | 6PT 009 107–271 | 735 |

| Eps | 1.830.098 | 1080 |

Sources: autopiter.ru, exist.ru.

Interesting fact. Some owners buy exclusively foreign spare parts for their “tens”. The same shock absorbers, struts, springs, timing belts, electrical equipment and other parts “from there” last much longer.

Removing the sensor

Currently, there are many devices that allow you to determine a controller malfunction in a matter of seconds. And above all, we are talking about Bluetooth and Wi-Fi adapters that connect directly to the vehicle’s on-board system.

If such a universal device is not at hand, then the driver will have no choice but to dismantle the temperature sensor himself.

In particular, to do this you will have to adhere to the following instructions:

- First of all, you need to wait until the engine cools down to at least 50 degrees Celsius.

- Next, you need to drain the antifreeze as much as possible, which will prevent you from burning your hands.

- The next stage involves disconnecting the battery from the vehicle’s electrical network, for which it is necessary to disconnect the “negative” terminal.

- After this, the entire thermoelement with wires is turned off.

- At the final stage, the part is unscrewed, for which you will have to select a suitable wrench.

It should be remembered that if the device is placed at the top in the general electrical system of the car, there is no need to completely drain the coolant. But with lower placement, you should do exactly the opposite, draining all the antifreeze.

How to check

There are many cases in history when the owner installs a new spare part, but it does not work. Therefore, after purchasing a temperature sensor, it is recommended to measure the resistance before installing it on the same VAZ or another car. To do this you will need a multimeter (tester). We convert it to an ohmmeter. At room temperature (+23 °C, +25 °C), the readings should be around 2780 Ohms (as in table No. 1). If you lower the DTOZH into a glass of boiling water (+100 °C), hold it for a while and take readings, a result in the range of 175–180 Ohms should appear on the tester screen. This means the purchase is in good condition. Can be installed on a car.

Replacement

Before repairs, it is necessary to carry out a number of preparatory measures. First, you should choose a level area for the machine. It can be in the garage, it can be outdoors. Secondly, prepare the tool: open-end and ring wrenches (19 mm, 13 mm, 10 mm, 8 mm). You will also need a capacious medical syringe of 100–250 ml, a 15–20 cm dropper tube and a 0.5–1 liter jar (so as not to drain the antifreeze/antifreeze). The sequence of actions is as follows:

- We wait until the engine cools down completely.

- Use a syringe to pump out the coolant from the expansion tank (100–200 ml).

- Unscrew the negative terminal of the battery (10–13 mm wrench).

- Unscrew the air filter housing fasteners (8 mm wrench).

- Carefully tilt the “pan” to the right.

- Disconnect the power supply from the DTOZH.

- We unscrew the sensor (19 mm wrench).

- We clean the landing area from dirt.

- We screw in the new DTOZH.

The assembly must be done in reverse chronology. There is no need to use sealant, since the copper O-ring fits perfectly and seals the connection. Let's start the engine. We check its operation and inspect the repair area for antifreeze leaks. The entire event takes 15–20 minutes.

Where to buy car accessories

Spare parts and other products for the car are easily available for purchase at auto stores in your city. But there is another option that has recently received significant improvements. You no longer need to wait a long time for a parcel from China: the AliExpress online store now offers the opportunity to ship from transshipment warehouses located in various countries. For example, when ordering, you can specify the “Delivery from the Russian Federation” option.

Follow the links and choose:

| 12V car alarm, engine start/stop button, anti-theft system | SPEEDWOW car window auto-closer | Automotive Electric Throttle Actuator Controller |

| Backlit Tire Pressure Gauge, High Precision Digital Meter | Set of screwdrivers for removing seals | 20 pcs crimp clamps with pliers |