Messages [ 10 ]

1 Topic from Sergey Afipsky 05/12/2016 16:58:07

- Sergey Afipsky

- Participant

- Inactive

- Registered: 13.06.2012

- Messages: 13

Subject: Help! Knocking sound when moving the pulley.

Help, I don't know what to do. Something is knocking on the shnivy when starting, at the moment of starting to move, when the clutch pedal is released, a dull single knock or blow is heard, then when driving there is no knock, it doesn’t sound like the transmission (the transmission knocks louder), it even seems to be making a noise on the bottom and into the clutch pedal . A knock somewhere in the front, either in the center, or to the left. I've already changed a bunch of things: the lower silent blocks (the top is intact), ball bearings, steering linkage, left wheel bearing, engine mounts, I've been to several mechanics, they've pulled out anything that might come loose, they say everything seems to be normal, but there's a knocking noise. Tell me what you think?

2 Reply from Alexander Osipov 05/12/2016 17:36:38

- Alexander Osipov

- Participant

- Inactive

- From: st. Pavlovskaya

- Registered: 05.04.2016

- Messages: 212

Re: Help! Knocking sound when moving the pulley.

Help, I don't know what to do. Something is knocking on the shnivy when starting, at the moment of starting to move, when the clutch pedal is released, a dull single knock or blow is heard, then when driving there is no knock, it doesn’t sound like the transmission (the transmission knocks louder), it even seems to be making a noise on the bottom and into the clutch pedal . A knock somewhere in the front, either in the center, or to the left. I've already changed a bunch of things: the lower silent blocks (the top is intact), ball bearings, steering linkage, left wheel bearing, engine mounts, I've been to several mechanics, they've pulled out anything that might come loose, they say everything seems to be normal, but there's a knocking noise. Tell me what you think?

If the axles are worn unevenly, a knocking sound occurs when starting abruptly and changing gears. I had a similar story: I checked the front axle and at the same time tightened the adjusting nut, thereby reducing the play from the flange to the drives. The same knock was missed by the crosspiece and it was just knocking on the clutch pedal. In general, check the difference in play from the transfer case to the axles. if the play is not uniform, then you get a knock, but there is no crime here.

3 Reply from Central 05/12/2016 17:41:07

- Central

- Participant

- Inactive

- From: Krasnodar

- Registered: 22.03.2013

- Messages: 8391

Re: Help! Knocking sound when moving the pulley.

This single click when starting is a sore of the Niva. And even if you change half of the Niva’s transmission with new parts (cardans, crosspieces, internal grenades, elastic, rebuild the gearbox, etc.), the sound may go away, BUT. not for long. Checked - scored. It's like the howl of a transfer case and vibrations. Niva, in a word

Here is a short video, maybe it will help [video] And faq on knocks/noises https://www.niva-faq.msk.ru/tehnika/neis k/shst.htm

Edited by Central (05/12/2016 17:57:41)

4 Reply from Sergey Afipsky 05/12/2016 19:33:10

- Sergey Afipsky

- Participant

- Inactive

- Registered: 13.06.2012

- Messages: 13

Re: Help! Knocking sound when moving the pulley.

Thanks for answers. But the knocking feels quieter and lower, as if it were hitting rubber. It doesn't sound like knocking in drives (from backlash). I know these knocks, this is my second Niva, and I went to the specialists who are knowledgeable about the fields, they all say that the play is normal. Plus, this knock is one-time only when starting, it does not appear when changing gears and appears when the car is warmed up. Yes, the field is a treasure trove of mysteries.

5 Reply from BROTHER VASILY 05/12/2016 20:11:51

- BROTHER VASILY

- Participant

- Inactive

- From: Novokubansk

- Registered: 25.12.2014

- Messages: 119

Re: Help! Knocking sound when moving the pulley.

I don’t know if my advice will help or not, but on my 213 Niva I had such a knocking noise in the industrial area. And also when you start moving. After replacement the knocking noise disappeared.

6 Reply from ZEN 05/12/2016 21:22:49

- ZEN

- Participant

- Inactive

- From: Timashevsk

- Registered: 05.04.2015

- Messages: 604

Re: Help! Knocking sound when moving the pulley.

Without seeing the car in person, it would take a long time to list it - there are a lot of things that can knock in the field. Pads in calipers. There was also a crack in the front gearbox bracket, the one that is attached to the beam.

7 Reply from Olegarh 05/12/2016 22:25:52

- Olegarch

- Participant

- Inactive

- From: Nevinka

- Registered: 18.03.2010

- Messages: 9

Re: Help! Knocking sound when moving the pulley.

Possibly a bent axis of the lower arm, I once had a Niva and I sent it to the curb on ice, then for half a year I looked for something that made a dull knock when starting off, when changing the direction of movement, like a spring at the bottom in the front, a characteristic non-propeller sound. There was nothing visible on the assembled lever.

8 Reply from filip84 06/15/2016 13:26:49

- filip84

- Participant

- Inactive

- From: Russia

- Registered: 15.06.2016

- Messages: 5

Re: Help! Knocking sound when moving the pulley.

It looks very much like a driveshaft. The car needs to be lifted.

9 Reply from Alexander83 06/16/2016 12:25:44

- Alexander83

- Participant

- Inactive

- From: Krasnodar-Gidrostroy

- Registered: 06.03.2015

- Messages: 409

Re: Help! Knocking sound when moving the pulley.

I had a knocking noise due to the elastic coupling, changed it and it was normal

10 Reply from toothmehanik 06/17/2016 01:35:09

- tooth mechanic

- Participant

- Inactive

- Registered: 10.12.2011

- Messages: 311

Re: Help! Knocking sound when moving the pulley.

It's knocking, which means it's still on the car and hasn't fallen off. You need to be happy. Joke! A knocking sound when starting off in the field, as well as playing with gas, switching with a sharp release of the clutch is almost the norm. Climb into the inspection hole, put an adequate person behind the wheel and you can try to localize the knock

Communities › Chevrolet Niva › Forum › Tell me about the knocking sound when starting and shifting gears)

It was a sin to put a new one on the RPM, but everything remained the same)

It depends on what the nature of the knock is. Most often this is play in the drives. the transfer case has a lot of play, the cardan shafts are splined (such a loud sound, it’s like using a wrench on a pipe) and crosspieces, in the gearboxes. It’s just that everything is superimposed a little bit and there’s a big gap)

I agree, there is some play, I also get bored when starting and when switching

I changed the universal joints, the drive and rebuilt the front gearbox, it became a little better, but the knocking remained, and the only gap left is the play in the transfer case itself

There is also a sound, but it starts off a little smoother and it’s not there. You can change the cardans to CV joints and it will become even smaller. Actually scored)))

I don’t know how much less, but after lacha I was shocked by the knock. I'm trying to get used to it and move off smoothly. ShNiva 15 years old.

as people explained to me, the clutch needs to work more smoothly

I also solve the knocking issue with this, and everything is fine. There’s no escape from them, that’s how constructive they are.

I'll join. The car is a year old and almost immediately there was this knock. I searched the forums, talked with mechanics and came to the conclusion that I would have to get used to it and work the pedal more smoothly...

I had a knock on all but the fifth one before, I changed the oil in the box - only the third one remained))) it’s strange somehow

No, it’s not so, I was also interested in this topic, does everyone have such a knock, it’s just necessary to move the clutch smoothly

And the most interesting thing is that if the clutch is released without adding gas, then there is not always a knock)

Yes, that's right, without gas there is no knocking.

I had a knock on all but the fifth one before, I changed the oil in the box - only the third one remained))) it’s strange somehow

I learned how to work the clutch more subtly

Same thing. Backlash is a feature of the transmission design. Humble yourself and forget it.

These are backlashes. I’ve already gotten used to it, just like on the lawn - I let go of the clutch, and I feel like I’m hitting the gas. When switching, I released it slightly, held it for a second and released it. well, the double-squeeze shifter was clearly hammered into us at school with the back of our heads =)

Knocking from the crosspieces. It was the same. Look at which crosspiece the screw came in and replace it.

Everyone also convinced me that this is a feature of the model and I need to get used to it. But I found a man who defeated this knock. According to him, it is necessary to make a set of washers and put them in place.

thanks, what kind of washers are they?

Don't know . I ordered myself from him. I’ll let you know how I install it

This question worries many to this day) what were the results with these washers?

Yes, the knocks from the legacy of the first cornfields and CV joint cardans did not help, there is now a subframe for sale on the transfer case for around 3500 rubles. They say the problems have been solved in part and in general things have become better, but I haven’t bought it yet, I’ll tell you from personal experience I’ll tell you from personal experience, and so the current conversations again the Chevenists

I changed all the crosspieces on the cardans, but the knock remained. The service department said, forget it, there is still a knock on the new tires.

They reassured me that it was not fatal. I, too, was shocked by this knock, in a week I adapted to switching the first or second without knocking, the rest do not always work. The CV joint cardans are in place.

I now have CV joints and there is a knocking sound when I switch from first to second

I have a disconnectable front axle, so the knocking is only on all-wheel drive, but on the rear axle everything is fine, I changed the front left CV joint, installed a new one, and now it is starting to play. quality of spare parts G.

Causes

According to the official statement of the manufacturer, all-wheel drive Chevrolet Niva, a little noise is allowed even in the absence of malfunctions. This is due to the fact that the gear clutches of the transfer case, gearbox and drive shafts are made taking into account thermal clearances. The size of the latter takes into account manufacturing tolerances and the coefficient of thermal expansion of materials. Knocks and noises when starting off and changing gears are caused by insufficiently smooth engagement of the clutch.

However, gaps are not the only cause of knocking. They occur when gears, bearings and transmission shafts wear out. Axles with gearboxes also make a lot of noise when the level of transmission oil in the crankcase is insufficient.

Diagnostic technique

Methodology for diagnosing a car and eliminating the defect notes “Vibration, jerking when starting the car”:

Test drive to confirm the defect. Is the defect confirmed?

Checking for the presence of fault codes in the ECM and KURKP. Are there any fault codes?

- YES – eliminate the causes of their occurrence in accordance with the relevant technical specifications, and then proceed to step 1;

- NO – go to step 3.

Are there any comments on the stability of the engine at idle and low speeds?

- YES – eliminate the comment and go to step 1;

- NO – go to step 4.

Are there any leaks of working fluids (oil, coolant) in the gearbox area? Was there a risk of getting caught in the clutch?

- YES – eliminate the causes of their occurrence and go to step 5;

- NO – go to step 6.

How to fix it?

To properly move off a Chevrolet Niva, you have to “catch the clutch” twice to select the gap: when starting the car from a standstill and when changing gears. The work of both legs is important here. You need to release the clutch as slowly as possible while simultaneously squeezing the accelerator.

Important! Jerks and shocks in the transmission lead to accelerated wear of parts and failure of gearboxes, axles and drives.

When bearings and gears wear out, play occurs, which cannot be compensated for by smooth operation of the pedals. In this case, it is necessary to replace the worn parts as soon as possible, before the knocking noise when changing gears of the Chevrolet Niva causes serious damage.

The same applies to noise caused by a lack of oil in the crankcase of axles and gearboxes. Operation of these components without lubrication is not allowed.

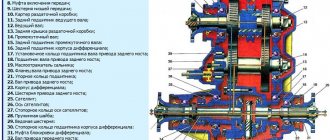

Features of transfer case Niva 2121, VAZ 2131, Lada 4x4

The Niva 2121 transfer case is used to change the amount of torque and distribute it between the front and rear axles. The box has two gears with ratios of 1.200 and 2.135. The front and rear axles are constantly driven and connected by a center differential, which redistributes torque between them depending on the resistance to wheel movement.

The Niva 2131 transfer case is attached to the body floor on two rubber-metal brackets. To adjust its position relative to the intermediate shaft flange, the holes in the brackets are made oval, and adjusting shims can be installed between them and the body. The procedure for centering the box is described in the section Determining the causes of vibration and centering the transfer case.

Also interesting: Amount of oils and fuel fluids VAZ 4×4 2121 Niva

The housing parts of the transfer case are cast from aluminum alloy and are connected to each other with studs and nuts. There is a hatch in the upper part of the crankcase, closed with a stamped steel cover. The front cover is centered on the crankcase using two locating pins. There are cardboard gaskets between the covers and the crankcase (during repairs, you can use a sealant gasket instead).

The drive shaft is mounted on two ball bearings in the sockets of the front cover and crankcase. The front bearing inner race is sandwiched between the shaft shoulder and the thrust ring by a self-locking shaft flange nut. The rear bearing inner race is sandwiched between the shaft shoulder and the thrust washer by a nut at the rear end of the shaft.

There are two drive gears on the drive shaft. The front (large) is the highest gear; it rotates freely on a heat-treated shaft journal. The rear (smaller) gear - the lowest gear - rotates freely on a heat-treated bushing mounted on the shaft with tension. The gears have two crowns. The helical (large) rings are in constant mesh with the corresponding gears of the intermediate shaft, and the gear shift clutch is connected to the spur (small) gears when the gear is engaged.

The Niva 2131 intermediate shaft is a block of two helical gears that are in constant mesh with the drive shaft gears. The front gear is also in mesh with the driven gear mounted on the differential housing.

The intermediate shaft rotates in two bearings: the front one is roller, the rear one is ball bearings. The shaft is secured against axial displacement by an adjusting ring in the groove of the outer ring of the rear bearing, which is sandwiched between the crankcase and the rear cover (the same as that of the drive shaft). A steel drive gear for the speedometer drive is pressed into the front end of the shaft.

On a VAZ-21214 car with distributed fuel injection, in addition to the mechanical speedometer drive, a speed sensor is installed on the transfer case.

The front end of the drive shaft of the Niva 2121 front axle rests on a ball bearing in the front axle drive housing, mounted on the front cover of the transfer case. The inner ring of the bearing is sandwiched between the shaft shoulder and the thrust ring by a self-locking shaft flange nut. The bearing is secured against axial displacement by a retaining ring that fits into a groove in the front axle drive housing.

The differential housing is detachable, both parts are connected by six bolts. The same bolts also secure the driven gear to the differential housing. The latter is mounted on two ball bearings. The inner race of the front bearing is held from displacement by a spacer spring washer resting on a retaining ring in a groove in the differential housing.

The groove on the outer bearing race includes a mounting ring, sandwiched between the transfer case front cover and the front axle drive housing. Thus, the differential housing is held against axial displacement by the front bearing; the rear bearing is not fixed. The front of the differential housing has splines along which the locking clutch moves. When the lock is engaged, the clutch is connected to the gear on the front axle drive shaft, connecting it to the differential housing.

In the holes of the differential housing of the VAZ 2121 there is an axis of the satellites, held by two retaining rings. Under one of the rings there is a spring washer that prevents axial movement of the satellite axis. The satellites (bevel gears) located on the axle are in constant mesh with the axle drive gears.

The transfer case control is manual, with a mechanical lever drive. The driver uses the rear lever to change gears, and the front lever to engage the differential lock. The design of the gearbox control drives is similar. The lever swings in the longitudinal direction on an axis installed in the bracket eyes in front of the Niva 2131 transfer case.

To reduce friction, plastic bushings are inserted into the hole in the lever. The lower end of the lever fits into the groove of the rod and is fixed with a figured spring. The other end of the rod is connected to the fork of the corresponding clutch (gear shift or differential lock) and is secured with a bolt. The rod at the exit from the box is sealed with an oil seal and protected from dust by a rubber corrugated cover.

To fix the drive in the selected position, a ball lock is used - a spring-loaded ball fits into the grooves on the rods. There are three of them on the gear shift rod - for “neutral”, high and low gears; on the differential lock rod of the VAZ 2131 there are two (“on” and “off”). A switch is screwed into the front axle drive cover, which closes the warning lamp circuit when the differential lock is engaged.

Read news about the new Niva

- All-terrain vehicle fracture 4x4: photo of step-by-step assembly video of a trip on an all-terrain vehicle

- Homemade all-terrain vehicle on low-pressure tires (45 photos)

- Dismantling and assembling the gearbox Niva 2121, Niva 2131

- Nissan engine on a Niva – Replacing a Niva engine with a Japanese one

- FROST car air conditioners // Online store // Prices // Air conditioners for cars Lada VAZ, VolksWagen Polo, Daewoo Matiz

- Transfer case Niva VAZ - do-it-yourself repair and replacement

- Transfer case Niva 2121: principle of operation, repair

- Gearbox VAZ-21213 Lada Niva, VAZ-21214 Lada 4x4, diagram

What could be the reason for a knocking sound when shifting gears in a Chevrolet Niva?

Most car enthusiasts have at least once heard extraneous sounds while shifting the gearbox. Knocks and squeaks sometimes occur in Niva Chevrolet. This is due to the operating characteristics of the machine. An SUV is used to travel on various types of surfaces. Unevenness, shaking or a particular driving style can negatively affect the condition of the components.

The article will tell you why there may be a knock when shifting the gearbox in a Chevrolet Niva and how to fix this problem yourself.

Chevrolet Niva knocking noise when starting from the front

Hello everyone, I looked at the balls, everything was fine, I knocked out the ice from all the cracks, and then extended the armor and everything disappeared somewhere, what the hell. All the knocking has disappeared, only occasionally something happens, but we’ll survive this bullshit. Happy New Year, everyone . and good luck on the roads. drinks:

Maybe the ice is rattling somewhere? Still, in the cold they are as hard as stones. In cold weather I don’t pay attention to extraneous sounds; with the thaw they usually go away

For a long time, I was bothered by dull knocks when driving slowly over rough terrain. Diagnostics (play detector, a good thing, they detect almost all knocks on the suspension) did not reveal anything. .

Causes of knocking

Car owners note that in most cases, the appearance of extraneous sounds, creaks, shocks and noises comes from the transmission . This is due to the fact that the node experiences increased loads more often than others. As a result, problems such as jerking when starting to move, clicks or crackling sounds when changing any gear may be observed. These signs are characteristic of different problems, so you need to know the main ones.

The manufacturer states that slight noise is acceptable . The design involves the use of all-wheel drive, so the load increases in off-road conditions. Extraneous sounds may appear even in the absence of breakdowns or malfunctions. The main reason for this behavior is due to the fact that the gear clutches of the transfer case, gearbox and drive shafts are designed to take into account the presence of thermal gaps. The size is adjusted to take into account the physical properties of the materials used to expand when heated.

Touching deserves special attention . At the moment the movement starts, gears are changed. At this moment, extraneous sounds, noises and tapping may occur. The problem is that the clutch is not warmed up and its activation is not smooth enough.

The presence of gaps is not the only reason for knocking when shifting the gearbox . It appears if it has become unusable:

Faulty axles with boxes can also make extraneous sounds. This is often caused by a low level of transmission oil in the crankcase. In the event that problems arise with the chassis, the driver may encounter the following changes in the behavior of the car on the road :

- noises appear when turning or rotating the wheels;

- difficulties arise when switching gears while moving (not at start);

- the selected gear is disabled;

- automatically switches to the “neutral” position;

- oil leaks are noted.

Owners may encounter similar problems already at a mileage of up to 10,000 km . The knocking noise in the transmission will only get worse.

also exist :

- backlash occurs;

- the move loses smoothness;

- The speed cannot be turned on or changed while in motion.

If such violations appear, it is recommended to conduct a detailed diagnosis of the machine’s condition .

Transmission malfunction

The second possible reason is the checkpoint. But if the gearbox is not completely working, then you can also observe other manifestations besides jerks at the start: difficulty shifting any gear, noise from the unit, etc.

If we are talking about a manual transmission, then repairing it can be inexpensive. It is difficult to replace any gear in such a mechanism, but it is possible, and this is something that specialists at service stations undertake. In case the situation becomes more complicated. Repairing it will be expensive. If the variator in an automatic transmission begins to jerk, then the service station most often offers its complete replacement, since repair in this case is impractical.

Troubleshooting

If there is a knocking noise when shifting gears in a Niva Chevrolet, you need to immediately diagnose the car. It is recommended to do this at a specialized service station, as they have all the necessary equipment.

Primary signs and consequences can be calculated independently:

- characteristic sound in neutral - you need to check the oil level, and also check the drive shaft bearing, with a 90% probability it requires replacement, you can fix the malfunction yourself;

- a knocking sound appears when turning on or changing gears - the locking device has become unusable, the synchronizer clutches require replacement, the transmission mount is loose;

- knocking is present in the box only while driving - the synchronizing clutches or bearings are worn out, the oil level in the box has dropped to a critical level;

- shocks are present when starting from a stop or changing gears in motion - the clutch pedal is not fully depressed, the oil level is low (90% when the shocks do not stop), worn gears.

Diagnostics makes it possible to identify a malfunction that is rare for such a problem - a broken linkage . This unit connects the transmission and the rod together by means of transmitting rotation in the box.

In turn, a problem with the rocker is identified if additional problems are present :

- gear shift lever play;

- difficulties with switching;

- difficulties in adjusting the mechanism.

The examination will help eliminate or confirm the need to adjust the transmission drive , since failure of this element can also lead to knocking. A sign of a malfunction in this case will be the erroneous inclusion of speeds.

Computer diagnostics will help identify problems with the clutch . If they are present, then when you start moving or already on the road, a characteristic twitching will appear. If no action is taken, a complete replacement of the unit will be required. It is recommended to pay attention to all parts of the mechanism when checking the clutch. They will help you understand more clearly why there are extraneous sounds or rapid wear of nearby parts.

Engine Troubleshooting

After first jacking up the engine, the old, broken cushions are unscrewed. New ones are installed in their place.

Now, if the engine is misfiring, you must first determine what the reason is. This occurs due to a bad armor wire, a defective spark plug, or wear of one contact in the breaker-distributor. In the case of an injection engine, the injector may become clogged. You can determine which cylinder is not working in a simple way - by removing the armor wire from the spark plug one by one and listening to the engine reaction. If the engine starts to work even more irregularly, then this cylinder is in order. If, after removing the armored wire, it did not react in any way, then this particular cylinder is not working. Now, having identified the non-working cylinder, you can begin to find the cause of its failure and eliminate this problem.

How to fix the problem yourself

Diagnostics will help you find the right solution. You can fix the problem either with the help of specialists or on your own . In the second case, certain knowledge and skills will be required, as well as a supply of free time. To remove all faults, you will also need tools (the kits may differ depending on the faults present).

Also, troubleshooting is facilitated by “catching the clutch” - you need to press it quickly 2 times . This is required to select the gap. The first time the action is performed is at the moment the movement starts. You will need to squeeze the clutch a second time directly at the moment of gear shifting. In this case, to remove the malfunction, you will need to use two legs at once. The clutch will need to be released as slowly as possible; in this case, you cannot rush. Simultaneous action - squeezing the accelerator. You also need to remove your leg slowly so that there is no increase in speed. You should not shift the gearbox at this stage.

Repairs or diagnostics, as the first step to solving the difficulties that have arisen, cannot be delayed . The whole reason is that the resulting jerks, shocks or extraneous sounds in the transmission can lead to accelerated wear of parts. As a result, a certain element will fail - the entire gearbox will need to be replaced. The drive or axle may also be damaged.

If bearings and gears fail, backlash occurs . It cannot be prevented by simply working with the pedals - the problem will persist. A complete replacement of a worn-out part will help solve the problem. You cannot delay repair work, as timely replacement of spare parts will help prevent a more serious breakdown or emergency situation on the road.

If noise occurs, you should also not delay inspection and subsequent repairs . The easiest way is to measure the oil level yourself. If it turns out that there is not enough of it, the first thing you need to do is top up to the required level. This will restore the node to full functionality. The fluid will need to be checked in the crankcase, bridge and box.

It is important to remember that operation of the listed components without lubrication (presence of oil) is not allowed . In the event that after changing the oil, after a short period of time, a lack of oil is noted again, the problem may be related to its leakage. In this case, you may notice oil particles on the box. To eliminate the malfunction, it may be necessary, for example, to remove the gearbox or rebuild it.

Transmission Troubleshooting

The first difficult task is removing the gearbox from the car. Depending on the drive of the vehicle, the work required to remove the transmission varies. Before starting work, be sure to drain the oil from it. On a rear-wheel drive car, first unscrew the cardan, the gearshift lever, and then the gearbox itself is unscrewed from the engine. In the case of a front-wheel drive car, the constant velocity joints are unscrewed and removed, and the shaft connecting the gearshift lever to the gearbox is dismantled. And only then the transmission is unscrewed from the engine and removed.

After disassembling the gearbox, you need to inspect the gears and synchronizers for signs of wear. Damaged and worn parts should be replaced. Upon completion of the work, everything is assembled and installed in its place in the reverse order. Once the gearbox is in place, the ideal option would be to change the oil in it.

avtoexperts.ru

From time to time, every car owner is faced with a situation where the vehicle begins to jerk when starting to move when pressing the gas pedal or driving at low speeds. This behavior of the car is often caused by not too serious disturbances in the operation of the internal combustion engine and other systems. However, they need to be diagnosed and eliminated as soon as possible. Otherwise, they can lead to a complex breakdown, which will take a lot of time and money to fix.

When can a car “jerking” appear and what are the causes of the phenomenon?

In the vast majority of cases, the symptom of unstable driving can be diagnosed in the following situations:

• While the vehicle is starting to move (pushing away).

• During slow driving at low engine speeds.

• If necessary, accelerate suddenly while driving on the road.

• While the power unit is operating at high speeds.

In addition, the described behavior of the vehicle may also occur in other operating modes. The reason for this may be malfunctions of the following systems and components of the machine:

1. System for supplying the fuel mixture to the combustion chamber.

2. Ignition system.

3. Incorrect operation of the transmission.

4. Malfunctions in the operation of the car's electronic engine control unit.

How to troubleshoot?

Let's take a closer look at the main and auxiliary systems of the car, which can cause the vehicle to “jerk” while driving. We will also focus on how to eliminate diagnosed problems.

Fuel mixture supply system

Quite often, the cause of unusual behavior of a car while driving is improper operation of the fuel supply system to the engine or the injection system of the air-fuel mixture into the combustion chamber. In other words, the internal combustion engine cannot obtain the required amount of gasoline or diesel fuel. As a result, there is not enough torque from the shaft to transfer mechanical force to the suspension, and you end up with a dip in power.

To get rid of troubles, you need to:

• Check the operation of the throttle assembly.

• Test the functionality of the idle speed sensors.

• Check the correct position of the throttle valves.

• Check the functionality of the mass air flow sensor.

In most cases, the defect is found in the injectors, which are responsible for injecting the fuel mixture. Less commonly, an uneven ride is associated with the air passages that connect the injector and the air filter. Depressurization is possible, which leads to loss of pressure.

The problem found can be corrected by replacing damaged parts. You can do this yourself, but it is better to seek help from service center specialists. After carrying out the work, it is important to additionally check the tightness of connections along all fuel and air supply lines.

The car jerks due to engine problems

Let's look into the heart of the car - the engine. What could be the reason why the car jerks when changing gears?

The first reason for engine operation may be uneven fuel distribution, which leads to instability in the movement of the power unit. Jerking of the car can also indicate unstable operation of the cylinders. In this case, the whole reason lies in the spark plugs. A low-quality or worn-out spark plug does not ignite mixtures in the cylinder well, and therefore disrupts its operation.

We should not forget about the human cause of problems with engine operation. Jerks when shifting gears can occur when the quality of the fuel is low. Remember that by saving on fuel and lubricants, you do not save on repairing your car.

If we consider modern injection engines, there may be many more reasons. The operation of such a motor is fully automated to increase the efficiency of the indicators. Yes, injection internal combustion engines are economical, easy to start and operate reliably, but diagnosing a malfunction is much more difficult. The main reasons for car jerking can be either the failure of one of the sensors or the wear of any element. Let's look at some of them:

- a malfunction of the on-board computer indicates a breakdown of the speed sensor;

- worn cables that do not allow fuel to be ignited on a regular basis for stable engine operation;

- clogs in the injector nozzles, interfering with the flow of fuel;

- idle speed sensor failure.

The car jerks due to engine problems

Let's look into the heart of the car - the engine. What could be the reason why the car jerks when changing gears?

The first reason for engine operation may be uneven fuel distribution, which leads to instability in the movement of the power unit. Jerking of the car can also indicate unstable operation of the cylinders. In this case, the whole reason lies in the spark plugs. A low-quality or worn-out spark plug does not ignite mixtures in the cylinder well, and therefore disrupts its operation.

We should not forget about the human cause of problems with engine operation. Jerks when shifting gears can occur when the quality of the fuel is low. Remember that by saving on fuel and lubricants, you do not save on repairing your car.

If we consider modern injection engines, there may be many more reasons. The operation of such a motor is fully automated to increase the efficiency of the indicators. Yes, injection internal combustion engines are economical, easy to start and operate reliably, but diagnosing a malfunction is much more difficult. The main reasons for car jerking can be either the failure of one of the sensors or the wear of any element. Let's look at some of them:

- a malfunction of the on-board computer indicates a breakdown of the speed sensor;

- worn cables that do not allow fuel to be ignited on a regular basis for stable engine operation;

- clogs in the injector nozzles, interfering with the flow of fuel;

- idle speed sensor failure.