The efficient operation of the injection engine is ensured by a set of sensors. They all connect to the ECU. Lada hatchbacks of the 2112 family were produced only with injection engines, and two varieties of these internal combustion engines are 16-valve. We will talk about them further. All VAZ-2112 sensors, their location and appearance will be shown in the photo.

The excess oil pressure sensor, which is not connected to the ECU, is shown in the video.

Injection system

Nowadays, cars have become more advanced and technologically advanced. The control process from a carburetor engine switched to an injection engine. A car engine injector is much more reliable than a carburetor.

The injection system will allow you to more correctly control the car engine, which allows you to use fuel more economically. Modern cars are equipped only with injection engines, since using a carburetor engine is not advisable.

The injection system uses a large number of different sensors that send signals to the electronic engine control unit. Since the injection system uses a large number of sensors, they often fail. This is due to aging or improper operation of the car.

In this article we will talk about all the sensors installed on Lada cars, what role they play and what they are needed for.

Where is the speed sensor located on Lada Priora 8 and 16 valves: diagram

- Replacing the sensor on VAZs

- for replacement

Measuring the speed of a car has long been carried out non-mechanically. A speed sensor is responsible for this, the operating principle of which is based on the Hall effect. This sensor supplies the controller with electromagnetic pulses, on the basis of which the latter calculates the speed of the machine.

Vehicle speed is measured as follows. For each kilometer of distance traveled, the sensor sends a fixed number of pulses to the controller - 6004. The faster the car moves, the higher the transmission frequency. Thus, the controller calculates the speed based on the time interval between pulses.

In addition to its main function, this sensor indirectly helps the car owner save fuel. When the car is coasting at a speed of over 20 km/h, the controller, based on sensor readings, does not open the fuel supply.

The speed sensor of the VAZ 2114, like all other cars of the VAZ family, including the VAZ-2109, Kalina, Priora, is located on the gearbox, or rather, on the speedometer drive mechanism. To find it, you need to crawl under the hood; it is advisable to remove the adsorber to open up the space (you can do without removing it, but getting to the speed sensor will be more difficult). On the side of the right inner CV joint, you need to find the wire that goes to the gearbox; it is this that is connected to the speed sensor connector.

Removing and replacing the speed sensor

To get to it you need to have some tools and a little time. Tools you will need:

- Two screwdrivers: flat and Phillips.

- Socket head for 10.

- Handle with ratchet.

To get to the location of the required element, you need to unscrew the clamps and remove the injector inlet pipe, which is routed from the air filter to the throttle assembly. To do this, unscrew the coupling bolts on both sides of the pipe, unscrew the bolt of the thin hose and remove the entire structure. After completing these steps, you will be able to see the location of the speed sensor.

Once nothing interferes with the view of the speed sensor, you can dismantle it.

- Disconnect the wiring going to the sensor from the power connector.

- Using a 10 mm socket and a ratchet, unscrew the nut on the stud.

- Carefully pull the sensor body out of the seat. If it is difficult to dismantle, you can use a flathead screwdriver to make it easier.

- Carefully pry the housing of the element being removed from below and remove it from the gearbox.

- Next, we install a new speed sensor and securely fix it, having previously lubricated the sealing rubber with machine oil.

- We return the air duct pipe to its original position and secure it.

- Connect power to the battery.

1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

If the engine stalls while idling , then most likely you will need to check several sensors (mass air flow sensor, air sensing sensor, speed control valve, air pressure sensor) in order to determine the culprit. Previously we looked at verification methods:

Now, checking the speed sensor yourself will be added to this list.

If this sensor malfunctions, it transmits erroneous data, which leads to disruption of not only the engine, but also other components of the car. The vehicle speed meter (VSM) sends signals to the sensor, which controls the operation of the engine at idle speed , and also, using PPX, controls the air flow bypassing the throttle valve. The higher the speed of the car, the higher the frequency of these signals.

Sensor selection

You need to purchase a new speed sensor to avoid problems. Visually, the sensor intended for the Priora is almost no different from the Kalina element, and many sellers claim that one model can easily be replaced by another model. Sensors that look similar have completely different fillings, and after installing an inappropriate element, frequent malfunctions in the operation of the ECU and incorrect readings on the speedometer will occur. Therefore, before purchasing, you need to carefully study the old part, rewrite the catalog number and purchase exactly the same model.

https://www..com/watch?v=7drLW_Qlgj4

Why does the speedometer on the VAZ 2110 not work? We solve minor breakdowns ourselves

In the vast majority of cases, injection VAZ-2110s are equipped with electronic speedometers. And, as a rule, they are often alarmed by malfunctions that can manifest themselves in different ways. And if a car owner encounters a problem when the speedometer on a VAZ 2110 does not work, he needs to find out the degree of complexity of the breakdown. After all, the device may not work at all or work, but partially and with visible malfunctions. For example, when the engine is not warmed up, the speedometer works properly, but then it starts to act up.

It may be that the needle jumps from one indicator to another or freezes at a certain mark. The speedometer on a VAZ 2110 does not work - the problem is quite common and easily solved. Moreover, such a malfunction needs to be eliminated as soon as possible, since it is difficult for the driver to navigate the speed of the car and thus there is a possibility of meeting with a traffic police inspector and receiving a fine for violating speed. To eliminate the problem, it is necessary to identify the reasons for its occurrence.

Typical causes of speedometer failure It is no secret that on the VAZ 2110 the on-board computer plays an important role in the operation of the speedometer. If you take an electrical circuit from a car, you will notice that the electronics are powered from a mounting block with a 10-amp fuse. When the speedometer breaks, the first thing you need to do is check all the contacts. Perhaps the malfunction occurred due to oxidation of one of the contacts. If the contacts are in normal condition, it is worth thinking about possible problems in the speed sensor. Or rather, in its connectors.

The fact is that they are located in such a way that they are constantly in contact with dust, dirt and moisture. Therefore, it would be a good idea to tug the wires a little to shake off any possible contamination. It’s better to try to get them out and clean them more thoroughly. Sometimes checking the connectors doesn't help. Then you have to test the speed sensor itself. Here you don’t need to be a specialist or have any special equipment in your garage. A regular drill or screwdriver will suffice. You will also need a partner for the job.

So, take a screwdriver, set it to counterclockwise rotation mode and clamp the sensor drive. The partner turns on the ignition and monitors the speedometer. At this moment you need to turn on the screwdriver. If the speedometer does not work, then it is time to replace the speed sensor. In the case of normal operation, you need to look for a problem in the drive located inside the transmission. If we are talking about a speed sensor, then it would be reasonable to check the socket of its drive shaft. Often the shaft wears out and takes on a round shape, which does not allow efficient transmission of torque.

By the way, this is most often the culprit for the constant twitching of the speedometer needle. Therefore, if such a problem is observed, then the first thing you need to do is check the shaft and only then consider other options. There are a number of other possible reasons for the speedometer malfunction on the VAZ-2110. But they can only be detected through in-depth diagnostics, available only at service stations. Features of the speedometer The speedometer on our car is located on the main instrument panel. Therefore, if the causes of malfunctions lie precisely in the speedometer, then it is necessary to change the entire shield, and not its individual element.

Unfortunately, spare parts for such dashboards are not currently available separately. This is precisely what complicates replacing the speedometer when it breaks. In principle, all of the above allows you to quickly deal with the problem that has arisen and quickly solve it. But we must remember that if the speedometer on a VAZ-2110 does not work, then it would not be a bad idea to contact a service station, where the reasons can be calculated much faster.

If the cigarette lighter of VAZ 2110, 2111 and 2112 does not work

| Often the cigarette lighter is used as a socket, so its failure entails the disconnection of additional devices connected through it. In the article you will find a number of reasons why the VAZ 2110 cigarette lighter stopped working. |

Cigarette lighter fuse blows

The first thing you should check after the cigarette lighter fails is the fuses, there are two of them:

- F6 for 15A, responsible for the portable lamp socket and cigarette lighter.

- F18 at 25A is responsible for the heating and ventilation control unit, as well as the barchak lighting lamp, which according to the circuit is connected through the cigarette lighter.

Checking the cigarette lighter wiring

It is necessary to check the integrity of the cigarette lighter wiring. First of all, pay attention to the connectors located near the passenger’s left leg; they should be inserted tightly. Then make sure that the connector on the cigarette lighter itself is not disconnected. Also make sure that the mounting block is in good condition. Based on the results of the test, the wiring to the cigarette lighter can be traced from Ш5-3 mounting block to the +12V connector of the cigarette lighter. If the wiring is intact, and the fault lies in the cigarette lighter itself (for example, it shorts), then only replacing it with a new one will help.

Source: https://prometey96.ru/obsluzhivanie/zamena-datchika-skorosti.html

Mass air flow sensor

The mass air flow sensor, also known as mass air flow sensor, is installed on all fuel-injected Lada and VAZ cars. The sensor is located between the intake receiver bellows and the air filter box. This sensor is involved in the process of forming the fuel-air mixture. It also estimates the amount of intake air, taking into account its temperature. If there is a malfunction, the “CheckEngine” light does not always light up.

Signs of sensor malfunction:

- Loss of vehicle dynamics;

- Unstable idle;

- Jerking when moving;

- Difficulty starting the engine;

- High fuel consumption;

Priora speed sensor: description and detailed replacement instructions

The Priora speed sensor differs from the sensors of domestic cars produced earlier in that it is electronic, while similar equipment, for example, on “tens”, works based on the Hall effect, as a result of which a signal of a certain pulse and frequency is transmitted to the controller . In this case, the frequency of the signal is directly proportional to the speed of movement and in quantitative terms is equal to approximately 6004 pulses per kilometer of travel.

This item has obvious defects

Signals from the speed sensor transmitted to the controller (via an electronic unit on Priora) allow the latter to use their values to control engine idle speed. In addition, the same signals are used by the odometer and speedometer located on the dashboard.

The speed sensor is important for driving safety

The speed sensor is the most important element of vehicle control, the serviceability of which must be constantly monitored, since incorrect display of vehicle speed is fraught with accidents and problems with regulatory authorities. In addition, a faulty piece of equipment can lead to increased fuel consumption, which, you see, is not economically profitable.

On Priora, the reliability of the speed sensor is rated as average. Possible disadvantages:

- Oxidation of the connector and wires near this element often occurs, which leads to instability of rotation or engine stopping at idle.

- There are manufacturing defects when the product body is not sealed enough. As a result, water vapor and oil contained in the gearbox environment enter the device. This affects the soldering of the electronic circuit, which fails.

- It is worth noting the damage this element receives at high speed. Here we can talk about deformations of the plastic and the loss of a metal rod or damage to the speedometer cable caused by mechanical means. The latter can be prevented by lubricating the cable with machine oil.

If there is a problem with the speed sensor, the controller enters data with code “24” into RAM and lights a signal indicating the need to check the engine. If the car has problems with the engine idling, but the “Check Engine” signal does not come on, then the problem may be with another sensor (mass air flow).

Checking the operation of the speed sensor begins with grounding on the third contact and supply voltage (12 V) on contact “1”. Pulse signals on the second contact are carried out at a speed of at least five kilometers per hour for the drive wheels.

To study the state of the second contact, an oscilloscope or multimeter is usually used; for the first and third contacts, you can use the dialing technique.

| Contact | Decoding |

| 1 | +12V |

| 2 | DSA+ |

| 3 | 0V |

Parts from Kalina are not suitable for Priora

Replacing a speed sensor begins with purchasing a spare part. In appearance, the Priora sensor is not very different from the Kalina parts, but has a gray color, a slightly different size and a different “filling”, so you don’t always need to listen to the sellers’ assurances that these elements are interchangeable.

Product markings are usually found in the form of numbers 2170-3843010-02, but there are also modifications with the last numbers 04 (for euros), so before purchasing you should definitely familiarize yourself with the car diagram. Installing an incorrectly configured sensor can lead to malfunctions in the ECU, as well as incorrect speed readings.

New sensor

Finding a speed sensor on a car like a Priora is quite simple - it is located on the gearbox. Its appearance depends on the time of production of the car: on very old cars it looks like a bolt, but is not original for the Priora, because at the beginning of production, parts from older models were installed on it.

Later assemblies contain sensors that are attached using latches on the housing.

Replacement work will take a few minutes

Once we have found where the speed sensor is located, we can begin work on replacing it. For this work you will need a 10mm spanner.

You need to start by disconnecting the negative terminal on the battery, then remove the air supply hose from the pipe on the throttle assembly, then release the latch, disconnect the block (with wires) from the speed sensor. Next, you need to unscrew the nut at the stud on the speed sensor mount and remove the speed sensor from the gearbox.

Installation of this element is carried out in the reverse order and takes several minutes for a Priora car. In some cases, it is not necessary to replace the entire sensor, because problems can sometimes be associated with damage to the rubber ring in the groove on the sensor rod. Here you can get by simply replacing the ring.

Loading …

You may also like

Source: https://1ladapriora.ru/modifikacii/datchik-skorosti.html

Speed sensor

The speed sensor is installed on the gearbox housing and is designed to measure the speed of the vehicle and calculate the kilometers traveled. The speed sensor also provides readings for preparing the air-fuel mixture while the car is moving. You can notice that when the car is rolling at neutral speed, the idle speed is slightly higher than when the car is stationary. When there is a malfunction, the “CheckEngine” light almost always comes on.

Signs of sensor malfunction:

- There are no increased speeds when driving at neutral speed;

- Speedometer does not show speed;

- The odometer does not work;

- EUR does not work;

What is a speed sensor on a Priora?

A Priora is rushing along an asphalt highway; the speedometer needle moves smoothly on the instrument panel, informing the driver about the pace of its progress. Everyone is used to this picture. Old experienced drivers remember the speedometer drives of old cars. It was a metal cable that rotated at a certain speed and drove the meter needle through a system of gears. But what about this situation on a modern car? In the age of widespread computerization?

Electronic speedometer and the basics of its operation

Even before the complete computerization of cars began, the speed indicator system was transferred to an electronic basis. This system consists of the following elements:

- Drive mechanism in the gearbox (gearbox).

- Speed sensor (signal reader) at the gearbox.

- Wiring harness.

- Speed indicator (speedometer) in the instrument cluster.

Although to be precise, the drive mechanism remained the same for both the cable indicator and the electronic one. All the salt was in the sensor and speedometer. Based on the Hall effect, the sensor reads the pulse frequency and transmits information through a wire to the speedometer, where the induction motor system is activated and drives the indicator needle.

Features of the Priora speed indicator drive

The disadvantage of the old sensor or cable rotation mechanism system was the plastic gear built into the gearbox. In case of breakage or wear of its teeth, it was necessary to dismantle the gearbox and completely disassemble it. At Priora, this problem was solved in a new way. The gear is no longer in direct contact with the sensor. Using the Hall principle, the sensor reads the rotation speed from the clearance in the gear. Therefore, the reader itself has a different shape from previous models.

Important! When replacing a device, you must find and rewrite the catalog number of the sensor in order to purchase a part of the corresponding brand in the store.

Signs of a malfunction of the Priora speed sensor

Of course, the most obvious sign that immediately catches your eye is the speedometer needle stopping while driving. Or, conversely, the arrow shows movement at a time when the car is standing still. This is a very unpleasant feeling.

Attention! The most reliable way to detect this breakdown is computer diagnostics of the electronic control unit (ECU).

But since the Priora is a modern computerized car, all actuators and sensors of the ECM (electronic engine control system) are under the supervision of this “brain”. And in the event of a malfunction of any component, the “Check Anger” warning lamp lights up. On the Priora dashboard there is a yellow silhouette of the engine. This means that you need to go to a service center and carry out diagnostics.

Very important! Even if you manage to fix this Priora malfunction, you will still have to go for diagnostics, a modern ECU accumulates errors in memory. And it’s better to erase them with hardware.

With all this, the Priora computer does not always detect this malfunction. Here is a typical example: the sensor is faulty, but it is faulty in such a way that it supplies the necessary signal to the panel. The arrow works fine. The speedometer, as a semi-mechanical device, has fewer requirements for signal accuracy. However, the signal to the block is distorted. The fact is that a certain speed limiter is built into the ECU at the factory.

The following picture emerges: the car starts and moves off perfectly, but at a speed of 20-25 km/h, it begins to twitch, stall, and the fuel pump works intermittently. What's the matter? And it is precisely in the speed sensor. And only diagnostics can reveal this. The fact is that the speedometer needle shows the above-mentioned speed, however, the “brain” receives a signal that the car has picked up a speed of 220 km/h in a few seconds. Considering the sensor to be operational, the computer takes action to limit the speed.

That is, it turns off the fuel pump. That's the whole solution. However, you can only see it on the screen of a special scanner.

Replacing the speed sensor

This is, in principle, one of the simplest operations in repairing the ECM system. It consists of just a few techniques and requires a minimum of tools, you only need:

- A wrench or a socket with a 10 mm wrench.

- Curly screwdriver.

- New speed reader.

- Marker.

First you need to lift the hood of the Priora. The sensor is located in the gearbox in the same place where the cable input was located on previous VAZ models. That is, access to it is convenient from above.

You need to remove the air pipe between the atmosphere filter and the throttle valve. These are just two clamps tightened with a screwdriver. After this, the sensor is completely accessible. Therefore, it is necessary to remove the connector from it and check the wires. Insulate if necessary.

After this, you need to unscrew the 10mm bolt that holds the sensor fixing plate. Mark its position. Remove the old one and insert the new one, paying attention to the rubber ring. Replace the reader clamp and carefully tighten this bolt. Connect the connector. The operation is completed. Check your computer's memory for errors, and you're ready to go.

In the video there are “glitches” of the speed sensor on the Priora:

Source: https://mashintop.ru/articles.php?id=2905

Coolant temperature sensor

Coolant temperature sensor, also known as DTOZH. Installed in the thermostat housing. Serves to prepare the air-fuel mixture when starting the engine. It also simultaneously displays coolant temperature readings on the car’s dashboard and turns on the engine cooling fan. If there is a malfunction, the “CheckEngine” light does not light up.

Signs of sensor malfunction:

- Loss of vehicle dynamics;

- Unstable idle;

- Jerking when moving;

- Difficulty starting the engine;

- High fuel consumption;

- Difficulty starting in the cold season;

How to check

After removing the sensor, it should be visually inspected for damage or corrosion. The easiest way to check the DTOZH is to replace it with a known good one.

- multimeter (in voltmeter mode, ohmmeter with a measurement limit from 100 Ohm to 10 kOhm);

- thermometer (with a measurement limit of at least 100 o C);

- heat-resistant container with a volume of 0.5 l.

The procedure for checking the power supply circuit of the DTOZH:

- Switch the multimeter to voltmeter mode;

- Remove the block with wires from the sensor and turn on the ignition;

- Connect the negative probe of the multimeter to the engine ground, and the other to terminal No. 1 of the block;

- The voltage at the output must be at least 12 V.

If there is no voltage or they are less than 12 V, it means that the battery is discharged, the power circuit or the computer is faulty.

Procedure for checking DTOZH:

- Switch the multimeter to ohmmeter mode;

- Prepare a container with hot water (about 100 o C);

- Connect the multimeter probes to the sensor terminals and lower its working part into water;

- We measure the resistance of the DTOZH as the water cools.

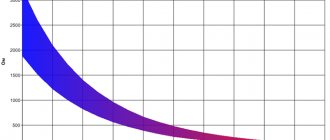

The sensor resistance should be close to the data shown in the table:

| Coolant temperature, °C | DTOZh resistance, Ohm |

| 100 | 177 |

| 90 | 241 |

| 80 | 332 |

| 70 | 467 |

| 60 | 667 |

| 50 | 973 |

| 45 | 1188 |

| 40 | 1459 |

| 35 | 1802 |

| 30 | 2238 |

| 25 | 2796 |

| 20 | 3520 |

| 15 | 4450 |

| 10 | 5670 |

| 5 | 7280 |

| 0 | 9420 |

The verification process is also shown in the video:

If the DTOZH turns out to be in good order, the cause of the malfunction may be poor connector contact, broken wiring, or a faulty ECU.

Do not forget to change the antifreeze/antifreeze in the cooling system on time, and use the coolant recommended by the manufacturer.

The Priora 16-valve coolant temperature sensor is no different in design from the 8-valve one. Essentially, these are the same device that measures the temperature of antifreeze.

- What problems arise?

- Priora temperature sensor

A distinctive feature of the Priora is the presence of two detectors that are not connected to each other. One works only with the dashboard, transmitting measurement data to it, while the other coordinates its work with the brains of the car. Together with them, ensuring uninterrupted engine operation by turning on additional cooling systems if necessary.

Temperature and coolant sensor

The detector operates based on the principles of resistance. Being a thermistor, the device's resistance values are directly related to changes in coolant temperature. Based on the readings of this meter, among other things, the on-board computer makes a decision on the supply of air and fuel to the engine. That is why when they talk about a malfunction of the DTOZ, they also talk about increased fuel consumption.

Crankshaft position sensor

Crankshaft position sensor, also known as DPKV. Installed on a bracket near the generator belt drive pulley. Works on the law of electromagnetic induction. Reads readings from the crown of the generator drive pulley. Sets the ignition timing angle (IAF). If there is a malfunction, the “CheckEngine” light comes on.

Signs of malfunction:

- The engine runs intermittently;

- The engine does not start (no spark);

Phase sensor

The phase sensor is installed on an engine with 16 valves, located near the fuel rail. Based on the law of electromagnetic induction, it takes readings from the intake camshaft master pulley. Participates in the process of formation of the air-fuel mixture for each cylinder separately. In the event of a malfunction, the engine begins to operate in emergency mode. When there is a malfunction, the “CheckEngine” light almost always comes on.

Signs of malfunction:

- The engine runs intermittently;

- Increased fuel consumption;

- Unstable engine operation at idle;

How to check the speed sensor on a Priora

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

If the engine stalls while idling , then most likely you will need to check several sensors (mass air flow sensor, air sensing sensor, speed control valve, air pressure sensor) in order to determine the culprit. Previously we looked at verification methods:

Now, checking the speed sensor yourself will be added to this list.

If this sensor malfunctions, it transmits erroneous data, which leads to disruption of not only the engine, but also other components of the car. The vehicle speed meter (VSM) sends signals to the sensor, which controls the operation of the engine at idle speed , and also, using PPX, controls the air flow bypassing the throttle valve. The higher the speed of the car, the higher the frequency of these signals.

Operating principle of the speed sensor

The speed sensor design of most modern cars is based on the Hall effect. During its operation, it transmits pulse-frequency signals to the vehicle's ECU at short intervals. In particular, over one kilometer of travel, the sensor transmits about 6,000 signals. In this case, the frequency of impulse transmission is directly proportional to the speed of movement. Based on the frequency of signals received, the electronic control unit automatically calculates the speed of the machine. It contains a program for this purpose.

The speed sensor itself is located next to the gearbox, in particular, in the speedometer drive mechanism. The exact location differs between different car brands.

How to determine that the speed sensor is not working

You should immediately pay attention to such signs of malfunction as:

- no idle stability;

- the speedometer does not function correctly or does not function at all;

- increased fuel consumption;

- reduced engine thrust.

Also, the on-board computer may display an error about the absence of signals on the DSA. Naturally, if BC is installed on the machine.

Speed sensor location

Most often, the malfunction is caused by a broken circuit, so first of all, you need to diagnose its integrity. First you need to disconnect the power and inspect the contacts for oxidation and dirt. If it is, then you need to clean the contacts and apply Litol.

often break near the plug , because this is where they bend and the insulation can fray. You also need to check the resistance in the grounding circuit, which should be 1 ohm. If the problem has not been resolved, then it is worth checking the speed sensor for functionality. Now the question arises: how to check the speed sensor?

On VAZ cars, and on others too, a sensor is often installed that operates according to the Hall effect (as a rule, it produces 6 pulses per full revolution). But there are also sensors of a different principle: reed and inductive . First, let's look at testing the most popular DSA - based on the Hall effect. The sensor is equipped with three contacts: ground, voltage and pulse signal.

Checking the speed sensor

First you need to find out whether there is grounding and 12 V voltage in the contacts. These contacts are wired, and the contact with pulse signals is tested by torsion.

Method 1 (check with a voltmeter)

- We remove the speed sensor.

- We use a voltmeter. Let's find out which terminal is responsible for what. We connect the incoming contact of the voltmeter to the terminal that outputs pulse signals. We ground the second contact of the voltmeter to the engine or machine body.

- By rotating the speed sensor, we determine whether there are signals in the operating cycle and measure the output voltage of the sensor. To do this, you can put a piece of tube on the sensor axis (twist at a speed of 3-5 km/h). The faster you rotate the sensor, the higher the voltage and frequency in the voltmeter should be.

Method 2 (without removing from the car)

- Place the car on a jack so that one wheel does not touch the ground.

- We connect the contacts of the sensor with a voltmeter.

- We rotate the wheel and diagnose whether voltage appears - if there is voltage and frequency in Hz, then the speed sensor is working.

Method 3 (check with a control or light bulb)

- Disconnect the pulse wire from the sensor.

- Using the control, we look for “+” and “–” (after turning on the ignition ).

- We hang one wheel as in the previous method.

- We connect the control wire to the “Signal” wire and rotate the wheel with our hands. If “-” lights up on the control panel, then the speed sensor is working.

Checking the DS with a tester

Checking the speed sensor drive

- We jack up the car to hang up any front wheel.

- We look with our fingers for the sensor drive that sticks out of the box.

- We rotate the wheel with our foot.

Source: https://o-ladagranta.ru/kak-proverit-datchik-skorosti-na-priore/

Idle speed control

The idle speed regulator, also known as IAC, is installed in the throttle valve. Designed to regulate idle speed on engines without the E-GAS system. The sensor is quite unreliable and fails very often. It is a motor with a worm gear. If there is a malfunction, the “CheckEngine” light does not light up.

Signs of malfunction:

- Not smooth idle;

- The revolutions are floating;

- Troubles the engine;

Throttle Position Sensor

The throttle position sensor (TPS) is installed on the throttle valve on cars without the E-GAZ system. Designed to regulate engine speed. The sensor is not reliable and often fails. If there is a malfunction, the “CheckEngine” light does not always light up.

Signs of malfunction:

- Not smooth idle;

- The revolutions are floating;

- Troubles the engine;

- When starting the engine, the speed is increased;

- Spontaneous increase or decrease in speed;

Oil pressure sensor

The oil pressure sensor is installed in the cylinder head. Designed to indicate oil pressure and indicate oil pressure when the engine is running. A very reliable sensor that rarely fails. The “CheckEngine” light does not light up when there is a malfunction.

Signs of malfunction:

- The oil pressure light is constantly on;

- The oil pressure light does not light up when the ignition is turned on;

DTOZH for the pointer on the instrument panel

The operating principle of this sensor is to change the resistance when the internal element heats up. Passing through the indicator on the instrument panel, the current flows through a single wire to the device. And here the principle of induction in coils comes into play. Simply put, the higher the resistance, the more the needle on the indicator rises, due to the circulating currents in the coil located inside the indicator.

Possible malfunctions of the Priora coolant temperature display system

Most motorists, having discovered that the engine temperature gauge needle does not rise, believe that it is necessary to change the sensor. However, you should first make sure that this is the case. After all, there are several reasons for this state of the panel:

- Failure of the pointer on the instrument board.

- Break in the wiring.

- Direct failure of the sensor.

Therefore, it is better to conduct a small check on your own.

Location and serviceability check of DTOZH

This device is located directly above the Priora flywheel housing. The sensor is embedded in the engine block near the thermostat. It is connected to a single wire with a female connector. The test method for this device is very simple. And it has been used by drivers for a very long time. You need to do this:

- Turn on the ignition.

- Disconnect the connector from the sensor.

- Connect the wire to the block body.

If the DTOZH itself is faulty, the indicator arrow will rise to its highest position. But if no changes occur on the instrument panel, then the reason must be looked for elsewhere. Maybe the circuit is broken, the pointer is broken, or the whole combination.

How to replace the Priora coolant temperature sensor

This is a fairly simple operation. It is available to any driver.

To access the right place, it is better to dismantle the air filter. Then the work area will be completely accessible. Prepare a new temperature sensor.

Using a 21 key, unscrew the old one and quickly screw the new one into place. Pour in antifreeze, making sure that no air pockets form. Replace the filter and start the engine. Wait for the fan to operate. At this time, watch the arrow. When you turn on the ignition, it should rise by 2-3 millimeters. And then, according to the degree of heating, smoothly enter the working zone of 92-98 degrees. If this is what happened, then the operation to replace the coolant temperature sensor for the Priora instrument panel can be considered successfully completed.

Useful video on this topic.

The standard coolant temperature sensor in the automotive electronic control system is designed to establish the temperature values of the power plant at the current moment of its operation. The impulse emanating from this electrical device forces the on-board computer to set the required optimized number of idle speed control steps, while simultaneously regulating the supply of the fuel mixture.

Oxygen sensor

The oxygen sensor is installed in the exhaust manifold of the car. Serves to monitor exhaust gases and adjust the air-fuel mixture. A reliable sensor rarely fails. If there is a malfunction, the “CheckEngine” light does not always light up.

Signs of sensor malfunction:

- Loss of vehicle dynamics;

- Unstable idle;

- Jerking when moving;

- Difficulty starting the engine;

- High fuel consumption;

- Black smoke when driving at high speeds;

Pinout of the lighting control unit on Priora

This switching and control combined module has several functions and is used to turn on/off parking lights, headlights, select the desired light switching mode, turn on/off fog lights, adjust the brightness of the backlight combination, control the headlight range control, on/off and control light inside the cabin and instrument lighting. The module is connected to the vehicle’s on-board network via chip No. 1118-3724500.

The standard terminal pinout on a VAZ 2170 is as follows:

| G, 56b | To the gear motor for adjusting headlights |

| 58b | Output to backlight sources |

| 31 | Weight |

| Xz | +12 volts (from terminal 15 of the ignition switch) |

| 56 | To the relay for switching high and low headlights |

| 1,3 | From rear and front fog lights |

| 2,4 | To the rear and front fog lamp relays |

| 58 | To the size lamps |

| 30 | +12 V from terminal No. 30 of the ignition switch |

Knock sensor

The knock sensor is installed on the cylinder block under the intake receiver. Based on the principle of the piezo element. Engine detonation is measured and the air-fuel mixture is adjusted. Quite a reliable sensor. If there is a malfunction, “CheckEngine” does not light up.

Signs of sensor malfunction:

- Loss of vehicle dynamics;

- Unstable idle;

- Jerking when moving;

Air conditioner sensor

The air conditioning sensor is installed under the bumper next to the air temperature sensor. Designed to turn on the air conditioner or protect against turning on at low temperatures. Let us remind you that the air conditioning in Lada cars only works at outside air temperatures of +5 degrees. Reliable sensor, no breakdowns were detected.

Signs of malfunction:

- The air conditioner clutch does not engage;

Mechanical engineering keeps up with the times, so new sensors appear quite quickly in car engine control.