07/17/2021 10,339 VAZ 2109

Author: Ivan Baranov

The tachometer is one of the many measuring devices on a vehicle. All domestic cars today are equipped with these devices, although their installation during production was not provided for on “nines” with low panels. Why the tachometer does not work on a VAZ 2109 high panel car with a carburetor engine and what to do in such cases - read in this article.

[Hide]

Why doesn't the tachometer work on the VAZ 21099?

Indications of various engine operating parameters displayed on the VAZ 21099 dashboard allow you to monitor its operation in various operating modes.

Incorrect operation or failure of one of these indicators deprives the driver of visual control over the key characteristics of the engine. Such a malfunction can subsequently cause serious damage to engine components and parts.

One of these devices is the tachometer. It is used to record the rotation speed of the crankshaft. What to do if the tachometer of the VAZ 21099 does not work?

Reasons for the malfunction of the tachometer of the VAZ 21099

Before you begin to eliminate the presented malfunction, it is important to identify its cause. Malfunctions in the operation of the tachometer can manifest themselves in sudden changes in engine speed or absence of readings, regardless of the impact on the gas pedal during acceleration or when moving away. Among the most common reasons are:

- damage to the wiring and poor contact at the connection points of the underwater terminals;

- failure of the crankshaft speed sensor;

- mechanical damage to the speed indicator needle;

- switching to another type of ignition;

- high-voltage wires do not meet the conditions for correct operation of the tachometer;

- broken or missing fuse contacts.

Irregularities in the operation of the speed indicator can be caused by poor contact of conductive connections. Therefore, you should initially conduct a visual inspection of the entire tachometer electrical circuit to identify poor contact.

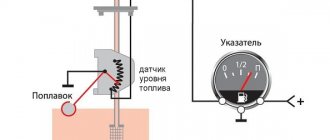

Practice shows that malfunctions in the tachometer often occur due to the fault of the crankshaft speed sensor. It plays a key role in the operation of this device, sending it a pulse signal of a certain frequency. Malfunctions in the operation of this sensor lead to distortions in the tachometer readings.

It often happens that the reason for the tachometer failure lies in mechanical damage to the device itself. For example, due to a manufacturing defect or third-party mechanical influence, the indicator arrow may simply jam or touch the housing.

Another reason is the transition to a different type of ignition. Due to certain circumstances, car owners do not attach importance to the fact that in this case the functioning of the tachometer is radically impaired. Depending on the type of device, the way you connect it will differ.

When replacing high-voltage wires, it is necessary to take into account the resistance value of the conductive part. Even minor deviations will not have the best effect on the operation of the tachometer. The error of its readings in this case will increase noticeably.

To rule out another reason, you should look at the fuse panel. There is a possibility that the corresponding fuse has simply blown or is not secure enough.

Diagnosis of tachometer faults

Diagnostic measures to identify the causes of malfunctions in the tachometer are more focused on the electrical equipment of the car. In this case, it is necessary to take into account a number of specific features due to various design characteristics of the engine.

Carburetor engine

If the tachometer of a VAZ 21099 with a carburetor engine does not work, the following diagnostic steps must be taken:

- check the resistance of high-voltage wires;

- check the wiring for breaks/loose connections;

- make sure that the required on-board network voltage is available;

- make sure that the capacitor of the breaker-distributor is in good condition.

When replacing standard armored wires with silicone analogues, interruptions in the operation of the speed indicator may occur. The tachometer needle on a VAZ 21099 with a carburetor engine will jump in this case. In order to exclude this version from the list of possible causes, it is enough to replace the wires with previously used ones. At this stage, you should check the circuit to the ignition coil terminal and the switch. If possible, you can test each wire for a break using a multimeter in ohmmeter mode. It is important to remember that before proceeding with the above steps, the machine must be de-energized.

The source of the problem of tachometer failure may be directly related to the voltage of the vehicle's on-board network. If the voltage does not have a stable value, characteristic jumps in the tachometer needle will be observed.

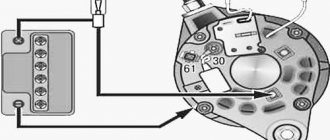

This phenomenon can be caused by a number of reasons. First of all, you need to make sure that the generator drive belt does not sag or slip. If everything is in order with the belt, you should take a closer look at the generator itself. Diagnostics, in this case, should start with the relay regulator.

To identify malfunctions in its operation, you need to check the condition of the slip rings. If there is increased wear on the face caused by burnt contact parts, the surface should be cleaned with sandpaper. If after this procedure, the tachometer continues to convulse, it is worth checking the functionality of the relay itself. To do this, you need to use the same tester in voltmeter mode. With the engine running and idling, the voltage at the battery terminals should be 13.5–14 V. As the speed increases, up to their average value, the multimeter should register at least 14.2–14.5. Otherwise, there is a question about measuring the relay regulator.

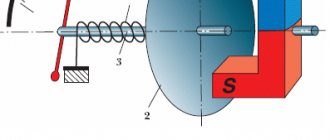

With a contact ignition circuit, problems often arise with the operation of the capacitor installed on the distributor body. It helps to increase the voltage in the secondary circuit of the ignition coil. If there are malfunctions in its operation, the tachometer needle will twitch continuously.

So that there is no doubt about its malfunction, it is enough to connect a 12 V lamp to the open circuit between the terminal of the secondary winding of the short circuit and the underwater end of the capacitor. The lamp is on - the capacitor is broken. The lamp does not light - the capacitor is in order. It is worth saying that if the capacitor is broken, the engine simply will not start due to insufficient voltage required to ignite the combustible mixture. So the reason presented can only be caused by short-term malfunctions in its operation. However, if they make themselves felt, it needs to be replaced.

Injection engine

If the tachometer of a VAZ 21099 with an injection engine does not work, you must first of all pay attention to the condition of the crankshaft speed sensor. Among the associated factors of DPKV malfunction are:

- interruptions in engine operation at idle;

- stopping the engine while driving;

- manifestation of signs of detonation under load.

Diagnostics of the sensor is carried out after its dismantling. At this stage, it is important to remember its fixed position. After a visual inspection, it must be cleaned of dirt particles using a rag soaked in gasoline. After this, using an ohmmeter, the resistance mounted in the coil sensor is measured. Its working value is 560 - 750 Ohms. Deviation from the specified parameter indicates its malfunction.

Diagnostic methods related to identifying violations of wiring integrity and malfunctions of the generator are applicable for both injection and carburetor versions of the VAZ 21099.

It is advisable to monitor malfunctions in injection engines using error codes on the instrument panel. Such diagnostic indicators will help detect malfunctions in the operation of a specific unit that affects the tachometer readings.

Tachometer troubleshooting

In order to restore the functionality of the VAZ 21099 tachometer in each specific case, it is not at all necessary to seek the help of professional auto mechanics. All that is required of you at this stage: a minimum of tools and the will to win.

So, the tachometer needle of the VAZ 21099 twitches. Diagnostics showed that the regulator relay unit is faulty. Its replacement is carried out as follows:

- the vehicle's mass is switched off;

- the wiring block in the rear cover of the generator is disconnected;

- the protective cap is removed along with the supply terminal;

- unscrews the relay regulator.

The installation sequence of a working voltage regulator is performed in reverse order.

How to troubleshoot speed indicator problems caused by replacing high-voltage wires? To do this, it is necessary to slightly supplement the tachometer connection diagram. Namely, a capacitor with a capacity of no more than 900 pF must be connected to the instrument cluster board. It will help reduce the nominal resistance of the external resistor, and will significantly improve the performance of the tachometer.

It is worth noting that this method is applicable only when the tachometer does not work on the injection model VAZ 21099, but not on the carburetor modification, the distinguishing feature of which is a high dashboard.

Installation

That’s it, the tachometer is in your hands, so you can safely take it to your own garage and start connecting the device.

There is no need to be afraid of self-installation. Although the tachometer is an electrical device, it consists of three wires. Therefore, even inexperienced drivers will be able to cope with the task without any problems.

Wiring is no problem

Decide in advance on the location where your crankshaft speed reading device will be located. Here the choice is entirely yours. Some are installed directly on the instrument panel, others are mounted near the ignition switch. Try to choose an area where the device will not interfere and will not spoil the appearance of the interior.

We have decided on the location, so we can safely begin work.

- Route the tachometer wire from the passenger compartment to the engine compartment. Practice shows that it is most convenient to remove it through the hole intended for the speedometer cable.

- To make your task easier, take a stiff but fairly thin wire. You will need about a meter in length. Tape the tachometer cable to one end using electrical tape. Just do it carefully so that it can fit through the hole in the speedometer cable.

- Insert the second end of the wire into the output hole and begin to push out. This way you can pull out the wiring to the engine compartment without any hassle.

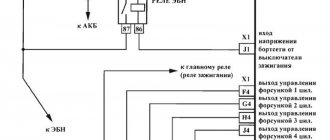

- Distribute the wires. +12 - B ignition coils, Signal - K ignition coils, and Minus is the mass of your car in any accessible or convenient place. For reliability, make sure that the mass can be pressed with a nut.

- Even with fairly high-quality tachometers, the wires in the cable are thin and fragile. To get rid of this is not enough, solder full-fledged, high-quality, durable wires with a cross-section of 1 sq. mm to the device wires. Try to select wires that will match the standard tachometer wiring colors. Then put ferrules on the other side of the 1 sq mm wire.

Connection diagram

- Unscrew the mounting nuts on the ignition coil using a 10 mm wrench, and then connect the wiring according to the diagram above.

- Tighten the nut, just don’t tighten it, demonstrating your own strength. Otherwise, you risk breaking the thread, and eliminating such a defect is problematic.

- Connect ground. To do this, select an area where the wire will not interfere, will not get caught with other units, overheat, etc.

- Check the device in operation. To do this, turn on the ignition. At the same time, a proud 0 should light up on your tachometer. This indicates that the revs are now zero, the crankshaft is not spinning.

- Start the car. When idling, the normal speed for the VAZ 2109 is 750-850 rpm. The relevant information should appear on the device in the cabin.

- If the tachometer has an additional voltmeter function (a very useful functionality for those who prefer to repair and diagnose the performance of their car with their own hands). Having selected the voltmeter mode, data about the current network voltage should appear on the screen - about 11-12 V when the battery is charging normally.

That's it, the installation of the tachometer can be considered complete. There is nothing complicated in this process, so even a beginner can do the job.

Self-connection of a tachometer on a VAZ 2109

The tachometer is one of the many measuring devices on a vehicle. All domestic cars today are equipped with these devices, although their installation during production was not provided for on “nines” with low panels. Why the tachometer does not work on a VAZ 2109 high panel car with a carburetor engine and what to do in such cases - read in this article.

Purpose of the tachometer

The tachometer on the VAZ 2109 is a device installed on cars to measure engine speed. Thanks to this device, the driver can find out what crankshaft speed is currently supported by the power unit. This device also allows you to prevent exceeding the possible permissible engine speed.

Dashboard with installed digital device

The main purpose of the tachometer on the VAZ 21099 carburetor is to facilitate the selection of the required gear, and this, in turn, makes it possible to increase the service life of the engine. At the moment when the instrument needle begins to approach the red zone, it is recommended to switch to a higher gear. This device can also be used for adjustment work while driving or when the internal combustion engine is idling.

If you decide to purchase a VAZ 2109 tachometer, first you need to decide on the type:

- Digital devices allow you to display information about the operation of the power unit on a special display. If you install this device on a VAZ 2109 carburetor, the device will be able to more accurately set the forced idle economizer thresholds.

- Analog devices are more popular today. Such devices allow you to clearly demonstrate the number of engine revolutions using a scale and an arrow that moves along it (the author of the video is Ilya Popov).

Possible faults

It’s understandable why drivers decide to install the device on cars with low panels, but before you connect the tachometer, you need to understand its main faults.

Symptoms of device failure are:

- when starting the power unit or while driving, the instrument needle may begin to jump;

- When the engine is running, the needle on the scale points to zero.

To begin with, if malfunctions are detected, you should diagnose the wiring and condition of the contacts. If the circuit for connecting the tachometer to the ignition switch was made using silicone wires, this can also lead to incorrect operation of the device. Sometimes the reason for a non-working device lies in a breakdown of the motor speed controller. As for digital devices themselves, in this case the digital display most often breaks down, so in the event of such a breakdown, the display will have to be replaced.

DIY installation instructions

Installing a tachometer on a VAZ is done as follows:

- First, a place is selected where the device will stand, after which the cable from it must be routed into the engine compartment.

- Before connecting the VAZ 2109 tachometer, it is necessary to distribute the wiring. The +12 volt terminal is connected to the coil (contact B, the signal is connected to contact K), and the “-” is connected to the ground of the car, and the ground must be securely fixed. If the wiring is very weak and fragile, then it is better to connect more reliable wires in advance.

- After the wires have been distributed, they need to be connected. To connect the ground wire, it is advisable to choose a place where the cable itself will not interfere with or interact with moving parts.

- To diagnose the functionality of the device, you need to turn on the ignition and start the car. During normal engine operation at idle speed, the needle on the instrument scale will remain in the region of 750-850 rpm. If the device is additionally equipped with a voltmeter function, you can check it - when you select this option, information about the voltage level in the on-board network should appear on the display. If the battery is operating normally, this parameter should be approximately 11-12 volts.

Device connection diagram

Video “What nuances should be taken into account during installation”

How to install the device correctly with your own hands - watch the video (author - Viktop channel With These Hands).

Installing a tachometer

You bought and brought home a new tachometer. Now you can go to your garage to install the device on a car that has a carburetor. Installing and connecting it is not that difficult. This is an electric device, but don't be afraid of it. How to connect it? The tachometer connection diagram is extremely simple. Even a less experienced person can easily connect the 3 wires coming from the device. So let's get started. You should:

- choose a location for the device in the car;

- lead the wires out of the passenger compartment into the space under the hood;

- distribute the wires on the ignition coil and on the ground of the car;

- check the operation of the device.

The choice of location is up to you. You can install a tachometer on the instrument panel or next to the ignition switch. As long as the device does not interfere with the driver and does not spoil the appearance of the interior. Then the wires are brought out. The best way to do this is through the hole through which the speedometer cable passes. To help, you can take a meter-long piece of rigid, but rather thin wire. The cable coming from the tachometer is wound to the end of the wire with electrical tape so that it passes through the hole. In this way, you can run all the wires under the hood without any problems. Connect the +12 wire to terminal B, the signal to terminal K. For the negative one, you need to find a suitable place on the ground of the car. It is better to tighten it with a nut.

Standard tachometer wires are very thin and very fragile. It makes sense to first solder high-quality wires with a cross-section of about 1 mm² to them. It's better not to change colors. The ends should be equipped with standard ferrules. Now you can unscrew the nuts on the ignition coil, connect the wires and tighten the fasteners. Do not use much force when tightening the nuts. You can very easily break the thread.

After installation, you need to check the operation of the tachometer. When you turn on the ignition, the instrument scale should read 0. Start the engine. At idle speed, the device should show approximately 750-850 crankshaft revolutions per minute. If there is a function to check the mains voltage, turn it on. When the battery is normally charged, the voltage should be 11-12 V. If all readings correspond to the above, the device can be considered installed.

Why does the VAZ 2108 tachometer not work? VAZ 2108 tachometer malfunctions

Today we will talk about tachometer malfunctions. You will learn why the tachometer does not work, as well as about the main malfunctions of the VAZ tachometer .

What is a tachometer and why is it needed?

A tachometer is a device that, as I already said, shows the number of engine revolutions per minute (thousand rpm). The tachometer readings are necessary to make it easier for the driver (usually a beginner) to navigate and correctly select the desired gear (up or down). A tachometer is also necessary in order to monitor the correct operation of the engine by the number of revolutions. For example, when the speed fluctuates or is too high, a fault can be detected in time.

The first tachometers were analog (they are also called dial gauges). Analog tachometers have a dial with numbers and an arrow. One division of the analog tachometer is equal to 1 thousand revolutions. A little later, digital (electronic) tachometers began to appear on mostly Western-made cars. Data in electronic tachometers is displayed on a display (LCD or LCD display). In modern cars, digital tachometers look like analog ones because, like older tachometer models, they display information in the form of a dial and an arrow that indicates the number of revolutions.

Signs of a tachometer malfunction

- The idle speed is floating (the tachometer needle twitches even when the car is standing still and your foot is not on the gas pedal).

- The arrow does not respond to the gas pedal (it is at the zero mark or in another extreme position).

VAZ tachometer does not work - common reasons

- The first step is to check the condition of the wiring and contacts. Often, tachometer malfunctions lie precisely in a broken wire or poor contact. Carry out a visual inspection for defects (tears, poor fastening, oxidation, etc.).

- Malfunction of the crankshaft speed sensor. There are situations when the tachometer does not work due to a malfunction of the engine speed sensor. Checking the sensor or replacing it will help solve this problem.

- It may not be strange, but in some cases the reason for a non-working tachometer may lie in the banal wedging of the arrow or its rotation on the pulley.

- Installing contactless ignition often results in the tachometer not working. To resolve the problem, I advise you to contact an electrician who will solve the problem of the conflicting device.

- Incompatible ignition wires. The so-called silicone ignition wires, which car owners use to replace standard wires, often cause the tachometer needle to twitch. The reason lies in differences in the linear resistance of both wires; as a result, the shape of the current pulse changes and the needle behaves incorrectly. The solution to this problem is described in many manuals for self-repair, and it boils down to replacing (reducing the value) of the resistor on the control panel board.

- Check fuses. Sometimes they are the cause of problems with the tachometer. Make sure that all fuses are intact and have no signs of oxidation or melting.

In conclusion, I would like to note that the reasons and diagnostic methods described above are superficial and the most common. possible to study the issue in more detail and understand why the tachometer does not work or why the tachometer needle twitches only with special equipment. Therefore, if it is impossible to independently diagnose a tachometer malfunction, I recommend turning to specialists at a service station for help.

Why did the tachometer on the VAZ 21099 stop working?

What to do if the tachometer of the VAZ 21099 no longer works? This device was installed only on cars with a high panel; the tachometer connection diagram depended on the type of engine - carburetor or injection.

Possible malfunctions of the device

It is known why drivers decide to install the device in a car, but before connecting the device, it is necessary to determine its key damage.

Factors of adjustment disorders are as follows:

- When igniting the engine or while driving, it happens that the tachometer needle of the VAZ 21099 jumps.

- When the motor is operating, the pointer on the scale indicates 0.

First, if a breakdown is detected, you need to test the wiring and the position of the connections. If the program for connecting to the ignition switch was carried out using silicone wires, this can lead to improper operation of the device.

In some cases, a factor in the non-functioning mechanism may be damage to the speed controller of the power unit. Regarding digital devices, the digital panel in them often breaks down, you will need to change the monitor.

There are circumstances when the tachometer with a carburetor engine does not work, a notification is sent to the unit from the terminal on the ignition bobbin, and in a situation of incorrect life activity, the search should begin with the ignition bobbin, it is to it that 2 wires are twisted.

If the tachometer with an injection-class power unit does not work, defects must be identified by inspecting the wire that goes from the ignition unit to the 5th connection of plug connector “A” of the dashboard.

If this line breaks, you will need to test the dashboard PCB. Disturbances in the functioning of the device are caused by changing standard high-voltage ignition wires to silicone ones due to the difference in their resistances.

As an information source about the rotation speed of the crankshaft, the VAZ 21099 uses an ignition bobbin, which is designed to produce a spark; it ignites the fuel-air composition in the combustion compartments.

In theory, this is a small pulse transformer that converts 12 Volts to 30 kV. In a 4-cylinder engine, a spark is created twice per 1 revolution of the crankshaft. Considering that the mechanism sets the number of its revolutions/min. and proportionally deflects the indicator. And the tachometer itself may not work for some reason.

The normal life activity of the “silovik”, despite the fact that the tachometer needle is jumping, indicates a breakdown of the mechanism itself, damage to the wiring or defects in the components associated with the ignition coil, and there may be breakdowns in the carburetor. You will have to do some wiring diagnostics.

The device removes the alarm from the “-” coil; the connection occurs through the configuration of the terminals and the fuse module. If visual inspection does not detect a violation, you can directly connect the ignition coil using a 1 m long wire. If the problem goes away, you can keep this temporary connection unchanged by tying the wire to standard harnesses.

Why does the tachometer needle jump on a VAZ 21099 carburetor?

To find out why the tachometer on a VAZ 21099 may be faulty, you should do the following:

- On the “tidy”, look for the “Check” light and check whether it is on. If not, then infrastructure testing will not be able to identify the failure;

- verify email. wiring, by auditing the degree of voltage on the “+” and “-” wires, and also inspect the position of the joints;

- if other equipment or mechanisms do not work accurately, you should definitely check the mass, since this item is often missed;

- diagnose the condition of the connections of the distributor and heat exchanger on its cover, because during use it happens that it is broken;

- Also, you need to check the circuits in the ignition structure;

- if the device has recently been repaired or replaced, it should be adjusted;

- if the indicator jumps when the “power” reaches high rotations, this means the distributor is broken and should be replaced.

Primary low panel brands were produced without these devices. Cars with a high panel, of course, have this mechanism.

It is possible to investigate the issue in detail and evaluate why the tachometer needle in a car twitches only if you have special equipment.

In general, this device is a technical tool that reflects the number of revolutions of the engine crankshaft, and also helps to reflect data on the acceleration of the car. To eliminate violations, you simply need to systematically inspect the vehicle for possible breakdowns.

In general, you can choose a version of the device with an LCD numeric indicator. It will sit comfortably on the dashboard along with the ignition switch. The device is located next to the speedometer.

Malfunctions of the carburetor version

An ignition coil is used as a source of information about the speed of rotation of the crankshaft in the VAZ 2109 carburetor. It is designed to generate a spark that ignites the fuel-air mixture in the combustion chambers. Essentially, it is a mini pulse transformer that converts 12V to 30KV. In a four-cylinder engine, a spark is generated twice per revolution of the crankshaft. Taking this circumstance into account, the tachometer determines the number of revolutions per minute and deflects the needle proportionally.

Normal operation of the engine while the tachometer needle of the VAZ 2109 is jumping indicates a failure of the device itself, a wiring fault or problems in the units associated with the ignition coil. Start by checking the wiring. The device removes the signal from the negative coil, switching occurs through the terminal system and the fuse block. If a visual inspection does not reveal a problem, you can connect the coil to the tachometer directly using a meter-long piece of wire. If the problem disappears, you can leave this temporary connection as a permanent one, attaching the wire to the standard harnesses.

Inspect the high-voltage wires, distributor and switch. A very likely cause of the needle jumping is a faulty switch. In the VAZ 2109 this device cannot be repaired and can only be replaced. Experienced motorists carry this inexpensive and easy-to-install spare part with them.

Connect the replacement switch without installing it, and if the arrow stops moving, replace the switch. If all this does not help and the tachometer still does not work, consider replacing the device.

VAZ tachometer connection diagram

The first car from the Zhiguli family equipped with a tachometer was the VAZ 2103. Neither 2101 nor 2102 had such a device. The tachometer is used to measure the crankshaft speed. It is a revolution counter, showing their number by deflecting the scale needle to a certain angle. The tachometer is also indispensable when setting up the carburetor - its indicators are taken into account when adjusting the idle speed and the quality of the fuel mixture.

VAZ-2106 tachometer connection diagram

The “Sixes” were equipped with a tachometer model TX-193. This tachometer consists of:

- plastic cylindrical body with glass holder;

- a scale divided into zones of safe and dangerous modes;

- backlight lamps;

- a milliammeter with an arrow attached to its shaft;

- electronic printed circuit board.

The principle of its operation is based on measuring the number of electric current pulses in the primary (low-voltage) circuit of the car’s ignition system. In the VAZ 2106 engine, for one revolution of the distributor shaft, corresponding to two rotations of the crankshaft, the contacts in the breaker close and open exactly four times. These pulses are removed by the device from the final terminal of the primary winding of the ignition coil. Passing through the parts of the electronic board, their shape is converted from sinusoidal to rectangular, having a constant amplitude. From the board, the current flows to the winding of the milliammeter, where, depending on the pulse repetition rate, it increases or decreases. The arrow of the device reacts precisely to these changes. The greater the current, the more the arrow deviates to the right and vice versa.

Connecting a tachometer in carburetor VAZ 2106

Electric circuit of the speed counter of the carburetor “six”

In a contactless ignition system, the tachometer is connected not to the coil, but to the switch

Connecting a tachometer in injection VAZs

It should be taken into account that the colors of the wires and their purpose may differ depending on the manufacturer of the device, but for the standard “TX-193” device, which is usually used in “sixes”, the diagram is as follows:

- A white cable is required to connect the backlight.

- The red wire is connected to the ignition switch, a fuse is used for this, this cable supplies power when the ignition is activated.

- A white cable with a black break is required for connection to the car body.

- The brown wire connects to the K+ terminal on the coil.

- The black wire is connected to the charging current indicator relay. The latter, in turn, is installed on the right in the engine compartment.

- The gray-black cable is required to connect to the engine fluid pressure regulator installed to the left of the engine.

Connection diagram for tachometer VAZ-2108 and 2109

Let us immediately note that the fuel supply system – injector or carburetor – does not play a special role here. As you know, currently the most common are cars with the following engine types: gasoline or diesel. Depending on this, the tachometer is selected, unless, of course, it comes in the stock version. The thing is that on gasoline engines the tachometer reads data from the ignition coil, or rather, the impulses that arise here. However, the design of diesel power plants does not provide for this unit. Accordingly, here the tachometer reads pulses not from the ignition coil (for lack of one), but from the generator.

Classification by operating principle

- Mechanical or electromechanical tachometers with direct drive. The revolutions are transmitted to the dial indicator through a flexible shaft, which, through a worm gear, receives rotation directly from the crankshaft or one of the transmission shafts. The operating principle of the indicator is based on the phenomenon of eddy current induction. The operation and design of a magnetic tachometer are extremely similar to the operating principle of a car speedometer. In modern cars, a similar tachometer design is not used.

- Electric machine. A distinctive feature is the connection to a generator. It is used primarily on diesel engines, but for the purpose of unification, a device of this type can also be used on gasoline engines.

- Electronic. The signal can be taken either from the ignition system or directly from the computer. Installed on gasoline and diesel internal combustion engines.

Design and principle of operation

Main components of electric machine and electronic tachometers:

- measuring unit, or signal converter. It can be based on elements of analog circuitry or built using special microcircuits;

- display unit with analogue or digital display of the number of revolutions;

- auxiliary elements.

The operation of electronic tachometers is based on the conversion of individual signals or pulses captured from the computer, ignition system or generator into a signal “understandable” for the display unit.

Connection diagram

When looking for the reason why the tachometer does not work, it is first of all important to understand the connection diagram and the type of signal. There are 3 typical connection schemes:

- to a contactless ignition system (the tachometer wire is connected to the primary circuit of the ignition coil). The operating principle is based on measuring the frequency of voltage surges in the primary circuit of the ignition system. Calculating the ignition angle is impossible without focusing on the number of crankshaft revolutions, therefore the sparking frequency directly depends on the crankshaft rotation speed. On 4-cylinder internal combustion engines, a full revolution of the crankshaft corresponds to 2 voltage pulses in the primary circuit. Accordingly, the higher the crankshaft rotation speed, the greater the frequency of voltage surges;

- connection to the contact ignition system. The operating principle and connection diagram are similar to the BSZ, but the design of the measuring unit will differ depending on the voltage of the input circuit;

- connection to the engine ECU. The principle of operation is still based on recording voltage pulses in the primary circuit of the ignition system, but the signal to the tachometer comes from the engine control unit;

- connection to the generator (the tachometer signal contact is connected to terminal W of the generator). The rotation of the generator pulley is carried out by a belt drive from the crankshaft, so the rotation speed of the generator rotor will always be proportional to the crankshaft speed. The change in the number of revolutions of the crankshaft can be calculated by constantly measuring the amount of EMF generated on the winding. According to its principle of operation, an electric machine tachometer resembles a regular one class=”aligncenter” width=”448″ height=”412″[/img]

Typical faults

If the mechanical tachometer on a car stops working, there is mechanical damage to any of the structural elements. A broken cable of a flexible shaft, wear of the worm gear elements, the appearance of backlashes, deformations - all these reasons can cause the engine speed indicator to fail.

What to pay attention to if the electronic tachometer does not work:

- integrity of electrical wiring. In this case, it is important to check not only the signal wire, but also the ground and power supply of the instrument panel;

- quality of contacts. The presence of oxides and loose contact inside the chips may well cause the tachometer to fail;

- the integrity of the elements of the measuring unit, which are located behind the protective glass inside the dashboard. Among mechanical damage to transistors, burnout of microcircuits, tracks or swelling of resistors, the most common reason for a non-working tachometer is a violation of solder integrity. For example, on the Mitsubishi Padjero II, the appearance of microcracks in the soldering areas of the tachometer elements is a generally recognized disease.

On vehicles with an alternator connection, a non-functioning tachometer may indicate a faulty alternator. In this case, the breakdown is accompanied by the lighting of the low battery charge indicator and the sporadic lighting of a “garland” of warning lights on the dashboard.