During operation, the temperature of the exhaust gases in the engine reaches 2000 degrees. But only a small part of this energy is used to propel the car. The rest of the heat is removed outside using the cooling system.

If the engine temperature is exceeded relative to the norm, the process of burning out the lubricant will begin, which will lead to a decrease in the gaps between parts, and subsequently to their wear.

It is also undesirable to operate the engine at low temperatures. When overcooled, power is reduced due to large heat losses. In this case, condensation forms on the cylinder walls, which prevents the flow of lubricant. Because of this, in addition to wear of parts, the risk of corrosion increases.

The engine cooling system is designed to maintain balance in the system. Two types of cooling are commonly used: liquid and air. Air cooling is used quite rarely due to its low efficiency. Liquid cooling is more common in automobile manufacturing. It, in turn, is also divided into open and closed. An open cooling system is less perfect; steam is released into the environment, so refilling of liquid is very often required. A closed system is used in all modern cars and is characterized by higher fluid pressure in the system. In this case, the temperature of antifreeze or antifreeze can rise to 120 degrees.

There are also differences in the type of fluid circulation: thermosiphon and forced.

Thermosyphons work due to different densities of the liquid in the engine and radiator. In forced cooling systems, liquid circulates due to a built-in pump or pump.

There are also combined systems in which the cylinder heads are cooled forcibly, and the cylinder blocks are cooled due to the natural movement of the heated fluid.

The Chevrolet Niva cooling system uses a closed type with forced circulation. The device consists of components such as a radiator, pump, fan, pipes and expansion tank.

The liquid around the cylinders is in the so-called cooling jacket. The heated antifreeze then enters the radiator, which is cooled by air currents. After this, the cooled coolant again enters the cooling jacket.

In order to ensure uniform circulation of the liquid, a pump is used. To cool the radiator faster, a fan is installed on it. To maintain sufficient pressure in the system, an expansion tank is installed. The Niva Chevrolet cooling system holds approximately 5 liters of liquid on average.

The main purpose of a radiator is to remove heat from the coolant. It usually consists of cores, upper and lower tanks. According to the design, radiators are plate or honeycomb. Inside the plates there are oval or round tubes in which antifreeze flows. Oval tubes are usually used because they can withstand high pressure better. Also, when they freeze, they do not burst, but only change shape, expanding. The presence of plates increases the rigidity of the structure and promotes faster cooling.

An expansion tank is used to avoid excess pressure that forms when the coolant heats up and increases in volume. The tank is always equipped with a special cap with a valve that bleeds air, reducing the pressure in the system. Typically, white or transparent plastic is used to make the reservoir so that the antifreeze level can be monitored. They usually check on a cooled engine.

The pump or pump promotes the circulation of antifreeze in the system. Usually it is an impeller that is driven by the engine crankshaft. To prevent leaks, gaskets and seals are installed on the shaft.

To increase the air flow passing through the radiator, install a fan. It is usually attached to the body, ensuring maximum air flow between the plates. In order to reduce the energy consumption to keep the fan running, it turns on and off automatically when a certain temperature is reached. A special temperature sensor, which is usually built into the radiator housing, is responsible for triggering the fan. Depending on the type of sensor operation, a smooth change in the fan speed can be configured, depending on the temperature.

The fan is driven by a separate electric motor. The connection is made through a temperature sensor. When heated, the resistance of the sensor changes, providing a smooth change in fan speed. Typically, the fan turns on when driving at low speed, in heavy traffic, or in traffic jams. When driving in suburban areas at high speeds, natural radiator airflow is usually sufficient.

Another important component of the Chevrolet Niva cooling system is the thermostat. The main purpose of the thermostat is to redistribute coolant flows. For faster warm-up in winter, the thermostat closes and antifreeze circulates in a so-called small circle inside the engine, bypassing the radiator. When the temperature reaches 80-85 degrees Celsius, the valve automatically opens, switching to a large circle, transferring the flow to the radiator.

In order to monitor the engine temperature from the car, there is a system of sensors and warning lights located on the instrument panel.

Antifreeze.

It is the main component in a car's cooling system. At the beginning of the production of equipment, water was used, but its use had a number of disadvantages - low boiling point, the formation of corrosion on structural elements of the engine and low freezing point. Currently, ethylene glycol-based solutions are used. The advantage of these liquids is their safety when in contact with the skin or the environment. To get rid of corrosive qualities, various additives are added to the composition. If the ambient temperature drops below zero, then such a solution becomes loose, but does not expand and does not destroy the parts of the cooling system.

The main elements of the system and what are the benefits of silicone pipes

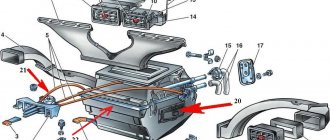

The details of the system are presented in the diagram above, these include:

- air cooling radiator (art. 2123-1301012);

- casing with fans (art. 2123-1300025-01);

- temperature sensor (art. 2101-3808600-02 and 2112-3851010);

- water pump (art. 2123-1307010);

- thermostat (art. 2123-1306010);

- pump (art. 21230-1307011-82).

All elements of the cooling system are connected to each other through various hoses and pipes, which in most cases are made of rubber or polymers with similar properties.

Note: the material used depends solely on the manufacturer of the specific spare part, so when choosing, you should pay attention to this point.

As a reasonable alternative to rubber hoses, car enthusiasts increasingly prefer silicone analogues, which are significantly more expensive. The main reason for this is that silicone does not “tan” in the cold and does not crack. This prevents coolant from leaking out of the system, which greatly affects its performance. Complete set of Chevrolet Niva cooling system pipes:

- Upper radiator hose - 1 piece;

- Lower radiator hose - 1 piece;

- Thermostat and water pump pipe 1 piece;

- Heater radiator supply hose;

- Heater radiator outlet hose.

The strength of the silicone itself largely depends on the thickness of the tube walls, as well as the presence of special reinforcement. Parts made from this material, made specifically for cooling systems, are often characterized by double reinforcement, which makes their design much stronger and more durable.

If you believe the reviews of the Shniva owners themselves, then all the additional costs of replacing rubber cooling pipes with silicone ones are completely justified. This is especially true if the car is operated in harsh northern conditions.

It should also be noted that in most cases the connections are clamped with spring clamps and only in rare cases are screw clamps used. Another undoubted advantage of silicone is the fact that it resists the effects of gasoline well without changing its physical properties.

Design of the Chevrolet Niva 2123 cooling system

Structurally, the 2123 car is similar in design to its predecessor, the Niva 2121. But it is devoid of those shortcomings that appeared during the mass operation of this car. Thus, the new model lost the tap on the stove. For the outflow of coolant, a special hole in the thermostat is now used, which is ensured by the operation of a special damper system.

The main difference is a fundamentally new thermostat design.

And the principle of its operation:

Bottom line

In Niva, the designers have developed a competent cooling system, and in order for it to maintain its performance, it needs timely and good care, and it is also necessary to monitor the coolant level and, if necessary, top up.

Home / Catalog / Chevrolet / Chevrolet Niva / Lada / VAZ 2123 from 2001 (+ restyling 2009), repair book in electronic form / ...Show book contents

Content

Introduction

User manual

How to pay and download

Our thermostat (2123)

And the purpose of its pipes

In the new thermostat model, the coolant moves in a different direction. This allows you to regulate the operation of the stove with a thermostat by lowering its temperature. The new thermostat also has a steam outlet tube, which allows you to quickly reduce the pressure in the system.

Possible faults

Most often we are talking about fluid loss during operation, but there are other third-party factors.

Leaking antifreeze or antifreeze

Antifreeze is leaking from the pipes

The cooling system pipes and hoses are made of rubber, which is susceptible to low temperatures.

At the same time, its physical properties change and the material becomes more fragile, easily crumbles and bursts at the joints through which antifreeze or antifreeze “leaves.”

Most often this happens in the area where the clamps are sealed, since this is where the greatest load occurs. There are also cases when the clamps themselves become loose due to engine vibrations during operation.

In this case, leakage largely occurs due to the inattention of the owner himself, since excessive pinching of the joint leads to negative consequences. Most often, a leak is observed at the junction of the cooling pipe to the radiator, as well as to the heating system. The problem can be solved by replacing the failed tube or pipe.

Important : In most cases, it is easier to prevent a breakdown than to fix it later. To do this, you need to regularly check the fluid level and watch the instrument panel - too high an operating temperature is the most important indicator that there is a problem with the system.

Determining a leak is quite simple, since it is enough to check all the connecting elements with a cooled engine and determine the presence of moisture there, which should not be there.

Expansion tank not sealing

Many car owners are faced with a problem when the tank bursts due to excessive pressure in the system. The reason for this is the low quality of the product’s materials. The problem is solved quite simply:

- reducing the pressure level in the system due to less tight closure of the tank lid;

- replacing the element with a higher quality analogue.

Both options do not require large financial investments. It is noteworthy that this problem occurs much more often than others, so there are quite a lot of options for replacing a standard tank with a high-quality analogue.

Radiator leak

Most often, problems with the radiator arise due to its physical wear or mechanical damage.

In the first case, destruction occurs due to the wrong choice of liquid in the cooling system - excessive density leads to corrosion of the metal and gradual destruction of the honeycomb.

Mechanical damage occurs when the car is driven on roads with poor quality surfaces, excess gravel or crushed stone. Small solid particles with high acceleration can hit the housing and thereby break the seal of the radiator. In this case, there are two solutions to the problem - welding or complete replacement of the radiator.

Cooling system malfunctions Niva Chevrolet

First of all, the breakdown can be determined by the engine temperature. Significant overheating or hypothermia can be caused by many factors. First of all, you should pay attention to the temperature threshold at which the fan on the radiator turns on. If the thermostat fails, there will be a significant difference in the temperature of the engine and radiator. It is also necessary to check the belt that drives the pump.

The system may depressurize due to damage to the expansion tank or the valve in its cover. This will lead to a decrease in pressure in the system, the antifreeze will boil at a lower temperature, but not enough to turn on the radiator fan.

Attention! Antifreeze can only be added when the engine is turned off and cooled down, as hot antifreeze can splash out, causing severe burns. This also increases the risk of poisoning by vapors that are formed as a result of boiling antifreeze.

If the thermostat sticks in the open position, it is possible that the engine will become overcooled when driving at high speed. This also leads to serious problems in winter: the engine cannot warm up to the required temperature, the ECU increases fuel consumption for warming up, and a large amount of carbon deposits forms on the cylinder walls. This also helps to reduce the viscosity of the oil and reduces the service life of the catalyst.

Principle of operation

While the car is running, the engine begins to heat up, and the temperature in the cylinders can reach 2000 degrees, and in order to relieve the temperature stress, there is this cooling mechanism, which has a kind of air jacket - a system of channels through which the coolant moves. With the help of this circulation, heat is removed to the outside.

The flow of antifreeze or antifreeze occurs due to the water pump, which operates due to the poly V-belt from the crankshaft pulley. If the engine temperature does not exceed 78 degrees Celsius, then the thermostat is in the closed position and circulation occurs in a small circle through the throttle heating unit and the heating radiator, bypassing the cooling radiator.

When the temperature exceeds 80 degrees, the thermostat begins to open and circulation begins to occur through the main Chevrolet Niva cooling radiator, which consists of a pair of plastic barrels and an aluminum part made of horizontal channels. Coolant begins to flow into the right tank through the upper pipe, and leaves from the left barrel through the outlet pipe. There is also a plug for draining the liquid.

Fan switching principle

The cooling fan is powered by a constant voltage of 12 V from the battery. They turn on when two sensors located in the engine reach a certain temperature. So, when the first sensor reaches a temperature of 99 degrees Celsius, it is triggered, which causes the first fan to turn on. It has two rotation speed positions - high and low rotation speeds. When the second sensor reaches a value of 101 degrees, then, accordingly, the second device turns on. Thus, the cooling devices of the Chevrolet Niva engine are briefly activated. But we are interested in what role such a small device as a relay, of which there are three on the Chevrolet Niva, plays in this process.

Control system

Electronics in a car dominate the elements of any system, and the cooling system is no exception. "Niva Chevrolet" has control of the antifreeze circulation circuit, based on the operation of the controller, the data to which comes from the temperature sensor, and the control unit. A casing with two twin fans is attached to the cooling radiator. People call them “Carlsons.” Information about the excess temperature of the antifreeze comes from a temperature sensor, which is installed in the engine block. And the control is carried out directly by the ECU (electronic control unit).

At a certain, programmed temperature rise, first one right fan is turned on, and then both in enhanced mode. For different firmware of the control unit, the first fan turns on at 98°C, and both at once - at 100°C or 102°C. The enhanced operating mode turns off after the temperature drops to 93°C. There are options when only two fans work at the same time, which is not always convenient. This nuance is one of the weak links of the cooling system. Sometimes it is enough to reflash the ECU to achieve optimal fan operation mode, and everything gets better.

Checking and removing fans

To understand whether they work or not, you need to disconnect the connector from their motors, and connect a lamp to the wires through which voltage is supplied; we do the same with the sensor; if both lamps light up, then the problem is in the fans.

To remove them you need to do the following:

- Disconnect all wires

- Removing the upper pipe

- Removing the bumper

- If there is an air conditioner, bend the tubes (this must be done carefully, as they may burst) or drain the freon (filling it back will not be cheap), then remove the air conditioner radiator.

- You need to loosen the nuts on the radiator casing

- Tilt the radiator so that you can remove the fan unit

- Unscrew the bolts that secure the block and remove it

After removal, it is recommended to immediately replace both with new ones, since there is a possibility that a little time will pass and the second element will fail and all replacement work will need to be done again. You can do this procedure from below, but you will need special equipment, and you will need to move the engine ten centimeters back, which is very labor-intensive.