What does “diesel gasoline engine” mean?

A special feature of diesel engine is the increase in engine operating noise. It is better to leave a car with such a breakdown in the garage; it is unsafe to drive it. Typically, diesel power indicates damage to the power unit, which is best eliminated at the time of its early manifestation. Otherwise, you will soon have to carry out major repairs.

Diesel engines make more noise than gasoline engines because their ignition system is designed in a special way. Dieselization of a gasoline engine is the appearance of noise characteristic of diesel engines. Usually noise appears when the engine is running cold or idling. There can be many reasons for this unpleasant phenomenon, but they are all related to the timing belt assembly.

Knocks due to detonation

To identify the problem and answer the question why a gasoline engine began to knock like a diesel engine, you must immediately start by checking the quality of the fuel and the level of the engine oil. A gasoline engine can operate like a diesel engine due to the fact that it is filled with low octane fuel, which is not suitable for this type of engine. Increased noise when the engine is running on low-octane gasoline will partially appear during a cold start, and is also very noticeable during further driving.

The cause of the knocking is detonation in the cylinders. It is worth noting that the detonation is vaguely similar to the muffled “diesel” sound. Modern gasoline units are equipped with solutions to counteract detonation, but the possibilities for making adjustments are within narrow limits. The ECU is only capable of slightly shifting the ignition timing (ignition timing).

The appearance of detonation knocks can be clearly heard at the moment when the engine is under load during acceleration of the car. The knocks are loud, reminiscent of high-frequency impacts of metal on metal. Also, detonation can be caused by a malfunction of the knock sensor, driving in high gear in cars with manual transmission at low crankshaft speeds, dense carbon deposits on the valves and in the combustion chambers. Detonation is also caused by incorrect settings (ignition too late) on cars where the OZ is set independently. The working mixture burns out on the exhaust stroke, causing the engine to work shockingly and roughly.

Detonation under normal conditions is heard when a manual car is going up a hill, but the driver does not downshift, trying to maintain the set speed by pressing the gas pedal to the maximum. The car moves, but does not accelerate further, the engine does not gain momentum. It turns out that the internal combustion engine does not “pull” in high gear under load. In such conditions, the ringing knock of detonation appears most clearly.

Correct driving style, timely maintenance of the unit and driving on suitable fuel will help you get rid of detonation knocks. If the fuel tank is accidentally filled with low octane fuel, then the simplest solution is to immediately dilute the existing gasoline with a more suitable one. The second way is to add a special additive from the group of octane correctors, which allows you to increase the octane number and knock resistance of the fuel.

Why does a gasoline engine work like a diesel engine: reasons

Car manufacturers have always struggled to make engine operation silent. This also applies to domestic automakers. The engines of rear-wheel drive VAZs worked quietly at first, but after a certain mileage a loud noise appeared. To eliminate it, it was necessary to adjust the valves, because the “noisy” operation of the engine caused an increase in fuel consumption. The causes of noise were structural wear and metal expansion. I had to make manual adjustments every now and then.

But then timing belts with hydraulic compensators appeared, which made adjustments automatically. Thanks to this, the car drove silently for a long time. The mechanism required high-quality oil to operate, so synthetics were developed. However, diesel burnout still happens with modern engines. Let's look at the reasons for the phenomenon point by point.

Oil

This may seem trivial, but filling in “non-original” or, God forbid, counterfeit oil can cause the engine to growl. By the way, the problem can also appear when using high-quality working fluid - if it is not changed for a long time. You should not drive more than 20,000 km on one oil - this can completely “kill” the internal combustion engine. It is better to buy branded oil from trusted sellers.

Failure of hydraulic compensators is not such a rare occurrence. If they malfunction, noise appears in the area of the motor. This happens especially often with cars from Russian manufacturers.

Camshafts and valves

The valves eventually wear out their life, which leads to noise. Typically, breakdowns occur at the points of contact between the camshaft and valve mechanisms (cams, spots). But the defect also occurs due to high mileage - at least 200,000 km.

Shaft mount (pastel)

On some machines the pastel is initially slightly expanded. Because of this, engine operation may be accompanied by a strong roar. True, it is not always audible. When the metal is heated, it expands, which leads to a decrease in the gap and, accordingly, to the disappearance of noise. By the way, noise can occur on almost all cars with high mileage due to wear on the pastel mounting.

Valve train chain

A timing chain is more reliable than a belt drive, but it can also stretch. This is especially true for powerful TSI engines. The chain has tensioners, but if the chain is stretched too much, they become ineffective. Hence the rumble.

Timing belt

The belt itself cannot make noise, and it doesn’t stretch that often—it just breaks. But the belt tension system can make noise.

Valve system

Often a rumble appears after a major overhaul. The point is probably that the technician filled the valve mirror incorrectly - because of this, it cannot close normally, since there is an obstacle in its path. If the cylinder has low compression, this is most likely the problem.

“Dieselite” gasoline engine - what is it? Causes of the phenomenon.

Dieseling of the engine is one of the common problems associated with improper operation of the engine. This phenomenon is characterized by a high level of operating noise of the power unit. Driving with such a problem is not only uncomfortable, but also dangerous in terms of consequences. Often, “diesel” indicates damage to the engine, which it is advisable to deal with at an early stage, otherwise major repairs cannot be avoided.

Will the article be useful? Don't forget to give a "thumbs up"

and

subscribe to the channel

!

As you know, in normal condition, a gasoline engine should run quietly.

.

It does not make unnecessary sounds, regardless of the temperature. Diesel engines are much noisier than gasoline engines

.

They emit a characteristic roar that can be heard several meters away. This is due to the special ignition system and the design principles of the power unit. Accordingly, the “dieseling” of a gasoline engine is characterized by the appearance of a rumble characteristic of diesel engines

.

Today we will talk about what may cause extraneous noise.

, and how a car owner should act.

First of all, we check the presence of oil in the engine and its condition

.

“Dieselization” of the engine can occur due to a lack of lubricant or the use of a low-quality product. It is recommended to use oil that meets the manufacturer's approvals

and purchase it only from trusted places. If necessary, we replace the material and look at the result.

If the problem is not in the oil, then you will have to look deeper for the problem. First you need to assess the condition of the hydraulic compensators

(if present in the engine). Due to the high wear of these elements, extraneous noise may occur, which is not typical for a gasoline engine. Sounds appear at high speeds; at idle they can be barely audible. Replacing hydraulic compensators is inexpensive.

It is worth noting that on some cars, “dieseling” of a cold engine is normal.

.

This feature is especially pronounced in winter during cold starts. Increased engine noise is associated with the specification of the dimensions of the camshafts and their mountings. From the factory, they are deliberately not tightly adjacent to each other, so that when the metal expands on a warm engine, there is no increased load.

Diesel often appears after a major engine overhaul. This situation frightens car owners, especially in cases where the warranty has already expired or was not given at all. “Dieselization” of an overhauled engine is most often associated with improper processing of the valves

. In this case, you need to measure the compression; if it is significantly lower than normal, you will have to disassemble the engine again.

At the final stage of the test, it is recommended to check the timing belt (chain) for the presence of extraneous sounds. Think about the last time you replaced the bearings, which can make noise when worn at high levels.

Source

How to fix the problem

Each specific case has its own algorithm of actions. If it is determined that the rumble is a consequence of using low-quality oil, you just need to switch to another fuel oil. It should be remembered that it is inadmissible to use oil without changing it for a long time. The same applies to broken hydraulic compensators, valves and camshafts.

The problem of a loose timing chain is easily solved - the chain needs to be tensioned. Although the chain can stretch so much that it is no longer possible to tighten it. Then the chain drive must be replaced. If a timing belt is used as a timing drive, it will also have to be changed, and this must be done together with the tension rollers. The problem with valves is also solved by replacing these elements.

To avoid engine diesel build-up, it is better to use only high-quality oil and change it more often - at least once every 10,000 km. It is the use of low-quality working fluid that causes an unpleasant rumble, similar to the noise of a diesel engine. In addition, it is important to use high-quality gasoline and constantly monitor the timing drive. The absence of a rumble similar to the noise of a diesel engine can only be guaranteed if these conditions are fully observed.

You can often hear such a phrase as “diesel engine” from drivers or old-school car mechanics. This is what they say when an additional sound is heard in the operation of a gasoline engine, similar to that produced by diesel engines. Gasoline engines are generally quieter than diesel engines, so this state of affairs can be called a malfunction. And if there is a breakdown, then it needs to be repaired. Diesel is often the first sign of more serious problems. In theory, everything is simple, but “dieseling” is a very subtle area where it is difficult to say anything categorically.

Extraneous sounds The main problem is that we write in words about a sound phenomenon. Ask two different people to describe “diesel” in words and they will have completely different descriptions, maybe they will give a completely different description. The sound is loud/quiet, soft/hard, clicking/gurgling - these characteristics cannot describe the entire gamut. It is not always clear what the problem is and where to look for it.

If you read the forums, it turns out that almost half of the drivers who complained about diesel engines had a different problem. The word is easy to hear, but not everyone has enough hearing to determine the exact sound.

In addition, some engines have design features that lead to noise. A few examples.

- Motors GM 1.4; 1.6 and 1.8 liters often begin to make noise as the mileage increases due to the characteristics of the phase shifters.

- The Volkswagen CFNA engine has a known bug with pistons knocking when cold.

Engine 1.6 CFNA

- The “Korean” Solaris and Rio injectors “chirp” very loudly during operation, which some owners consider a sign of a malfunction.

- In Logan with “mechanics”, at idle, a background rumble is clearly audible when the engine is running. And the reason is not even in the engine, just depress the clutch pedal and the rumble disappears - this is a feature of the release bearing, which is installed from the factory.

There are dozens and hundreds of such examples, we will not list them all. If you hear extraneous noise, rattling, rumble, tapping, or bubbling noises when the engine is running, search the Internet for something that applies specifically to your motor model. Perhaps this is a design feature that, although it does not paint the manufacturer, does not require immediate repair.

“Dieselite” gasoline engine: what is the reason?

The expression “diesel engine” can hardly be called a common one. A kind of professionalism is used mainly by car service technicians to describe the uncharacteristic sound of a gasoline power unit, reminiscent of the specific noise of a diesel engine.

Since a working gasoline engine is much quieter than its diesel-powered counterparts, such a phenomenon means a malfunction of the unit. Identifying the cause of a malfunction is quite difficult. Take for example the fact that the sound of an engine can be interpreted in different ways, depending on the experience and hearing of car enthusiasts.

In addition, the appearance of an unusual sound is often associated with design details of a particular brand of motor. Let's look at just a few examples:

1. Engines of the American brand GM with a displacement of 1.4 - 1.8 liters have a special phase shifter. This is what causes the engine noise to increase as the mileage increases.

2. The CFNA power unit produced by the Volkswagen concern is “famous” for the knocking of the pistons when the engine is not warmed up.

3. Popular representatives of the Korean automobile industry Solaris and Rio are equipped with injectors that literally “chirp” during operation.

4. The Renault Logan engine with a manual transmission produces a special background rumble when idling. The problem is related to the factory release bearing and is solved by pressing the clutch pedal as much as possible.

Such cases indicate that you should not immediately contact a service center if extraneous sounds appear in the engine. First, it’s worth studying the experience of owners of cars of the same brand. Perhaps this is due to the design of your car and urgent repair of the problem is not required.

If the search for “like-minded people” does not produce results, you should contact a service center for diagnostics. Most often, the noise characteristic of diesel engines occurs in a gasoline engine for the following reasons:

1. Problems with the gas distribution mechanism. Most often, failure occurs due to tensioners, regardless of the design, be it a chain or a belt. The sound of a diesel engine may appear due to a stretched chain; less often, a strange echo appears due to a worn belt. To eliminate the problem, it is necessary to replace failed or faulty timing system parts.

Design Features

Diesel engines, of course, do not have such colossal differences as the Wankel rotary piston engine, the design of which is absolutely not similar to the “anatomy” of a traditional internal combustion engine, but it has a number of features that draw a line between it and gasoline engines.

The diesel engine also has a crank mechanism, but its compression ratio is significantly higher - 19-24 units versus 9-11 units, respectively. The fundamental difference between a diesel engine and a gasoline engine is how the fuel-air mixture is formed, ignites and burns.

A diesel internal combustion engine does not have spark plugs and, accordingly, ignition of the fuel-air mixture occurs from compression. At the same time, air and diesel fuel are supplied separately. It should also be noted that almost no modern diesel engine can do without a supercharging system, which is used to improve the performance of the unit. Variable geometry turbochargers are used to optimize boost over the widest possible speed range. A diesel unit has a higher efficiency, but it is heavier and produces more torque at low speeds than a gasoline internal combustion engine.

Operating principle of a diesel engine

How does a diesel engine work and, most importantly, how does fuel ignite in the combustion chamber if this type of unit does not have spark plugs? First, air enters the cylinders. At the end of the compression stroke, when the piston has almost reached top dead center, the air temperature in the combustion chamber reaches high values (about 700-800 degrees) and then diesel fuel is injected into the cylinders, which ignites independently, without spark ignition. However, there are still spark plugs in a diesel unit, but they are glow plugs, not spark plugs, which heat the combustion chamber to make it easier to start the engine in cold weather.

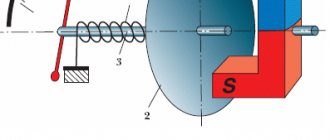

Glow plug operation in a diesel engine

They are a spiral (there are metal and ceramic), can be installed in a vortex chamber or in a pre-chamber (if we are talking about units with a separate combustion chamber) or directly in the combustion chamber (if it is inseparable). When you turn on the ignition, the glow plugs almost instantly, in a matter of seconds, they heat up to temperatures in the region of a thousand degrees and heat the air in the combustion chamber, facilitating the process of self-ignition of the fuel-air mixture.

Types of diesel engines

Motors with a separate combustion chamber are widespread - fuel is injected into a special chamber in the block head above the cylinder and connected to it by a channel, and the combustion process does not occur exactly like in gasoline internal combustion engines. In this vortex chamber, the air flow swirls more intensely, which contributes to more efficient mixture formation and self-ignition, which continues in the main combustion chamber. By the way, diesel engines with a separate combustion chamber are less noisy due to the fact that the use of a vortex chamber reduces the intensity of pressure build-up during self-ignition.

In diesel engines with an undivided combustion chamber, the process of self-ignition occurs directly in the space above the piston. Units of this type are somewhat noisier.

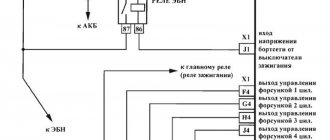

What is Common Rail

Common Rail is a modern fuel injection system developed by Bosch and using the principle of supplying diesel fuel to the injectors from the fuel rail, which is a high-pressure accumulator. Common Rail allows you to make the unit quieter, while being more economical and environmentally friendly. Another advantage of using a common fuel rail is the wide range of possibilities for adjusting fuel pressure and injection timing, since these processes are separated.

The system includes a fuel injection pump (high pressure fuel pump), piezoelectric injectors, a fuel rail, a fuel pressure regulator and a fuel metering valve. It is interesting that at the dawn of their evolution, diesel units had much simpler fuel equipment with mechanical injectors and incomparably lower diesel pressure compared to modern systems.

Child of progress

Not so long ago, diesel engines were environmentally “dirty” and quite weak, but for some time now units of this type have changed dramatically, and some representatives of the tribe are worthy of sports cars. These include the BMW 3.0 liter inline six-cylinder engine with four turbochargers.

By the way, the design of this engine clearly demonstrates the progress of “heavy fuel” units. The technological masterpiece is equipped with two low-inertia low-pressure turbochargers and two more high-pressure ones, with one of them coming into action beyond 2500 rpm. Piezo injectors inject fuel under a colossal pressure of 2500 bar. Output – 400 hp. and 760 Nm. Interestingly, 450 Nm is available already at 1000 rpm! This is what modern diesel engines are like.

Subscribe to us on Facebook and Vkontakte!

You can often hear such a phrase as “diesel engine” from drivers or old-school car mechanics. This is what they say when an additional sound is heard in the operation of a gasoline engine, similar to that produced by diesel engines. Gasoline engines are generally quieter than diesel engines, so this state of affairs can be called a malfunction. And if there is a breakdown, then it needs to be repaired. Diesel is often the first sign of more serious problems. In theory, everything is simple, but “dieseling” is a very subtle area where it is difficult to say anything categorically.

In the photo: the engine from the inside

Extraneous sounds

The main problem is that we write in words about a sound phenomenon. Ask two different people to describe “diesel” in words and they will have completely different descriptions, maybe they will give a completely different description. The sound is loud/quiet, soft/hard, clicking/gurgling - these characteristics cannot describe the entire gamut. It is not always clear what the problem is and where to look for it.

If you read the forums, it turns out that almost half of the drivers who complained about diesel engines had a different problem . The word is easy to hear, but not everyone has enough hearing to determine the exact sound.

In addition, some engines have design features that lead to noise. A few examples.

1. Motors GM 1.4; 1.6 and 1.8 liters often begin to make noise as the mileage increases due to the characteristics of the phase shifters.

2. The Volkswagen CFNA engine has a known bug with pistons knocking when cold.

Engine 1.6 CFNA

3. The “Korean” Solaris and Rio injectors “chirp” very loudly during operation, which some owners consider a sign of a malfunction.

4. In Logan with “mechanics”, at idle, a background rumble is clearly audible when the engine is running. And the reason is not even in the engine, just depress the clutch pedal and the rumble disappears - this is a feature of the release bearing, which is installed from the factory.

There are dozens and hundreds of such examples, we will not list them all. If you hear extraneous noise, rattling, rumble, tapping, or bubbling noises when the engine is running, search the Internet for something that applies specifically to your motor model. Perhaps this is a design feature that, although it does not paint the manufacturer, does not require immediate repair.

Problems in the motor

If no widespread problems were noticed with a particular motor model, then you need to deal with a specific instance. We have compiled a list of common causes of diesel noise during operation. This is not a complete list, but it includes the most common points.

1. Gas distribution mechanism . Depending on the design of the mechanism, the problem can be in different elements, but often the cause is tensioners, both in the case of a chain and in the case of a belt. A stretched chain can also give a diesel sound, but a belt is rarely the cause; if it is worn out, it is more likely to break.

Stretched chain of BMW M57T2 engine

Repair in the timing system comes down to replacing problematic and expired elements.

2. Valves . “Excessive” sound from valves in an engine occurs even more often than from the timing belt, but usually it has a pronounced knocking sound and is not very similar to a diesel “rumbling”, but in some situations it can be confused. Valves knock either due to incorrect clearances or due to poor-quality repairs (poor “grinding”). Failed hydraulic compensators will also make knocking noises. Most often this occurs when it is cold, but not necessarily.

valves

3. Camshafts . Another popular reason. Usually the problem is in the bed, which either from the factory (this also happens) or simply due to wear has become a little wider than it should be. When starting such a motor, it may make a rumble. Sometimes this only happens when it’s cold, sometimes it always rumbles - it depends on the situation.

Camshaft output

4. Lubrication system . This is such a general point that includes a whole block of problems. Extraneous noise in engine operation can be caused by counterfeit oil, incorrectly selected oil (for example, too thin), poor operation of the oil pump, or a clogged oil receiver screen. Whatever it is, it’s all the same, the motor elements are not lubricated as they should be and rub against each other a lot, causing noise.

Let us remind you that these are only the most popular causes of diesel fuel. In simple situations, checking these four parameters should help; in more complex situations, the reason may be in a completely different area. In any case, it is better to consult with experienced mechanics - they will be able to determine the suspected cause by the shades of extraneous noise. And diagnosis based on descriptions of sounds is like treatment based on photographs.

Problems with the cylinder-piston group

If the engine suddenly and distinctly knocks, knocks, pops, friction and crunching are heard, then operating the car is strictly prohibited. It is necessary to immediately determine the cause of the knocking. In some cases, it will be preferable to abandon the decision to go to a car service under your own power and deliver the vehicle in a tow or tow truck.

A low knocking sound at the bottom of the engine crankcase, which intensifies when the engine is under load and when the crankshaft speed increases, may indicate that the main bearings are knocking. When this sound occurs, the engine must be turned off immediately. Main bearings may knock due to critically low oil pressure in the lubrication system. Additionally, the emergency lamp on the instrument panel lights up and does not go out. You can't drive under your own power with that kind of noise.

No less dangerous is the ringing, distinct metallic sound that comes from the middle part of the internal combustion engine (in the area of the cylinder head gasket). This can cause the connecting rod bearings to knock. The sound is heard most clearly under load. You can identify a malfunction in one of the cylinders by disconnecting the spark plugs one by one. A shutdown in a faulty cylinder will cause the rhythmic and ringing sound to disappear. Driving with such damage is prohibited.

Another reason why a gasoline engine sounds like a diesel engine could be the high-pitched ringing sound of the piston pins knocking. This knocking sound is slightly similar in tone to detonation, but is clearly audible in all engine operating modes and intensifies under load. It is determined similarly by the method of disconnecting the spark plug. You can get to the service center with such a knocking noise yourself, having first checked the oil level. It is necessary to drive smoothly, avoid increasing speed and minimize the load on the engine.