Cars admin26.02.2020

Help with advice. The tachometer and power steering don't work, the speedometer jumps, the generator gives 14.5. It all started about two weeks ago. I tried almost everything, but still nothing. After replacing the phase sensor, everything worked for a couple of days and again everything remained the same. Or rather, the speedometer has also been added while driving like a dragonfly under 200 km. Moreover, the speed was city, although after 40 minutes it was restored to normal mode. And everything else is the same. Where else to go. I'm thinking.

Hurray, it worked! The problem is resolved, it’s just that antifreeze flooded the brain. I didn’t visually notice small drops between the microcircuit legs, I thought that was it. As a result, alcohol-based cologne) and a day of drying the board on the radiator. We turned on the ignition and EVERYTHING WORKED. My wife sat up to the ceiling with joy that the EUR worked))

Today, all Lada Kalina owners are interested in the question: why does the electric power steering on the Kalina not work? After all, this car began to be produced back in November 2004, with electric power steering as standard. The ten-year anniversary has passed, but according to reviews from car enthusiasts, this problem still exists.

The electric amplifier consists of an electric motor, a force transmission mechanism and an electronic control system. The operation of the electric booster is controlled by an electronic unit with three special sensors, which must quickly determine the speed of the car, engine speed and the required force to turn the front wheels.

When starting the engine with the starter, the electric power steering (EPS) does not work. It turns on only when reaching 400 rpm

crankshaft and stops working when the car accelerates over 60 km. at one o'clock.

Symptoms of a problem

It is impossible to immediately understand why the electric power steering does not work on Kalina. However, in most cases of malfunction (EUR), a light indicating a steering wheel with an exclamation mark should light up on the instrument panel. After which, specialists from the VAZ automobile plant recommend driving at low speed to a car service center.

Why at low speed? Because in the first years of production (EUR) by the Makhachkala plant, it had the peculiarity of turning the drive wheels of the car as far as possible to the left or right and independently locking itself in this position.

The electric motor and mechanical part (EUR) rarely cause complaints, but the electrics and electronics require a detailed study of breakdowns.

Classification by operating principle

- Mechanical or electromechanical tachometers with direct drive. The revolutions are transmitted to the dial indicator through a flexible shaft, which, through a worm gear, receives rotation directly from the crankshaft or one of the transmission shafts. The operating principle of the indicator is based on the phenomenon of eddy current induction. The operation and design of a magnetic tachometer are extremely similar to the operating principle of a car speedometer. In modern cars, a similar tachometer design is not used.

- Electric machine. A distinctive feature is the connection to a generator. It is used primarily on diesel engines, but for the purpose of unification, a device of this type can also be used on gasoline engines.

- Electronic. The signal can be taken either from the ignition system or directly from the computer. Installed on gasoline and diesel internal combustion engines.

Design and principle of operation

Main components of electric machine and electronic tachometers:

- measuring unit, or signal converter. It can be based on elements of analog circuitry or built using special microcircuits;

- display unit with analogue or digital display of the number of revolutions;

- auxiliary elements.

The operation of electronic tachometers is based on the conversion of individual signals or pulses captured from the computer, ignition system or generator into a signal “understandable” for the display unit.

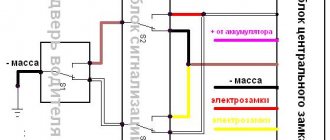

Connection diagram

When looking for the reason why the tachometer does not work, it is first of all important to understand the connection diagram and the type of signal. There are 3 typical connection schemes:

- to a contactless ignition system (the tachometer wire is connected to the primary circuit of the ignition coil). The operating principle is based on measuring the frequency of voltage surges in the primary circuit of the ignition system. Calculating the ignition angle is impossible without focusing on the number of crankshaft revolutions, therefore the sparking frequency directly depends on the crankshaft rotation speed. On 4-cylinder internal combustion engines, a full revolution of the crankshaft corresponds to 2 voltage pulses in the primary circuit. Accordingly, the higher the crankshaft rotation speed, the greater the frequency of voltage surges;

- connection to the contact ignition system. The operating principle and connection diagram are similar to the BSZ, but the design of the measuring unit will differ depending on the voltage of the input circuit;

- connection to the engine ECU. The principle of operation is still based on recording voltage pulses in the primary circuit of the ignition system, but the signal to the tachometer comes from the engine control unit;

- connection to the generator (the tachometer signal contact is connected to terminal W of the generator). The rotation of the generator pulley is carried out by a belt drive from the crankshaft, so the rotation speed of the generator rotor will always be proportional to the crankshaft speed. The change in the number of revolutions of the crankshaft can be calculated by constantly measuring the amount of EMF generated on the winding. According to its principle of operation, an electric machine tachometer resembles a regular one class=”aligncenter” width=”448″ height=”412″[/img]

Debriefing

The electronic control unit (ECU) for the electric power steering is mounted in a bad place, under the heater radiator

. Any leakage of this part causes the ECU to get wet, after which you will feel that the power steering is not working and the steering wheel has become heavy.

If while driving you notice that the tachometer or speedometer needle is at zero and does not move, rest assured that the ESD of your car is not working. This happens because these devices and (EUR) are activated from the same sensors.

Most often on Kalina, the speed sensor fails. Buying a new sensor and replacing it solves this problem. There are very often cases when replacing sensors does not help, (the electric power steering) still does not work. Begin to methodically probe the entire chain of wires related to the system (EUR).

Due to the constant vibration of the car and poor quality of production, connecting plugs and blocks independently break electrical circuits at the most inopportune moment.

Kalina's power steering behaves poorly during on-board voltage fluctuations

. If an old generator produces less than 30 volts instead of 15 volts, then the electronic control unit of the power steering may also refuse to work.

Tachometer needle is not at zero on Lada Kalina, problem treatment

Some Lada Kalina car owners encountered a problem when the tachometer needle rose and then did not return to its place. There may be several reasons for the malfunction. Experience shows that most car owners first remove the battery terminal for 5-10 minutes to reset errors, but this, as a rule, does not help.

Causes of malfunction

So, basically the malfunction appears due to disassembling the instrument cluster. On many forums, car owners complain that after disassembling the panel, this defect appeared.

But this may not be the only reason. Let's consider the main ones:

- The tachometer control motor burned out.

Thus, the main problems have been found.

Disassembling the dashboard

Treatment methods

In order for the tachometer needle to return to its place, it is necessary to eliminate the causes of this effect. So, let's look at how to treat various malfunctions with your own hands:

- The motor burned out. It is necessary to unscrew the panel and unsolder the element contacts. Check the resistance, which should be 300 ohms. If necessary, clean the contacts and solder the motor back. If this does not work and there is no resistance, then you need to install a new motor.

- Tachometer controller. If the motor is sealed and the tachometer does not return, then you need to find the control controller and check it. Replace if necessary.

- If replacing the controller does not help, then you need to look for the problem in the ECU. To do this, you should connect a laptop through the connector and use a special program to diagnose errors. Most likely, there will be a lot of them and they all need to be eliminated. In rare cases, you will need to install new firmware.

- The last reason may lie in the combination of partings itself, and eliminating the cause will require a significant amount of money.

Now we know how to eliminate the causes of the malfunction.

conclusions

The occurrence of a malfunction when the tachometer needle does not return to zero in the Lada Kalina is quite a rare occurrence, but it is present. This problem may or may not be easy to fix. Usually, as practice shows, everything ends with a trip to a car service center, but for those who like to fix everything with their own hands, this is not an option.

Malfunctions on VAZ

The speedometer on the VAZ stopped working.

Most domestic autospeedometers and odometers are mechanical. So, when a mechanical odometer fails, the main reason (almost always) is a broken cable.

This problem can be easily diagnosed by a characteristic noise in the front of the dashboard.

After breaking, the steel wires begin to touch the inside of the shell and “ring.” The main reason for the break is the large radius of curvature during cable installation.

POPULAR WITH READERS: Car repair NISSAN ATLAS 1999-2004, ISUZU ELF / N-series 1993-2004

A mechanical speedometer malfunction can manifest itself in different ways. For example, the needle on the device often lies as a “dead weight” or, conversely, shows deliberately false information.

In such a situation, you need to make sure that the speed sensor is working and that there is voltage on it. Also inspect the terminals for moisture penetration.

If there is voltage at the sensor, then the problem must be looked for in the device itself. In such a situation, it is easiest to replace it.

It happens that a sensor malfunction is associated with some kind of mechanical damage. In this case, you can try to disassemble the drive and fix the problem yourself.

If there is no voltage on the sensor, it is necessary to check all electrical connections on the way to the device - wires, blocks, terminals. It is likely that the contacts are broken or oxidized.

New cars have electronic speedometers and odometers, which receive data from the speed sensor at the gearbox.

Consequently, there can be two breakdowns - either in the odometer itself (in this case it is necessary to change the entire dashboard).

Or in the sensor (we talked about it above).

VAZ tachometer malfunctions.

In the VAZ tachometer, the causes of the malfunction may differ, depending on the type of engine.

On a carburetor car there are three wires from the tachometer.

One wire is connected to the “K” terminal of the ignition coil, and the other two supply power (respectively, “plus” and “minus”).

To find out the cause of the breakdown, you need to disconnect the terminals going to the tachometer and connect the latter directly to the battery (terminal “K” remains in place).

Malfunctions on Priora

Speedometer.

If the speedometer on a Priora stops working, the first thing you need to do is temporarily remove the terminals from the battery.

Did not help? - Then look for a fault in the device circuit. First, check the integrity of the instrument panel fuse.

If it burns out, replace it (but first make sure that all contact connections are intact).

If the problem persists or the fuse is normal, check all the wires on the path from the speed sensor to the instrument panel. This can be done using a multimeter.

If there are no complaints about the wiring, check the motion sensor with a special scanner. If there are malfunctions, the element must be replaced.

The serviceability of the motion sensor can be determined by the behavior of the odometer. If the speedometer does not work, but the odometer counts kilometers, then the sensor is working, and the breakdown must be looked for elsewhere.

For example, problems may be in the soldering on the dashboard circuit board or, even worse, in the gearbox. But this can only be found out at a service station with the help of a qualified technician.

Tachometer.

As for the tachometer on the Priora, there are three causes of malfunctions:

- violation of the tachometer supply circuit. In this case, you need to carefully crimp all the tips and replace damaged wires (if any);

- violation of the functionality of the controller (the signal does not reach the tachometer). Only replacing the device will help here;

- failure of the tachometer itself. This option is the most expensive, because it is not possible to change the device separately - you need to buy a new panel.

POPULAR WITH READERS: The generator overcharges the battery, where to look for the reasons

EUR and tachometer do not work - Questions about diagnostics and repair - AvtoMastera.net

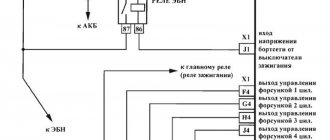

Blue color indicates contacts used in systems with 2 DCs (Euro III) Red color indicates contacts used in 16 cell systems 21124

| № |

| 21114 - Not used / 21124 - Ignition coil 2 cylinders. |

| 21114 - Ignition 2-3. Control of the primary winding of the ignition coil, act. level is low. / 21124 — Ignition coil 3 cylinders. |

| Ignition circuit weight |

| 21114 - Not used / 21124 - Ignition coil 4 cylinders. |

| 21114 - Ignition 1-4. Control of the primary winding of the ignition coil, act. level is low. / 21124 - Ignition coil of cylinder 1. |

| Injector 2. Active level low |

| Injector 3. Active level low |

| Output to tachometer. |

| Not used |

| Fuel consumption signal |

| Not used |

| Battery, terminal 30 of the ignition switch. |

| Nutrition. Ignition switch terminal 15 |

| Contact "A" DPKV |

| TPS mass / TPS mass, DND |

| Input - oxygen sensor |

| Input - knock sensor |

| Knock sensor weight |

| Not used |

| Not used |

| Not used |

| Not used |

| Bosch Only - High Current Output, Reserved |

| Bosch Only - High Current Output, Reserved |

| Injector 1. Active level low |

| Not used / DK2 heater control output |

| Not used / Engine cooling fan control output 2 |

| Not used |

| CE lamp, act. level low |

| Power supply TPDZ / Power supply TPDZ, DND |

| DPKV input, contact “B” |

| Weight of DTOZH / Weight of DTOZH, mass air flow sensor, 1 DC (UDK), 2 DC (DDK) |

| Signal input from mass air flow sensor |

| Not used |

| Signal input from DTOZH |

| Signal input from intake air temperature sensor |

| Not used |

| Not used / DND signal input |

| Not used |

| On-board voltage input at the main relay output |

| Phase sensor power output |

| Canister purge valve control output |

| Injector 4. Active level low |

| Oxygen sensor heater control output |

| Not used |

| Additional starter relay control output |

| Controller weight |

| Not used |

| Controller weight |

| Not used |

| Not used / Signal input DK2 (DDK) |

| Not used |

| Input for encoding calibration data options. The controller memory can contain 2 sets of calibration data; switching is performed by shorting to ground. |

| Not used |

| Speed sensor |

| Not used |

| Weight of output stages |

| Not used |

| On-board voltage input at the main relay output |

| Engine cooling fan relay control output, act. level - low |

| Air conditioner relay control output, act. level - low |

| Fuel pump relay control output, act. level - low |

| Not used |

| Not used |

| Not used |

| Input request to turn on the air conditioner, act. level - high |

| Power steering request input, act. level - high |

| Not used |

| Not used |

| Phase sensor signal input |

| Weight of output stages |

| Not used |

avtomastera.net

Tachometer failure. — Lada Kalina Hatchback, 1.6 l., 2007 on DRIVE2

Yesterday I started the engine, and the tachometer needle is at zero. The EUR also did not work due to the inability to count engine speed. After about five minutes of driving, the tachometer and power steering came to life again. After I turned off the engine, I started it - again the ESD and tachometer did not work, again drove for about five minutes and everything came to life, then it turned off and did not turn on again. During the tidy test, the tachometer functions. In addition, I noticed today that the BC does not show fuel consumption.

I will try, following the advice, to change the speed sensor, although the speedometer works. This is the second day in our city of rainy weather, crawling under the hood is not an option, but we need to move around. To prevent the power steering from turning on unexpectedly when taking a turn, I removed fuse F31.

EUR fuse. F31. The largest fuse in the mounting block.

Without an EUR, it’s bad when parking and at low speeds, but on the highway without it, the information content of the steering wheel has increased.

Addition: As it turns out, it’s still not a speed sensor issue, I’ll look into it further.

Addendum 2 In the afternoon I had to take my wife to work. I started the engine and the tachometer surprised me, it works. Miracles... I haven’t put the EUR fuse back in place yet.

Mileage: 93272 km