The constant presence of a small canister of gasoline in the car or the car owner voting on the highway with a request to refuel, all this is a consequence of the fact that the fuel sensor in the car does not work. The breakdown of this sensor does not affect the operation of the main mechanisms of the iron horse, but it significantly affects the comfort of using the car, since there is always a need to calculate how much the car has traveled since the last refueling and how many more kilometers can be driven without stopping at a gas station.

Author of the article: mudriy_lev Specialization: repair of auto generators and servos in cars. Place of work: service center. Experience: 2 years. Education: higher education – electrical engineer, secondary specialized education – mechanical assembly mechanic.

Let's look at the main reasons.

Potentiometer and its problems

Modern cars are equipped with a wide variety of fuel level sensors. The widest niche has been occupied by sensors based on potentiometers. This type of conversion of fuel level information into an electrical signal has many advantages. There are two types of sensors based on this method of measuring fuel level:

- lever (widespread)

- tubular (used mainly on large vehicles)

If the lever-type fuel level sensor does not indicate the fuel level correctly, the reason associated with the potentiometer and causing this malfunction may be as follows:

- Potentiometer contacts have oxidized

- there has been natural wear on the tracks or slider of the resistor

- natural aging of the resistor

- resistor does not match the nominal value

Potentiometer Diagnosis and Troubleshooting

A symptom that the potentiometer contacts have oxidized is a temporary lack of accurate information about the fuel level in the gas tank. The owner notices that from time to time the indicator shows reliable information. Usually, in this case, the light indicating the end of fuel works flawlessly.

To diagnose this malfunction, it is necessary to visually inspect the variable resistor of the fuel level sensor. The oxides will appear different from the normal color. Based on their number, a decision is made on what to do next:

- clean (in case of a small amount of oxides)

- move the slider (if only part of the tracks are oxidized)

- replace the fuel level sensor with a new one (if the oxides are significant and have led to damage to the tracks or slider)

A symptom of natural wear of the tracks and runner is either a complete failure of the sensor, or its correct operation only in certain areas. A visual inspection in this case shows that the tracks are worn out, and in more rare cases, damage to the runner.

If it is possible to move (bend) the slider to an undamaged area, the sensor will please the owner with its long-term, proper operation. But if the runner is damaged, or the tracks are seriously damaged, repairs do not make sense. It is necessary to purchase a new fuel level sensor.

To establish the next reason why the fuel sensor does not work, you need a multimeter or an ohmmeter of any design. A resistor can change its resistance and, as a result, display unreliable information. Checking the resistance value with an empty, full and half-filled gas tank will help identify this problem. Repair in this case is not advisable, since it is safer to install a new sensor.

If problems with inaccurate fuel level arose after installing a new sensor, then a common cause is a resistance mismatch with the nominal value. This situation arises due to the fact that the sensors are similar in appearance, but their different modifications have different resistance values.

Faulty fuel level sensor: consequences

A faulty fuel level sensor is a fairly serious problem, in the presence of which it is not recommended to operate the car until it is completely eliminated.

Firstly, the driver risks being left without fuel on a section of the road far from gas stations, and this means a long period of vehicle downtime, a colossal loss of time, and possibly money.

Secondly, due to a faulty fuel level sensor, other parts and mechanisms may fail. For example, the fuel pump of an injection engine, which is constantly located in the fuel tank and is cooled with the help of fuel. If the needle deviates significantly from the actual parameters or the fuel level sensor is always at zero, the motorist cannot determine the actual volume of fuel. If there is too little of it in the tank, the fuel pump overheats. In addition, debris gets into the fuel tank, which clogs the filters.

The float is not informative

Problems when the fuel gauge does not work are often related to the float. There are 2 types of floats installed on cars:

- hollow (plastic, plastic, metal)

- made of lightweight porous material

The first type of float faces the problem of mechanical damage. As a result, the indicator needle gradually does not reach the maximum when the tank is full more and more. The float fills with gasoline and the gasoline sensor shows the wrong level more and more every day. Repair in this case is carried out by replacing the float.

The second reason why the fuel sensor is lying is encountered by both types of float. As a result of mechanical damage to the gas tank, the float becomes jammed. In this case, the indicator will show either a single value or work only in a small range. Elimination of this breakdown is possible only by replacing the gas tank.

How does the device work?

To understand the problem yourself, you need to understand how the fuel level is measured and information is transmitted to the device indicator. The circuit implemented in most vehicles includes the following main elements:

- a float made of lightweight polymer is immersed in the gas tank and is often combined with the pump block;

- gasoline sensor – lever-type potentiometer (otherwise known as rheostat);

- pointer arrow with scale;

- connecting wires.

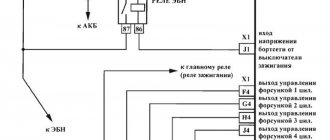

In many modern cars, an electronic control unit is connected to the system.

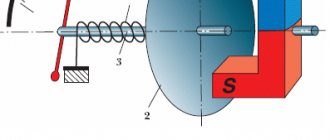

The classic rheostat is an open coil of high resistance wire. A lever equipped with a contact and attached to the float rises or falls with the level of fuel in the tank, and the contact moves along the turns of the winding. The classic scheme works simply:

- The rheostat and the pointer device are connected in series in the circuit, both are powered from the vehicle's on-board network.

- When moving the float with the lever, the resistance of the potentiometer changes.

- A change in resistance causes an increase or decrease in the current in the circuit, to which the indicator arrow reacts. The scale is graduated according to the resistance values corresponding to the filling of the gas tank.

The updated version of the system works with the participation of a controller. The fuel level arrow receives a processed digital signal from the electronic unit that supplies power to the potentiometer. The principle of operation does not change, but the circuit allows you to obtain more accurate readings.

What's the result?

Taking into account the above, it becomes clear that although the fuel level sensor is structurally simple, various breakdowns (both mechanical and electrical) can disable this element or cause malfunctions in its operation.

One way or another, the problem needs to be solved, otherwise the driver will have to constantly separately record data on how many kilometers have been traveled since the last refueling, how much more can be driven and when to refuel.

Finally, we note that often the best option is to replace the FLS with a new one; at the same time, it may also be necessary to change the fuel level sensor float. Less often it is possible to carry out repairs by removing oxides, moving to working sectors, etc.

It will be useful: How to choose a battery for a car: by brand and VIN code, estimation of service life, types of models and their differences in capacity and size

At the same time, the most serious nuisance that leads to incorrect fuel level readings is considered to be a damaged gas tank. In order for the fuel sensor to work normally, in this case it is necessary to repair or replace the fuel tank.

What is the FLS fuel level sensor intended for: the design of the fuel sensor, types of fuel sensors and features, the operating principle of the FLS.

Why is it necessary to clean the fuel pump mesh? When is it better to change and how to clean the fuel pump mesh? How to properly remove the fuel pump, subtleties and nuances.

How to change a fuel pump. Location of the fuel pump, releasing pressure in the system, unscrewing the fuel lines, removing the pump, reassembling.

How to determine why the fuel pump does not pump or works poorly. Fuel rail pressure, pump diagnostics. Wiring, relays, fuel pump fuses.

The causes of whistling and increased noise during operation of the fuel pump are overheating of the pump. How to diagnose and fix the problem yourself. Tips and tricks.

Why does the fuel pump grid need to be changed? How to remove the fuel pump yourself to replace the filter. Features of reassembly after replacing the fuel pump mesh.

Modern sensors: advantages

There are not many situations when the product in question does not work correctly. Most of them happen after 5-10 years of operation of the vehicle, when the mechanical part of the product wears out. The design, materials and tightness of most FLS allow them to function until the vehicle is disposed of. Among the main advantages of the product it should be noted:

- affordable price;

- complete tightness;

- simplicity and reliability of design;

- high level of resistance to mechanical stress.

On average, the price of FLS is in the range of 1-2 thousand rubles. If necessary, they can be easily dismantled and replaced. Among the disadvantages of fuel sensors, we highlight the low oxidative resistance of metal plates, as a result of which there is often a discrepancy between the position of the fuel needle on the dashboard and the current level in the tank.

Eliminating the causes of malfunctions - repairing the automotive fuel level sensor

Some fuel sensor malfunctions can be resolved yourself. A damaged float can be easily changed, either in tandem with a lever or without it (depending on the make of the vehicle). Broken or damaged wires are repaired using a regular soldering iron. The resistive element plates can be replaced with new ones. However, you need to choose the right parts according to the make and model of your car.

In most cases, in order to avoid serious breakdowns, you need to contact a specialized service to diagnose the FLS, identify the exact causes of malfunctions and take adequate measures to eliminate them. Most often, carrying out repair work is not economically feasible.

Experienced specialists are ready to provide a full range of services in this area. If the fuel level sensor does not work, contact our company to replace the faulty element. The cost of a new part is quite affordable.

How to fix the problem?

If the fuel sensor is not working correctly, repair work will be required. For each car model, the process of dismantling this device may differ significantly and may also require special tools. However, the general steps are similar and are as follows:

- the negative terminal is disconnected from the battery;

- access to the device is provided by removing the trunk trim;

- unscrew the mounting bolts that fix the position of the sensor, and remove the plate;

- the product is dismantled, the metal elements are cleaned (if it will be used again).

It is necessary to remove the FLS only after disconnecting all wires and foreign elements. The product should be removed easily, without visible effort. On older cars, the device may become stuck: in this case, it will need to be lubricated with a special liquid (for example, WD).

Repair or replacement

First you need to carry out diagnostics, that is, find out which part is damaged - the sensor, wiring or the indicator itself. For this, a regular multimeter is used, but you can replace it with a test lamp.

First you need to gain access to the fuel section and the fuel level sensor itself. To do this, with the car running, you need to remove the connector in the service hatch under the rear sofa of the car. Then, using the electrical supply diagram, you need to determine which wire goes from the sensor to the fuel indicator. One connector of the multimeter must be connected to the ground of the car, the other to the positive terminal of the wire coming out of the hole. The multimeter should show the on-board voltage (12 V). If you close the positive terminal to vehicle ground, the indicator arrow should show a full tank. If this does not happen, the wiring or the indicator itself is to blame. If the needle shoots up to the extreme position, the problem is in the fuel sensor.

Modern fuel sensors are best replaced as an assembly. Their price is not so high as to make repairs that do little to help the business. However, in some cases, you can try to clean the sensor from dirt and try to adjust the slider. To do this, you will have to remove the sensor (you must first drain the fuel, turn off the car and remove the negative terminal from the battery). After removing the sensor, you need to inspect the working surface of the sectors for wear. If the width of the wear line is small, you can adjust the slider so that it moves along the undamaged surface of the sectors.

If incorrect readings of the fuel level indicator are not associated with the fuel sensor, then you will have to remove the indicator from the dashboard. Wiring problems can also be diagnosed using a multimeter. The malfunction of the device itself is determined manually after removing the device - if the arrow is jammed, you can try to clean it and adjust it.

conclusions

Despite the structural simplicity of the FLS, it is not immune to various breakdowns, which are individual in each case. They can be associated with electrical or mechanical damage of various types.

The sensor may become confused or completely fail. As practice shows, minor repairs and replacement of individual components of the device do not make much sense, since the malfunction will recur quite quickly, and the sensor will have to be removed again. To get rid of wasted time and unnecessary actions, it is better to replace it entirely at once.

In the absence of a sensor, the driver will have to constantly independently monitor the fuel level, remember it or write it down, but this is quite difficult, since the car’s consumption is usually not standardized and may differ from the approximate value. Just in case, you will have to carry a can of gasoline with you, and this is not always convenient or safe. If the fuel level drops critically, you risk not only getting a faulty fuel pump, but also a number of other problems, which are often not so easy to get rid of, and the cost of repairs is quite high. By saving on a sensor, you will pay much more for repairs and cleaning of the fuel system.

It is worth noting that when replacing the fuel level sensor, you need to pay attention to its condition. If it is simply oxidized or the tracks are out of alignment, you can clean it and return the tracks to their working position. Such repairs may last a long time. The most common cause of malfunction is oxidation, followed by mechanical damage to the gas tank. Before disassembling the panel, inspect the car visually: the tank may be bent.

Faulty fuel level sensor float

There are different reasons for a faulty fuel level sensor. One of the most common is damage to the float. This element can be of two types:

- hollow - made of metal or plastic;

- foam - made of microporous material.

If the hollow float is damaged, fuel gets inside it, causing the indicator to show incorrect data. To fix the problem, it is necessary to remove the fuel level sensor and replace the float. If there is a suspicion that the float is sticking, you need to carefully inspect the fuel tank - it is quite possible that its integrity has been compromised.

Typically the fuel tank is between 30 and 70% full. It is in this range that the resistive track is most susceptible to wear. The result of wear is obvious - the fuel level sensor does not work.

Another reason for the element to “wedge” is incorrect bending of the lever. As a rule, in this case, the range of travel of the pointer arrow is significantly reduced. The situation can be corrected by removing the fuel level sensor and adjusting the bend. However, if it repeats, the gas tank may be subject to mechanical stress. It is necessary to inspect it for damage and, if necessary, repair or replace it.

DUT ESCORT TD-BLE

5,500 rub.

DUT ESCORT TD-150

4,500 rub.