The VAZ 2114 camshaft sensor is one of the most important measuring instruments of the fourteenth, which, through a pulse signal, transmits information about the current engine operating cycle to the car’s brains. Based on the information received, the electronics adjusts the timing of supply and ignition of the fuel mixture in the engine cylinders.

A normally functioning DF is the key to the correct functioning of the engine, which achieves the optimal ratio of the amount of fuel consumed and the operating power of the power unit.

From this article you will learn the main causes of DF malfunction and how the failure of the device affects the operation of the car. The technology for replacing the DF on the VAZ 2114 will also be examined in detail.

Features of the VAZ 2114 phase sensor

You can determine that the phase sensor on a VAZ 2114 has failed by the following malfunctions in the vehicle:

- Gasoline consumption has increased significantly;

- The acceleration dynamics of the fourteenth have worsened, and dips are observed in the engine’s idle speed;

- The engine idles;

- Errors No. 0343 and 0340 are displayed on the on-board computer screen, which indicate that the DF is faulty and the ECU is operating in emergency mode.

The reason why the phase sensor failed can be determined only after dismantling and visual inspection of the device, in some cases - after diagnosing it. As a rule, the main causes of DF failure are as follows:

- A short circuit has occurred on the internal DF circuit;

- Mechanical damage to the device mounting ears, due to which the housing has shifted in the mounting socket;

- The toothed disk on the pulse signal converter has broken;

- The DF was damaged due to the increased temperature of the engine.

PHASE sensor

If the device breaks down, the ECU starts working exclusively on the readings of the crankshaft sensor. In this mode of operation, it is impossible to carry out phased fuel injection, as a result of which the brains of the fourteenth switch the engine to twin injection, which results in excessive consumption of gasoline and deterioration in acceleration dynamics.

Repairing the device in most cases is not advisable, since a DF that has once failed is unlikely to work normally in the future.

Fortunately, the cost of DF is low - the price of a new device is 400-600 rubles, depending on the manufacturer (prices are also relevant for sensors on the VAZ 2115).

If typical signs of DF failure occur, or if errors 0343 or 0340 are displayed on the on-board computer of the fourteenth, it is necessary to check the functionality of the DF. This is done using a conventional multimeter.

Fourteeners with 16 and 8 valve engines have different DFs, so the specifics of checking them will be slightly different.

How to check the camshaft sensor VAZ 2114 8v:

- On the first probe of the tester we set the voltage to 13.5 Volts and connect it to contact “E” on the DF, on the second probe, which must be connected to contact “B” - 0.9 V;

- Having closed the contacts, we bring a metal screwdriver to the end of the sensor. If the DF is working properly, you will see on the tester screen that the voltage of contact “B” has dropped to 0.4 Volts. If this does not happen, the DF is broken;

How to check the camshaft sensor VAZ 2114 16v:

- We set the following voltage on the multimeter: contact “E” – 13.5 Volts, “B” – 0.4 Volts;

- We close the contacts and insert a screwdriver into the hole on the phase sensor. If the device is working properly, the voltage at pin “B” will increase to 0.9 Volts.

A multimeter is a standard device for checking the performance of any sensor.

Having determined that the DF is faulty, you can begin to replace it. The process is easy enough that you will only need a ratchet wrench with a 10 mm head to do all the work yourself.

First, let's figure out where the VAZ 2114 phase sensor is located. It is located on the right side of the engine compartment, near the air filter. It is secured to the cylinder block body with one screw.

Replacement of the VAZ 2114 phase sensor is carried out in the following sequence:

- Open the hood and disconnect the power terminals from the fourteenth battery;

- Disconnect the wire block from the DF;

- Using a 10mm wrench, unscrew the screw fixing the sensor on the cylinder block;

- We remove the DF from the mounting socket.

After dismantling the old device, inspect it visually; perhaps the cause of its malfunction is metal dust magnetized on the DF body. If found, wipe the device with a cloth and reinstall it. If it does not come to life and the on-board computer continues to generate errors, the sensor needs to be replaced.

The new camshaft position sensor of the VAZ 2114 is installed in a similar way. As you can see, the work here only takes 10-15 minutes (replacing the VAZ 2115 phase sensor is carried out using the same method).

Important: when installing the DF into the mounting socket to seal the fixation, it is prohibited to use any sealing agents, since the device is located in an environment with a constantly changing temperature regime, in which the sealant will simply melt and bring you a bunch of additional troubles with the engine.

There are often cases when, even after installing a new DF, errors 0350 or 0343 continue to be displayed on the on-board computer of the fourteenth.

There are two possible scenarios for the development of events. You may have come across a faulty DF (even salespeople in auto stores say that if for 10 domestically produced phase sensors there are 5 workers, without manufacturing defects, this is already good).

Checking the functionality after replacement is carried out using a multimeter, as described in the previous section of the article. If the tester data corresponds to the indicators of a fully working sensor, then the problem is not with it. Errors 0350 and 0343, indicating a faulty DF, can also occur due to a timing belt that is stretched or has slipped by 1-2 teeth, or a loose crankshaft gear.

In this article we will tell you about the location of the camshaft sensor, list the main symptoms of its failure, and also tell you how you can check this part yourself and replace it.

This sensor is necessary so that the control unit can determine the position of the pistons and correctly adjust the ignition timing. The sensor has an electronic communication with the ECU. To determine where the camshaft sensor is located on a VAZ 2114, it is necessary to inspect the power unit in the area of the air filter.

Where is the camshaft sensor located on the VAZ 2114?

The part is installed on both 8 and 16 valve engines. The main difference is the number of timing shafts. The camshaft sensor on the VAZ 2114 is located at the top of the engine next to the air filter .

This location is due to the operating principle of the sensor. During operation of an internal combustion engine, the camshaft rotates constantly. The operating principle of the phase sensor is based on an electromagnetic field.

A specialized gear is installed on the camshaft. In one place it has two missing teeth.

At the moment the control point coincides with the place where the camshaft sensor is located on the VAZ 2114, the piston of the first cylinder is located at TDC or BDC. In this case, an electrical signal is sent to the electronic control unit. This is how the ECU controls the position of the pistons at a certain point in time.

Description of phase sensor 2114

The camshaft position sensor or phase sensor in a VAZ 2114 car is a device necessary to ensure normal operation of the car engine. The main function of the regulator is to determine the position of the camshaft at a certain point in time.

Working principle and functions

The operating principle of this element is similar to the operation of a Hall sensor. The device reads information from the motor shaft thanks to a special gear that lacks two teeth. They are installed in such a way that when it hits the regulator, the first piston is in any case at the top or bottom dead center.

The signal transmitted by the VAZ 2114 camshaft position sensor is transmitted to the control unit, which subsequently, analyzing the information received, monitors and changes the ignition angle, if necessary. It should be noted that the main task of the sensor is to constantly adjust the ignition angle during engine operation. Thanks to the use of these devices, domestic power units at one time became more efficient.

Location

To correctly check the signs of a malfunction of the camshaft position sensor on a VAZ 2114, you first need to find out where this regulator is located. So where is it located? In VAZ 2114 cars, as in most other cars, the device is located directly on the power unit, next to the air filter, in close proximity to the cylinder head.

Symptoms of malfunction

The vehicle owner can independently determine the failure of a part. Incorrect operation of the device leads to deterioration in engine power and the appearance of other symptoms such as:

- Difficulty starting the power unit, regardless of its heating temperature. When you try to start the engine, the time it takes for the flywheel to spin up with the starter increases.

- Incorrect engine operation at idle. Lack of stability, floating speed. Due to lack of information, the electronic control unit cannot select the correct ignition timing. Car owners note the lack of stability in the operation of the power unit.

- Deterioration in response to pressing the accelerator pedal. Reduced dynamic performance of the vehicle. The symptom is especially noticeable when changing gears; there is a failure.

- Spontaneous stopping of the power unit at idle speed.

- Gasoline consumption increases significantly. Incorrect operation of the gas distribution mechanism and the lack of information supplied to the control unit make it impossible to correctly select the air-fuel mixture.

If the above symptoms appear, you should check the performance of the DPRV and, if necessary, replace it. Particular attention should be paid to checking the electrical wiring.

In some cases, the reason for the lack of information transmitted to the control unit may be a broken wire or oxidation of the connectors.

How to check the phase sensor?

If the outer part of the DPRV does not have visible mechanical damage, it is necessary to remove it from the car and check it with a multimeter.

Diagnostic measures are performed in the following order:

- Dismantling the device. In order to remove the part, disconnect the electrical connector, unscrew the fastening nut and remove the part from the installation site. For dismantling, use a socket wrench or a 10mm socket.

- The tester is set to DC voltage measurement mode. To carry out measurements, select a range of up to 20 volts.

- Measure the voltage at the negative and positive contacts of the electrical connector. To do this, turn on the ignition. When checking, there should be voltage on the contacts.

- Connect the positive and negative contacts of the part to the on-board network. The voltage coming from the battery must be measured. The norm is considered to be 12-14 volts.

- The tester probes are connected to the positive and signal contacts. For convenience, you can use specialized clamps. After connecting the part, the voltage on the multimeter should be at least 90% of that coming from the battery.

- Bring a metal product to the working part of the device. When holding the metal plate, the reading on the tester display should drop to 0.4 V.

If during the diagnostics it was possible to determine that the part is working, then the electrical wiring should be checked for integrity. If necessary, clean oxidation from the contact pads of the connectors. If the indicators deviate during the measurement process, the product will need to be replaced with a new part.

Replacing the camshaft sensor on an 8 valve VAZ 2114

- Disconnect the negative terminal from the battery.

- Disconnect the electrical connector of the sensor.

- Unscrew the fastening element.

- Remove the product from its seat.

Installation of the new part is carried out in the reverse order. After installation, it is necessary to start the engine and check the operation of the phase sensor.

Many motorists have encountered the fact that the camshaft sensor, or in other words, the VAZ-2114 phase sensor, has failed. There can be many reasons for this phenomenon, but as a rule it is wear and tear. Not all car enthusiasts are able to diagnose this sensor, although there is nothing complicated or abstruse in the process itself.

Video review of the symptoms of a camshaft sensor failure on a VAZ-2114:

Operating principle of the sensor

General view of the camshaft sensor

The camshaft sensor or phase sensor is a part of the main power unit of the car, which is responsible for reading information about the location of the camshaft and is also involved in adjusting the ignition angle.

This meter is similar in principle to a Hall sensor .

Reading occurs using a special camshaft gear that has no teeth. The missing elements are located in such a way that when this gap hits the sensor, the first piston is at the dead center, at the top or bottom.

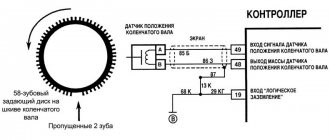

Phase sensor operation diagram

A signal is triggered and transmitted to the engine's electronic control unit when the sensor hits the missing teeth. In turn, depending on the received indicator, the ECU adjusts the ignition angle. Thanks to the installation of such a system, Samara-2 engines have become more efficient and popular.

Location of the sensor under the hood of the VAZ-2114

The camshaft sensor on the VAZ-2114 is located near the air filter, at a very close distance from the cylinder head. This meter location is almost always standard for other cars in the injection group.

Camshaft sensor location

The main reasons for sensor failure

Before proceeding directly to the diagnostic process, it is necessary to find out the causes of the malfunction of the VAZ-2114 phase sensor.

So, let's move directly to the most direct and indirect indicators:

Electrical circuit of the sensor

- Check Engine on the dashboard indicates that a malfunction has occurred. In this case, the engine starts without waiting for a response from the camshaft sensor, and the ignition system works based on the latest indicators.

- Increased consumption of the fuel mixture can also serve as an indirect indicator of a malfunction of the air flow control valve.

- The car begins to lose power and dynamics as a whole.

The combination of these reasons can serve as an indirect indicator of a malfunction of the camshaft sensor.

What is a phase sensor used for and how does it work?

The camshaft position sensor determines the operating cycles of the internal combustion engine. The camshaft cams drive the valves, and the DF determines which valve is open. This is an integrated control unit, that is, it includes a sensitive element and a signal conversion system. There is a Hall element there - data is taken based on changes in the magnetic field.

The converter has a bridge circuit, a converter block, and an output stage. The work is that the DF determines the intake and exhaust phases of the 1st cylinder.

For carburetor engines it is not needed because the spark is supplied at the moment of compression and at the end of the exhaust gases. DPKV is sufficient for this.

Roughly speaking, the VAZ 2114, 2115 phase sensor functions as a fuel injection system. If it breaks down, the work of sparking falls on the crankshaft position sensor. The designs that are used on 16-valve cars differ from eight-valve ones.

Now let's try to explain in simple words how the phased injection system works. It turns out something like this: the DF gives a signal to the electronic engine control system (ECM), and it, in turn, gives a command to inject fuel, while the intake valve begins to open, and after it has opened, air is sucked in and mixed with gasoline to form a mixture.

Checking the operation of the camshaft sensor

So, when all the questions have been considered, you can proceed directly to diagnostic operations.

The first method is manual diagnostics . How is it carried out? Let's consider this issue step by step:

- We dismantle the sensor.

- The first diagnosis is visual.

It is worth inspecting the condition of the case, the presence of damage and cracks. Sensor wire pinout

Multimeter to help

Now you need to check the contact group using a multimeter. First, we inspect the contacts for the presence of moisture, and then “ring” them. If the tester does not respond, then the sensor is faulty.

Diagnostics is carried out as follows: the “minus” probe of the tester is connected to the left contact on the sensor, and the “plus” to the central one. Next, we bring the metal plate to the sensor. A change in the voltage reading on the sensor will be immediately visible on the multimeter.

Checking the sensor using a multimeter

The second diagnostic method is to connect to the vehicle's electronic control unit. In it, when the Check Engine appears, error codes remain that indicate a malfunction. There are two errors associated with the phase sensor, namely:

- FAZ sensor error 0340 - shows that the ECU does not receive a signal from the camshaft sensor. You should check the breakage and condition (oxidation) of the contacts before damaging the sensor itself.

- Error 0343 - high signal level of the camshaft sensor.

Most often this is damage to the wiring from the ECU to the sensor, or breakage and oxidation of the terminals, or an unreliable connection. Working principle of the camshaft sensor

Oscilloscope

The third method of diagnostics is an oscilloscope. Using this device, you can almost immediately determine whether the camshaft sensor is faulty. But, unfortunately, not every car enthusiast has this device in his arsenal.

Checking with a computer or oscilloscope

What is Camshaft Position Sensor CMP

Mass air flow sensor signs and causes of malfunction

The camshaft controls the opening and closing of the intake and exhaust valves

The cylinder head of your car's engine contains 1 or 2 camshafts, which are equipped with lobes necessary to operate the intake and exhaust valves. The joint shaft is located in the cylinder block, which, receiving torque from the movement of the pistons in the block, transmits it using gears, a timing chain (or timing belt) to the camshaft.

Camshaft

To determine which engine cylinder is on stroke, your vehicle's computer monitors the rotation position of the camshaft relative to the crankshaft position using the camshaft sensor (CMS). The information received from the CMR sensor is necessary to adjust the synchronization of the spark supply to the combustion chamber and the operation of the fuel injectors. Thus, the camshaft sensor directly affects the fuel consumption of the car and the number of emissions in the exhaust.

The most common camshaft sensors are magnetic and Hall effect. Both types of sensors transmit a voltage signal to the electronic engine control unit or to the vehicle's on-board computer.

The magnetic image of the camshaft sensor produces its own alternating current (sine wave). Typically this sensor has two wires. A Hall effect sensor uses an external power switch to receive a digital signal and usually has three wires.

Camshaft position sensor

Depending on the make and type of your vehicle, your engine may have one or more camshaft sensors. There are also two types of CMP sensors that may be used in your vehicle.

Symptoms of a faulty camshaft sensor

The CMP sensor, like any other part in your vehicle, is subject to wear and tear and will eventually need to be replaced. This will happen in any case once its maximum service life has expired. This usually occurs due to wear on the internal wire wrap or associated component.

In this case, the engine may run rough and the symptoms will vary depending on the type of sensor wear. Thus, the connector in the sensor may wear out, the internal circuit of the sensor, or a related component may fail.

— On some vehicles, if the camshaft position sensor is faulty, the transmission may lock in one gear until you turn off the engine and start it again. This can be repeated with a certain cyclicity.

— If the camshaft sensor begins to work incorrectly while the car is moving, you may feel that the car is moving jerkily, losing speed.

- If the camshaft sensor fails, you may experience a noticeable loss of engine power. So, your car will not be able to accelerate over 60 km/h.

— The engine may stall intermittently due to a faulty CMR sensor

— If the sensor fails, you will notice poor engine performance: loss of dynamism, misfires when turning on the ignition, jolts during acceleration, popping noises in the exhaust system, etc.

— On some car models, if the camshaft sensor is faulty, the ignition spark may disappear entirely, which will ultimately lead to failure to start the engine.

Once your vehicle's computer detects a faulty camshaft position sensor, it will cause a Check Engine light to appear on your dashboard. After detecting poor operation of the CMR sensor, the computer will write the sensor error code into memory. In order to accurately determine the cause of the camshaft sensor malfunction, it is necessary to conduct computer diagnostics of the car by connecting special equipment to the diagnostic connector of the car. Then, using a special computer program, read the error code. Below we present you a table of diagnostic error codes that are associated with wear on the camshaft sensor.

conclusions

Checking the camshaft position sensor of the VAZ-2114 is quite easy and simple. Almost every motorist can cope with this task. But, it is still recommended to start diagnostic operations by connecting to the ECU and identifying error codes.

The VAZ 2114 car is equipped with a phase sensor. It is necessary to determine the position of the camshaft in relation to the parts of the crank mechanism. Symptoms of a malfunction of the phase sensor on a VAZ 2114 8 valves may differ individually for each case, and in this article we will consider all possible manifestations of this malfunction.

Signs of breakdown

There are several signs that indirectly indicate a breakdown of the phase sensor:

- Increased fuel consumption.

- Changing acceleration dynamics.

- Machine self-diagnosis problems.

- "CheckEngine" or errors 0343 and 0340.

The latter happens when the phase sensor on the VAZ 2114 dies completely.

The algorithm for detecting an internal error by the machine is as follows:

- The key is turned to the “Ignition” position.

- The starter turns on and the ECU sends an injection request to the sensor.

- If there is no response, the ECU switches the car to dual injection mode.

The car drives, but the injection is controlled only by data received from the DCPV. It is impossible to drive a car normally without a sensor, but do not rush to change it, you need to check it first.

If you notice one of the signs of this breakdown, you need to check the functionality of the device, this is done using a multimeter (universal automotive electrical tester). It is inexpensive and useful, often better to buy it.

On 8-valve VAZ 2114, a sensor model 21110-3706040 is installed; it can be checked independently without the need to contact specialists.

Verification algorithm:

- On the multimeter, we connect one probe to contact “E”, the second to “B”, on the first one you need to set the voltage to 13.5 V, and on the second 0.9 V. The multimeter should be in V1 mode.

- We close the circuit at the above contacts and bring a metal object to the end of the mechanism (the easiest way is a screwdriver). If the device is working normally, then contact “B” will show a voltage drop to 0.4 V at the moment the screwdriver appears and an immediate return to 0.9 when the metal object is removed. If the readings are different, then the sensor is to blame for the problem and needs to be replaced.

Signs of a faulty phase sensor on a VAZ 2114

Checking the phase sensor of a VAZ 2114 with an 8-valve engine is possible using a multimeter. Signs of a malfunction may vary from person to person. Most often, failure of the DPRV is manifested by the following symptoms:

- Difficulty starting the engine, regardless of its temperature. This is due to the formation of an incorrect composition of the air-fuel mixture.

- Incorrect operation of the power unit at idle. Car owners note the lack of stability in the operation of the power unit at idle. This symptom is explained by the fact that the electronic control unit, due to the lack of data from the DPRV, cannot correctly select the ignition timing.

- Slow response to pressing the accelerator pedal. Reduced dynamic performance of the vehicle. The symptoms are due to the fact that the electronic control unit has selected the wrong air-fuel mixture. The symptom is especially noticeable when shifting to a higher gear.

- Fuel consumption increases significantly. Incorrect operation of the gas distribution mechanism and the lack of information supplied to the control unit make it impossible to correctly select the air-fuel mixture. Supplying a large amount of gasoline leads to excessive consumption.

- Spontaneous stopping of the power unit at idle speed. This is especially common when the engine is not warmed up. This indicates that the ECU has selected the air-fuel mixture too lean.

- There is a dip when you press the gas pedal sharply. The ignition timing is incorrectly adjusted.

The vehicle owner can independently determine the failure of the DPRV based on the above signs. If symptoms appear, replace the part with a known working part. In some cases, it may be necessary to additionally check the functionality of the wiring.

Features of checking and replacing the VAZ 2114 phase sensor

The VAZ 2114 camshaft sensor is one of the most important measuring instruments of the fourteenth, which, through a pulse signal, transmits information about the current engine operating cycle to the car’s brains. Based on the information received, the electronics adjusts the timing of supply and ignition of the fuel mixture in the engine cylinders.

A normally functioning DF is the key to the correct functioning of the engine, which achieves the optimal ratio of the amount of fuel consumed and the operating power of the power unit.

From this article you will learn the main causes of DF malfunction and how the failure of the device affects the operation of the car. The technology for replacing the DF on the VAZ 2114 will also be examined in detail.

Features of the VAZ 2114 phase sensor

REASONS AND SIGNS OF MALFUNCTION

You can determine that the phase sensor on a VAZ 2114 has failed by the following malfunctions in the vehicle:

- Gasoline consumption has increased significantly;

- The acceleration dynamics of the fourteenth have worsened, and dips are observed in the engine’s idle speed;

- The engine idles;

- Errors No. 0343 and 0340 are displayed on the on-board computer screen, which indicate that the DF is faulty and the ECU is operating in emergency mode.

The reason why the phase sensor failed can be determined only after dismantling and visual inspection of the device, in some cases - after diagnosing it. As a rule, the main causes of DF failure are as follows:

- A short circuit has occurred on the internal DF circuit;

- Mechanical damage to the device mounting ears, due to which the housing has shifted in the mounting socket;

- The toothed disk on the pulse signal converter has broken;

- The DF was damaged due to the increased temperature of the engine.

PHASE sensor

If the device breaks down, the ECU starts working exclusively on the readings of the crankshaft sensor. In this mode of operation, it is impossible to carry out phased fuel injection, as a result of which the brains of the fourteenth switch the engine to twin injection, which results in excessive consumption of gasoline and deterioration in acceleration dynamics.

Repairing the device in most cases is not advisable, since a DF that has once failed is unlikely to work normally in the future.

Fortunately, the cost of DF is low - the price of a new device is 400-600 rubles, depending on the manufacturer (prices are also relevant for sensors on the VAZ 2115).

CHECKING PERFORMANCE

If typical signs of DF failure occur, or if errors 0343 or 0340 are displayed on the on-board computer of the fourteenth, it is necessary to check the functionality of the DF. This is done using a conventional multimeter.

Fourteeners with 16 and 8 valve engines have different DFs, so the specifics of checking them will be slightly different.

How to check the camshaft sensor VAZ 2114 8v:

- On the first probe of the tester we set the voltage to 13.5 Volts and connect it to contact “E” on the DF, on the second probe, which must be connected to contact “B” - 0.9 V;

- Having closed the contacts, we bring a metal screwdriver to the end of the sensor. If the DF is working properly, you will see on the tester screen that the voltage of contact “B” has dropped to 0.4 Volts. If this does not happen, the DF is broken;

How to check the camshaft sensor VAZ 2114 16v:

- We set the following voltage on the multimeter: contact “E” – 13.5 Volts, “B” – 0.4 Volts;

- We close the contacts and insert a screwdriver into the hole on the phase sensor. If the device is working properly, the voltage at pin “B” will increase to 0.9 Volts.

A multimeter is a standard device for checking the performance of any sensor

WE REPLACE THE PHASE SENSOR

Having determined that the DF is faulty, you can begin to replace it. The process is easy enough that you will only need a ratchet wrench with a 10 mm head to do all the work yourself.

First, let's figure out where the VAZ 2114 phase sensor is located. It is located on the right side of the engine compartment, near the air filter. It is secured to the cylinder block body with one screw.

Replacement of the VAZ 2114 phase sensor is carried out in the following sequence:

- Open the hood and disconnect the power terminals from the fourteenth battery;

- Disconnect the wire block from the DF;

- Using a 10mm wrench, unscrew the screw fixing the sensor on the cylinder block;

- We remove the DF from the mounting socket.

After dismantling the old device, inspect it visually; perhaps the cause of its malfunction is metal dust magnetized on the DF body. If found, wipe the device with a cloth and reinstall it. If it does not come to life and the on-board computer continues to generate errors, the sensor needs to be replaced.

The new camshaft position sensor of the VAZ 2114 is installed in a similar way. As you can see, the work here only takes 10-15 minutes (replacing the VAZ 2115 phase sensor is carried out using the same method).

Important: when installing the DF into the mounting socket to seal the fixation, it is prohibited to use any sealing agents, since the device is located in an environment with a constantly changing temperature regime, in which the sealant will simply melt and bring you a bunch of additional troubles with the engine.

There are often cases when, even after installing a new DF, errors 0350 or 0343 continue to be displayed on the on-board computer of the fourteenth.

There are two possible scenarios for the development of events. You may have come across a faulty DF (even salespeople in auto stores say that if for 10 domestically produced phase sensors there are 5 workers, without manufacturing defects, this is already good).

Checking the functionality after replacement is carried out using a multimeter, as described in the previous section of the article. If the tester data corresponds to the indicators of a fully working sensor, then the problem is not with it. Errors 0350 and 0343, indicating a faulty DF, can also occur due to a timing belt that is stretched or has slipped by 1-2 teeth, or a loose crankshaft gear.

How to check the phase sensor on a VAZ 2114?

Before checking the VAZ 2114 phase sensor with a multimeter, you must first inspect the part for damage. If there is visible mechanical damage to the product body, it must be replaced with a known working one. If there are no cracks or chips, diagnostics are carried out in the following order:

- Remove the phase sensor from the car. To do this, disconnect the electrical connector and unscrew the fasteners securing the products in the seat. To speed up the process, you can use a ratchet head.

- The multimeter switch is set to DC voltage measurement mode. For testing, select a range of up to 20 volts.

- Measure the voltage at the positive and negative contact pads of the electrical connector. With the ignition on, the multimeter should show the presence of constant voltage.

- Connect the positive and negative contacts to the battery. At the same time, the voltage applied to the part is measured. It should be between 12-14 volts.

- The multimeter is connected to the positive and signal pads, and readings are taken. The voltage between the positive signal contact must be at least 90% of the supply voltage.

- Bring a metal plate to the working surface of the part. As the plate approaches, the voltage should drop to 0.4 volts.

If during diagnostics it turns out that the DPRV has failed, it must be replaced with a new sensor. Otherwise, you should pay attention to the integrity of the electrical wiring. If necessary, clean the connector pads from oxidation.

Product replacement

- Disconnect the on-board power supply by removing the negative terminal from the battery.

- Disconnect the electrical wiring plug.

- Unscrew the fastening element.

- Remove the sensor from its seat.

- Install the new product in reverse order.

So, in this article we have listed the main symptoms of a faulty phase sensor on a VAZ 2114, talked about how you can check this sensor, and also described the process of replacing it. If you have any questions, be sure to ask them in the comments. We will try to help you help!

Sources used:

- https://autovaz-2114.ru/electrical-equipment-in-the-car/osobennosti-proverki-i-zameny-datchika-faz-vaz-2114-poshagovye-instrukcii/

- https://vaz-2114.info/gde-nahoditsya-datchik-raspredvala-na-vaz-2114/

- https://carfrance.ru/kak-proverit-datchik-raspredelitelnogo-vala-vaz-2114/

- https://vaz-2114.info/priznaki-neispravnosti-datchik-faz-na-vaz-2114-8-klapanov/