How does the throttle position sensor work?

When the engine is idling, the valve is closed, air enters the power unit through a separate channel, and for proper idling, a signal is sent to indicate the supply of gasoline.

- If you measure the voltage at the output, the value will be no more than 0.5 volts.

- By pressing the gas pedal, which is connected directly to the controller, the resistance in the electrical circuit changes and the damper opens slightly.

- The voltage in the electrical circuit increases, is recorded by the microprocessor and information about the state and position of the bypass valve is sent to the engine control unit.

- Its function is to dose the incoming air into the internal combustion engine and control the proportions of air and fuel.

- When checking the output voltage when the damper is open, the voltmeter shows about 5 volts, this is the maximum value.

MUST WATCH VIDEO:

If the driver is attentive to the behavior of his car and constantly monitors the performance of the car’s electronics and engine, then he can be confident that no surprises await him on the road. You must constantly remember that your car will serve you for a long time and faithfully only if you take care of it and its insides. Any car loves care, even after leaving the car wash you can feel how softly the engine starts running and how smoother the car drives on the road.

If you find an error, please select a piece of text and press Ctrl+Enter.

What types of throttle position sensor are there?

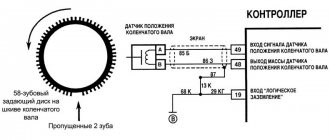

This sensor comes in two types: film-resistor and non-contact, working on the magnetic resistor effect. Film-resistor ones are installed by the VAZ manufacturer and, as a rule, their service life is short (50 thousand km). The cause is mainly damage to the resistive field that the slider comes into contact with when the shutter position changes. The contact is broken, the signal does not go to the controller, thereby causing unstable operation of the automation.

Non-contact throttle sensors

Non-contact units are an order of magnitude more expensive than the previous version, but are highly efficient in operation and complex in design. The electronic version does not have a gas pedal cable. The role of the cable is played by a special block that transmits a signal through a sensor system. The device operates on the magnetoresistive principle. It includes a rotor and a stator. At the base of the rotor is a magnet. The stator is necessary to capture the electromagnetic field. A device of this category is intended for installation in electrical control units. There is an opinion that the absence of such an important component as a cable reduces the response of the gas pedal, but the reliability is undeniable. Cars with an electronic unit must have an on-board computer, which contains all the information about the engine tasks being performed. It is difficult to determine any breakdowns of this mechanism without special equipment.

Film resistor throttle sensors

Film-resistor components installed on the VAZ 2114, as well as on other VAZ representatives, especially during long-term use, can cause unstable idling, and when changing gears, the engine stops. When the first signs of malfunctions appear, diagnostics will rule out, as an option, a breakdown of the XX sensor, air flow sensor, or detonation, since in this case the symptoms are similar. When the XX regulator is not working, for example, the damper also opens significantly. The entry of a large amount of air into the chamber leads to rapid combustion of the fuel-air mixture. The revolutions increase and the engine power decreases.

The cause of failure of the 2114 throttle sensor itself may be oxidation of the contacts and, as a result, burnt contacts. In the first case, they can be restored by applying an anti-corrosion lubricant, but in the latter, only radical actions are required.

Throttle sensor diagnostics

You can perform diagnostics yourself without calling technical assistance for help. Testing the effectiveness of the 2114 throttle sensor requires a voltmeter and two insulated wires. Next, the block with wires from the TPS is released, the “plus” on the voltmeter is connected with a wire marked “A” on the block. “Minus” – with a car body.

Turn the key to “ignition” and look at the voltmeter reading:

- a value close to zero or “zero” means that the TPS is in good condition and you need to look for the cause in the electrical circuit or in the electronic engine control unit.

- The voltage reading is close to 5V – the sensor is faulty.

The cause of a part malfunction may be corrosion or incomplete closure of the damper. Before changing the TPS on a VAZ 2114, there is an option to check the mobility of the damper (it is possible that due to microcracks, the dynamics at the tip disappear).

Throttle Position Sensor Repair

You have decided to repair this sensor, for example, to fill a microcrack in one of the contacts with conductive glue. Theoretically, this is doable, but if the problem is in the resistive layer, then it is impossible to restore it.

One of the options for extending the life of the unit is cleaning and flushing. Gasoline, WD40, and carburetor cleaning fluid are used for operation. Cleaning dirt from the outside is not difficult. But the assembly itself, its internal part, with its contaminated channels remains untouched. Therefore, it is necessary to completely disassemble and wash the part.

It is recommended to carry out this procedure periodically. Using cleaning sprays, a Phillips screwdriver, a throttle gasket (for a 1.5-liter engine), O-rings for the receiver (for a 1.6-liter engine), and keys, perform the following steps:

- We completely dismantle the module - remove the corrugation and the pipe channel from the filter. It is recommended to drain the antifreeze

- pull out the adsorber with the pipe (remove the fasteners of the unit, disconnect the cable from the accelerator, thereby removing the throttle valve)

- Having removed the unit, we disassemble it into components, first the meters - TPS and IAC. We clean it using WD40 or its equivalent, wash the damper on all sides, blow out the holes so that no moisture remains, and assemble the assembly in the sequence, but in reverse.

This is not at all difficult to do if there are no problems with disassembly. Gaskets and rings are replaced with “new” ones.

Setting the throttle position sensor

Now it's time to configure the sensor. With the throttle open, we try to turn the device drive or pull the accelerator cable. If it doesn’t work, it means the sensor was installed incorrectly. We remove it again and mount it at a right angle to the damper axis. It is adjusted manually. Often the controller's memory retains the same data that does not allow the valve to open completely. Then you need to disconnect the battery terminals for a while or reset the settings on the on-board computer.

After the above actions, if the valve is open by at least one degree, then the TPS must be replaced. This will be the best decision.

Replacement is performed with the engine turned off. It is necessary to disconnect the negative terminal from the battery and the sensor clamp. Using a screwdriver, unscrew the two screws that secure the sensor to the throttle. The sensor has been removed.

Make sure that the throttle valve is closed. Don’t forget about the O-ring; as a rule, the “new” spare part comes with it. We put the ring on the throttle pipe, do not forget to remove the old one, tighten it with screws until it seals. All that remains is to connect the connector and secure it with a latch. To reset the old sensor parameters to the ECU, disconnect the battery terminals.

Replacing TPS

You can replace a non-working TPS quickly and without much effort. To do this, you only need one Phillips screwdriver. The replacement process occurs in the following order:

- The terminals are removed from the battery.

- The TPS connector is disconnected. To do this, you need to pull the connector lock and pull it towards you.

- The sensor is removed. To remove it, you need to unscrew two screws from the pipe.

- There is always a foam rubber gasket between the pipe and the TPS, which acts as a seal. The same one should be included with the new TPS, so when replacing the sensor we also change the gasket. Tighten the sensor mounting screws until they stop until the gasket is completely compressed.

- We connect the connector with the wiring to the damper position sensor.

- We return the battery terminals to their original location.

KEY-DOP

After replacing the sensor, it must be checked and adjusted if necessary. To check the correctness of the replacement, you need to press the gas pedal, and if this is not possible, you should remove the sensor and turn it 90 degrees relative to the damper.

There is a special offer on our website. You can get a free consultation with our corporate lawyer by simply submitting your question in the form below.

Tuning the VAZ throttle position sensor on the VAZ 2114

As an alternative to replacing the sensor, in some cases tuning can be carried out. What is the tuning of the VAZ throttle position sensor on the VAZ 2114?

When installing a throttle position sensor on a car 2114, design flaws were made. If desired, they can be corrected and the throttle can be modified. Modernizing the throttle valve consists of grinding a groove in the rear wall of the valve with an ordinary file. A recess 3 mm wide is made. This recess creates a powerful vortex air flow, thereby forming a high-quality, homogeneous combustible mixture in the intake manifold, which burns in the engine chambers and not in the catalyst. This allows you to reduce fuel consumption and improve the dynamic performance of the car.

Correction of a factory miscalculation

Operating principle of the throttle position sensor

It is quite common for a throttle assembly to come out of the factory with something that cannot even be called a defect, but can still be attributed to design errors. In theory, air should flow into the space behind the throttle, for which a channel of approximately 2.5 mm is specially made.

But the whole problem is that this channel was pressed against the wall of the receiver, thus blocking the possibility of air flow. A slight modification of the throttle assembly can help in this case.

Bored channel for air flow in the throttle

To do this, just take a file and use it to make a small groove in the indicated place. 2 - 3 mm will be enough. But before doing this, it is necessary to remove the throttle.

On a VAZ 2110, the throttle assembly is removed in the following sequence:

- Disconnect the connectors of the sensor that regulates the position of the throttle valve, its drive cable and the XX regulator;

- We partially drain the coolant;

- Next is the removal of the air hose located on the body of the mass air flow sensor. Why do you just need to loosen the clamp;

- We also loosen the clamps: where the throttle pipe is attached to the air hose; where the hose of the 2nd crankcase exhaust circuit is attached to the cylinder head cover pipe. We remove the connected hoses - the air and 2nd crankcase ventilation circuits;

- Having loosened the clamp, remove the hose of the 1st crankcase gas exhaust circuit from the throttle assembly fitting;

- Having loosened the clamps, we remove the hoses supplying and discharging coolant;

- You will need a wrench with a 13mm head, with which you need to unscrew the nuts securing the throttle assembly to the receiver on a VAZ 2110;

- It is now possible to remove the throttle assembly from the studs;

- It remains to remove the sealing gasket and, if your VAZ 2110 has a system that traps gasoline vapors, disconnect the hose for purging the adsorber.

Even if the purpose of removing the throttle was to modify it, still do not forget that for stable operation it also needs periodic cleaning

There is, frankly, nothing complicated in this procedure, but it will help the engine perform better, which is quite important

For cleaning you will need:

- short and long screwdrivers;

- toothbrush (soft, or just old);

- cotton buds;

- cleaning agent;

- rubber or cotton gloves.

For cleaning to give the desired result, it must be carried out very carefully. First, you can go through all the cavities with a toothbrush, at the same time cleaning the idle speed control (it must also be removed). Further, more delicate, cleaning is done with cotton swabs

Pay special attention to the area where the throttle valve is located and the place where the XX regulator fits.

Please note that cleaning the crankcase ventilation duct with conventional means is not possible, but it can be easily done using the foot pump available in each trunk. The diameter of the fitting is similar to the wheel one, you just need to add cleaning agent and pump your foot several times.

If you have problems mentioned at the beginning that started recently, cleaning should fix them. If there were problems from the beginning, do not forget about improvements. Sometimes only replacing the throttle assembly helps.