Calm, just calm, as the Great Lord of the impeller said) Actually, everything is fine with me. Now. I am writing this post so that people whose working fuel pump suddenly stops working can find it in a search. I had this problem for a long time, and I suffered for a very long time, and did not know how to eliminate the consequences of this unknown crap, while flipping through a lot of information. And so, this morning, when at minus 35 the car did not start, and I stupidly forgot about this trick, and having drained the battery I almost went to work on a minibus, I again remembered what needed to be done. I'll tell you what the point is. The fuel pump just refuses to turn on. The brain should supply a minus voltage to the fuel pump turn-on relay, but for some reason it does not supply it periodically. Either a glitch in the brain, or a bug in the signaling. But I’m not the only one, and the problem, as it turns out, visits many.

What should we do if the fuel pump does not work when we turn on the ignition?

On the front passenger side we open the side of the torpedo, it is indicated under the number 3

Having opened the hatch, we see 3 pres and 3 relays. Mine is approximately as shown in the photo below. What should I do to make the car move? There are 2 options here:

1. The photo shows the negative contact. You need to pull out the relay a little, attach a wire to the relay contact, and throw it onto the body ground. After that, put the relay in place. What does it give? The fuel pump will start working when the ignition is turned on. I should immediately note that the fuel pump will work constantly. I just don’t recommend leaving the ignition on with this modification, because... You could burn out the fuel pump.

Option 2. Using the same principle, you need to close the positive contacts, they are shown in the photo. This procedure will allow you to start the fuel pump even with the ignition off, and you will be able to get to the service center, or wherever you planned to go.

Do not forget, after you have reached the place, to delete the modification data, because... I recommend using them only in emergency cases. Using it “on a regular basis” may not be safe and may lead to unpleasant consequences.

Gasoline (diesel) by itself cannot get from the car tank to the engine; for this you need a pumping mechanism - a fuel pump. And if it fails, the consequences are easy to predict - the machine will stop. There can be many possible reasons for this, and since they are typical for almost any brand of car, it is better to talk about them using a specific example. Let's say that the VAZ-2110 fuel pump does not work.

Reasons why the fuel pump does not pump gasoline when the ignition is turned on

The gasoline pump serves to supply fuel from the tank and maintain the pressure in the line necessary for the operation of the injectors. Interruptions in the supply of gasoline lead to a disruption in the composition of the air-fuel mixture, which leads to poor-quality combustion and misfires, the engine begins to stall, respond sluggishly to the gas pedal or stall. If the fuel pump (FP) does not pump, the engine will not start at all.

Symptoms of a fuel pump malfunction and methods for diagnosing them on an injection engine

The power systems of modern fuel-injected internal combustion engines use an electric fuel pump. Depending on the installation location, there are submersible (installed in the tank) and flow-through fuel pumps (cut into the fuel supply line).

Main components of an electric fuel pump:

- two-piece body;

- DC motor;

- pumping section.

According to its design, the section can be rotary, blade, gear or turbine type. The latter option, due to its simplicity of design, has earned the greatest popularity. The rotation of the impeller attached to the electric motor shaft creates zones of high and low pressure, due to which fuel is taken and pumped from the tank into the pipelines.

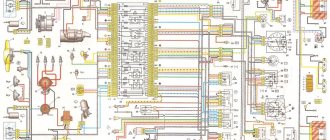

Motor power circuit

In addition to the submersible fuel pump, the fuel module located in the tank includes:

- float type fuel level indicator sensor;

- critical gasoline level sensor;

- coarse filter;

- built-in fuel pressure regulator (RDT). This type of RTD is found on returnless power systems. Another type of design involves the presence of a fuel return line and a regulator mounted in the fuel rail;

- inlet and outlet fuel lines;

- electrical connectors.

Symptoms of a worn fuel pump motor:

- uncertain engine start;

- failures when sharply pressing the accelerator pedal;

- insufficient power at high speeds;

- The engine periodically stalls and refuses to start for some time. Often in such cases, several blows to the tank help bring the fuel pump back to life.

The cause of the described symptoms is worn brushes and the electric motor commutator. When the brushes are worn out, they do not press well against the lamellas of the commutator, which is why the current in the circuit drops, which leads to a decrease in the performance of the fuel pump.

Wear of electric motor components is the most common reason why the fuel pump does not pump gasoline well.

If power comes to the connector, but fuel does not flow from the pump, the reason may be melting of the plastic housing due to overheating or critical wear of the brushes/commutator. In this case, when you turn on the ignition, you will not hear a characteristic buzzing sound from the fuel module. Sometimes a situation in which the fuel pump pumps, but no gasoline comes out, occurs due to poor fixation of the corrugation going from the pump to the outlet fittings of the fuel section. Due to the pressure created by the pump, the corrugation jumps off the fitting.

If the gas pump works but does not pump enough gasoline, first of all pay attention to the coarse and fine filters. Clogged filters can be identified by the fact that the fuel pump hums louder than usual. Please note that operation under load reduces the service life of the transformer. The cause of insufficient pressure may also be a faulty fuel pressure regulator, which discharges too much fuel into the return line.

Failure of the fuel pump due to wear of the elements of the pump section occurs only in the case of low-quality components. You are more likely to replace the fuel pump due to worn brushes than to face mechanical wear on the pump section components.

How to check the fuel pump?

The most reliable diagnostic method is to check the gasoline pressure in the fuel line.

On sale you will find ready-made kits with adapters for connecting to the most common power systems. You can build the device with your own hands from a pressure gauge with a scale of up to 6 kg/cm2, a hose, adapters and fittings. To check the pump you need:

- Relieve the residual gasoline pressure in the line.

- Connect the pressure gauge across the engine power supply system. Some cars have a standard fitting to check the performance of the pump.

- Turn on the ignition. A value of 3-4 kg/cm² is considered normal. The exact parameters for a specific engine are in the repair and operation manual.

- Start the engine. A working fuel pump creates excess pressure (about 7 kg/cm²), which is released into the tank by the regulator. Therefore, in all engine operating modes, the pressure in the ramp should not deviate significantly from the standard values. When diagnosing, try to simulate the conditions under which the symptoms of a faulty fuel pump manifest themselves most often (engine temperature, load, etc.)

How to check the functionality of the pump?

If the engine is absolutely “dead”, follow this algorithm:

- Turn on the ignition without turning the starter. A working electric fuel pump should respond with a quiet but distinct buzzing sound coming from the rear row of seats. If there is no sound, go to the next step.

- Using the car's operating instructions, find the number of the fuse that protects the pump's power circuit. Try replacing it; if unsuccessful, check the wiring and clean the contacts from oxides.

- If previous manipulations did not produce results, you need to measure the fuel pressure in the fuel rail.

Pressure measurement is also practiced when identifying symptoms of insufficient fuel supplied to the cylinders of the power unit.

To take measurements and compare signs of a breakdown with a fuel pump or other element, you need to reset the initial fuel pressure in the system, no matter how low it turns out to be.

If the pressure is below normal, proceed to find out the reasons according to the recommendations:

- There are pressure surges in the range of 0.2...0.3 Bar at idle - look for a problem in the filters. Surely the coarse mesh or secondary element is clogged.

- Use pliers to pinch the return line hose coming out of the RTD. The gasoline pressure should increase to 5 Bar, with the new pump - to 6 Bar. If the readings are 4 Bar or lower, the cause should be sought in the regulator or the pumping unit itself.

- The best way to identify a fuel pump malfunction is to exclude other parts of the system and take a measurement directly at the outlet fitting. If the pressure gauge shows 5 Bar, the unit is working properly and you need to change the RTD, which dumps half of the fuel into the tank.

To measure the pressure at the outlet of the electric fuel pump, you will need to remove the rear seat, dismantle the service hatch and connect a pressure gauge to the supply fitting of the unit.

Here you may need adapters in the form of plastic clamps or threaded tubes. Before changing the pressure regulator, make sure that the gas lines and filters are of normal capacity. Due to refueling with low-quality fuel, even the flow area of 8–10 mm tubes can become clogged. Then the pressure gauge on the ramp and pump will show different values, and the RTD will regularly drain excess fuel into the tank.

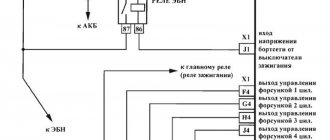

Connection diagram

Above is a standard connection diagram for a fuel injection pump. The ECM (controller), after successfully polling the immobilizer, energizes the coil winding of the fuel pump relay (pins 85, 86). Under the influence of electromagnetic induction, power contact 30 (constant “+” from the battery, protected by fuse X) and contact 87 close, which leads to the inclusion of the fuel pump. Main faults:

- fuse blown; Attention! Replace the burnt-out fuse-link with a fuse of standard rating. Installing an insert designed for high current may result in a vehicle fire.

- formation of oxides inside the connectors, burning of the power contacts of the fuel pump relay. Parasitic resistance leads to a drop in current in the circuit and a decrease in the performance of the nose;

- chafing, breaking wires;

- breaking off the latch of the power connector going to the fuel module. Often in this case, contact is broken when driving over uneven surfaces.

Video: Fuel pump does not work. How to find and eliminate the cause.

Power check

You can establish the presence of voltage at the TN connector using a simple test to check electrical circuits. To check the fuel pump, in the electrical diagrams for your car model, find the pinout of the electrical connector of the fuel module. For the pump motor to operate, “–” and “+” are required. If, after turning on the ignition and connecting the control contacts to the corresponding pins of the block, the light comes on, then everything is in order with the supply voltage. Using this method, you can check for the presence of +12V and ground in the fuel pump relay connector, and establish the presence of supply voltage from the ECM to the relay. If the fuel pump does not turn on, but there are no problems with the components of the electrical circuit, the reason is in the fuel pump itself.

The most convenient way to determine why there is no power to the fuel pump is to use a multimeter. Let's say that + 12V to the pump comes from the relay, but does not reach the fuel module connector. In this case, it is necessary to ring the wires from the relay to the fuel section. In ohmmeter mode, you will not only find an open, but you will also be able to see the parasitic resistance in the circuit. When considering possible reasons why the fuel pump does not pump, do not forget about the immobilizer failure. Often in such cases the engine starts, but stalls after a few seconds.

Carburetor power system

Possible reasons why gasoline does not flow into the carburetor:

- clogging of the fuel line from the tank to the mechanical fuel pump;

- diaphragm breakthrough;

- clogging of the filter element;

- wear of the eccentric, pusher and/or balancer;

- production of valves and their seats;

- Broken spring diaphragm.

Source

What to do if the fuel pump does not work?

I think for those who do not understand at all what and how it works in a car. You should read one of the articles on the topic “car fuel system”. So at least you will have an idea of what will be discussed next. And for those who have an idea of what a fuel system is, let’s move on.

Diagnostics

In order to understand what is wrong with the system. It is necessary to carry out diagnostics. You can create a checklist of possible faults for yourself:

- relay

- circuit breakers

- ECU

- fuel pump (wiring, motor)

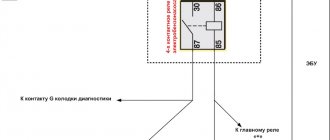

CHECKING THE ECU, RELAYS AND FUSES KALINA

First, let's check the fuel pump relay. Its location is under the passenger's feet on the left. Where is the air duct located?

Unscrew the screw and tighten the panel. Next we will see the relay block. Unscrew the nut with a 10mm wrench or a socket. We take out the block with the relays and find what we need. Look at the photo below:

Relay 30A, 12V. In order to check for functionality. You can remove exactly the same relay, with the same parameters, and install it in place of the previous one. If the engine does not start, then the problem is not with the relay. It's working for us. So we are looking for the problem further.

You can also check the ECU there. The fact is that on the Lada Kalina the ECU unit is located under the heater radiator. And it often happens that antifreeze gets on the block. As a result, the ECU floods. Which, in turn, stops working correctly. And one of the reasons may be a refusal to start the car engine.

To check the ECU simply, look for the possibility of a leak in the heater radiator. When will you diagnose the fuel pump relay?

CHECKING FUSES

To check the integrity of the fuses. It is necessary to open the panel near the gear shift knob. Where is the diagnostic connector located? And there find fuse 3 (count from the driver). We take it out and see if it is intact. If it’s intact, then we look for the reason further.

Preventing fuel pump breakdowns

To extend the life of the fuel pump, you need to:

- Monitor the quality of fuel filled into the car.

- Completely eliminate even the possibility of water getting into the tank.

- During scheduled maintenance, be sure to change the fuel filters.

- In case of mechanical damage to the fuel tank, it is necessary to dismantle the fuel pump and check its condition.

- Periodically clean the fuel tank from possible accumulation of sediment, consisting of tiny solid particles found in gasoline.

Following these simple rules will have a beneficial effect not only on the fuel system, but also on the engine itself.

Fuel block diagnostics

If all of the above did not give positive results. The engine still doesn't catch on. Then it's time to move on to diagnosing the fuel unit.

Now we need to disassemble the fuel block and check the pump itself. As well as a fuel level sensor with wiring.

Checking the fuel pump

There are several ways to check the fuel pump for functionality. But since we already took out the fuel block. Then I will tell you only about one thing.

And so, we take out the fuel pump and connect it to the battery for a few seconds. That is, we apply 12V voltage for a few seconds. 1-2 seconds is enough to check. During this time, you will have time to hear the hum of the motor. If there is no buzzing, then we replace the pump.

In my case, the motor was fine. But the fuel pump still didn't work. All that remained was to check the fuel level sensor and the wiring from it. Which is what I did next.

Checking the fuel level sensor

We remove the fuel level sensor and check the wiring.

Now we see that one contact has burned out and the power has disappeared. it is necessary to replace the sensor along with the wiring. And the fuel pump will work as before.

Diagnostics

The very first thing when diagnosing, as noted above, listen when you turn on the ignition to see if there is any noise from the fuel pump. The absence of a characteristic buzzing may indicate that:

- VAZ 2107 fuel pump fuse is faulty;

- relay malfunction;

- open circuit of the fuel pump;

- motor malfunction;

- ECU malfunction.

Below is a simplified connection diagram for a VAZ 2107 injector fuel pump:

You can check the fuel pump on a VAZ 2107 injector simply by checking the voltage at its connection block with a tester. The presence of voltage will indicate a malfunction of the electric motor. Instead of a tester (multimeter), you can use a test lamp to diagnose a malfunction.

In the absence of one, this can be done by disconnecting the connection block for the fuel pump and fuel level control and applying voltage with wires from the battery to the place where the gray wire is connected +12 and to the place where the black wire is connected - minus. A humming pump will indicate a faulty fuse, power circuit or ECU.

Why doesn't the fuel pump deliver gasoline?

One of the most important elements of the fuel injection system of a gasoline engine is the electric fuel pump, which is located in the fuel tank of the car. The fuel pump pumps fuel into the system from the gas tank, creating a certain pressure.

Auto repair experts identify the following common fuel system problems that are related to the fuel pump:

- The fuel pump pumps poorly and does not create the required pressure;

- the fuel pump does not pump when the ignition is turned on;

Considering that the fuel pump is an electromechanical device, the most common fuel pump malfunctions are related to both the mechanical and electrical parts. Next, we will look at what signs indicate a breakdown of the fuel pump and why the fuel pump stops pumping partially or completely.

The electric fuel pump does not work, possible causes of failure

In an injection engine, the fuel pump operates from the vehicle’s on-board electrical network, so its failure is not always associated with a breakdown of the pumping mechanism itself. The cause of the malfunction may also be: a failed fuse, relay or oxidation, burnt contacts on the wires powering the electric motor.

Another common reason why the VAZ injector fuel pump does not work may be the strainer installed at its inlet. Despite the fact that it is intended for initial, rough cleaning of fuel, its mesh has a rather dense structure. And since the pump is located in the tank, it practically touches its bottom and the sediment that accumulates there, which pollutes it.

Well, the worst thing is a breakdown of the motor responsible for the circulation of gasoline inside the pump or failure of its structural elements.

Signs of fuel pump malfunctions

The main symptoms of fuel pump failure, as well as malfunctions in its operation, are:

- the car starts with difficulty, the engine runs unstable, there are dips, jerking when pressing the gas pedal, etc.;

- the pump does not pump after turning on the ignition, does not turn the starter and does not pump the fuel pump, the engine does not start;

There have also been cases when the fuel pump stops pumping while driving. In such a situation, the engine begins to malfunction and stalls immediately after the remaining gasoline in the fuel line is used up. The problem can occur either regularly or periodically.

Other causes of fuel pump malfunctions

Quite often, unprofessional installation of additional electrical equipment or security anti-theft systems leads to the fact that the power to the fuel pump is lost due to mixed up contacts or other connection errors.

Also, one should not exclude the possibility that a malfunction occurred in the car alarm or security system, after which the power supply to the fuel pump is blocked. In other words, the alarm blocks the engine from starting.

Finally, let’s add that the gas pump in the gas tank is immersed in gasoline, in which it is actively cooled. The habit of driving with an empty tank can quickly damage the electric motor of the fuel pump, as it burns out.

The fuel pump does not pump: causes and diagnostics

Let's start with the fact that if the gas tank is full, the battery is charged, the spark plugs are dry and there is a spark, the starter turns the engine normally, but the engine does not seize, then you should pay attention to the gas pump. A common problem is that there is no power to the fuel pump after the ignition is turned on. In a similar way, the malfunction manifests itself in motion, when the power to the fuel pump is lost and the engine suddenly stalls.

An equally important point is how much the fuel pump pumps. In other words, the pump may hum and buzz (power is being supplied), but not create the required pressure in the fuel line. The pressure in the fuel system with a working fuel pump must be more than 3 bar (which depends on the specific car model). The indicated pressure is accumulated in the fuel rail and has an indicator of 300 kPa and above.

To check, you need to measure the pressure in the fuel rail with a pressure gauge, taking into account the indicators that are the norm for a specific car model. Using the example of injection VAZs, the pressure when the ignition is turned on is 3 atmospheres, at idle the figure is 2.5 atmospheres, when you press the gas 2.5-3 atmospheres. This method will help you accurately determine:

- malfunction of the fuel pressure regulator in the rail;

- breakdown of the fuel pump or a noticeable decrease in its performance due to wear;

- severe contamination of filters (fuel filter and/or fuel pump mesh);

In the second case, when you press the gas, the pressure does not increase; in the latter case, the pressure gauge needle rises, but very slowly or jerkily.

A decrease in pressure below the norm will lead to the fact that the engine may not start or start with difficulty, stall, jerk, operate unstably and with failures. If this happens due to the fault of the pump and not the fuel filter, then there is a high probability that the coarse filter screen of the fuel pump is clogged. In this case, there is no need to change the fuel pump itself, since it will be enough to replace or even clean the mesh.

If you suspect that there is no voltage to the fuel pump, there is a quick way to check. It is enough to turn the ignition key and listen, as when you turn the key you should hear a slight hum from the fuel pump. If such a buzzing noise is not heard, it means there is no power to the fuel pump, there are problems with the wiring, etc.

Methods for checking the fuel pump

It is very simple to find out whether a mechanical fuel pump is working or not; to do this, simply disconnect the end of the hose connecting the pump to the carburetor, and, lowering it into an empty bottle, press the manual pumping lever located on the pump several times. Gasoline should flow out of the hose in a pulsating stream. This will allow you to find out whether the internal elements of the pump are working properly or not.

To understand why the fuel pump does not work on an injection engine, you should first “ring” its electrical circuit. It is better to start checking from the end point, that is, from the pump itself. A test lamp is connected to its terminals, and if, when you turn the key in the ignition switch, it lights up, then everything is in order with the electrics, you need to look for a breakdown in the pump itself, if not, then in the fuse, relay or wiring.

To check the fuel pump itself, you need to find out what pressure it creates in the fuel rail:

- At idle speed, its value should be in the range of 0.23-0.25 kPa.

- During engine start – 0.3 kPa.

- When you press the accelerator - 0.28-0.3 kPa.

- When the return tube that returns excess gasoline to the tank is compressed, the pressure should rise to 0.4 kPa.

If in any of the modes the pressure does not correspond to the norm, therefore, the fuel pump does not work as it should - its elements are severely worn out and require repair or replacement.