What to do if the clutch slips?

The normal service life of clutch system discs is about 70 - 85 thousand kilometers.

A quiet ride, without “pressing into the seat” acceleration, as well as frequent gear changes, helps increase their resource intensity. On the contrary, a “sporty” start and frequent driving with a trailer (both options are acceptable for the VAZ 2107) can wear out the coupling mechanism prematurely. All complaints about the malfunction of the coupling mechanism come down to two groups:

The clutch does not disengage completely (drives) - the pedal travel is long, tighter than necessary, gears are engaged, and a crunching sound is heard during shifting.

The clutch does not fully engage (slips) - the opposite situation, then there is insufficient pedal travel, slipping in the discs even if the pedal is completely free and released..

How to determine if the clutch is not fully engaged?

It's easy to do it yourself. We start the engine, put the gearshift lever in the neutral position, and fully tighten the handbrake. After this we “gas”. Then fully depress the clutch and engage first gear. If the clutch operates correctly, there should be no difference in sounds on the VAZ 2107. Now slowly release the pedal. If the clutch works well, the engine will stall. If it continues to operate even though the pedal is fully released, the clutch is slipping.

Why does the clutch slip and what should I do? Let's take a closer look at what these situations are and how to avoid them. The reasons are most often the following:

- oil getting into the clutch : on the friction linings of the driven disc, on the surface of the flywheel or pressure plate (most often in the VAZ 2107 - leaking crankshaft rear oil seal, high oil level in the gearbox housing, poorly lubricated bearing on the gearbox shaft, clogged drain hole on the flywheel shaft and etc.). In this case, the clutch slips because only the dry part of the linings works. After eliminating the causes, you need to thoroughly wipe the parts that got oil on them with gasoline or white spirit, and clean the friction linings with sandpaper after drying.

- The friction linings of the clutch discs are severely worn down to the rivets. In this case, the free play of the pedal decreases. When inspecting the gaskets, it is also necessary to replace them if they are cracked or burned out.

- The pressure springs have failed . If they have lost their elasticity, then they are unable to create sufficient pressure on the disc. In this case, they are replaced;

- no gaps in the clutch release drive

- small free play of the clutch pedal. To determine the amount of pedal displacement, take a ruler and measure the amplitude of the displacement at the center of the pedal pad. Normally, the VAZ 2107 should have a range from 25 to 35 mm

Once you have determined the reason why the clutch mechanism is slipping and have eliminated it, you need to adjust the clutch drive.

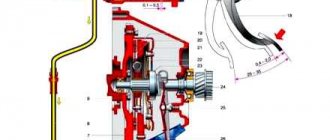

- We take an open-end wrench, they need to unscrew the M 10 nut in the interior, which limits the play of the pedal. To do this, we turn the limiting device (it is marked with the letter A), then you need to set the desired gap.

- We free the clutch pusher belonging to the cylinder from all kinds of dried dust and generously spray WD-40 on the threaded area.

- Do not forget that whatever the size of the reach stroke, the same exact absolute length will occur synchronously on the release bearing. To check this, pull the coupling fork completely backwards with your own hand. At the same time, the free release of the coupling pusher is normally about 4.5 mm in the VAZ 2107.

- To adjust the pusher play, use a 17 mm open-end wrench to stop the pusher adjustment nut from turning, and use a 13 mm wrench to “give slack” to the lock nut.

- To set the free play of the pusher, use a 17 mm wrench to fix the adjusting nut, and at the same time loosen the lock nut using a 13 mm wrench.

- Holding the clutch mechanism pusher from the threat that it will turn, using a small 8mm wrench, using a 17 mm open-end wrench, turn the nut to adjust and set the free reach of the pusher in the range from 4 to 5 mm.

- Now, using one wrench, we hold the adjustment nut, and with the other, we tighten the lock nut.

- Now in the cabin we again measure the travel of the clutch pedal. In normal condition on a VAZ 2107, it should be equal to 2.5 cm to 3.5 cm from the uppermost position until the start of shutdown.

VAZ 2107 clutch slips

- home

- Blog

- Repair and service

- Transmission

- How to adjust the clutch?

- New items in the world of cars

- Automotive market news

- Popular

- Engine

- Body

- Salon

- Cooling system

- Transmission

- Filters

- Tires and wheels

- Electrical equipment

How to adjust the clutch?

After repairing or replacing the clutch, and sometimes when using the car, the gears stop shifting clearly and smoothly, the car jerks, and slips when starting off. This happens due to an unadjusted clutch, and we will talk about this in our article.

You can adjust the clutch yourself

The main signs by which you can understand that it is time to adjust the clutch

The approximate mileage interval at which it is recommended to check and adjust the clutch operation is 10,000 kilometers. It is worth checking the car maintenance schedule established by the manufacturer - other numbers may be indicated here.

Clutch adjustment is required after replacing/repairing the clutch or its elements, for example, the drive cable. The procedure is required even if there is a suspicion of deviation of the pedal amplitude from normal values:

- the car starts moving jerkily;

- the clutch pedal sinks or moves with difficulty;

- the fluid level in the hydraulic drive decreases;

- When changing gears you notice shock, noise and vibration.

A simple test will help you determine if the clutch needs adjustment. We start the engine, smoothly release the clutch pedal and slowly move away. If the car remains in place when the clutch is fully released, then the pedal travel has increased. If the car starts moving before you even take your foot off the pedal, its travel is too slow.

What happens if you don't adjust the clutch in time?

A clutch that is not adjusted in time will quickly fail, so it will soon have to be repaired or completely replaced. With increased pedal travel, the clutch is not completely disengaged; its disk is constantly pressed against the engine flywheel. With a small stroke, the clutch is not able to fully engage the driven disc, which leads to slipping and lack of torque.

Driving a car with an unadjusted or faulty clutch is dangerous and can lead to an accident!

Lack of adjustment is the reason for rapid clutch failure

Can I adjust the clutch myself?

You can adjust the clutch without going to a technical center. But if you are not sure of the causes of the problem, you do not have the necessary tools and have never encountered car repairs before, entrust the work to professionals.

To adjust the clutch you will need a ruler, liquid lubricant, pliers and open-end wrenches of two sizes - 17x14 and 13x14.

Clutch adjustment steps

Most often, modern cars have two types of clutches:

- with a mechanical drive

- the clutch fork is connected to the pedal in the cabin using a cable; - with a hydraulic type drive

- the gas pedal is connected to the clutch slave cylinder by a pipeline filled with working fluid.

The adjustment procedure depends on the type of unit.

Adjusting the mechanical clutch

First, let’s find out whether the pedal stroke decreases or increases. We press the pedal all the way and measure how far from the floor it stops. Let's release the pedal and take measurements again. From the second indicator we subtract the first. For most models, the normal stroke amplitude is in the range of 12 - 14 cm, this can be clarified in technical documents. If the number is less, the pedal stroke needs to be increased, if it is more, it should be decreased.

After the measurements, we move on to the adjustment procedure itself:

Stage 1

– open the hood, find a rod near the transmission lever that secures the cable coming from the clutch pedal.

Stage 2

– lubricate and loosen the nuts that secure the rod with liquid lubricant.

Stage 3

– using wrenches, turn the nut that was closer to the pedal. If you turn the nut towards the clutch pedal, the free play of the pedal will become greater, if in the opposite direction - less.

Stage 4

– again measure the amplitude of the pedal stroke. If it is within the normal range, tighten the second nut – the control one – until it stops. This is necessary to record the adjustments made. If the stroke is still too large or small, tighten the nut that is closer to the pedal.

Checking the clutch operation. The pedal should be pressed easily, without noise or friction. When starting, the car should not slip or move jerkily. Speeds should change smoothly and accurately.

Adjusting the hydraulic clutch

Hydraulically operated clutches are mostly self-adjusting. But you can also adjust them manually if the pusher on the working cylinder has a thread and a control nut. Here's how to do it:

Stage 1

– check the level of working fluid in the clutch. It should be at a normal level.

Stage 2

– we create conditions for working under the machine. You can place the car on a ramp or risers, use a lift or inspection pit.

Stage 3

– we look for the pusher of the working cylinder.

Stage 4

– unhook the spring from the fork with pliers. Push the fork forward as far as possible and measure the distance between it and the pusher rod. We release the fork and take the same measurements. We get the size of the clutch gap, which we check with the standard one. If it does not fit into the range specified in the technical documentation (usually about 5 mm), we make an adjustment.

Stage 5

– remove the spring installed on the bracket of the working cylinder and fork.

Stage 6

– loosen the fixing nut on the threaded connection of the pusher, turn the adjusting nut in the direction of the working cylinder to increase the size of the gap. Or in the opposite direction - to reduce them.

Stage 7

– tighten the control nut when the gap dimensions become normal.

At the end, we carry out a control check of the clutch operation.

The hydraulic clutch, like the mechanical clutch, can be adjusted manually

Are adjustments done differently on different brands of cars?

The above procedures are universal and can be performed on machines from any manufacturer. The essence of the procedure is always the same - to reduce or increase the pedal stroke by tensioning or loosening the cable, or adjusting the hydraulic pusher.

But when adjusting the clutch in cars of different brands, there may be some differences. For example:

- normal pedal amplitude or clutch clearance;

- procedure for accessing the clutch adjusting and control nuts. So, in a VAZ-2114, 2115 you will have to remove the battery before starting work, and in a Lada Kalina you will have to unscrew the air filter.

Causes of wear of the clutch mechanism

As car manufacturers assure, the average service life of clutch discs ranges from 75 to 80 thousand kilometers. A quiet driving mode and infrequent gearbox shifting help to extend the service life of the analyzed elements. Unfortunately, not all car owners adhere to such recommendations, and this, in turn, leads to rapid wear of the clutch mechanism. As a result, the worn mechanism slips while moving and at speed.

A clutch disc malfunction is manifested by incomplete engagement or periodic slipping.

In the first case, the pedal travel is too large. That is, if the pedal fails when the gearbox is turned on, and at the moment of shifting there is a kind of crunching sound, these are clear signs that the clutch discs are not fully engaged.

When slipping occurs, on the contrary, there is insufficient pedal travel, which can be completely released and free.

In any case, the operation of the clutch disc system should be adjusted as quickly as possible.

Causes of slippage

Most often, VAZ-2107 owners complain that their faithful iron horse is slipping. Let's look at the causes of the analyzed breakdown:

- The main reason is the penetration of oil substances into the clutch system. Eliminating this problem is quite simple - using a rag soaked in gasoline or white spirit to wipe all parts on the surface of which oil is found. Next, you will need to thoroughly clean the friction attachments using sandpaper, which will eliminate slipping.

- Long-term use of friction linings that have not been replaced in a timely manner can also lead to clutch slipping. Worn linings reduce the free play of the pedal, which causes slippage. Of course, they cannot be repaired, so they must be replaced.

- Failed pressure springs are another cause of slippage. An insufficiently elastic element is not able to create the required pressure on the clutch disc, so they need to be replaced with new and high-quality ones.

- Insufficient pedal travel can cause the clutch to slip. The normal range can vary from 25 to 35 mm. A regular ruler will help you determine whether free play is normal. Using a measuring device, you need to measure the distance from the pedal to the central part of the platform.

Clutch drive adjustment

Having determined the cause of the slippage and eliminated it, you should definitely adjust the car clutch drive in the following sequence:

- using an open-end wrench, the M-10 fixing nut, which controls the movement of the pedal, is unscrewed inside the passenger compartment;

- Next, you need to set the required gap by turning the restriction device to the right;

- the cylinder pusher is thoroughly cleaned of debris and dust;

- to adjust the pusher play, use a size 17 wrench;

- This key holds the adjusting nut, and the second, 13, loosens the fixation of the main fastener;

- as a result, the reach of the pusher in free mode should be no less than 4 and no more than 5 mm;

- While continuing to hold the nut with one wrench, we tighten the main one, which is often called the “lock nut.”

At this stage, the adjustment process can be considered complete. Owners will only have to measure the pedal stroke inside the cabin, which can vary from 2.5 to 3.5 cm.

If any stage of the adjustment is not completely clear or the owners of the VAZ-2107 are not ready to figure out the cause of slippage on their own, we suggest watching a training video on the Internet resource conducted by professionals at any time.

Why the clutch slips on a VAZ 2107 and repairs

If, as they say, the clutch on a VAZ-2107 begins to slip, you need to find out the cause of the malfunction as quickly as possible in order to correct it in a timely manner.

VAZ-2107 clutch slips

In order for the VAZ-2107 to work properly and not let the driver down while driving, the serviceability of all systems and components must be carefully monitored.

It often happens that the clutch on a VAZ-2107 begins, as they say, to slip. Of course, slipping that has not previously been observed should be eliminated, but first of all you need to understand what caused the clutch mechanism to fail.

Causes of wear of the clutch mechanism

As car manufacturers assure, the average service life of clutch discs ranges from 75 to 80 thousand kilometers. A quiet driving mode and infrequent gearbox shifting help to extend the service life of the analyzed elements. Unfortunately, not all car owners adhere to such recommendations, and this, in turn, leads to rapid wear of the clutch mechanism. As a result, the worn mechanism slips while moving and at speed.

A clutch disc malfunction is manifested by incomplete engagement or periodic slipping.

In the first case, the pedal travel is too large. That is, if the pedal fails when the gearbox is turned on, and at the moment of shifting there is a kind of crunching sound, these are clear signs that the clutch discs are not fully engaged.

When slipping occurs, on the contrary, there is insufficient pedal travel, which can be completely released and free.

In any case, the operation of the clutch disc system should be adjusted as quickly as possible.

Causes of slippage

Most often, VAZ-2107 owners complain that their faithful iron horse is slipping. Let's look at the causes of the analyzed breakdown:

- The main reason is the penetration of oil substances into the clutch system. Eliminating this problem is quite simple - using a rag soaked in gasoline or white spirit to wipe all parts on the surface of which oil is found. Next, you will need to thoroughly clean the friction attachments using sandpaper, which will eliminate slipping.

- Long-term use of friction linings that have not been replaced in a timely manner can also lead to clutch slipping. Worn linings reduce the free play of the pedal, which causes slippage. Of course, they cannot be repaired, so they must be replaced.

- Failed pressure springs are another cause of slippage. An insufficiently elastic element is not able to create the required pressure on the clutch disc, so they need to be replaced with new and high-quality ones.

- Insufficient pedal travel can cause the clutch to slip. The normal range can vary from 25 to 35 mm. A regular ruler will help you determine whether free play is normal. Using a measuring device, you need to measure the distance from the pedal to the central part of the platform.

If there are no gaps in the clutch system activation drive, this will also lead to pedal slipping.

Clutch drive adjustment

Having determined the cause of the slippage and eliminated it, you should definitely adjust the car clutch drive in the following sequence:

- using an open-end wrench, the M-10 fixing nut, which controls the movement of the pedal, is unscrewed inside the passenger compartment;

- Next, you need to set the required gap by turning the restriction device to the right;

- the cylinder pusher is thoroughly cleaned of debris and dust;

- to adjust the pusher play, use a size 17 wrench;

- This key holds the adjusting nut, and the second, 13, loosens the fixation of the main fastener;

- as a result, the reach of the pusher in free mode should be no less than 4 and no more than 5 mm;

- While continuing to hold the nut with one wrench, we tighten the main one, which is often called the “lock nut.”

At this stage, the adjustment process can be considered complete. Owners will only have to measure the pedal stroke inside the cabin, which can vary from 2.5 to 3.5 cm.

If any stage of the adjustment is not completely clear or the owners of the VAZ-2107 are not ready to figure out the cause of slippage on their own, we suggest watching a training video on the Internet resource conducted by professionals at any time.

What to do if the clutch slips on a VAZ 2107

Clutch slipping in a passenger car is a common malfunction that leads not only to inconvenience in driving the car, but also to unplanned financial costs. Failure occurs due to improper operation of the transmission system and untimely maintenance.

A detailed review will help the car owner figure out why the VAZ 2107 clutch is slipping, and will introduce you to ways to fix the problem yourself, without resorting to the help of a service station.

VAZ 2107 clutch fails: causes and solution to the problem

If the clutch of a VAZ 2107 slips, this is immediately noticeable by a deterioration in traction and a decrease in dynamics. There are a number of factors that cause this malfunction, and we will try to analyze some of them in detail.

The transmission is one of the most important systems of a car, and not only driving comfort, but also the serviceability of other systems and components depends on its smooth and stable operation.

Signs of a slipping clutch

The driver can detect slippage as follows:

- Difficult gear shifting, a kind of crunching sound.

- The car moves poorly and begins to slip.

- When driving fast in lower gears it jerks (working jerks).

- Loss of power when climbing.

- Vibration or noise occurs.

- Pedal device failure.

Why is this happening?

To understand why the clutch slips on a VAZ 2107, you need to understand its structure and operating principle.

The entire mechanism consists of the following elements:

- crankcase;

- driven disk of the basket;

- riveted friction linings;

- diaphragm spring;

- pressure plate;

- hydraulic clutch release.

The parts are placed in a steel basket; The driven disk contains splines and damper springs that ensure smooth gear shifting.

The operating principle is based on friction between the working parts. The clutch connects the power unit and the transmission and transmits torque from the engine flywheel to the intermediate shaft of the vehicle's gearbox. When you press the pedal, the disc moves away, the connection between the motor and the gearbox is disconnected, and the rotation of the gearbox shaft stops. When the pedal is released, the flywheel and gearbox shaft are connected, and rotation is transmitted to the gearbox.

The coupling device slips for the following reasons:

- Oil leakage, liquid getting on the surface of the basket parts.

- Overheating of the drive disk. When the temperature is exceeded during use, the discs expand. This phenomenon is not noticeable on the go. It is determined during inspection of the part. Soot deposits and fumes are visible on the surface.

- Wear or delamination of friction linings. The elements not only wear out, but can also get burned. An unpleasant odor appears in the car interior.

- Damaged or worn compression spring. If there are defects, the spring is not able to create the required pressure on the disk.

- No gaps in the shutdown hydraulic drive.

- Reduced freewheel parameter.

Experts combine the reasons why this happens into 2 groups:

- The hitch does not fully engage (drive). Due to the increased distance of the pedal to the platform.

- The clutch does not fully engage (slips). The discs slip relative to each other, and the pedal stroke decreases.

How to check whether the clutch is slipping or not

To check the system yourself without special technical devices, perform the following steps:

- Turn on the engine and set it to neutral.

- Release the parking brake.

- Press the gas lever.

- Engage first gear.

- Squeeze the pedal.

- Squeezing is done several times.

When the assembly is operating correctly, the engine stalls. If the engine does not turn off, or there are extraneous sounds (clicks, creaks, knocks) and a burning smell, the clutch is considered faulty. Particular attention is paid to pedal travel. The lever should lower smoothly, without jerking or interruption.

What to do when the clutch slips

Depending on the cause of slipping, the progress of repair and restoration work is determined.

If the fault lies in the pressure spring, it must be replaced with a new one. When the friction linings are worn, the driven disk is replaced. When repairing or replacing some linings, be sure to inspect the gaskets. If they are damaged or have burnt spots, they are also replaced. If oily liquid gets on parts of the driven disk, it is necessary to treat the surface with kerosene or white spirit and clean it with fine-caliber sandpaper.

Grease may get on the surface of the flywheel and pressure plate if the fluid level in the gearbox housing increases excessively or if there is a leak in the rear crankshaft bearing. To solve the problem, carry out visual diagnostics and eliminate the cause of the leak, then clean the parts.

The car repair instructions will tell you what to do if there are no gaps in the hydraulic drive or insufficient free play of the lever.

The free stroke according to the specifications is 30-35 mm, the full stroke is 140 mm. Any deviation of the parameter is associated with a malfunction of the transmission system and requires adjustment work to change the pedal stroke and the position of the disk relative to the flywheel.

Considering the vulnerability of the clutch due to inept operation, experts recommend examining the amount of travel when undergoing maintenance. The parameter is checked using a measuring ruler. To do this, measure the distance from the pedal to the central part of the platform.

Repair work is carried out inside the car using open-end wrenches 13x17 mm and 17x19 mm. The M10 adjusting nut is screwed onto the tip. Tightening and unscrewing the element increases or decreases the distance from the pedal lever to the floor. The pusher should first be treated with a universal WD-40 aerosol to remove dried dirt. The pusher adjustment nut is turned with rotational movements to the required value, a 17 wrench is used to prevent rotation, and the control fastener is loosened with a 13 wrench.

Upon completion of work, tighten the locknut so that the settings do not go astray. The adjusted clutch is checked by squeezing the pedal several times, after which the distance from the floor is re-measured.

On a VAZ 2107, adjustment of the free play of the fork rod is performed in the inspection ditch. The fork can deviate within 2-4 mm.

Algorithm for performing the procedure for adjusting the free play of the fork:

- Using pliers, remove the ends of the return spring under the fasteners of the working cylinder.

- The adjusting nut is held with a 17 key, the main fasteners are loosened with a 13 key.

- The rod is locked using adjustable Cobra pliers.

- By rotating the wrench by 17 on the adjusting nut, the free stroke of the rod is adjusted.

- Tighten the locknut.

Checking the clutch operation:

- Start and warm up the engine to operating temperature.

- Squeeze the pedal.

- Switch to first gear.

- Turn off and go into reverse.

Reasons for replacing and adjusting the VAZ 2107 clutch

Replacing a VAZ 2107 clutch is a rather labor-intensive and expensive process. Therefore, before replacing, you should consider adjusting the mechanism.

Clutch replacement

To install a new clutch you will need an inspection hole, overpass or lift

It is important to detect in time the signs indicating the need to replace the clutch (it is impossible to replace it on the road), and take the car to a garage or car service center. Driving with a faulty clutch is very dangerous - you can get into an accident when crossing a railway crossing or a main road

The VAZ 2107 clutch cannot be repaired, but is replaced as a kit, which includes a basket, driven disc and release bearing

The entire VAZ 2107 clutch is replaced, so auto shops sell a kit consisting of a driven disc, a basket and a release bearing. You should consider replacing the clutch in the following cases:

- the car climbs heavily uphill when the accelerator pedal is pressed all the way down, and you can smell a burning smell - these are signs of slipping of the driven part of the clutch;

- when the clutch is disengaged, noises appear in the area of the flywheel housing - this indicates a malfunction of the release bearing;

- when starting the car, it is difficult to engage first gear (the gearbox “growls”) - this is a sign that the clutch is not completely disengaged (the clutch is moving);

- when accelerating, the car begins to twitch, rattling sounds are heard - the reason for this is usually broken damper springs or loose sockets for them on the driven disk, deformation of segments or loose rivets on the hub.

Any noise, vibration, or whistle in the clutch area requires more detailed diagnostics and diagnosis.

Clutch adjustment

If the clutch pedal becomes too soft, falls down, and does not return to its original position, then most likely air has entered the system or the hydraulic drive adjustments have been disrupted. Clutch slipping after prolonged use usually indicates a failure of the clutch. It will probably have to be changed.

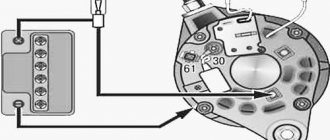

When adjusting the hydraulic clutch of a VAZ 2107, the regulated values of the gaps and the pedal stroke are set

If the clutch drives, that is, shifts gears with difficulty, in about half of the cases the reason is a discrepancy with the required values:

- play between the rod and the piston in the working cylinder;

- clearance between the release bearing and the fifth basket;

- free and working travel of the foot pedal.

Why the clutch slips: reasons, do-it-yourself adjustment

Hi all! Clutch failure does not bode well for the car and its owner. The sooner signs of problems can be detected, the better. A fairly common question on this topic is why the clutch slips or slips. Different terminology is used, but the essence remains the same.

It is important to understand that modern cars use dry and wet, also known as oil, clutches. In the first case, we are talking about simple friction, while in the second, the procedure is carried out in a special oil, which additionally cools the clutch discs and other elements. Most often we encounter the dry type. Wet is used on cars with dual clutch and robotic gearboxes. It is difficult to adjust and repair a wet clutch with your own hands. This requires the help of specialists.

The most common sign of unit malfunction is slipping. Moreover, for some it happens constantly, while for others it sometimes stalls, sometimes not. This can happen both hot and cold, that is, before and after the unit warms up.

Clutch adjustment

The entire clutch adjustment process consists of two parts.

One of them takes place directly inside the car, while the second is performed from below the car while it is either on the inspection pit or on a lift. To adjust the clutch you will need the following tools:

- open-end wrenches for 13 and 17;

- a key for 10 or 8 (it all depends on which model of the clutch slave cylinder).

The first adjustment also involves setting the clutch pedal travel. This stage of work is performed directly from inside the car, under the steering column. There is an adjusting screw that serves to limit the full stroke. It is secured with a locknut. By turning the screw first to one position, then to another, you can achieve normal pedal travel, which, according to the instructions, should be 14 cm.

But, as a rule, there is no need for this, since the pedal travel is set at the factory and can spontaneously change only in very rare cases.

The second stage of adjustment is to set the pedal free play, which in normal mode should vary in the range from 30 to 35 mm. Nevertheless, quite often car enthusiasts prefer to adjust the pedal free play to their personal preferences.

To check and adjust the clutch, you need to go down to the very bottom of the inspection hole. You can check the gap size by pulling the fork away from the pusher. The free play distance should be about 4-5 mm. But if this indicator differs significantly from the specified one, then adjustment is necessary.

To make the adjustment you need:

- remove the spring that retracts the clutch fork;

- loosen the locknut on the pusher;

- using an 8 or 10 wrench, as mentioned earlier, screw or, conversely, twist the nut until the gap is the desired size;

- use a locknut to secure the thrust nut;

- check the gap again;

- install the spring in its original place.

At this point, the procedure for adjusting the clutch on the VAZ-2107 can be considered completely completed. However, in order to be sure that everything is done correctly, you should check the operation of the clutch. To do this, you need to start the car, engage the gear and smoothly release the clutch pedal. If the work is carried out successfully, the car should move off at approximately half the pedal stroke. Although some other types of adjustments are possible, in which the car “wants” to move with the pedal barely released or almost fully pressed. It all depends on the preferences of the driver himself. However, do not forget that in this case, the malfunctions indicated at the very beginning of our article may occur.

The VAZ 2107 clutch is designed to connect the engine crankshaft and the gearbox input shaft with the possibility of briefly stopping the transmission of torque. The reasons for its failure can be very diverse. However, all of them can be easily diagnosed and eliminated on their own.

How the problem manifests itself

Most often, the cause of clutch slipping is normal mechanical wear of the assembly elements. This allows you to diagnose an impending problem even before serious consequences appear. This is done by simply observing changes in the behavior of the machine.

If you notice one of the following signs on your Niva, passenger car or scooter, be sure to diagnose the clutch or contact a service center.

- Extraneous sounds occur during system operation. They appear in the form of knocking noises when the pedal is depressed or released;

- If the noise disappears when the clutch pedal is depressed, the problem is most likely in the release bearing;

- There are signs of vibration on the pedal;

- In this case, the pedal may sink too much or be pressed too hard;

- A characteristic burning smell emanates from the clutch. The clutch usually burns if the driver operates it incorrectly.

The manufacturer provides each vehicle with instructions that indicate all recommendations for routine maintenance and replacement of clutch assembly elements. Most often, the driven disk needs to be replaced.

Before you try to adjust the system yourself, be sure to familiarize yourself with the principle of operation of the clutch. In our previous article we discussed this issue.

Possible consequences

A slipping clutch is a fairly common occurrence. This is especially true for domestic cars, motorcycles and cars with high mileage.

Practice and experience clearly show that slipping is usually associated with wear and damage to elements. This can happen on any car or other vehicle. Judging by the requests of fans of self-repair, most often the problem of a slipping clutch is solved on the following vehicles:

- VAZ 2107;

- VAZ 2114;

- IZ Planet;

- UAZ Bukhanka;

- Jupiter;

- KAMAZ;

- Minsk;

- VAZ 2110;

- Renault Logan;

- Kia Rio;

- Lada Priora;

- GAZelle, etc.

Despite the obvious cause of such problems, many car owners stubbornly continue to ignore all recommendations for maintenance and timely repair of the unit.

If you feel characteristic signs of problems, you should take prompt action.

When buying a used car or getting behind the wheel for the first time, some people think that they are simply driving the vehicle incorrectly, are not yet fluent in manual shifting techniques and are making some mistakes. In reality, it may turn out that the clutch is failing.

It is important to pay attention to the characteristic signs. Namely:

- the car loses dynamics;

- cravings drop;

- the car is difficult to climb;

- speed is gained slowly;

- the pedal vibrates;

- there is a smell of burning in the cabin;

- the pedal is too tight;

- the pedal fails;

- gear shifts with a crunch;

- Extraneous uncharacteristic sounds appear when switching.

If you do not pay attention to this in time, the engine flywheel is highly likely to be damaged, not only the coupling unit, but also the gearbox will suffer. The problem mainly affects the gearbox input shaft.

Independent and quick diagnostics

If this is just the beginning of the emergence and development of a problem associated with clutch slipping, inexperienced drivers may not notice it.

There is a fairly simple diagnostic method that is almost error-free. You can do it yourself after replacing the clutch, when adjustments have been made, or simply when you suspect that the system is not working correctly.

- place the machine on a level surface;

- start the engine;

- turn on the handbrake;

- go into first gear;

- start trying to move away;

- gradually press on the gas;

- release the clutch at the same time;

- watch the result.

If the engine stalls during such manipulations, this is good. That is, the clutch does not slip. But when the engine does not stall, the car begins to move, the unit actually slips.

Appropriate measures should be taken immediately to correct the problem.

Video - How to adjust the clutch drive

The most rational and correct solution is to replace the clutch, but before that, you need to get to the garage. This must be done with extreme caution. To avoid problems, you need to drive with the lowest number of revolutions. It is necessary to start moving “under load”. This means that the clutch needs to be released as smoothly as possible, but at the same time add a minimum of gas, or even not at all. Gear shifting should be performed according to the number of revolutions prescribed by the manufacturer.

Causes of slipping and ways to eliminate them

Not in all cases you will necessarily have to buy a completely new clutch. Once, out of inexperience, I changed a unit, which turned out to be almost completely serviceable. In reality, it was just necessary to change one inexpensive component. But sometimes you have to learn from your mistakes.

From everything I have learned, I realized that determining the cause of clutch slipping plays a key role here. Your further actions directly depend on this.

- The clutches are worn out. Your actions depend on the degree of wear. When the distance between the working elements used is less than 0.2 mm, you can simply adjust the free play of the pedal. In case of severe wear, the driven disk and linings are replaced;

- Oil appeared on the linings. Oil on the friction linings may appear due to certain problems in the flywheel drainage or an excessive amount of lubricant in the box. The oil should be removed and the surface dried. Kerosene works well. After cleaning, go through with fine sandpaper;

- Damage to the integrity of the rubber components of the hydraulic drive. When they swell, the clutch very often begins to slip. Here you will have to remove both cylinders (worker and main), wash them with alcohol, replace the rubber elements and clean the expansion holes. Don't forget to bleed the clutch and the brakes themselves;

- Loss of elasticity of pressure springs. This problem occurs on old cars that have been in use for over 10 years. Elasticity decreases gradually, which causes the required level of pressure on the driven disk to drop. As a result, the clutch slips. The check is carried out by removing the clutch disc. If elasticity has decreased, they will have to be replaced.

There are cases when changing individual components or trying to restore their functionality is pointless. The wear or damage is so severe that repairs will only have a short-term effect. A better solution here would be to completely replace the clutch.

Clutch adjustment VAZ 2107

Clutch adjustment is a mandatory step after troubleshooting or replacement. When dismantling the gearbox, basket, or driven disk, the control rod is usually unscrewed, so after assembly, the adjustment must be done again. This is also necessary if during the operation of the car, for one reason or another, the clutch on/off mechanism is broken. It's quite easy to make the adjustment yourself. To do this, you will need an inspection hole, overpass or lift.

Tools and materials

- open-end wrenches for 8, 10, 13 and 17;

- measuring ruler or construction corner with divisions;

- pliers;

- Cobra pliers;

- water-repellent composition WD-40.

The clutch adjustment is carried out after bleeding the hydraulic drive.

Adjusting the pedal free play

The pedal free play should be from 0.5 to 2.0 mm. It is regulated from inside the car by changing the reach of the clutch pedal limiter.

The procedure for this is as follows

- Using one 17mm wrench, loosen the locknut by 2-3 turns, and with the other same wrench, rotating the head of the limiter, change its length.

Adjusting the free play of the fork rod

The free play of the fork rod is the gap between the release bearing and the fifth diaphragm spring of the pressure plate. Its adjustment is carried out on the inspection pit or lift as follows.

- To make it easier to control the free movement of the fork, use pliers to remove the ends of the return spring from the clutch fork and from the plate under the working cylinder mounting bolts.

Adjusting the fork rod

The threaded part of the rod is not protected from dirt and moisture, so the adjusting nut and locknut may not immediately unscrew. It is recommended that after cleaning the rod from dirt, apply WD-40 to the threaded part. You are then prompted to perform the following steps.

- Holding the adjusting nut with a 17 wrench, use a 13 wrench to loosen the lock nut by 2-3 turns.

After adjustment, it is recommended to check the operation of the clutch. To do this you need:

- start and warm up the engine to operating temperature;

- Depress the clutch pedal and engage first gear;

- turn off first gear and engage reverse.

A properly adjusted clutch should press out easily, without jamming. Speeds switch on without difficulty or noise. When driving, there should be no slipping of the driven disk.

Signs of clutch slipping on VAZ 2107-2104

The classic VAZ 2107 is equipped with a single-disc clutch, the service life of which is about 150 thousand kilometers. This design of the unit is considered very reliable in comparison with multi-disc competitors. However, the manufacturer does not allocate the service life of the part and does not indicate it, since reliability largely depends on driving style, as well as on the conditions of use of the car. Considering the high mileage of almost all VAZ 2107 models, problems with this part are very likely. And one of the main ones is clutch slipping when changing gears. Moreover, also in comparison with its competitors, this part is considered very reliable and can be repaired or replaced with a new assembly.

As a result, if symptoms appear and there is no repair or prevention, this unit will quite quickly fail completely, essentially immobilizing the car. However, before a complete breakdown, the part’s behavior will indicate the presence of a malfunction. Such signs of future slipping and, accordingly, the threat of premature failure of the entire unit include:

- Difficulty changing gears. This can be expressed in the inability to move the gearshift lever, high pedal effort and various vibrations. The gears do not shift due to wear of the main elements, and accordingly, movement becomes difficult. These are the first signs of future slippage. If breakdowns are eliminated at this stage, major problems will be avoided.

- Noise when switching. Increasing noise or unusual hum of the box both when engaging and disengaging the clutch also indicates a malfunction of the unit. Over time, this noise will intensify and turn into slipping with subsequent failure of the system. This type of malfunction most often results from bearing failure, which also results in loss of oil fluid.

- Clutch pedal failure when pressed is also a fairly common failure, since in this case the master cylinder or clutch fork may fail. Such a breakdown in itself makes it impossible to use the clutch, but if there is no repair, over time it will completely destroy the entire assembly, which will also be accompanied by slipping of the clutch on the VAZ 2106.

- Jerks when driving and changing gears. This situation, when unnatural jerks occur when changing gear, regardless of which direction it was engaged in, is a sure sign of wear on the basket and other leading parts of the system and very often quickly develops into slipping.

All these signs indicate certain breakdowns of the moving parts of the clutch assembly and lead to the effect of slipping at a certain time. This phenomenon will require serious repairs with internal intervention in the clutch system and, accordingly, replacement of failed parts.

Causes of clutch slipping

There may be several reasons causing this effect. As a rule, they arise due to a characteristic driving style, which is commonly called sporty. Sharp acceleration and braking, frequent gear changes significantly reduce the working life of the clutch, although AvtoVAZ defines it as 75-85 thousand kilometers. In addition, experts say that the performance of a car’s clutch can be significantly affected by the use of trailers. It is believed that they are capable of significantly shortening the life cycle of components and mechanisms of an automotive element. Let's look at the most common actual causes of clutch slipping.

Why does the clutch slip on a VAZ 2107-2104

The main reasons when the clutch of a VAZ 2105 slips include not only the design features of the car, but also the consequences of the formation of accompanying faults.

Damage to the compression spring

This part is located directly in the system. This element delivers normal pressure, but as a result of deformation, both due to age and mechanical damage, the element becomes unusable. The pressure decreases, the clutch cannot engage adequately, the disc does not engage, which leads to slipping.

Primary drive overheating

As a result of non-compliance with the temperature regime during vehicle operation. Such a breakdown entails increased wear and tear on the entire system. As a result of increased temperature, mechanical parts expand, resulting in greater friction losses and increased wear of these parts.

Oil getting on the mechanical rubbing parts of the clutch

This phenomenon is common on cars with high mileage and wear of key elements, such as fluid reservoirs, cylinder bodies and other elements. In this case, the brake fluid gets on the working surface of the disc, as a result of which its operation is disrupted, the grip disappears, which, accordingly, leads to slippage and incorrect operation of the part. At the same time, the pedal travel also decreases, and the discs simply slip during their operation, respectively, not allowing the gear to engage correctly.

For what reason does the clutch slip on a VAZ-2107?

The problem with clutch slipping on cars that are usually classified as domestic classics is quite well known. This defect not only causes serious inconvenience in driving, but also entails unplanned financial losses. Clutch slipping leads to fairly rapid failure of the release bearings, wear of the discs and combustion of the entire basket as a whole. This article is intended to answer the questions: why does the clutch slip and what needs to be done in a particular case?

How to determine this defect?

Clutch slipping can be easily detected independently, without the use of special equipment.

To do this, you need to perform the following series of simple steps:

- start the engine;

- engage neutral gear;

- apply the handbrake;

- press the gas pedal;

- depress the clutch;

- go to first speed;

- release the clutch pedal.

By all rights, as a result of these manipulations, the engine should eventually stall. If this does not happen, the engine continues to work, and even extraneous sounds or a burning smell appear, this means that the clutch is slipping and measures to repair it should be taken immediately. This is caused not only by financial reasons, but also by reasons of personal safety.

Causes of clutch slipping

There may be several reasons causing this effect. As a rule, they arise due to a characteristic driving style, which is commonly called sporty. Sharp acceleration and braking, frequent gear changes significantly reduce the working life of the clutch, although AvtoVAZ defines it as 75-85 thousand kilometers. In addition, experts say that the performance of a car’s clutch can be significantly affected by the use of trailers. It is believed that they are capable of significantly shortening the life cycle of components and mechanisms of an automotive element. Let's look at the most common actual causes of clutch slipping.

Oil ingress

Often, if the clutch slips, the reasons for this lie in oil or other technical fluid getting into the basket. Oil gets onto the surface of the release disc, flywheel or driven disc lining due to a leak in the rear crankshaft oil seal. Often the cause of a leak is an excessive oil level in the gearbox housing. In these cases, if the clutch slips, the VAZ-2107 can be repaired very simply. It will be enough to eliminate the cause of the leaks and clean those parts of the system that have received oil. This can be done using white spirit or gasoline. If liquid gets on the friction linings, they will also have to be cleaned with fine-caliber sandpaper.

Disc lining wear

Friction linings on discs tend to wear out over time.

As a rule, this not only causes the clutch to slip, but also significantly reduces the free play of the pedal. In this case, there can be only one way out of this situation - replacing the entire clutch linings or discs. It must be remembered that if only the linings are replaced, then you need to pay careful attention to the condition of the gaskets. If they have damage or burnt areas, they also need to be replaced.

Spring damage

Another reason why the clutch slips may be failure of the pressure spring.

In this case, the spring is simply not able to create the necessary pressure on the disk. A damaged or worn spring must be replaced with a new one.

No gaps in the shutdown drive

Another fairly common reason why the clutch slips (whether it’s a VAZ-2107 or 2105, it doesn’t matter) is the incorrect operation of its drive. Most often this is caused by the fact that the required clearance for the clutch release drive is simply missing. This problem can be easily resolved by adjusting to the required values.

Insufficient pedal free play

The clutch often slips (the VAZ-2107 often suffers from this) also because the pedal has too little free play.

The manufacturer has established a value range of 25… 35 mm. This indicator can be easily measured with a simple ruler and adjusted if necessary.

There are other reasons why the clutch of VAZs of any model, and the “Seven” in particular, slips.

They are not as common as those listed above. But you still need to know about them. In particular, the following malfunctions can be mentioned:

- Detachment of the friction lining. The lining itself may not have visible damage or burnt areas. But as a result of delamination, it ceases to take the load over its entire surface, which leads to slipping.

- Overheating of the release disc. As a result of the temperature exceeding the maximum possible heat-absorbing characteristics of the clutch disc, it permanently expands, which causes a slipping effect. Of course, this defect cannot be determined on the fly. But it can be determined quite easily by the characteristic residue of burning and scale on the disk itself.

This article lists the main reasons why the clutch slips on domestic classics and on many other models of cars and trucks. It is important to remember that, whatever the cause of clutch slipping, it must be eliminated at the first appearance of symptoms of the defect. It is best to entrust such work to highly qualified specialists.

Disassembling, repairing and replacing clutch parts is quite labor-intensive work and requires fairly deep knowledge, extensive experience, as well as the availability of special tools and equipment.

In addition, when doing repair work yourself, there is a fairly high risk of violating the correct settings and adjustments, which will turn replacing parts into a Sisyphean task. Very soon the clutch will again begin to slip, make grinding and crackling noises, and the smell of overheated discs and linings will be clearly felt in the car's interior.

What to do if the VAZ 2107-2104 clutch slips

The main action when the VAZ 2104 clutch slips is to diagnose the fault, as well as preventive repair of failed parts. The clutch system is quite complex for car owners without relevant experience in carrying out repair work. Therefore, for inexperienced owners, the best solution would be to contact a specialized service.

Experienced owners can dismantle the system and diagnose the malfunction in terms of checking the functionality of individual units. If there is slipping of the VAZ 2106 clutch, an effective method of prevention is a visual inspection of the engine compartment for leaks and cracks, especially in the case of mechanical impact or after an accident.

The VAZ 2107-2104 clutch slips: reasons, what to do

When the owner's VAZ 2107 clutch slips, comfortable driving virtually becomes impossible. The clutch is an important unit in the gear shift system, but over time this unit becomes unusable, which is accompanied by slipping.

Signs of clutch slipping on VAZ 2107-2104

The classic VAZ 2107 is equipped with a single-disc clutch, the service life of which is about 150 thousand kilometers. This design of the unit is considered very reliable in comparison with multi-disc competitors. However, the manufacturer does not allocate the service life of the part and does not indicate it, since reliability largely depends on driving style, as well as on the conditions of use of the car. Considering the high mileage of almost all VAZ 2107 models, problems with this part are very likely. And one of the main ones is clutch slipping when changing gears. Moreover, also in comparison with its competitors, this part is considered very reliable and can be repaired or replaced with a new assembly.

As a result, if symptoms appear and there is no repair or prevention, this unit will quite quickly fail completely, essentially immobilizing the car. However, before a complete breakdown, the part’s behavior will indicate the presence of a malfunction. Such signs of future slipping and, accordingly, the threat of premature failure of the entire unit include:

- Difficulty changing gears. This can be expressed in the inability to move the gearshift lever, high pedal effort and various vibrations. The gears do not shift due to wear of the main elements, and accordingly, movement becomes difficult. These are the first signs of future slippage. If breakdowns are eliminated at this stage, major problems will be avoided.

- Noise when switching. Increasing noise or unusual hum of the box both when engaging and disengaging the clutch also indicates a malfunction of the unit. Over time, this noise will intensify and turn into slipping with subsequent failure of the system. This type of malfunction most often results from bearing failure, which also results in loss of oil fluid.

- Clutch pedal failure when pressed is also a fairly common failure, since in this case the master cylinder or clutch fork may fail. Such a breakdown in itself makes it impossible to use the clutch, but if there is no repair, over time it will completely destroy the entire assembly, which will also be accompanied by slipping of the clutch on the VAZ 2106.

- Jerks when driving and changing gears. This situation, when unnatural jerks occur when changing gear, regardless of which direction it was engaged in, is a sure sign of wear on the basket and other leading parts of the system and very often quickly develops into slipping.

All these signs indicate certain breakdowns of the moving parts of the clutch assembly and lead to the effect of slipping at a certain time. This phenomenon will require serious repairs with internal intervention in the clutch system and, accordingly, replacement of failed parts.

Why does the clutch slip on a VAZ 2107-2104

The main reasons when the clutch of a VAZ 2105 slips include not only the design features of the car, but also the consequences of the formation of accompanying faults.

Damage to the compression spring

This part is located directly in the system. This element delivers normal pressure, but as a result of deformation, both due to age and mechanical damage, the element becomes unusable. The pressure decreases, the clutch cannot engage adequately, the disc does not engage, which leads to slipping.

Primary drive overheating

As a result of non-compliance with the temperature regime during vehicle operation. Such a breakdown entails increased wear and tear on the entire system. As a result of increased temperature, mechanical parts expand, resulting in greater friction losses and increased wear of these parts.

Oil getting on the mechanical rubbing parts of the clutch

This phenomenon is common on cars with high mileage and wear of key elements, such as fluid reservoirs, cylinder bodies and other elements. In this case, the brake fluid gets on the working surface of the disc, as a result of which its operation is disrupted, the grip disappears, which, accordingly, leads to slippage and incorrect operation of the part. At the same time, the pedal travel also decreases, and the discs simply slip during their operation, respectively, not allowing the gear to engage correctly.

What to do if the VAZ 2107-2104 clutch slips

The main action when the VAZ 2104 clutch slips is to diagnose the fault, as well as preventive repair of failed parts. The clutch system is quite complex for car owners without relevant experience in carrying out repair work. Therefore, for inexperienced owners, the best solution would be to contact a specialized service.

Experienced owners can dismantle the system and diagnose the malfunction in terms of checking the functionality of individual units. If there is slipping of the VAZ 2106 clutch, an effective method of prevention is a visual inspection of the engine compartment for leaks and cracks, especially in the case of mechanical impact or after an accident.

Tips and tricks

The main advice is to prevent this phenomenon from causing slippage. First of all, responsible drivers are obliged to promptly carry out preventive measures to inspect the body and components, promptly lubricate the necessary elements, timely replace cracked clamps and failed clutch elements.

However, the method of operating the car is also an important factor. Sudden starts from a standstill, hard gear shifting, the use of cheap counterfeit materials during repair work, as well as vehicle operation under high loads do not contribute to the long-term operation of all vehicle components, especially the clutch. Because of hard switching, the disk and basket constantly collide, causing mechanical damage due to friction. As a result, even a high-quality foreign clutch will not be able to exist in good condition for a long time. That is why responsible drivers should not allow natural slipping when the unit is working properly, and also follow the rules for using the car, since the standard clutch is not designed for high loads.

Also, when increasing engine power, tuning and improving other driving characteristics, it is necessary to take into account the torque limit for which this part is designed. Since classic VAZ cars have modest torque, the clutch is therefore also designed for low power. However, when tuning the engine, owners often forget about installing a reinforced clutch, which often leads to rapid breakdown. The standard part simply cannot cope with the increased power. Therefore, when increasing power, it is necessary to look for a clutch that is suitable in terms of geometric and other parameters, which can “digest” the increased torque without loss of service life and reliability.