Clutch master cylinder VAZ 2101

Stable operation of the clutch master cylinder (MCC) has a direct impact on the functioning of the gearbox and its service life, as well as the smoothness of gear shifting. If the hydraulic drive breaks down, control of the gearbox becomes impossible, as does further operation of the vehicle.

What is it for?

The main function of the GCS is to briefly disconnect the power unit from the gearbox when changing gears. When you press the pedal, pressure is created in the system, which acts on the clutch fork rod. The latter drives the release bearing, controlling the clutch.

How it works

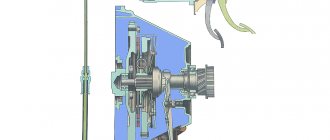

The main components of the node are:

- outer cuff;

- sealing collar;

- union;

- stock;

- return spring;

- frame;

- case for protection.

The GCS housing contains a return spring, cuffs, working and floating pistons

Principle of operation

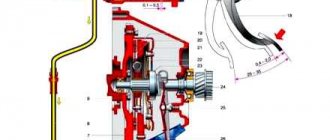

The hydraulic clutch consists of two cylinders - the main and the working (GC and RC). The operating principle of the hydraulic drive is based on the following:

- Liquid enters the GC through a hose from the tank.

- When the clutch pedal is acted upon, the force is transmitted to the rod by a pusher.

- The piston in the main center moves out, which leads to the valve closing and compression of the liquid.

- After the fluid is compressed in the cylinder, it enters the hydraulic system through a fitting and is supplied to the DC.

- The slave cylinder drives the fork, which moves the clutch with the release bearing forward.

- The bearing presses on the friction spring of the pressure plate, releasing the driven disk, after which the clutch disengages.

- After the pedal is released, the cylinder piston returns to its original position under the influence of the spring.

The pedal moves the pusher, which, in turn, moves the piston and creates pressure in the hydraulic drive system

Where is

The GCS on the VAZ 2101 is installed under the hood near the vacuum brake booster and the master cylinder of the brake system. There are also reservoirs near the clutch cylinder: one for the braking system, the other for the hydraulic clutch.

The GCS on the VAZ 2101 is located in the engine compartment near the vacuum brake booster and the master cylinder of the brake system

When is replacement needed?

The cylinder elements wear out over time, which leads to interruptions in the operation of the mechanism. Repair or replacement of the main circulation system is necessary when the following symptoms appear:

- airiness of the system;

- leakage of working fluid;

- wear of cylinder components.

The presence of air in the hydraulic drive system disrupts the performance of the system, making its operation impossible. Air can enter the hydraulic drive through microcracks in the sealing elements of the cylinder or in the connecting hoses. If, when checking the system, a constant lack of fluid in the expansion tank is discovered, you need to inspect the entire clutch mechanism, since fluid can leave not only the master cylinder. If the amount of fluid in the hydraulic drive system is insufficient, the required pressure to move the clutch fork will not be able to be generated. This problem will manifest itself in the inability to separate the engine and gearbox when pressing the clutch pedal. If the leak is caused by wear of the connecting hoses, then replacing them does not raise any special issues. If the problem is related to the GCS itself, then the product will have to be dismantled, disassembled and the cause found out, or simply replaced with a new part.

Clutch drive system

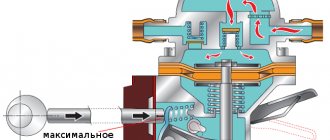

There are only two main components in the VAZ-2106 clutch system. The clutch master cylinder allows pressure to be created in the pipes using the driver's muscular strength. The worker acts on the fork, which drives the release bearing. Briefly, the operation of the entire system can be described as follows:

- When you press the pedal, the rod in the master cylinder moves. Since the system is closed, the pressure rises sharply.

- Under the influence of this pressure, the piston is extruded in the working cylinder, which is installed on the clutch housing.

After releasing the pedal, the reverse process occurs:

- When the pedal is released, the master cylinder rod returns to its initial position, as a result of which the volume inside the system increases and the pressure decreases.

- A return spring acts on the working cylinder, which allows the rod to move to its initial position.

- The system has an expansion tank into which liquid is filled.

DOT-3 type brake fluid is used as the working fluid. It contains many additives, they contribute to the normal operation of the mechanism. These additives have a beneficial effect on the metal and allow the cylinders to cool better.

Try to fill the system only with those fluids recommended by the manufacturer. Effective operation depends directly on the quality of the liquid that is poured into the system. Never allow the level to drop to the minimum level. Add fluid if necessary.

Which one is better to put

On the VAZ 2101 it is necessary to install a hydraulic clutch designed for the VAZ 2101–07. Cylinders designed to work in UAZ, GAZ and AZLK vehicles are not suitable for installation on a “penny” car. The situation is similar with imported analogues. It will be quite problematic to introduce a GVC from any foreign car, which is due to different mounting of the unit, different threads and tube configuration. However, a hydraulic drive from a VAZ 2121 or from a Niva-Chevrolet is suitable for the “classic”.

Manufacturer's choice

Today there are many companies that manufacture clutch master cylinders. However, when choosing and purchasing the unit in question, preference should be given to the following manufacturers:

- JSC AvtoVAZ;

- Brick LLC;

- Kedr LLC;

- Fenox;

- ATE;

- TRIALLI.

When choosing GVCs, it is better to give preference to well-known manufacturers

The average cost of a hydraulic clutch is 500–800 rubles. However, there are products that cost about 1,700 rubles, for example, cylinders from ATE.

Table: comparison of hydraulic clutch actuators from different manufacturers by price and reviews

| Manufacturer, country | Trademark | Cost, rub. | Reviews |

| Russia, Tolyatti | AvtoVAZ | 625 | Original GVCs are made with high quality and are more expensive than analogues |

| Belarus | Fenox | 510 | Original GVCs are inexpensive, made with high quality, and are popular among drivers |

| Russia, Miass | Brick Basalt | 490 | Improved design: the absence of a technological plug at the end of the cylinder and the presence of an anti-vacuum cuff increases the reliability of the product |

| Germany | AND THOSE | 1740 | The originals are of the highest quality. The price is tied to the EURO exchange rate |

| Germany | HORT | 1680 | Original GCS are reliable and durable in operation. The price is tied to the EURO exchange rate |

| Russia, Miass | Cedar | 540 | The original GVCs do not cause any particular complaints |

Bleeding the clutch

In order to eliminate the possibility of failure of the clutch mechanism, the hydraulic drive system must be pumped after the repair is completed. To carry out the procedure, the car must be placed on an overpass or inspection hole, and the following must be prepared:

- brake fluid;

- wrenches for loosening brake pipes;

- rubber tube of suitable diameter;

- transparent container.

What kind of liquid to fill

For classic Zhiguli cars, the factory recommends using RosDot 4 brake fluid in the hydraulic clutch system. A 0.5 liter container will be sufficient for repairs. The need to fill the fluid may arise not only during repair work, but also when replacing the fluid itself, since over time it loses its properties.

It is recommended to fill the clutch system of classic Zhiguli cars with RosDot 4 brake fluid.

How to bleed the clutch

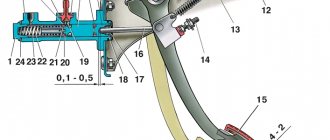

It is better to do the work with an assistant. The liquid level in the tank should be below the neck. We perform the following steps:

- We pull one end of the hose onto the fitting of the clutch slave cylinder, and lower the other into the container.

- An assistant presses the clutch pedal several times until it becomes tight and holds it down.

An assistant in the cabin presses the clutch pedal several times and holds it pressed. - We unscrew the fitting and drain the liquid with air into the container, after which we tighten the fitting.

To bleed the hydraulic drive system, you need to unscrew the fitting and release the liquid with air bubbles - We repeat the procedure several times until the air is completely removed from the system.

Monitoring the brake fluid

One of the main signs of failure of the clutch slave cylinder in VAZ 2106, 2101, 2107 cars is partial or complete failure of the pedal inside the car when pressed. This indicates a lack of tightness in the system - gradually the amount of brake fluid decreases, and the harder and more often you press the pedal, the more fluid will leave at a time.

This will cause the clutch to stop working and changing gears will be difficult or impossible. If you do not monitor the level of brake fluid in the reservoir and do not eliminate leaks in a timely manner, then consequences may arise - the clutch basket and release bearing will fail, not to mention the creation of emergency situations.

To eliminate the cause of the breakdown or completely replace the working cylinder, depending on the nature of the breakdown, you will need a new working cylinder, brake fluid and a standard set of tools. It is best to replace the working cylinder in a VAZ 2106, 2101, 2107 car from an inspection hole or on a lift. Before starting work, it is necessary to drain the brake fluid that is in the clutch system. Having all the necessary tools at hand, the procedure for removing the cylinder is very easy.

The first step is to pull out the pusher clamp, then remove the tension spring. Next, slowly unscrew the nut on the hose with the liquid, after placing a container to collect it. Then proceed to unscrew the cylinder mounting bolts, after first pulling out the pusher with the clutch fork. Move the fork with the pusher so that it does not interfere with you. Between the working cylinder and the rubber hose there is a rubber gasket with a sealing washer. It is very important not to lose it, because it is not included in the repair kit.

Replace the clutch slave cylinder and proceed with reassembly in reverse order. If necessary, you can adjust the depth of pedal pressing on the cylinder fitting. After completing all the work, fill the brake fluid into the clutch reservoir. Filling will help to completely flush the entire hydraulic clutch system of a VAZ car. Bleeding is performed to clear your system of air that is in the brake fluid.