How to replace a bearing on a transfer case in a Niva

09/08/2019 mr.Podshipnik 0 Comment

HOME »

- Auto components

- »

- Replacing transfer case bearings

»

All drivers operating a NIVA car are well aware of the features of this car. Its distinctive feature is all-wheel drive. It has drive axles, two and three differentials. Also, this car has a transfer case, which differs from other VAZ models.

In this article you will learn how to replace the bearing on the transfer case in a VAZ NIVA car with your own hands.

How to detect a faulty transfer case on a VAZ NIVA

If you hear any external symptoms, you need to think about what the reason is. A significant part of Niva cars suffer from body vibration. It lies in the fact that the transfer case on the car is incorrectly centered. The reason may be wear of the transfer case bearing. To make sure of this, just in case, check the chassis of the car, it may be the cause of the vibration. The fixation of the cardan shafts may not be of good quality or the wheels may not be balanced. Rattling may occur if the fasteners for the transfer case mounting support are loose or the rubber band on it is torn. What needs to be done in order to diagnose this cause? Accelerate the car to 100 km/h and listen carefully to the noise in the area of the floor of the front seat of the car. If you hear rattling, immediately check how the car’s mechanisms are working, including the transfer case. Perhaps the reason lies in the violation of the distance of the intermediate shaft parts. Perhaps the elastic coupling has delaminated, or the constant velocity joint is installed incorrectly. Check if a complex of these problems occurs, then it is better to immediately replace the intermediate shaft assembly. If there is noise in the transfer case, then most likely the bearing in it has become unusable or the bolts and flanges of the elastic coupling are deformed.

Niva transfer case alignment

For a long time, drivers of Soviet Nivas have been convinced that aligning the car’s transfer case significantly reduces vibration, noise levels in the cabin and saves fuel consumption. Therefore, if you have just purchased a VAZ-21213, then you should immediately start this work. When you purchase a car second-hand, you should not rely on all the promises and assurances of the previous owner. Even if he assured that the alignment was carried out and everything was fine, it is best to check this fact and make sure of it. This work in itself is not difficult, but it requires additional hands, since the presence of an overpass cannot be done alone. Car service specialists recommend using a lift, because other devices require additional fastenings. The process itself is like this:

- one person sits in the driver’s seat, the car is lifted with him;

- the lock must be disabled and 4th or 5th gear engaged;

- it is necessary that the pins are in the middle of the support holes (to do this, move the dispensing supports apart with your hands);

- the second person from below must loosen the 4 nuts that secure the transfer case;

- the person in the driver’s seat must pick up speed and inform his partner about this (the assistant “on the go” tightens the clamps to the required level);

- in a car service center for centering, the car must pick up speed to 60 km/h (the speed must be set in 4th gear).

We recommend: We repair and modernize the rear lights of VAZ 2107 cars

It is important to know! On Niva 21213, the intermediate shaft is not a cardan, but a CV joint. For this reason, factory settings may dispense with height adjustment. But in the case when the dynamic alignment does not live up to expectations, you can try to tighten or lower the transfer case and repeat the alignment.

How to dismantle the transfer case on a Niva

As a rule, the transfer case on a VAZ NIVA car can be disassembled without problems, but this will require considerable time. In order to “get” to the transfer case, it is necessary to dismantle some more parts of the car. You need to select a set of tools, including:

— keys No. 13, heads and ratchet possible; - you need to have different screwdrivers.

To remove the transfer case, you need to remove the plastic trim inside the car that covers the transfer case. Unscrew the four screws and then the three fastening elements. Unscrew all shift knobs and remove the cover together with the corrugated rubber bands.

Attention: do not forget to disconnect the electrical wires, there are two of them.

The work in the interior is over at this stage, move to the outside of the car. There are two options: either drive into a hole in the garage, or put the car on a jack. When you jack up the Niva, you need to disconnect two cardans and drive the gearbox. To disconnect the cardan shafts, you need to unscrew all the nuts with a No. 13 wrench. When turning bolted connections, secure them with a screwdriver. Next you need to remove the speedometer cable. In this case, you need to unscrew the fasteners and disconnect the cable and secure it with wire. Unscrew the transfer case bolts and disconnect it from the gearbox. At the final stage of dismantling, you need to substitute some kind of support so that the transfer case does not fall. Just do it very carefully so as not to drop the transfer case.

Extraneous noise and hum in the work of the Republic of Kazakhstan

Transfer case lever vibration. This phenomenon occurs when there is deformation or play of the intermediate shaft or crosspiece of one of the cardans. In rare cases, vibration may be caused by a broken arm bracket.

- Transfer case vibration. The reason for this is the imbalance of the cardan shafts.

- Shafts, wear on crosspieces, damage or poor tightening of transfer case or engine mounts. The transfer case also vibrates when the gears and bearings are faulty.

- The differential lock does not engage. This problem is typical for the Chevrolet Niva, like its predecessor from AvtoVAZ. Difficulty turning on the lock does not always mean that it is time to repair the transfer case. Often the lever and hinge joint rust and lose mobility due to infrequent use of the function. In this case, it is enough to treat the problematic parts with WD-40.

- Oil leak. Lubricant leaks out if the oil seals or gaskets wear out. Leakage also occurs if the housing is damaged.

- Difficulty switching modes. Difficulties with switching occur when parts are worn out or incorrectly adjusted.

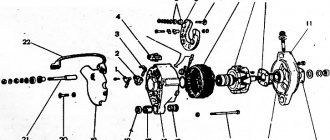

How to disassemble and reassemble the Niva transfer case

How to perform this operation correctly? Start by cleaning the transfer case from oil, dust and dirt. Next, you need to drain all the oil and rinse the transfer case with diesel fuel. Then you need to fix it on the bench table and loosen all the fasteners. It is necessary to unscrew the front axle housing fasteners and remove it. Remove the speedometer drive and driven gear. Next, remove the lock washer and pull out the axle and remove the lever that locks the differential. Then you need to dismantle the crankcase cover and the front axle drive and remove the spring with the retainer ball. Next, you need to unscrew the bolt that locks the differential lock fork. Then you need to remove: the rod, the fork and the locking clutch. The rear cover, together with the rear axle drive shaft, must also be dismantled. We remove the drive shaft and the flanges on it together with the front axle drive. Next, you need to remove the front axle drive shaft from the crankcase. And finally you get to the bearing. Remove it together with the thrust ring and oil deflector. Remove the rear axle drive shaft from the rear cover. Then remove the cover that protects the front drive shaft bearing and the inspection hatch. Next, dismantle the lever bracket that changes gears and remove the lock washer. And then you can very easily remove the axle and lever. The next step is to remove each of the mounting rings and the rear bearing, which “sit” on the intermediate and drive shafts. We take them out of the distribution box. Then we remove the rear bearing and remove the thrust ring. Removing the bearing is done using a special puller. We take out the gear, which is located on the drive shaft of the low gear (together with the bushing). The gearshift clutch, hub, and gear also need to be dismantled. Next, disassemble the differential. To do this, you need to press out the oil seals that are located in the front axle drive housing. Pay attention to their condition. As a rule, they all need to be changed. When you have removed the bearings with pullers, install new ones that you previously purchased at a specialized auto store. We do not recommend buying bearings at the market or secondhand. You may purchase a defective, low-quality product. Then again you will waste time, money and mood, and they will not last you long. When installing the bearings, do not forget to lubricate the seats with lithol 24. Assemble all parts of the transfer case in the reverse order as you did during dismantling. After installing the transfer case, be sure to fill in high-quality oil and check for noise while driving. Do not use used oil even if it has not reached its service life.

Chevrolet Niva Dobry Behemoth › Logbook › Replacing transfer case covers

Dear boys and, perhaps, girls, I finally decided to eliminate the vibration of the transfer case by switching to new type covers with double-row bearings. Especially huge play in the rear bearing! A description of replacing the back cover with a cover of a new type can be found in 3 seconds in any search engine, but I still couldn’t find a replacement for the front cover (prrrrr :-P). In short, the process itself...: Due to the fact that I decided to change both sides at once, I stupidly removed the transfer case from the car. You can figure out for yourself how to do this (evil laugh).

We remove the covers one by one, I started with the back. From the back cover we need a shaft, a flange, a nut (preferably a new one), and a washer. The retaining ring came with the cover.

We press the shaft out of the old cover. We take a new cover of a new type. We put it on the workbench, put something on it so that it is horizontal and lies flat, without swaying.

We take a hair dryer, set the temperature to 620 degrees and heat the bearing seat in the cover in a circular motion. This will take approximately 15 minutes. We warm up the entire lid in general. As soon as the lid is warmed up, we take the bearing and simply throw it into the lid well. It flies like a pencil into a glass, we immediately install the retaining ring and the shaft slides in easily into the already heated bearing from the cover. As soon as the cover can be touched with your hands, install the oil seal, install the flange and you can place it on the transfer case.

Don't forget to drill a hole in the housing for the oil supply.

Remove the front cover. We press out the shaft, everything is the same as on the rear one.

Warm up the old cover with a hairdryer and pull out the drive shaft bushing and the centering bushing (indicated by arrows) from it.

We also heat the new cover with a hairdryer at 620 degrees, throw in the bearing, retaining ring, shaft, and bushings from the old cover. Cools down to a tolerable temperature, install the oil seal. I assembled everything without sealant on the gaskets. While the transfer case is not installed, you can add oil!

We put it on the car and have a blast! We're having a blast, today we're having a blast...

Source

A few more tips:

— when dismantling the transfer case, so that all parts can be unscrewed well and without problems, it is necessary to spray them with penetrating, lubricating liquid VD 40; — the drive and intermediate shaft must be installed in the transfer case in its entirety; - do not forget to lubricate the oil seals with Litol 24; — It is advisable to tighten all bolted connections with a torque wrench. However, if you don’t have one, then you can do this: tighten the bolts and nuts completely and then loosen them counterclockwise by turning the wrench twenty degrees.

If you follow the above instructions, you can easily carry out repairs and replace the bearings in the transfer case on your VAZ NIVA yourself without any problems. If you have any questions, you can always ask them in the comments on our website. I will be happy to give practical advice.

Recommendations for centering the control gear

After any operations to remove and install the transfer gearbox, it must be centered. To do this you will need:

- loosen the transfer case so that it “sits” more freely and can move slightly;

- accelerate to a speed of 80 km/h, after which the transfer case will sit in its seats;

- tightening occurs as quickly as possible and with the engine running, so that through vibration, the manual transmission does not have time to take an inappropriate position.

After such repairs, the transfer gearbox can serve faithfully for a very long time. Unfortunately, the operation of the transfer case under conditions of increased loads often significantly affects the reduction of service life due to its weak design. To increase the reliability of the manual gearbox, you can install a subframe, which will allow the transfer case to sit firmly in its place, as well as eliminate strong vibration from the operation of the transmission.

The finished subframe for the Niva has ready-made holes and fasteners for attaching it to the body. Also, to increase reliability, an additional transfer case support was installed. To install the subframe, you will need to place a jack under the transfer case, loosen the fastening nuts and lower the transfer case. Next, the subframe is tried on the seats. I strongly recommend lubricating the holes in the bottom well to prevent possible corrosion. The subframe is screwed onto the transfer case seat, and the box itself is screwed onto the subframe. Due to the fact that the subframe is rigidly connected to the body, vibrations will still transfer to the body, but not so significantly. Thanks to reinforced supports and high-quality rubber cushions, the transfer case will no longer have the tendency to move out of its seat, which means that all elements of the chassis will last much longer.