The front and rear suspension of Vesta differs significantly from the one that AVTOVAZ used on Grant, Priora, Kalina, etc. All the reviews tell us that the new chassis design is better than before. However, during the first months of operation, the owners began to notice extraneous noises (knocks, creaks, rattles, crunches) in the front and rear suspensions of Vesta, which occur when driving over speed bumps or other road irregularities...

And again about creaking stabilizer bushings

If you are not the owner of a newly-made Vesta, then you have probably already encountered the problem of a terrible squeak emanating from the suspension when driving over bumps, especially speed bumps. Let's try to figure out how and where the creaking comes from and how you can deal with it.

Like any new model, Lada Vesta is not without some design flaws, which, fortunately, can be quite easily eliminated with your own hands.

How to solve the problem yourself

This issue has already been discussed quite a lot on the Internet in car forums about the Lada Vesta and quite a lot of solution options have been proposed. Let's talk about the most popular methods.

- Bushing lubrication. Here you can follow the path of dealers, but only use higher quality lubricating fluids for lubrication. The choice here is limited only by your imagination. From banal lithol to Japanese expensive lubricants. The disadvantage of this method lies in its fragility. Be prepared for the problem to return to you after the first good rain.

- Replacing bushings. If the problem needs to be solved once and for all, then we suggest taking the path of replacing the rubber bushings. Today, automakers from different countries are trying to follow the path of unification, so car owners are very lucky in that a low-quality part can be replaced with an analogue from another car brand. The same can be applied to the rubber bushings of the anti-roll bar on the Lada Vesta car.

Replacing bushings

We offer you to look at several options for replacing bushings with analogues.

- Bushings from Chevrolet Niva. As practice shows, bushings from Niva fit Vesta well. You can take advantage of this similarity and solve the “creaky” problem. However, some owners note that such bushings sometimes also begin to “sing”.

If you want to order them through the online store, then write down their article numbers: 2123-2906046, 2123-2906040 (a little more). The average cost in stores is from 150 rubles. per piece There are also products made of polyurethane (bright yellow color).

The cost of such bushings is 100-150 rubles higher. Sometimes they also continue to creak, so we do not recommend using them. - Bushings from Kia Rio. This is the most reliable, most expensive and most inconvenient in terms of replacement of the listed methods for eliminating squeaks. The cost of foreign analogues from KIA can reach 1000 rubles. and more. If the cost and long replacement time do not scare you, then you can find products by catalog number: KSBSOULF or 54813-2K100.

Along with the bushing, you will also need to purchase a bracket for its fastening, because... it has a different shape from Vesta. Its article number is 54814-1G000, the cost in stores is from 300 rubles.

Creak of stabilizer bushings

The driver and passengers often feel a squeaking sound when the car is moving. They especially begin to creak in severe frosts.

Let's look at the reasons why bushings squeak:

- The bushings were made of low grade material.

- In the cold, rubber becomes like oak and loses elasticity, which is why squeaks appear.

- The bushing is badly worn.

Ways to eliminate the creaking of car stabilizer bushings:

Logically, in order to eliminate the squeak, you need to lubricate the bushings, which is what some drivers do. But lubricant, be it lithol 24, various oils - all this attracts dust and sand. Adhering abrasives will only cause the bushings to wear out quickly.

Also, lubrication will lead to a partial loss of function of the bushings themselves, since they must tightly hold the stabilizers. The bushings are torsional and therefore protect against vehicle roll. For the bushings to function properly, they need to be seated tightly. And, if you lubricate them, they will already slide and can rotate.

There are ways for folk craftsmen to improve the efficiency of stabilizer bushings. They wrap some of the bushings with electrical tape to make sure they fit tightly.

The video shows the process of replacing conventional bushings with polyurethane ones.

How to make a replacement

Replacing the bushings can quite realistically be done only by removing their brackets. To do this you will need a TORX T40 sprocket and a lot of patience.

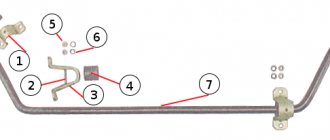

- The purchased bushings must first be modified by making a slot in the side. In the photo below, the incision site is conventionally shown with an orange stripe.

- Gain access to the front of the vehicle from below. This could be a viewing hole or a lift.

- Unscrew the bolts securing the brackets. One should be unscrewed completely, and the second - all the way to the rail. This will be enough to completely replace the bushings. If you change the bushings to an analogue from KIA, then you can no longer do without removing the rack.

- Place the new bushings on the stabilizer (the cut you made will come in handy here), insert them into the brackets and tighten the bracket bolts.

- Enjoy the quiet and soft operation of the Lada Vesta car suspension.

We invite you to watch a video of one of the car enthusiasts who encountered a problem and solved it by replacing the bushings with analogue ones.

How much does it cost to replace a stabilizer?

All work is performed on a lift from below the car. This takes 1 hour 30 minutes. Today the stabilizer can be purchased at a price of 3,400 rubles. The bracket costs 90 rubles. Work to replace the stabilizer along with adjusting the wheel geometry will cost 3,400 rubles.

According to the regulations, after replacing the stabilizer, it is necessary to check and adjust the wheel alignment. Do not be confused, on the Lada Vesta, as on most modern cars, only 1 wheel alignment parameter is adjusted at the wheel alignment stand. The camber is not adjustable, since it is determined by the geometry of the chassis parts and the body itself.

We independently eliminate the creaking of stabilizer bushings on Lada Vesta

As Vesta was used, defects began to emerge, which, in principle, is normal for any new model. Typically, such defects do not in any way affect the safety and other vital parameters of the machine. However, when some little thing constantly annoys, this one begins to irritate. This is exactly the situation with the Vesta stabilizer bushings. Therefore, you need to understand the situation and try to resolve the issue.

What's the matter?

The reason for the dissatisfaction of many Newsmakers is the creaking. It is no secret that the stabilizer bushings of the domestic model very soon begin to creak, and sometimes this happens almost immediately after purchase. There have been cases when the car did not have time to travel even 1,500 km, and some manage to drive without making noise for less than 1,000 km. As for the frequency of squeaking, surveys show that this happens in approximately 60% of cars.

Creaking is typical for many Vestas

This creak can be clearly heard in the video.

It is also worth noting that such a squeak is rarely heard constantly. Usually it appears and then disappears. In this case, the problem is extremely clear - the quality of the material or the manufacturing of the components is not high enough.

Contacting the dealer and AvtoVAZ’s position

If you have decided to contact a Lada dealership, you will most likely be unpleasantly surprised. The fact is that the Russian automaker, although it recognized the problem, took the simplest path to solving the issue.

At the dealership, the bushings are lubricated with grease.

The craftsmen do not replace the bushings, but simply lubricate them with PMS 400 grease. To carry out lubrication work, the unit is disassembled and then reassembled. PMS 400 is an emulsion-based lubricant with adhesive properties. It is widely used in defoamers and in plastic-to-metal contact areas. It has hydraulic, shock-absorbing, cooling and damping properties.

The result of using this lubricant is twofold. The Vesta stabilizer bushings actually stop squeaking, but this does not last long. The reason is that the lubricant is quickly washed out (literally within 100-150 km) and the sounds are heard again. This moment is especially pronounced in the fall, during rainy weather.

How to diagnose the rear suspension yourself

To subsequently troubleshoot minor problems, you need to identify them and fix them yourself:

1. If the handbrake cable is loose, you need to tighten the tie; 2. Sounds are heard from the trunk lid dampers, lubricate them with grease, silicone will do; 3. Increased play in the trunk lid knocks, you can also get rid of it by lubricating the lid; 4. If the rear seat locks creak, electrical tape will save you; you need to wrap it around the locks and pre-lubricate it with grease; 5. Place things in the trunk so that they do not create unnecessary noise when driving.

Independent work

In this case, there are several ways:

- Bushing lubrication;

- Replacement with analogues.

Bushing lubrication

If you choose this option, everything is done exactly the same as when contacting a dealership. However, car owners choose the lubricant themselves. Some people buy regular mastic, others use foreign lubricants, for example, Japanese ones.

Owners buy different lubricants

Be that as it may, these are only temporary measures, since mastic and other lubricants are still quickly washed out. It may last a little longer, but that doesn't solve the problem.

Replacement with analogues

According to reviews from owners, most often either bushings from Chevrolet Niva or components from KIA are used.

Bushings from Chevrolet Niva

Elements from this model are suitable for Lada Vesta, which can be bought at almost any car store. In addition, they can be ordered online using the following article numbers:

Stabilizer bushings from Chevrolet Niva

The second type of product has larger dimensions, so it is used more often. The price of bushings from Chevrolet Niva is about 150 rubles per pair. However, there are also polyurethane products on sale, which are often painted in bright colors (yellow, red, etc.). The price of polyurethane products reaches 250 rubles per piece.

You can purchase products from one of the resources below:

- https://www.autopiter.ru/goods/21232906046/rossiya/ >However, Vest owners note that elements from the Chevy Niva also often creak, and it doesn’t make much difference what material they are made of - rubber or polyurethane.

Bushings from KIA

These are more expensive components, which can be purchased under article number KSBSOULF or 54813-2K100. The price for such products is significantly higher than for similar ones from ChevyNiva. Usually the cost varies between 400-650 rubles, but the price can reach 850 rubles per piece. Therefore, it is recommended to monitor offers from various suppliers before purchasing. In this case, you need to buy only original products. Purchasing a non-original one is fraught with the same creaking noise, which is extremely unpleasant, because bushings from a Korean manufacturer are not cheap.

You can purchase them on one of the following sites:

- https://koreanaparts.ru/product/548132K100/730

- https://www.autodoc.ru/part/hyundai-kia—647/548132k100/

- https://www.autopiter.ru/goods/548132k100/hyundai-kia/id11105217

- https://plentycar.ru/autopart/1981834

In addition, it is worth taking into account the configuration of parts from HYUNDAI-KIA, which differs significantly from that of the Lada Vesta. For this reason, along with the bushings, you need to buy brackets for them, which are sold under article number 54814-1G000. The price tag for them ranges from 300 to 500 rubles per piece.

Comparison of Russian and Korean elements

You can order brackets online at the following addresses:

- https://koreanaparts.ru/product/548141G000/730

- https://nomer52.ru/kronshtejn-vtulki-stabilizatora_hyundai_elantra-hd_548141g000_mobis_i126/

- https://www.autodoc.ru/part/hyundai-kia—647/548141g000/

- https://www.autopiter.ru/goods/548141g000/hyundai-kia/ >

Bracket for bushings from Kia

Lada Vesta: a problem with a creaking suspension that has not been solved for a year and a half

The problem exists and concerns almost all Lada Vesta owners (it does not affect only completely new cars, but this is not for long, and those who are in the tank and do not hear anything) - the creaking of the front stabilizer bushings.

The car has been produced for a year and a half, but for a year and a half they cannot solve this problem. We tried to solve it by lubricating the bushings, but it doesn’t last very long, sometimes literally just leaving the dealer. So, I decided to call dealers to find out how things are going with solving this problem at the moment.

Honest dealer - Bright Park

Bright Park began by deceiving me even at the stage of the telephone call: I listened to the phrase “...in a few seconds they will answer you...” I listened for more than two minutes, but when they answered me, it turned out that they knew about the problem, they offered to come in two weeks, since the repair zone is supposedly “fully occupied until this date.”

To my reasonable question, how can I drive for two weeks on a creaking suspension, what if something serious is there and something falls off, they haven’t even seen the car, they immediately stated that absolutely ALL cars have this situation (.) and nothing won’t happen (are they psychics there, can they make diagnoses over the phone?).

At the same time, when I called the second time, they were ready to make an appointment for tomorrow (that is, when for money, their repair area is empty, and when under warranty, the repair area is suddenly completely occupied for two weeks? Well, well..).

At the end of the conversation, I was even offered to contact another dealer (this is customer-centricity - to lose a client by sending him to another dealer??).

Forward Auto

That's what I did: I called Forward Auto. They immediately surprised me with the first phrase after the greeting: they said that by not hanging up the phone, I agree to the processing of personal data and agree to the use of my phone number and the content of the conversation - no application!!

Well, okay, they offered to come to them tomorrow with a warranty card and order the new type of bushings that the plant produced, but they said, I quote: “within a MONTH (!!) MAYBE (.) they will come!” A limited number of them have arrived and they are calling clients who contacted us back in February (how poor they have been driving for one and a half to two months with a creaking suspension!), who also confirmed that “they used to lubricate, but the lubricant does not help.”

He asked: should I drive a creaking car for a month?

They answered: it turns out like this...

Do you have to drive for a month (maybe(!), or maybe more!!) with a creaking suspension?

What conclusions do I want to share with those who have bought or want to buy Vesta:

- Lada still doesn’t have a warranty: they either refer you to others, deliberately making unreasonable deadlines for claiming under the warranty, or they offer to wait for months without giving any deadlines..

- The car is “crude”, many problems have not been solved in almost a year and a half, they test drive it on you and collect breakdown statistics.

- There are no spare parts for VAZ, and you have to wait even longer for them than from any foreign brand (they usually have basic spare parts within a week, but most likely they keep the same bushings in stock) - this is nonsense, because it was always believed that spare parts for Lada on every corner - today this is far from the case.

- The cost of servicing the Lada Vesta is no longer budget-friendly and is at the level of its competitors.

- Problems with the car, as before, will have to be solved not by the dealer, as you hoped, but by yourself, using your ingenuity and straight hands, or your uncle from the garage.

- Stabilizer bushings are not the only knock and creaking in Vesta’s suspension: many also encounter a bunch of others.

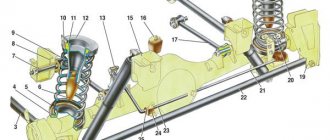

Installation

In general, the algorithm for replacing standard stabilizer bushings with an analogue one is simple and, by and large, the same for components from the Chevrolet Niva and for parts from KIA. The only difference is that, in the case of parts from KIA, you will have to install the purchased bracket.

As for the Chevy Niva, the bushings from it will need to be modified - it is necessary to make a slot on the side, and then grind the sides down to the same size as on Vesta.

The replacement process itself begins with installing the Lada Vesta on the overpass, after which you need to thoroughly clean the bolts that secure the stabilizer bar from dirt. Next, you need to arm yourself with a wrench and a Torx T40 bit, with which one bolt from the bracket is completely unscrewed (located further from the steering rack). The second bolt is also unscrewed, but not completely, but enough so that the mounting bracket can be moved to the side.

When the bolts are unscrewed, all that remains is to move the bracket and remove the bushing itself. A pre-prepared bushing is placed in its place, and the bolts are tightened. The second element changes similarly.

This method works provided that components from ChevyNiva are used. If you decide to install bushings from KIA, you will have to completely remove the brackets. In this case, simply unscrewing the bolts will not work, since the screw, which is located closer to the steering rack, rests on the clamp that secures the rack boot.

It can be seen that it will not be possible to unscrew both bolts

In this situation there are 4 options:

- Turn the clamp itself;

- Rotate the boot (together with the clamp, of course);

- Remove the rack protection, then loosen its fastening bolts and slightly lift the rack up;

- Remove the rail completely.

This will allow you to replace the bracket along with the bushing.

And also the bracket from it

As you can see, there are several options for getting rid of creaking Lada Vesta bushings, which differ strikingly in both the effort involved and the financial and time costs.

This form provides general recommendations for eliminating squeaks.

How to dismantle the stabilizer

We carry out the dismantling operation in strict adherence to the following algorithm of actions:

- We lift the Lada Vesta car so that the front wheels are hanging at the same level. This is required to prevent the occurrence of obliquely directed stresses in the stabilizer.

- We dismantle the lower protective casing to ensure easy access to the unit scheduled for repair.

- We unscrew the bolts that hold the stabilizer links to the suspension components. Now we release the racks from their seats.

- Correct installation of new bushings will require complete disassembly of the unit. We unscrew the bolts that secure the fixing brackets.

- We dismantle the stabilizer.

Removing old and installing new products

- We carefully pull the worn elements off the rod (you can cut them off).

- We clean the stabilizer itself from dirt and carefully inspect it to ensure there are no deformations. If any are present, it is recommended to replace the product.

Installing a stabilizer on Vesta

- Lubricate the surface of the stabilizer with the indicated product.

- We put on the elements. We achieve a tight fit. The presence of backlash is excluded.

If such requirements are achieved, then we assemble the unit using the reverse algorithm.

- We mount the stabilizer in its place. To do this, we install brackets that hold the bushings. We “bait” the fasteners.

- We attach the rack to the edges of the stabilizer. Here you can tighten the fasteners to the required torque.

- After this, you can tighten the fasteners of the brackets. The torque should be in the range from 18 to 24 N*m. This restriction is intended to “protect” the owner from the risk of stripping the threads in the fastener holes.

- We return the protective casing to its original place.

How to get rid of creaking stabilizer bushings on Lada Vesta

There are two ways to eliminate the squeak:

- contacting a service station if the car is under factory warranty;

- Do-it-yourself repairs, regardless of whether there is a warranty.

Both methods do not guarantee the disappearance of the annoying sound. The reason lies in the material from which the bushing is made.

In most service stations with a defect using a metal-rubber aerosol. In the best case, they use a Litol type lubricant with the addition of a graphite base.

This “potion” lasts for several thousand miles, after which the sound returns.

The most effective and efficient way is to install non-standard seals from other car brands. It is advisable that the elastic bands are made of polyurethane.

In terms of dimensions and parameters, bushings from:

| Name/items | Price in rubles |

| Chevrolet Niva: articles 2123-2906046, 2123-2906040 | the average cost is from 160 – 170 rubles per piece. Polyurethane ones are 120 – 140 rubles more expensive than analogues |

| Kia Rio: part numbers: KSBSOULF 54813-2K100, 54814-1G000 | cost per set from 800 rubles |

*price indicated as of 03/06/2019.

The principle of operation of stabilizer bushings

The main purpose of the stabilizer, bushings, struts (bones) is to evenly distribute the load along the entire perimeter of the suspension.

The stabilizer is activated when the car enters turns to minimize roll. The bushing is compressed and unclenched in a metal bracket under the influence of pressure from the torsion rod.

Where the body “sags” on its side, the rack raises the frame, and lowers it on the opposite side. The greater the angle of inclination, the stronger the drag force of the suspension.

The main element of the suspension is a torsion bar with sealing bushings at the edges. It is fixed to the suspension, and its edges are connected to the levers.

Conclusion

Despite numerous tips and recommendations, replacing the stabilizer bushings with new ones made of polyurethane remains an effective way. Preferably from a Kia Rio or Chevrolet Niva.

In the first case, additionally buy “native” Korean metal brackets, since the Lada Vesta brackets are not compatible along the external contour. How effective and efficient it is to buy non-original components is up to you to decide, but the quality of the latter has been approved by more than one thousand car enthusiasts.

When should I replace the front stabilizer bar bushings?

By carrying out a visual inspection of the stabilizer bushings from time to time, you can identify their wear. If there are cracks on the bushing, or the shape has changed (there are large abrasions), then the stabilizer bushings must be replaced.

The service life of stabilizer bushings for most brands and models of cars is 30 thousand km. If only one bushing is worn out, it is recommended to replace the complete set in order to increase the time between overhauls for replacing bushings.

If dirt is visible during visual inspection, it is better to clean them, thereby protecting them from accelerated wear.

Signs when it is necessary to change the stabilizer bushings in a car:

- if there is wheel play when turning;

- if the steering wheel shakes;

- if there are squeaks when the car tilts (roll);

- if the suspension vibrates (there is extraneous noise);

- if when driving straight the car pulls to the left or right;

- and, if at all, there is instability while driving.

These signs, first of all, indicate wear of the stabilizer bushings. The same signs may also be accompanied by wear of silent blocks. Such problems are eliminated by subsequent work on wheel alignment. Therefore, you should check them and carry out repair work with your own or someone else’s hands to replace the stabilizer bushings. Play can also appear if the wheel is severely imbalanced. It disrupts the balancing when hitting a hole, or, for example, when pumping to close a puncture.

Reviews

| № | Positive |

| 1. | Vasily , 34 years old (drive2.ru) Sverdlovsk: for the first time the seals creaked at 20,000 km, I went to the service station under warranty, the guys lubricated it with a metal-rubber aerosol. A year has passed - silence. |

| 2. | Petrovich , 44 years old (prom.ua), Krasnodar: the car is in its third year, no complaints, the suspension is working as normal. I've heard drivers complain about the crunching noise, but I didn't have that problem. |

| 3. | Alexander , 35 years old (autotoday.com), Omsk: I’m happy with the purchase of the Lada Vesta, I regularly visit the service station, I drive carefully, the speed limit is medium. |

| 4. | Ivanovich , 45 years old (rozetka.ua), Rostov-on-Don: my positive review of the Lada Vesta car in general. Good build quality, relatively cheap spare parts, developed network of car services. |

| 5. | Vyacheslavovich , 43 years old, Kursk (avtoflit.com): my first car was a Lada Priora, after which I bought a Vesta. The difference is noticeable in quality, assembly, and service life. Undoubtedly Lada Vesta is better. |

| 6. | Valery , 33 years old, Voronezh (autotoday.com): in three years of using the car, I visited a service station once to replace stabilizer bushings, not counting scheduled technical inspections. |

| 7. | Vasilievich , 46 years old, Ufa (drive2.ru): I take care of the equipment, periodically go to the inspection pit, check the fastenings and components. Over the course of three years, I lubricated the stabilizer bushings several times. I didn't do any more work on the suspension. |

| 8. | Semenych , 38 years old, Bashkortostan (drive2.ru): The Lada Vesta is well assembled, I’m pleased with the quality. I fix minor damage myself. Even when operating on rough terrain, the suspension absorbs bumps perfectly. |

| Negative | |

| 9. | Dmitrievich , 49 years old (prom.ua), Saratov: Vesta disappointed me, after 30,000 km the stabilizer seals creaked. I visited a service station, the guys lubricated it with an aerosol, and after 5000 km the situation with the “sound” repeated itself again. |

| 10. | Alexey , 46 years old, Moscow (avtoflit.com): in two years of using the car, I went to the workshop three times for suspension maintenance. Constant squeaks and crunches. The quality is raw, the machine has shortcomings that the manufacturer must eliminate. |

| 11. | Filippovich , 39 years old, Voronezh (drive2.ru): my opinion is that the Lada Priora was made with better quality than the Vesta. I bought it a year ago and now I regret it. There are a lot of shortcomings, defects, and expensive spare parts. |

| 12. | Valentin , 37 years old, Pskov (autotoday.com): if you are choosing a car between Lada Vesta and Renault Logan, then consider buying a French brand. |