Operations for removing the front suspension arm of the Lada Granta

We hang the car, remove the wheel from the side where we will remove the lever. Remove the engine protection. We remove the ball joint, see the article “Removing the ball joint from the Lada Granta.” Holding the extension with a 24-mm open-end wrench, use a spanner of the same size to unscrew the extension nut.

Unscrew the bolt securing the link connecting the arm and the anti-roll bar. Often, if the bolts have not been changed or loosened for a long time, they can break. It is best to have spares before removing the lever.

Use a soft metal drift to knock out and remove the bolt. Do not damage the thread.

Using two 19mm wrenches, unscrew the nut of the bolt securing the lever to the body.

We remove (or knock out) the bolt and remove the lever from the bracket.

Remove the washer from the stretcher and remove the lever.

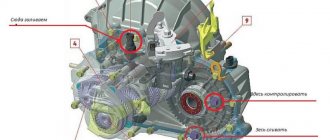

On the extension behind the large washer there are washers for adjusting the pitch angle of the rack's rotation axis (the photo shows three washers, there may be another number)

Clean up the washers and install them back in the same quantity. If the levers are removed from both sides, mark the washers so that they can be installed in their places.

Stabilizer struts for the Lada Granta: selection and replacement - AutoExpert

Tool:

- Straight box spanner 17 mm - 2 pcs.

- Driver for socket attachment

- Extension for the end attachment on the wrench

- 13mm wrench attachment

- Large hammer

- Punch

- Medium flat screwdriver

- Knife

Parts and consumables:

- Aerosol lubricant type WD-40

- Anti-roll bar strut - 2 pcs.

- Stabilizer bar cushion - 2 pcs.

- Metal brush

- Soap solution

Notes:

Remove the stabilizer bar struts and pads if they show significant wear, cracking, tearing or swelling of the rubber. Carry out the work on an inspection ditch or overpass. The operations for removing the right and left stabilizer bar struts are similar.

Removing the anti-roll bar link

1. Using a 17 mm spanner, unscrew the nut securing the stabilizer link to the front suspension arm, holding the bolt with a wrench of the same size.

2. Use a soft metal drift to knock out the bolt.

3. To make it easier to remove the strut from the stabilizer bar, unscrew the two nuts securing the stabilizer pad bracket from the desired side.

4. With the right side of the stabilizer lowered, remove the strut from the stabilizer bar.

Note:

As a rule, on cars with high mileage, worn struts can be easily removed. If the stand cannot be removed immediately, we recommend inserting a thin screwdriver blade between the rod rod and the rubber bushing and pressing out the rubber. After this, a penetrating liquid such as WD-40 should be injected into the resulting gap and, shaking the strut from side to side, remove it from the stabilizer bar.

5. Install the new stand in the reverse order, having first cleaned the end of the bar with a brush and lubricated it with soapy water.

Removing the anti-roll bar cushions

1. To replace the stabilizer bar cushions, unscrew the nuts of the bolts securing the stabilizer bar struts to the arms and remove the bolts (first photo of the article).

2. Using a socket with a 13 mm socket, unscrew the nuts securing the airbag bracket to the body and remove the bracket.

3. Remove the stabilizer link from the rod (see above).

4. Remove the pad from the barbell.

Note:

Typically, worn pads can be easily removed from the bar, but if you have difficulty, cut the pad with a knife and remove it.

5. Install the new cushion in reverse order, lubricating the rod and the hole in the cushion with soapy water.

6. Replace the cushion on the other side of the stabilizer bar in the same way.

Removing the anti-roll bar

1. To remove the anti-roll bar, disconnect the stabilizer links from the front suspension arms and remove the stabilizer bar cushion brackets (see above).

Replacing silent blocks in the front suspension arm of a Lada Granta

To replace the silent block for attaching the Lada Granta lever, you will need a vice. We press out the silent block with a suitable piece of pipe. We moisten the new silent block with soapy water and press it into the lever, also using a piece of pipe of a suitable diameter.

We knock down the silent block of the extension installation with a chisel. There are two of them, on one side and the other.

Having removed from one side, remove in the same way from the second.

We press the new silent block in a vice...

...and finally press it, striking a punch with a diameter of 8 mm through three windows in the rubber layer. We carry out the assembly in the reverse order. Tightening the threaded connections of all rubber-to-metal hinges of the front suspension arm of the Lada Granta must be done when the car is standing on its wheels, on a flat surface.

Every car enthusiast tries to pay as much attention as possible to his swallow. We have to change consumables on time and deal with broken parts. If you suspect that the silent blocks of the grant have served their purpose, then you need to quickly drive the car into the pit. It is worth paying attention to the harbingers.

Often there is an incomprehensible dull knock in the suspension either on the right or left. There can be knocking for various reasons, but the silent block of the grant is one of the popular ones. Speaking about the reasons, you can go through the options for a long time, because it could be a support, a rod in a rack, or a box bracket. It is worth paying attention to such a detail as stretching, it is often the cause.

Replacing silent blocks on Kalina

Front suspension silent block close up

The silent blocks on the Lada Kalina car are located exactly the same as in the VAZs of previous years. These elements are located generally on the wishbone or adjacent to it. You will have to change them either on the entire element at once, or by selecting the most damaged ones. Of course, if there is damage on one of them, the wishbone with rubber (stock – approx.) stabilizers must be removed and replaced with polyurethane analogues.

Removing the wishbone

- In order to begin work on replacing old silent blocks with new ones, you need to place the car on a viewing hole, a lift, or jack it up.

- Next, you need to remove the wheel and spray all the connections on the wishbone with WD-40.

- After the lubricant has penetrated into all hard-to-reach places, we begin to unscrew the bolts.

- First of all, we begin to dismantle the ball joint bolt, but before that we remove the cotter pin from the bolt.

- Then we unscrew the bolt securing the longitudinal tension hinge (where the “daisies” are attached - approx.) and remove it from the seat.

A generously lubricated bolt is a guarantee of success.

When dismantling this unit, there should be no problems.

For the best impact on the bolt, you can use a wrench extension.

Rubber-metal longitudinal tension joint

The rubber-metal longitudinal tension joint, or popularly simply “daisy”, is designed to take the brunt of the impact from uneven road surfaces; despite the fact that this element is very important, it is very easy to dismantle.

- Having previously clamped the lever in a vice, we knock out the silent blocks one by one using a chisel or a thin flat screwdriver.

Punching out “daisies” is not an easy task.

This is what the old suspension elements look like

To cause the least damage to silent blocks, it is better to place pieces of wood between the vices.

Stabilizer strut and cushion

- The stabilizer bar, or simply “eggs,” and the cushion provide the stabilizer bar with stable operation while driving the car.

- It is very easy to dismantle the “eggs”, just unscrew the mounting bolt from the transverse arm, and simply release the other end from the anti-roll bar by simple rocking.

Sometimes it happens that they just break

After unscrewing the fastening, it is very easy to remove the pillow, but putting on a new one is much more difficult.

What to do about the knocking?

If you do not pay attention to the problem and do not change the silent blocks on the grant, the knocking will become increasingly stronger. Therefore, it’s time to drive the car into the pit, remove the engine protection, and look at all the details. You can swing the car from the desired side, whether you hear a knock or not, but it will happen if the silent block on the grant has become completely unusable. If the problem is in the stretcher, then you need to pull it too, the resulting knock will be proof that the cause of the breakdown has been found.

You can replace the silent blocks with grants, the price of which seems reasonable, right in the pit, without the need to remove the levers.

Tools required:

1. 2 keys for 24. 2. Extension tubes. 3. Head 17. 4. Thin screwdriver. 5. Punch, it is better to give preference to the canonical one. 6. A hammer, it will hardly be possible to do without it in work when the silent blocks of the grant need to be replaced.

We install new silent blocks

Now the moment has come when you can install new silent blocks on the Lada Granta, the main thing is to know how to press them in. The landing site will need to be pre-lubricated, you can use graphite lubricant, then the nut is screwed on, the silent blocks of the grant are pressed in, the price for them is not high. In this case, you can do without special devices that allow you to press parts. And you don’t need to remove the lever itself, as some people do.

When you have figured out how to change the silent blocks on the grant, it is worth remembering that after replacing you need to loosen the nut so that you can attach the crab. It must be taken into account that the holes intended for fastening are displaced. So Lada Granta, replacing silent blocks is not complete without a hammer, which is useful for adjusting the holes. It will be necessary to use it on both sides.

After replacing the silent blocks on the grant is completed, you may encounter an amazing effect. Drivers notice that the roughness in steering disappears, the steering wheel becomes more obedient, and the road holds without problems. Therefore, if there is a suspicion that the silent blocks of the front levers of the grant have become unusable, it is better to immediately look for the cause and replace them. As a result, you will receive a machine whose performance will only please you.

How difficult is the job?

Any novice craftsman can cope with such repairs; the silent block of the grant will be shown in the photo; it is not difficult at all. It is worth doing the work in the following sequence. You need to hold the stretcher with one key, and use the second to unscrew the nut. Now you need to unscrew the 3 bolts that secure the crab, after which replacing the silent blocks of the fret grant involves removing the brace.

The attractive price for the grant silent block will allow you to purchase parts without extra costs. When you try to remove the stretcher, the rubber part may fall out towards you. Please note that the part also has metal clips; you will also have to deal with them. To do this, you can use a screwdriver and a hammer, or take a drift; you can see the work on replacing silent blocks in the video grant.

Polyurethane silent blocks

In general, the resource of the silent block is approximately 100 thousand kilometers. But the service life of the part is largely influenced by the operating conditions of the car. Since our roads leave much to be desired, the service life of these elements is noticeably reduced. The average mileage that the joint can withstand on bad roads is 50-60 thousand km, after which it must be replaced.

Video: Polyurethane silent block 2141

A number of other factors can affect the service life. The rubber used in the construction of the element is exposed to the negative effects of petroleum products or chemical reagents that are used to treat the roads in winter. Exposure to high and low temperatures first affects the properties of rubber (in summer it is too soft, and in winter it “freezes”). At the same time, the constant loads that the silent block experiences under different temperature conditions lead to “aging” of the rubber, loss of elasticity, delamination, and separation from the metal elements of the structure.

Silent blocks, in which the elastic element is not rubber, but is made of polyurethane, perform somewhat better in terms of operation.

Polyurethane silent blocks have significantly better performance properties. They are less susceptible to chemical influences, do not lose elasticity when exposed to different temperatures, both high and low, and are not affected by petroleum products.

Therefore, the polyurethane silent block can last longer before being replaced. But over time, such a hinge requires replacement due to aging and delamination.

Rear suspension

Unlike the front, it has undergone virtually no changes. Here, just like on the first Soviet G8s, a semi-independent beam is used. It is attached to the body on hinges (fortunately, there are no “crabs” in the design). A helical spring with constant stiffness is used as an elastic element. To dampen vibrations and prevent swinging, two shock absorbers are used.

- High reliability. The design does not have additional levers, which, in addition, can bend when falling into a large hole.

- Energy intensity. The Lada Granta absorbs all bumps perfectly, especially if oil shock absorbers are installed at the rear.

- Cheap maintenance. Due to its simple design, this pendant can be rebuilt even with your own hands. And the cost of new rubber-metal elements is unlikely to empty the pockets of even the most stingy car owner.

The main difference between the “Grant” suspension is the wheel alignment angles.

Where are the silent blocks located?

Front arm silent blocks

In the front suspension, silent blocks are used in the levers; through them, a movable and elastic connection of the levers with the wheel hub and with the car body is carried out. Silent blocks are often used at the junction of the anti-roll bar with the lever, if this is structurally provided for. It can also be used at the bottom of the shock absorber strut, where it is attached to the hub.

In the rear suspension, silent blocks can be installed on levers (longitudinal and transverse), at the point where the torsion beam is attached to the car body, and in shock absorbers.

In general, the number and location of installation of these rubber elements depends on the design of the car's chassis. For example, consider the location of silent blocks on a VAZ-2110 car. And let's start with the front suspension where these joints are used:

- in the transverse arms (at the place of their attachment to the body);

- at the ends of the anti-roll bar (its attachment to the wishbone);

- in the shock absorber struts at the bottom (the place where they are attached to the wishbone);

- in the extension of the transverse lever (at both ends - at the point of its connection with the lever and with the cross member);

In total, there are 5 silent blocks installed in the front suspension on one side only, and the same number in the other part of the suspension.

At the rear of this car, a torsion beam is used, so the number of rubber-metal hinges in its design is much smaller - there are only 4 of them. Two of them are used at the point where the beam is attached to the eyes of the body, and two more are used at the bottom of the shock absorbers.

Due to the fact that the design of a car suspension has different features, the number of hinges may differ.

Shock absorber

This element is a damping device. The shock absorber serves to reduce the range of vibrations of the car body. In other words, the element prevents spontaneous rocking. The work of the shock absorber is based on hydraulic resistance. Inside it there is a liquid of a certain viscosity. It moves through a special valve. Thus, the device absorbs sharp impacts while preserving vulnerable suspension parts. Therefore, the shock absorber is one of the most important components in the chassis. On our roads, this element lasts about 60-80 thousand kilometers. But this period may be shorter, even with careful driving. It is enough just to damage the protective boot, and all the dirt will accumulate in the rod seal.

Also note that the damping element changes in pairs. That is, in the event of a breakdown of the rear left shock absorber, the rear right shock absorber also changes. As for the front struts, they are more durable. Often they are replaced already assembled with a spring, since they fail no earlier than after 150-200 thousand kilometers.

Cause of malfunction

The main cause of element malfunction is a violation of the boot seal. Once it starts to crack, dirt and dust will get inside. They act on the ball like an abrasive. As a result, play appears and the support begins to break on its own. Is it possible to repair it? The Lada Granta suspension is designed in such a way that the ball joints cannot be restored and must be replaced entirely with new ones.

Causes of knocking in the front suspension

In total, there are four main reasons why noises and squeaks can annoy the Lada Kalina car owner, and three of them can be eliminated independently and everything can be returned to a safe state.

- The first reason why knocking occurs in the suspension is the poor quality of the road surface . A suspension that is in good working order can also produce some extraneous noise. If the noise disappears when you drive onto a good road, then everything is fine with your suspension, you can move on to the point below.

- If knocking and simultaneous vibration occur in the steering wheel, the reason may lie in a faulty steering rack . If you can tighten the steering rack yourself, then it is better to entrust its repair or replacement to professionals.

- The third reason is the front suspension strut spring that has lost its elasticity . Since the spring tone is significantly reduced, the suspension hits directly against the body. How to change the front struts, and along with it the spring, is described in detail in this article.

- And the last reason is cracked silent blocks, which are simply necessary to thoroughly dampen knocks and vibrations that occur while driving. Read below for information on how to properly replace these front suspension elements.