Subtleties of ShPG

Let's move on to the most interesting part - the connecting rod and piston group. On our plug-in engine, the pistons do not have grooves for the valves. We decided to replace the pistons with new ones, with grooves, and together with the connecting rods, since the old ones were bent. We ordered spare parts from the official dealer Federal Mogul. The kit for one cylinder includes a piston, rings, a pin and the connecting rod itself, along with bolts for securing the lower cover of its head. Grooves are visible on the bottom of the pistons, as well as the number 11189, an arrow indicating the direction of installation of the piston in the cylinder block, and the production date. The skirt has an improved iron oxide coating to protect it from damage.

Nikolay GANYUSHKIN, head of the engine design bureau

The modernization of the eight-valve engine for front-wheel drive models took two years. The main goals were to reduce fuel consumption and increase dynamic performance by reducing mechanical engine losses, and at the same time reducing harmful vibrations and noise. And of course, increased reliability. Euro 4 standards require that the engine maintain its original emissions parameters twice as long - up to 160 thousand km. And we almost doubled the resource: from 120 thousand to 200 thousand km. The connecting rod and piston group of the VAZ-21116, like the sixteen-valve one, is purchased. In the future, we plan to produce some parts ourselves, and we will continue to purchase some from foreign partners from the Federal Mogul group, who intend to localize the production of components in Russia. We also take into account the interests of the Renault-Nissan alliance. If engine production volumes increase, then it would be reasonable to purchase additional equipment and organize the production of connecting rod and piston group parts in Togliatti.

The updated LADA Granta family will now be equipped with modernized engines.

Cars from the updated Lada Granta family received not only a new appearance, but also a number of technical improvements. One of them will be welcomed by car enthusiasts. These are engines with “stickless” pistons. They will be used on both 8-valve and 16-valve engines. This solution allows you to avoid “Stalingrad” of the engine when the timing belt breaks. If the belt breaks, the valves will remain intact, since there are special holes in the pistons.

In addition to the “plug-in” engines, the updated LADA Granta received other technical improvements. Thus, the automated manual transmission (AMT) was modernized. Now the box has a Sport button, when turned on, the electronics keeps the tachometer needle at the red zone and does not increase the gear. In addition, the operation of AMT in urban modes was improved, thereby reducing the jerking of the car. The engineers also made gear shifting smoother and faster.

In addition, now all gearboxes on the LADA Granta, excluding the Jatco automatic, have received an increased number of final drives: 3,940 instead of the previous 3,710. This gear ratio was previously used on sports versions of the Grant.

New teeth

Let's move on to the timing belt drive. We chose the Gates kit, which includes a Dolz pump with gasket, belt and pulley with semi-automatic tensioner. By the way, different devices are used for tension. We selected a crescent-shaped grip designed for the roller. The gripper is placed on the roller, a bolt is screwed to the head of the latter, and the belt is tensioned. We preferred a large set with a pump to be on the safe side: our car has 68 thousand km on it, and it is unknown how long the pump installed on it will last.

It was also decided to change the auxiliary drive belt - peeling appeared on the old one. We bought a Gates 6PK995 belt and a new INA pulley to replace the whistling old one.

Running in the engine after replacing the piston rings

Regardless of whether the piston rings were only replaced or the engine underwent a major overhaul, the engine will require a break-in. This is due to the need to break in new parts. Running in the engine after replacing the piston rings should be similar to running in the engine of a new gasoline or diesel car.

Next, we will consider the opinions of experienced auto mechanics and answer the general question of how long the engine needs to be run in after replacing the piston rings. It is a fairly common statement among experts that it will take about 10-15 thousand km to completely grind in the rings. This leads to the conclusion that after a minimum run-in of the car after engine overhaul or replacement of rings (up to 5 thousand km), it is highly undesirable to spin the power unit above the average speed range for another 5 or even 10 thousand km. mileage

The main problems in the operation of the VAZ 21127 engine

Despite all the improvements made by AvtoVAZ designers in the 126th version of the engine, car enthusiasts note some problems in the operation of the 16-valve power unit of the VAZ 21127:

Options for 8-valve engines are well known to Lada Granta owners from previous AvtoVAZ models. These engines have indexes 11183 and (11186, 21116), their power is 82 and 87 horsepower, respectively.

Main article: What engines are installed on Lada Granta cars.

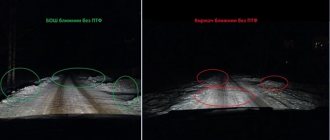

Domestic consumers are very afraid of a broken timing belt. Therefore, this issue plays an important role when choosing a car modification.

In the event of such a situation, bending of the valves may occur, which has given rise to the popular saying “ fist of friendship .” There is even slang that refers to motors that bend valves as “plug-in”, and motors that do not have this disadvantage as “plug-in”.

To prevent the belt from breaking, it is necessary to change the belt on time (read more about when it is necessary to change the timing belt according to the recommendation of the factory and the experience of Grantovodov here).

Weaknesses of the VAZ 11183 engine

Throttle valve. During the modernizations, the designers were able to solve the problem of rapid contamination of the throttle on previous AvtoVAZ engines and install an electronic throttle valve drive, but it still happens that the operation of the unit on the Granta engine is disappointing due to floating idle speed and spontaneous engine stops. The recipe is still the same - flushing the throttle assembly with carburetor cleaning fluid.

Mass air flow sensor. If you notice a loss of power, an increase in fuel consumption and a check light on the dashboard. These reasons indicate the need to check the mass air flow sensor, for which you need to arm yourself with a multimeter and a 10mm wrench. The driver should find the yellow wire output in the sensor connector (it is closer to the windshield) and the green output (third from the left on the same side ). These sensor outputs are exactly what we need. In cars of different years in the electrical circuits, the colors of these wires may differ, but the locations of the terminals are the same. To monitor performance, the voltage is measured between the indicated terminals with the ground turned on and the motor not running. The size of the tester probes is capable of passing through the rubber seals of the connectors, along the specified wires, without disturbing their insulation. We turn on the mass, connect the multimeter and observe. The voltage on a working sensor will be 0.996…1.01 Volts. If the voltage is up to 1 V, everything is in order - we look further for reasons, but if it is higher - we simply replace it with a new one and rejoice at the improvement in the throttle response and efficiency of the internal combustion engine.

New 16-valve VAZ 21127 engine and its features

The new VAZ 21127 engine was first installed on the Lada Granta in 2013. This type of power unit is an improved version of an earlier model of the VAZ 21126 engine with a service life of 200 thousand km, which was also installed on Priora and Kalina.

AvtoVAZ designers managed to increase engine torque by 10% by changing the crankshaft design and increasing the piston stroke. This also caused the power to increase to 106 hp. instead of 98 hp in the previous version. The 16-valve design of the gas distribution system is designed in such a way as to maximally free the combustion chamber from exhaust gases, resulting in high-quality combustion of the working mixture.

Along with this, AvtoVAZ implemented an innovation in the 21127 engine - intake adjustment. Depending on the engine speed, thanks to the standard damper, the length of the exhaust manifold changes, which is called the inertial charging system.

The disadvantage of the VAZ 21127 engine is its incompatibility with an automatic transmission, which domestic designers must correct in the near future. Unlike the latest model, the VAZ 21126 engine has been equipped with a four-speed automatic transmission since 2012.

Considering the advantages in improving speed performance and reducing vehicle acceleration time due to increased power, it should be noted that there is a slight increase in fuel consumption, as well as a higher value of transport tax, since the VAZ 21127 engine power exceeds 100 hp.

Disadvantages of the VAZ 11183 engine

This power unit, installed on the Lada, Kalina and Grant, cannot boast of its dynamic qualities. Despite the fact that it has been modified, received an electronic gas pedal and increased environmental friendliness, its high-torque performance in off-road conditions and driving in low gears goes against the acceleration speed and throttle response. This problem is faced by owners who, due to this feature, are unable to overtake in a short period of time. But despite this drawback, the engine power has already been increased due to a modified throttle valve and an electronic gas pedal.

Resource. The manufacturer tells us that the service life before major repairs is 150,000 km, but this figure cannot always be considered fair, but only in the presence of ideal conditions, which our regions cannot boast of, and in most of our country the quality of roads is very low . When used in favorable road conditions, the service life ends after a mileage of 200,000 - 250,000 km.

Unfortunately, the designers did not get rid of the old disease of all VAZs. The layout of the cooling system is such that the heater supply channels are installed under the radiator. The downside is that the heater core is tilted backwards, which causes air to accumulate in the radiator and cause partial operation. This design of the cooling system and interior heater forces owners to periodically struggle with air pollution.

Source

The most powerful Lada engine will become plug-inless

The Volga auto giant continues a large-scale modernization of its existing line of power units. It is planned that the most powerful (122 hp) VAZ 1.8-liter engine with the VAZ-21179 index will soon receive a “plug-inless” version. This will happen in the middle of summer of this year, reports the Quto.ru portal. Thus, the domestic automaker will completely switch to “plug-in” engines.

However, despite the innovation, employees of the dealer network have never encountered bent valves out of all the cases of timing belt breakage on 1.8-liter engines.

Let us remind you that from July 2021, AvtoVAZ began using new so-called “plug-free” pistons (with recesses) in all 1.6-liter engines. If the timing belt breaks, the valves, thanks to the optimization of the shape of the pistons, do not collide with them (do not bend). This allows car owners to avoid expensive and time-consuming repairs. You can safely drive such engines until the belt breaks or the pump jams. The supplier of pistons with special “samples” is Federal Mogul.

Pistons, pins, rings for Lada Granta (VAZ 2190, 2191) | Motorring online store

Product groups

- Freebie!

- New items

- Appearance

- Salon

- Engine

- Exhaust system

- Intake system

- Steering

- Transmission

- Suspension

- Brake system

- Fuel system

- Electrical and electronics

- Climate system and ventilation

- Alarms and anti-theft systems

- Windshield wiper and accessories

- Car accessories

- Special tools Roller cutters, countersinks, cutters, countersinks

- Cutting tool

- Those. engine maintenance and repair

- Chassis repair and maintenance

- Fuel pump pullers

- Special auto tools

- Special tools "AvtoDelo"

- Flaringers, pipe cutters, pipe benders

- Crescent keys

- Glass repair

- CV Clamp Pullers

- Steering rod and ball joint pullers

- Measuring instruments and tools

- Torque wrenches

- Tire inflation guns

- Mini ratchets

- Car jacks

- Spray guns

- Tools miscellaneous

- Technical hair dryers

- Tool sets

- Body work

- Stripping wires, crimping terminals

- Extractors, Nut Cutters, Hairpin Drivers

- Oil filter pullers

- Universal pullers

- Oilers, plunger syringes

- Impact and reinforced screwdrivers

- Hub pullers and wrenches

- Ties, cables

- Milling cutters for cylinder head modification

- Honing the cylinder

- Working with interior trim

- Retaining Ring Pullers

- Metal brushes

- Lada Granta

- Tuning for hunting and fishing

Shipping reports We accept

The group contains 68 / 68 positions

by popularity

by price

Purpose, device, malfunctions

Fuel savings and tighter emissions regulations are spurring engine manufacturers to take a fresh look at the car's main driving force: the piston. New piston designs with reduced weight, improved strength, and durability are being developed and introduced. Until recently, the piston remained a relatively low-tech component. Now, with the help of computer simulation analysis, piston manufacturers are developing and tuning pistons for specific engines, creating new designs in record time.

The piston withstands large explosive loads by transmitting reciprocating motion through the connecting rod and crankshaft to the wheels. Piston strength is one of its key characteristics, remaining unchanged in difficult racing conditions or tens of thousands of kilometers on the track. Whatever the engine - V6 or V8, turbocharged or diesel - the piston must withstand the load and ignition temperature of the air-fuel mixture. This, in turn, depends on the composition of the alloys from which the piston is made. Yesterday's cast iron pistons can no longer compete with their new high-tech counterparts.

Forged pistons have been around since the 1950s, when they were used as pistons in many engines during the heyday of automotive manufacturing. Today, forged pistons dominate professional racing. They are also widely used in aircraft, marine, heavy truck, diesel and agricultural engines due to their high reliability. Conventional cast pistons are made by pouring molten aluminum into a specific mold. The cooled metal is machined to the required size.

Most cast pistons undergo a heat treatment, which involves heating (a process called "aging") to relieve stress in the metal. Piston design today is not as simple as it once was. Increasing the amount of fuel supplied to the cylinder requires changing the shape of the piston top cup. Modern pistons are designed as special piston configurations with a unique dome shape to optimize the combustion process, and have recesses at the top to swirl the fuel mixture and direct it towards the spark plug, inducing a vortex when the piston is on the compression stroke.

Other manufacturers create a recessed cavity directly under the spark plug to concentrate the fuel mixture and speed up the combustion of the unburnt fuel, exposing it to greater temperatures, reducing the risk of detonation. All parts of the design can be changed, affecting the compression ratio, the size of the holes, piston rings and piston pin, up to changing the piston height and skirt length. A short piston skirt means less weight. Another way to reduce weight is to reduce the compression height.

Review of basic Lada Granta engines

Over the entire production period of the Lada Grant, the car was equipped with gasoline engines of the following modifications:

The engine of each type is a prototype of the earlier 1.5-liter version 2111. Improved designs with the “old” cylinder diameter of 82 mm by increasing the piston stroke to 75.6 mm turned out to be more powerful and productive.

The design of all types of power units is quite similar. Newer 16-valve modifications of the VAZ 21126 and VAZ 21127 engines provide good power indicators in comparison with the previous installed models. This result was achieved by investing 39% of the piston group.

Lada Granta Sport engine: main technical characteristics

The stylish, domestically produced sports car Lada Granta Sport is assembled by the AvtoVAZ subsidiary TMS-Sport. It is this version of a truly sports car that has been put into mass production and is one of the ten best representatives of its class.

The Lada Granta Sport is equipped with a modified 16-valve VAZ 21126 power unit. Among the modifications to the sport version, it is worth noting the installation of turbines, the operation of which reduced the acceleration of the car by 7 seconds to a speed of 100 km. At the same time, engine power increased to 200 hp. The turbocharging system creates pressure up to 1.2 atmospheres.

The power unit is equipped with a five-speed sequential gearbox with a cermet clutch. The engine is installed without tilting on five supports.

A specially prepared sports Lada Granta with a turbocharger was a participant in the World Championship in road racing for passenger cars WTCC in 2013. The following year, 2014, the turbine was installed on a 2-liter engine, which gave power up to 380 hp. This is what gave the Lada Granta Sport an advantage during the competition driven by Robert Huff, where the Lada Sport team received first place.