Electric fuel pump

In passenger cars with injection engines, electric fuel pumps are used. They are installed inside the fuel tank. Some brands of cars have two fuel pumps. The VAZ 2110 electric fuel pump first performs work under low pressure when the engine is running at high speeds, and the second under high pressure at low speeds. This article will describe not only the fuel pump itself, but also the entire electrical circuit for connecting the VAZ 2110 fuel pump.

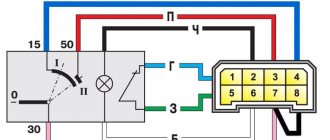

VAZ 2110 fuel pump diagram

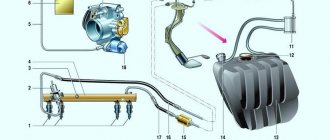

The electric fuel pump 2110 is a fairly simple device - the unit is an electric motor, which is supplied with a voltage of 12 V. The fuel pump is installed in a housing, and a mesh is installed at its inlet - a coarse filter. The filter element prevents dirt particles from entering the pump housing, which prevents clogging of the device.

The VAZ BN connection diagram includes the following elements:

- The engine control unit.

- Ignition.

- Wiring.

- Relay.

- Fuse.

VAZ 2110, produced before 2000, were equipped with mechanical fuel pumps.

It consists of the following parts:

- Metal body.

- Return spring.

- Top cover.

- Two valves.

- Diaphragm pusher.

Fuel is pumped from the tank by oscillating the diaphragm and opening and closing valves. The diaphragm with a pusher is driven by the camshaft eccentric, and the manual pumping lever is located on the lower casing of the fuel pump.

If everything has been checked, but the fuel pump does not work - article numbers

In general, the pump article number for VAZ-2112 engines looks like this: 21102-1139009-XX. Instead of the letters XX there are numbers, for example 02 or 03. They indicate the manufacturer. So, modules from different factories are not interchangeable! The resistance of the FLS resistor is different in them. However, when replacing the FLS sensor, you can borrow it from the “old” module. That's what they usually do.

Until April 2002, article numbers of the type 2112-1139009 were used.

Almost every module available for purchase contains a built-in pressure regulator. There are also exceptions - KSZC-A243, for example. The meaning is as follows:

- All internal combustion engines with a volume of 1.5 liters are equipped with a ramp with an “external” regulator (2112-1160010);

- The 21124 or 21114 motor requires a built-in regulator.

In conjunction with 1.5 liter engines, you can use any module – both with and without a built-in regulator.

Designations of analogues

- 21102-062213.0XX – instead of the letters XX there will be a plant designation (07, 13, etc.);

- KSZC-A233 or A243 – KSZC brand. No pressure regulator .

VAZ 2110 does not pump the fuel pump, reasons

First, let's look at breakdowns of mechanical refueling. All parts of a car engine are subject to aging and wear, and the life of a mechanical fuel pump also ages over time.

The main malfunctions in the operation of a mechanical device include:

- Valve fault.

- Diaphragm rupture.

- Shell deformation.

If the diaphragm is leaking air, the fuel pump may stop delivering fuel to the carburetor, or gasoline may pass through the ruptured diaphragm into the crankcase, where it mixes with the engine oil. When fuel gets into the oil, fuel consumption increases sharply and the engine begins to have difficulty starting, especially when warm. Checking the presence of fuel in the crankcase is quite simple - if you light the oil dipstick with a lighter, a fire will start. In addition, the sump will smell like fuel.

A common malfunction of mechanical fuel pumps is deformation of the mounting surface of the oil cylinder to the auxiliary housing. If the surface is deformed, engine oil begins to flow out at the meeting point of the planes.

Now about the electric fuel pump.

If it stops working, there may be several reasons for the failure:

- The fuel pump motor burned out.

- The relay has stopped working.

- The fuse has blown.

- Faulty electrical wiring.

- Engine control unit malfunction.

Signs of a fuel pump malfunction

Using these signs, you can determine that the fuel pump is not pumping.

- The most common sign of a faulty fuel pump is that the car drives intermittently. While driving, the car begins to sharply slow down and then accelerate. Uniform movement of the vehicle is ensured by a continuous supply of fuel.

- The second most common symptom is floating engine speed at idle. This way you can determine if the fuel pump is faulty before you start driving.

- The engine starts with difficulty or does not start at all. Quite often this happens because the fuel pump has completely failed. The symptom is not the most common, since the reason that the engine does not start may lie in a variety of malfunctions.

- The car's dynamics deteriorate. When you press the gas pedal all the way to the floor, the car jerks or does not respond at all to moving the pedal. In this case, the fault may lie not in the pedal, but in the fuel pump.

Do not forget that all the signs listed above are not one hundred percent. Such malfunctions can be caused by failure of various other engine parts. The engine speed may well fluctuate due to a malfunction of the mass air flow sensor or throttle position sensor.

Such malfunctions most often occur due to low quality fuel or uncleaned injectors.

Where are the fuel pump relay and fuse located?

The relay in every electrical circuit is designed to open and close the circuit; its primary role is to protect the elements of the electrical circuit from high inrush current. When starting the engine, the current required to turn the starter is 80-300 amperes, and if the relay is not installed, any element of the electrical circuit may fail.

On “tens” the fuel pump relay is standard, the plastic case has an electromagnetic coil and core, after applying voltage as a result of exposure to an electromagnetic field, the contacts close. On the VAZ 2110 the relay is four-wire and rated for a current of 30 A.

The fuel pump relay on the VAZ 2110 (injector) is located inside the car, under the instrument panel, near the center console. After removing the plastic protective cover, the relay responsible for the operation of the fuel pump will be in the center of three elements located in this place (in the figure, numbered 5). To the left of the relay is the fuel pump fuse.

What is a relay for?

Above we talked about the microcontroller system. It is worth noting that the output of the ECU does not allow direct connection of a powerful load. And the fuel pump, which is based on a DC motor, has quite a lot of power. And when it is turned on, a significant current consumption occurs. But if you turn on the VAZ 2110 fuel pump relay coil from the control unit, the injector will continue to operate in the same mode, and no excess current consumption will be observed.

Therefore, we conclude: a relay is a buffer cascade between the electronic control unit and the current consumer. However, most relays have precisely this purpose - they allow a very weak current to flow in the control circuit. In this case, the entire electrical system of the car is divided into two parts:

- Low-current control circuits.

- Power cables (connecting optics, fluid and fuel pumps, power windows).

The VAZ 2110 fuel pump relay is located on the right side, opposite the front passenger seat. There is an additional block designed for installing some elements of electrical equipment. It is quite possible that such a simple solution was caused by the reluctance of the designers to use other fuse blocks that would be very different from those installed on carburetor engines.

How to check and replace the fuel pump relay

If the electric fuel pump does not show signs of life after turning on the ignition, this does not mean that it has burned out. The cause of failure may also be the “relay”. The easiest way to test the pump relay through your ear is to hear a clicking sound when you turn on the ignition. If you don't hear a click, the relay is probably bad.

However, not everything is so simple - the breakdown can be “complex”, for example, the car does not start the first time. The cause of the malfunction may be burnt out relay contacts.

In this case, checking the operation of the pump is very simple:

- Remove the protective cover covering the fuse and relay box.

- Unscrew the fuse box and remove it, it will remain attached to the wires.

- Remove the relay from the block and place a jumper between the 2 opposite contacts, this will power the fuel pump directly.

- If, with this connection, the pump motor begins to make noise, then the pump itself is probably working and the problem is in the relay. In this case, the relay must be replaced.

how to connect the fuel pump directly

help, good people...it's a frosty morning, the starter is turning, the fuel pump is silent...nowhere to warm it up, visiting in Zhopodrischensk...the block for the fuel pump has six wires, where does it connect?...subaru impreza wrx 2001.

According to the cross-section of wires. The fuel pump is the thickest. Try charging directly. If it does not start, tap the pump assembly with a mallet (wooden piece) without removing it from the tank.

the relay does not work, either the relay or the signal is frozen

You can not touch the pump at all, but create a pressure of 2-2.5 atm inside the gas tank (no more - the tank inflates), I didn’t have a Subaru, but Toyotas with a non-working pump were revived in this way, you can drive home. You will need a second person, you give him an electric pump to inflate the tires, you connect this pump to a thin return hose or something else, there is always one thin hose coming from the gas tank, at worst you will have to ruin the gas tank cap - drill a hole in it and insert it there nipple for inflating tires. In general, the partner connects to the gas tank and uses a pressure gauge to pump up the pressure there to 2 -2.5 atm - the car starts to start, well, the rest depends on the well-coordinated work of the carrier and the pump, the main thing is not to overinflate!

It’s easier to put 10s from a basin, it costs a ruble and you can find it in any “Zhopodrischinsk”.

Message from

KATRANYou can not touch the pump at all, but create a pressure of 2-2.5 atm inside the gas tank (no more - the tank inflates), I didn’t have a Subaru, but Toyotas with a non-working pump were revived in this way, you can drive home. You will need a second person, you give him an electric pump to inflate the tires, you connect this pump to a thin return hose or something else, there is always one thin hose coming from the gas tank, at worst you will have to ruin the gas tank cap - drill a hole in it and insert it there nipple for inflating tires. In general, the partner connects to the gas tank and uses a pressure gauge to pump up the pressure there to 2 -2.5 atm - the car starts to start, well, the rest depends on the well-coordinated work of the carrier and the pump, the main thing is not to overinflate!

Excess from the tank will go through the absorber, kmk.

thank you everyone for your participation... everything was decided much easier - I threw the fan heater into the cabin through an extension cord and went to drink, by the way, HAPPY NEW YEAR EVERYONE... the next morning it started up with half a click

Your rights

- You cannot create new topics

- You cannot reply to topics

- You cannot attach attachments

- You can not edit your posts

Forum Rules

Coarse and fine fuel filters: where they are, when and how to change them

Russian gasoline is not always of the same quality, so over time, sediment accumulates in the tank due to low-quality fuel. Dirt also clogs the sieve of the electric fuel pump; as a result of accumulated dirt, fuel does not completely enter the fuel line and the engine fails. To fix the problem, you need to replace or clean the coarse filter. However, to get to the filter, you need to disassemble the fuel pump.

The fuel system must be relieved of pressure before disassembling, otherwise fuel may leak into the vehicle when disassembling the fuel line fittings. To relieve pressure, remove the fuel pump fuse, start the engine and wait until it goes out. Replacing the fuel pump sieve with a “ten” (nozzle) is done as follows:

- Turn off the ignition.

- In the rear, locate the hinges and pull them to fold the lower seats forward (right and left).

- There are two bolts under the seat on the underside that hold the hatch in place.

- Unscrew the bolts and remove the hatch.

- Disconnect the wire connector that supplies power to the electric fuel pump by opening the latch and pulling part of the connector away from you.

- We unscrew the fuel line connectors - main supply and “return” (17mm wrench).

- Unscrew the nuts of the fuel pump pressure plate, there are 8 bolts (at 7mm).

- Since the nuts are small, it is better to put them in a jar, otherwise you can lose them. Remove the plate and remove the pump assembly from the fuel tank. The pump must be removed with the sealing ring; lift the pump carefully so as not to damage the fuel level sensor. When removing the housing, tilt the fuel pump so that it comes out of the tank.

- We remove the screen from the fuel pump and install a new part.

- Install the fuel pump.

Electrical circuit design of VAZ 2115

The VAZ wiring diagram is a single-wire circuit, which supplies the positive pole from the battery to the remaining elements of the circuit, and the negative pole is the housing.

The electrical circuit of the VAZ is protected from current surges in the form of fuses with fuse links. They were placed under the hood.

Fuses provide reliable protection for such expensive equipment as:

- the circuit in which the ignition switch is included;

- battery charging circuit;

- generator circuit and starter.

No power to fuel pump 2110, how to check and fix

The wiring goes to the BN in the amount of three wires: fuel level sensor, minus and plus. The reason why the fuel pump does not pump may simply be a lack of power. To check the power supply to the fuel pump, you need to take a 12V light bulb and connect its wires to the negative and positive terminals on the external BN connector. After turning the key in the ignition switch, the warning lamp should light up. If this is not the case, the problem is in the external circuits. To do this, connect the negative and positive contacts removed from the HD connector alternately to the ground of the fuel pump, and then to the relay.

If the negative contact is on the ground, the ignition is on and the light is blinking, the contact does not work, the light does not blink, then the positive contact is not working. If the contact on the relay and the light is on, the wiring harness is damaged. in the section from the BN to the relay.

Lada 2107 Seed › Logbook › Installing a fuel pump on a VAZ 2107 or a smooth transition to an injector.

The other day I looked into the garage and, frustrated by the lack of time, decided to install a fuel pump. The staff one was being tricky even with the new one and I was tired of it. Therefore, after browsing the market, I settled on a universal fuel pump from Ali Express and a fuel pressure regulator from the same site. The fuel pump is installed immediately after the tank, and then a new fuel line goes through the cabin and exits next to the standard pipe. Next comes the standard filter and the fuel enters the carburetor through the hose. From the carburetor, fuel moves through a hose into the standard fuel line, and from there, at the outlet, it enters the fuel pressure regulator and through it into the tank. The fuel pressure regulator allows us to adjust the pressure we need, but in our case we don’t need the pressure. Therefore, I adjusted the regulator so that the fuel had a slight boost. The pump’s job is to supply sufficient fuel to the carburetor, but if we have pressure, then when the level in the float chamber rises, the needle simply will not close. Thus, if everything is set up correctly, then when the level in the float chamber rises, the needle is locked and the fuel simply circulates from the tank to the carburetor and back. And as soon as the level drops, a new portion of fuel immediately enters the carburetor. The advantages of such a modification are the absence of problems with a lack of fuel in hot weather and the advantage is the ability to use this fuel system to install an injection engine. I used this diagram to connect the electrical circuit.

I decided to run a separate minus wire to the battery. Therefore, from the fuse and relay connected to the fuel pump, I sent 3 wires to the engine panel. 2 wires + and - to power the fuel pump and 1 more to control on and off, which is connected to the ignition coil to terminal B, or in my case to terminal 15 since I have a coil from a BMW 5 series.

Source

Why does the fuel pump on the VAZ 2110 not work?

The fuel pump on the VAZ-2110 is submersible and is installed in the gas tank located under the body, near the rear seat. When the ignition is turned on, the driver should hear the sound of his work, because at this time the pressure in the fuel supply line, the engine power system, increases. Its operation involves an electronic unit, a fuel pump relay and a fuse that protects the circuit from overload.

If, after turning the ignition key to the “on” position, you do not hear a short sound of the fuel pump, the car engine will not start. Finding the cause of this malfunction should begin by checking the fuse. You should look for it not in the mounting block, but in the interior of the car. To do this, unscrew several screws on the right side of the front console on the passenger side and remove the plastic cover. You will then see three relays in front of you and three fuses.

In the center of this row there will be a fuel pump relay, and to the left of it there will be a fuse that protects the electrical circuits of the fuel pump and injectors. Remove it and check the integrity, at the same time check the contacts on which it is located. If they have oxidized, they should be cleaned. If the fuse is intact or intact, replace the fuel pump relay with a known good one or ask other drivers for a new one.

If even in this case the fuel pump does not work, it will have to be checked for functionality. To access it, remove the rear seat cushion. Underneath you can see a hatch with a metal cover, the screws securing the hatch are unscrewed and in the opening you can see the upper part of the tank on which the fuel pump is installed.

Disconnect the wiring harness and try to power the fuel pump directly from the battery. If it works, then the fault must be in the wiring from the fuel pump or electronic control unit (ECU).

If our car has an alarm system that has the function of turning off the fuel pump, the positive power wire of the fuel pump is cut, and in its place an additional relay is installed, which, if the car is broken into, should turn off the fuel pump, due to which the engine will stall and not restart. In this case, this relay should also be checked.

If actions to eliminate this malfunction do not bring results, you will need to go to a service station to see diagnosticians, since self-testing of the electronic control unit is unlikely.

Ground contact

Problems with the fuel pump ground can be indicated by an incorrectly indicating fuel level sensor. Poorly secured ground can cause the fuel pump to stop pumping fuel. The ground wire is located under the dashboard and runs through the entire interior of the car. You need to find it, clean the contacts and secure it properly to the fuel pump.

Next to the ground, under the dashboard, there is a fuel pump relay. After turning on the ignition, the operating relay allows the pump to create the required pressure in the system in a few seconds, after which it turns off. When you turn the key in the ignition, you can hear a soft click, which means that the fuel pump relay is turned on, and exactly the same when it is turned off. If the relay does not make a click, then the problem is in it or in its contacts. Then it is advisable to replace it with a new one.

When looking for the cause of a non-working fuel pump, you need to check the fuse. It is located under the hood and has a resistance of 15 A. It must be carefully inspected; if it is not working, it should be replaced with a new one. The fuel pump in the VAZ-2110 car is immersed in gasoline for active cooling, and the bad habit of driving a car with a minimum amount of gasoline in the tank can very soon cause the fuel pump motor to become inoperative due to burning.

Topic: Fuel pump does not work after turning on the ignition

One day in the morning my car (VAZ 21099) 1997 (injection filling from a VAZ2110) did not start. Generally speaking, the fuel pump did not work after turning the ignition switch. On the advice of friends, I changed the fuel pump (they thought it had burned out). Again it did not it started. I turned to an electrician, he rang all the wiring and said that all the positive and negative terminals that go to the ECU and come from it are fine, the fault is only in the ECU. I took it to the diagnostics and tried to check it through the connector, but there was no answer. Tell me what I need what to do and where to change it so that my machine comes to life.

2 Reply from Admin 2013-06-20 13:54:05

- Admin

- Administrator

- Inactive

- Registration: 2012-02-20

- Messages: 3,257 Thanks : 622

Re: Fuel pump does not work after turning on the ignition

If the fuel pump does not turn on, they usually start by checking the fuses and relays. https://xn--2111-43da1a8c.xn--p1ai/sprav ... -2110.html At a minimum, the fuel pump relay should have been checked. And then they look towards the fuel pump itself.

3 Reply from Maxim 2013-06-20 17:13:36

- Maxim

- Local

- Inactive

- From: Arkhangelsk region. Velsk

- Registration: 2012-03-16

- Messages: 472 Thanks : 229

- Car: VAZ 21124

Re: Fuel pump does not work after turning on the ignition

Admin is right, first the wires, relays and fuses. If, when connecting diagnostics and turning on the ignition, the scanner does not find the ECU, there are 2 options: 1. The ECU fuse has blown 2. The ECU itself has died. But this is with confidence that the wires are from diagnostics. The pads to the ECU are intact.

4 Reply from pam3ec 2013-06-21 05:53:03

Re: Fuel pump does not work after turning on the ignition

everything is checked. all the pros and cons fit as expected. all the wiring is fully connected, all the switches are working, in general, everything that cools and comes out of the ECU is normal. How can I restore the computer? Because moving to another block is a real hassle.

5 Reply from Admin 2013-06-21 06:18:09

- Admin

- Administrator

- Inactive

- Registration: 2012-02-20

- Messages: 3,257 Thanks : 622

Re: Fuel pump does not work after turning on the ignition

pam3ec . maybe try to reflash it first? changing is a last resort

- igorek

- Brother-in-law

- Inactive

- From: Bryansk region g Starodub

- Registration: 2013-05-05

- Messages: 415 Thanks : 191

- Car: VAZ-21102 1.5i-8V Bosch MP7.0H

Re: Fuel pump does not work after turning on the ignition

One day in the morning my car (VAZ 21099) 1997 (injection filling from a VAZ2110) did not start. Generally speaking, the fuel pump did not work after turning the ignition switch. On the advice of friends, I changed the fuel pump (they thought it had burned out). Again it did not it started. I turned to an electrician, he rang all the wiring and said that all the positive and negative terminals that go to the ECU and come from it are fine, the fault is only in the ECU. I took it to the diagnostics and tried to check it through the connector, but there was no answer. Tell me what I need what to do and where to change it so that my machine comes to life.

So in the evening you arrived normally, but in the morning your car didn’t start anymore. What brand of ecu? Try Powering the fuel pump Forcefully through the diagnostic block should turn on the fact that I once had a similar current, I dropped the pressure in the mains when I changed the grid of the gasoline pump and my pump no longer turned on I had to forcefully power it up when the pressure increased and the manufacturer began to say that it was in the ramp and the pump turned on with the delay after starting the engine, the fault was that the phase of the crankshaft pulley was knocked out; the pulley was replaced; the fuel pump began to turn on without fail, but strictly three times Bosch MP7, if the engine did not start, it will turn on the fuel pump 3 times and you shouldn’t blame the fuel pump motor itself and the ECU by feeding the fuel pump through the de-diagnostic block you bypass the relay, that is, turn it on in the primer in the Bosch MP7, the minus control plus goes to the relay permanently, therefore the relay is on the mainframe, so you should be happy to start it on the primer like a gasoline pump, turn it on for 3-4 seconds, and then drive the key to start as the manager, disable the forced activation of the controller itself it will turn on, if it doesn’t turn on, it will stall, then you can safely blame your brains or the relay if the computer controller doesn’t see it through the deognastic block, most likely there is no signal via the K Line, your car is 97, but it’s unlikely that you have an immobilizer, but the plug should be, find a black block, jumper in it, contact 9 and 18, you will connect the circuit in this way. To the line to the diagnostic block, the computer should see your computer

If you want to help a hungry person, don't give him fish, give him a fishing rod.

13 Reply from vasiliy.bondar.87 2013-06-24 10:40:30

Re: Fuel pump does not work after turning on the ignition

If there is a security system, then take off your beard and look for a break in the positive side of the fuel pump. They put a relay there that, in the event of a break-in, turns off the fuel pump. connect this plus directly, if it ends, throw out the guard

Thanks said: Admin 1

14 Reply from pam3ec 2013-06-24 16:32:59

Re: Fuel pump does not work after turning on the ignition

I have a January -4 ECU, thanks for the advice, I’ll try one of these days, if it works, I’ll post it

15 Reply from Oscolok100 2013-07-10 11:17:24

- Oscolok100

- New member

- Inactive

- Registration: 2013-07-10

- Messages: 8 Thanks : 4

- Car: Lada 111

Re: Fuel pump does not work after turning on the ignition

I have a January -4 ECU, thanks for the advice, I’ll try one of these days, if it works, I’ll post it

Rarity. Maybe you should think about converting to Ya 5.1?

16 Reply from stake97 2016-12-13 14:24:52

Re: Fuel pump does not work after turning on the ignition

My fuel pump also stopped working once in the morning (VAZ 21099, Motor 2111). My problem was the following: There was a bad contact on the “positive” terminal of the battery . The wire that supplies power to the ECU almost fell off. When I turned on the ignition, the pump was completely silent, and the relays did not click. We replaced the “mother” and everything worked as it should.

Thanks said: Admin 1

17 Reply from krasnopolskaya.y 2016-12-19 21:07:49

Re: Fuel pump does not work after turning on the ignition

if the check does not light up, it means the brains, if the light is on, the problem is not in them

Problems with the operation of the VAZ 2110 fuel pump

Every motorist wants to be confident in the reliability of the components of his car, one of which is the VAZ 2110 fuel pump. By delving into the possible causes and ways to eliminate its errors, you can avoid unplanned cash costs and a waste of time. Diagnosing a faulty fuel pump and repairing it is simple.

Purpose of the fuel pump, characteristics and possible breakdowns

The fuel pump is designed for uninterrupted supply of gasoline to the internal combustion engine (ICE) of a car. Since, depending on the gasoline supply system, cars are divided into carburetor and injection, respectively, the VAZ 2110 pump comes in two types: mechanical and electric. The mechanical fuel pump is unpretentious, repairable and does not cause problems in operation, but currently does not meet the parameters of environmental friendliness and performance.

The current requirements are met by an injection injector, which helps to implement the VAZ electric fuel pump. It supplies gasoline to the internal combustion engine through high-pressure injectors, which facilitates fuel metering, reduces wear and increases engine power. The main characteristic is the pressure of the fuel pump, which can range from 4 to 7 atm.

Due to pressure fluctuations or lack thereof, the car engine is unstable, does not start and causes problems at the most inopportune moment. At the same time, by showing self-control and using the recommendations presented here for repairing a VAZ fuel pump, you can correct the situation in a short time.

The main symptoms of a malfunction of the VAZ 2110 fuel pump are as follows.

- There is no roar of rotation of the fuel pump (it is located in the fuel tank under the rear seat) at the initial moment of starting the engine (the key is in the ignition position). The reason may be the failure of the VAZ fuel pump itself, loss of power on it.

- Unusual operating noise may be caused by an empty fuel tank or a severely clogged fuel filter.

- Low power of an internal combustion engine (operation only in 1st or 2nd gear) is typical for a fuel pump used by more than 90,000 people. km. Due to real operating conditions, the service life of the VAZ pump is reduced, which is manifested by a decrease in pressure.

- A jerking car means that the pressure in the fuel pump system is changing, usually due to a clogged filter.

After determining the type of fuel pump problem, it makes sense to find the cause to fix the problem.

How to ensure an uninterrupted supply of gasoline

A car with a carburetor always uses a mechanical fuel pump, while an engine with fuel injectors always uses an electric fuel pump. Pressure drop: the injector creates a lot of pressure in the fuel system, this is not necessary for the carburetor.

How does a mechanical fuel pump work?

The operating principle of a mechanical fuel pump is quite simple. The fuel pump pusher constantly moves back and forth, but the diaphragm moves to the lower plane only when it is necessary to fill the chamber with fuel. The return spring moves the diaphragm to the up position and fuel is supplied to the carburetor.

The mechanical pump consists of the following parts:

- fuel chamber;

- inlet and outlet valve;

- diaphragm;

- return spring;

- pusher and camshaft.

Since carburetor engines are becoming less and less common, the principle of an electric fuel pump is much more interesting. Moreover, it is installed on all engines with injectors.

Electric fuel pump operation

The principle of its operation is in many ways similar to mechanical. It is based on a solenoid valve that retracts a diaphragm until a pulse is sent to a group of contacts, causing the circuit to open and apply voltage. The valve opens the chamber; after the voltage is removed, the valve closes the access of fuel.

The electric fuel pump consists of the following components:

- chamberfuel;

- inlet and outlet solenoid valve;

- diaphragm with return spring;

- fine filter;

- contact Group.

In general, the mechanism of a conventional fuel pump is equipped with electrical devices. If the mechanical pump is located under the hood, look under the rear passenger seat for the electric fuel pump.

Selecting a fuel pump

The pump power in an engine with injectors must be at least 7 atmospheres. It is better to choose from a range of imported models. A high-quality product not only serves without complaints for many years, but also extends the life of the engine. At the outlet of the injectors, the quality of the fuel-air mixture increases.

Bosch products are a great example of such a device. They can be distinguished by their significantly longer length, and sometimes by a different arrangement of contacts. Therefore, in order to avoid reworking and adjusting the device in standard places, it is recommended to go to the store with the faulty pump removed.

The main thing is not to buy fakes. The original Bosch fuel pump is packaged in a sealed container filled with purified gasoline. There should be no smell of gasoline from the packaging. If so, the seal is already broken and corrosion may have begun.

Features and replacement rules

If you follow the instructions, the process won't take long. The procedure is as follows:

- disconnect the negative terminal from the battery and thereby disconnect the voltage from the on-board network;

- Tilt the rear seat back and locate the fuel pump cap;

- Open the cover by unscrewing the screws, then disconnect all connectors;

- loosen the fuel hose clamp (there is no need to remove it completely);

- unscrew the fuel hoses;

- remove the gaskets (replace if possible);

- unscrew the fuel pump mounting bolts and remove the ring;

- Remove the pump from the fuel tank and replace it with a new one.

Assembly is carried out in the reverse order of disassembly. A faulty pump is rarely repaired, since after eliminating one fault another may appear. Therefore, it is recommended to immediately replace the device; besides, prices in stores are not very high. With proper practice, replacing the fuel pump will take no more than half an hour. All activities must be carried out strictly according to the instructions and not engage in amateurism. Otherwise, you may lose the device due to a breakdown, or you will have to turn to car service specialists for help, and this also costs money.

Diagnostics

A malfunction of the VAZ 2114/2115 fuel pump can be caused by:

- malfunctions in the device’s power supply circuit;

- failure of starting and protection elements (relay and fuse);

- wear of electric motor parts.

Checking the electrical circuit

At the beginning of the diagnosis, you should check the electrical circuit of the fuel pump. To do this you will need:

- car tester (multimeter);

- crosshead screwdriver;

- two pieces of wire about 2 m long.

Checking the electrical circuit is carried out in the following order:

- Turn on the ignition without starting the engine. When the key is in the first position, a click should be heard, characteristic of turning on the relay, followed by a slight whirring of the pump electric motor. If there is no click, the relay is faulty or is not receiving power. If there is a click, but no buzzing, the wiring coming from the relay or the pump motor itself is faulty.

- Under the glove compartment, find an additional mounting block consisting of three relays and three fuses. The pump relay is located in the middle, and the fuse is located to the left of it. Remove the fuse from its socket, test it with a multimeter, and if the result is negative, replace it. When replacing the fuse, please note that it is rated for a maximum of 15 A.

Troubleshooting, simple tips for reliable operation of the fuel pump

- If the VAZ fuel pump does not spin, first of all you need to check the serviceability of the fuses and relays by replacing these parts. They are located behind the console panel on the lower front passenger side. If their condition is satisfactory, to check their operation, the supply voltage must be supplied directly to the fuel pump. To do this, remove the rear seat cushion and open the cover secured with screws. It should be remembered that if the alarm is installed, the power supply to the VAZ pump will have an additional shutdown relay during run-in. If the fuel pump does not respond to voltage or you need to check and replace the filter, follow these steps to remove the fuel pump from the fuel tank. To relieve pressure in the fuel lines, turn off the fuel pump with the fuse and start the car. After stopping the engine, open the gas tank at the filler neck to relieve gasoline vapor pressure, disconnect the negative clamp from the battery (to prevent fire), disconnect the electrical connector from the pump mounting flange on the gas tank, and disconnect the gasoline hose. connections (it is necessary to replace the gas-tight rubber ring on the trunk), unscrew the flange (8 7 mm hex nuts), remove the rubber gasket and remove the VAZ fuel pump complete with a float and a strainer (pre-covered with a cloth nearby so as not to contaminate the interior with gasoline). Pump filter main points of its effective operation:

- Driving a car with an empty fuel tank is an extreme challenge for the gas pump, and in the long run it costs much more than simply filling up;

- The gasoline pump “does not like” suspicious gasoline, which also leads to frequent replacement of the filter and pump;

- When replacing a VAZ 2110 fuel pump, preference can be given to imported analogues, which have higher pressure and whose operation is more stable.

- To feel like you own a car means to take care of it like a family member. In this case it will last a long time. And every trip will be counted as gratitude to the owner for his care.

- Domestic cars have a significant advantage: spare parts and consumables are cheap. In addition, everything is structurally very simple. That's why our cars are easy to repair yourself. However, if you are a beginner and have never serviced or repaired equipment before, you should not gain experience in the industry by replacing a gas pump. To start getting acquainted with an independent car service, it is better to choose simpler tasks. If you dare to replace the fuel pump with your own hands, then you need to remember that the mechanism is installed in the fuel tank strictly so that the indicator arrow points towards the rear of the car. After completion, it is recommended to measure the pressure in the fuel system and make sure there are no leaks.

Malfunctions and repairs

Since the fuel pump module is a part that works constantly, providing a given level of pressure in the fuel line, it is very susceptible to various malfunctions. Therefore, we can highlight the most common breakdowns that require replacing the module assembly or a separate pump:

No pressure in the system is the most common problem that is associated with problems with the pump. This indicates that the roller mechanism has worked, there are scuff marks on it, a backlash has formed and the gasoline is being bleed back out. That is, in fact, the motor turns idle. Cannot be repaired; replacement is required.

Break in windings or brushes . Despite the fact that it is immersed in fuel, the engine is equipped with a brush device that wears out over time. By this point, the pump unit usually wears out, so replacing it with a new one solves everything.

Klin . Often the device jams for the same reason - clogging with large particles that have penetrated through a torn or homemade mesh. The filter is removable, so it is recommended to change it more often.

The entire pump module is replaced in the assembly if the fuel level, which is implemented using a resistive plate and a sliding contact, does not work.

You can buy an original pump for VAZ 21073 with delivery and warranty in our online store. Make a purchase using the form or call us by phone.

Source