What should the fuel rail pressure be?

Unlike the internal combustion engine cycle of a Diesel with a Common Rail injection system, in the fuel rail of a gasoline engine with distributor injection the pressure on the valves rarely exceeds 5 Atm. A working fuel pump is capable of delivering up to 7 Atm., but the RTD will dump excess gasoline back into the tank.

Fuel pressure gauge

On this page we will consider such an interesting topic as measuring fuel pressure with your own hands using a homemade device. There will also be a verification video at the end.

I will not describe the theory for a long time, since it was described in detail on the Fuel Pressure page.

I strongly recommend that you read that article in order to fully understand the essence of measuring fuel pressure.

In the "Murzilki" for repairing Chevrolet Lacetti they write that the fuel pressure in our car should be 2.8-3.2 bar. This information is reprinted by everyone and everything, without even thinking about the fact that they are engaged in outright deception. Because of this, to a large extent, the Internet is called a “cesspool.”

I have seen people, based on this information, seriously try to find out the reason for the high fuel pressure in their cars.

After reading the article about fuel pressure, I think you already understand that the fuel pressure on cars with a dead-end system should be 4 bar! That is, on a Chevrolet Lacetti it should also be 4 bars!

Important to remember

When you check the fuel pressure with the ignition on, note that after the ignition is turned off, the pressure in the rail drops to 0.7-1 atmosphere and remains at this level. If it drops to 0, the problem is in the fuel pressure regulator.

.

Try increasing the number of revolutions to 3000 - if the pressure gauge needle does not stay constant, but falls, this may mean that it is time to change the fuel pump

.

If the pressure builds up for a very long time or is lower than required, the fuel filter, fuel pump filter or fuel line may be clogged.

I hope you found it interesting and will take note of this. Subscribe to the channel and give it a thumbs up to see even more interesting articles on automotive topics in your feed every day.

Do-it-yourself fuel pressure measurement

Measuring fuel pressure is the first stage of diagnosis if the following symptoms are observed in your car:

- failures when starting off

- dips when pressing the accelerator pedal sharply

- Stalls when you press the accelerator pedal hard

- Unstable operation of a warm engine

- “light” spark plugs indicating a lean mixture

We will measure fuel pressure using a homemade and simple device called “Do it yourself”

To make it we need the following:

- fuel hose - 50 UAH/m. You should not use a non-fuel one, as it may not withstand a pressure of 4 bar and may not be gasoline-resistant.

- clamps 10-16 in the amount of four pieces - 16 UAH. for all

- quick-release double fuel fitting from VAZ 2110 - 30 UAH.

- cut-off fitting from an old fuel filter for injection cars - free

- pressure gauge - 60 UAH. It is advisable to purchase one with a measurement scale up to 6 bar. Considering that the pressure in our cars is 4 bar, you can get more accurate readings with such a pressure gauge.

- adapter from pressure gauge to hose with fitting - 15 UAH. It is necessary to connect the fuel hose to the pressure gauge. This stuff can be purchased at any plumbing store.

- Fum tape - 10 UAH. It is necessary to seal the connection between the pressure gauge and the adapter

That's all we need

Here is a pressure gauge with a scale up to 6 bar

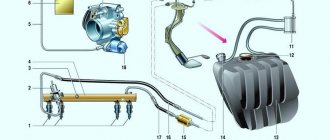

And here is the entire structure assembled. I think the photo shows what to connect to what. We connect the hose from the cut-off fitting of the fuel filter to the direct outlet of the quick-release fitting, and connect the hose from the pressure gauge to the side outlet. It's not a tricky thing and comes together pretty quickly

The next step is to relieve the pressure in the fuel line. To do this, remove the fuel pump fuse from the fuse box in the engine compartment.

How to measure

All you need is a pressure gauge, which is designed to measure tires. It just needs to be modified a little by changing the scale. It is better to measure the pressure in the injection system with a device scale showing a variation within 6-7 atm.

There are other, more advanced measuring instruments. A special tool kit with a pressure gauge, adapter and drain hose is sold at an auto parts store. Costs about 1.5 thousand rubles.

Pressure can be measured at any car service center. They will charge nothing for the service - 500-600 rubles.

Professional pressure gauge for measuring fuel

But whatever one may say, an experienced motorist should have his own pressure gauge among his tools. If it is purchased, then with it the driver receives all kinds of adapters that allow pressure measurements on a wide variety of car brands. In addition, commercial pressure gauges are equipped with a better scale that allows you to measure pressure more accurately. And a professional pressure gauge is generally a godsend, since it makes it possible, among other things, to relieve residual pressure in the system, which increases the accuracy of the readings.

If you decide, nevertheless, to use a homemade pressure gauge, then remember!

- It is better to use a regular air pressure gauge from VAZ, since it can also measure oil pressure (you just need to unscrew the fitting).

- Instead of an adapter, you can use a regular threaded fitting.

- It is important to use high-quality clamps so that there are no gaps.

How to take measurements.

- Most often they are carried out with the ignition on. It is necessary to check whether the arrow has jumped in comparison with the standard value.

- Measurements are also carried out in XX mode.

- Measurements are carried out with the “return” compressed and with the RTD reset.

How to measure pressure in the fuel rail?

In a modern gasoline engine, the combustible mixture is injected into the cylinders by injector nozzles at the command of the electronic control unit. Typically, diagnostics of the engine fuel supply circuit is carried out in a car service center, although the car enthusiast can determine obvious problems on his own. To find the cause of the malfunction, you need to check the pressure in the fuel rail and other points in the system.

In what cases is it necessary to check pressure?

The pressure in the fuel rail should be checked if certain problems arise with the fuel system. The main signs of a malfunction include the following factors:

- Increased fuel consumption;

- Unstable engine operation at idle speed;

- Engine tripping occurs;

- An increased CO content is observed in the exhaust gases.

Sometimes the problems listed above may indicate a problem with the electronic control unit. Therefore, before starting to check the pressure in the fuel rail, the driver is recommended to make sure that the ECU is working properly.

When should measurements be taken?

The operation of the power system is structured as follows:

- An electric fuel pump located in the tank pumps fuel along the line into the fuel rail and further to the injectors.

- The regulator limits the gasoline pressure at a certain level, releasing excess into the tank through the return pipeline.

- The injector mixes fuel with air, then the mixture is directed to the nozzles, which open at the command of the controller.

When the wear of the regulator (abbreviated as RTD), pump or injectors reaches a critical level, the pressure in the gasoline circuit will change towards a decrease or increase. There are 2 possible scenarios: there is not enough fuel mixture for normal engine operation, or there is an excess of it - the spark plugs are literally flooded with fuel.

In both cases, checking the pressure in the fuel rail located next to the cylinder head will help identify the problem. The element is a manifold with branches for injectors, to which the main gasoline line is connected.

The fuel pressure in the manifold should be measured if the following symptoms occur:

- the car accelerates poorly, after sharply pressing the accelerator pedal, jerking and deceleration are felt;

- the engine of a loaded car “does not pull” and starts poorly when cold;

- shots are periodically heard in the exhaust manifold;

- a warm engine does not start after a short period of parking (especially in summer); the starter needs to be turned for 20–40 seconds.

The first two signs indicate a clear lack of gasoline, resulting from a drop in pressure in the ramp. The third case is unburnt fuel entering the exhaust manifold with subsequent combustion (a popping sound is heard). The fourth symptom indicates leaking injectors when the cylinders are filled with pure gasoline during parking. Until the pistons release excess fuel, the engine will not start.

Preparing for measurements

We string a hose onto the inlet fitting of the pressure gauge and secure it with a clamp - we must avoid pressure losses during measurements.

Then you need to remove the cap from the fuel rail. There will be a nipple under it - remove that too. Be careful - if you recently started the car, there will be residual pressure in the fuel system and gasoline may spill out, so have a cloth ready and try to protect your eyes.

When you have removed the plug and nipple, install the second end of the hose that goes to the pressure gauge. We also fix everything with clamps.

Measuring devices

To check the pressure of the fuel pump with your own hands, you need to prepare a set of simple devices:

- a pressure gauge designed for a maximum pressure of 10 Bar (1 MPa), a suitable device for checking tires;

- gasoline hose with an internal diameter of 8 mm;

- a cap for unscrewing spool valves from wheel valves;

- clamping clamps 10–15 mm – 2 pcs.

To take measurements at other points in the fuel supply circuit, you will need homemade adapters to connect a gasoline hose with a pressure gauge. If the line is assembled with quick-release plastic connections, you need to buy one such clamp with a fitting. To connect to a threaded joint, purchase the appropriate tube with nuts and cut it into 2 parts.

Diagnostic instructions

The first step is to free access to the ramp and fitting installed at the end of the manifold. Remove elements that interfere with measurements - air duct, filter housing, crankcase ventilation pipe, etc. (the list of parts depends on the car model). Proceed to measuring, following the instructions:

- Unscrew the protective plastic cap from the diagnostic fitting on the ramp.

- Place a cut-off plastic container and use a cap to unscrew the spool valves to release the pressure previously pumped up by the pump. You can press the valve or turn the spool 2-3 turns.

- Place one end of the gasoline hose onto the pressure gauge fitting and secure with a clamp. Unscrew the spool from the manifold, pull the second end of the hose onto the pipe.

- Turn on the ignition, and the electric fuel pump will pump fuel into the system. Make sure there are no leaks at the joints of the diagnostic tool.

- Start the engine and record the fuel pressure in the rail using the pressure gauge.

Advice. It is better to take readings from the device twice - after turning on the ignition and starting the engine. If you notice a difference, you need to additionally check the regulator and fuel pump.

The pressure level in the fuel supply circuit depends on the design of the system. In cars where the RTD and the discharge tube - “return” - are located in the engine compartment, the pressure gauge should show 2.7 Bar. The upper and lower permissible limit is 2.7–3.0 Bar. If the measured values are outside the specified range, you should continue the diagnosis and find the cause of the problem.

On many cars, including VAZ, the pressure regulator and the fuel return hose are located next to the fuel pump. The normal manifold pressure for such machines is 3.8 Bar, the maximum value is 4 Bar.

If during the measurement process periodic pressure surges within 0.2 bar are observed, the primary strainer needs to be cleaned or replaced. Typically, it is installed in the gas tank along with an electric pump.

What about the injectors?

An alarm bell indicating that the entrance to the fuel rail will still have to be opened is detected even at the stage of diagnosing the fuel pressure regulator. At the moment the return line is compressed, the pressure rises slightly. It is also noteworthy that at this moment the injectors begin to actively overflow, causing the engine to operate unstably. The same thing is observed in a system without “return”, when the output from the RTD is muffled.

The final diagnosis is made based on measuring the pressure upstream of the ramp (the inlet chip/nut is disconnected and a pressure gauge is connected to it). In this case, we exclude clogging of the fuel line in the fuel pump-fuel rail section. If the pressure is restored to the passport 5-6 atmospheres, then the problem is with the injectors.

In conclusion, I would like to note that the pressure in the ramp is 2.5-2.7 atm. and 5-6 atm. at the pump outlet are diagnosed under different conditions: with the engine running and in ignition mode, respectively.

Checking individual elements

When measuring the pressure in the fuel rail shows a deviation from the norm, the following reasons must be considered:

- the electric fuel pump is unable to develop the required performance;

- the regulator has failed, causing the gasoline pressure in the circuit to decrease or increase above normal;

- the fine filter is completely clogged, preventing the normal passage of fuel;

- Worn injector valves leak – the engine “floods” with fuel.

One way to check the fuel pump is to press the return hose located in the engine compartment with pliers. When the return line is blocked, the pressure gauge should show at least 5 Bar, with a new pump - 6 Bar. A pressure of 4 bar is critically low.

Since the above method does not give an absolutely accurate result and is not applicable to all car models, it is advisable to check the fuel pump by directly connecting a pressure gauge. Other elements of the system should be excluded - pipelines, fine filter and regulator. Remove the back seat of the car, get to the unit and connect the meter directly to the outlet fitting.

If the readings on the ramp and on the pump fitting are equally low, change the pumping unit. Otherwise, the problem needs to be looked for elsewhere, following the algorithm:

- Purge the fuel line and change the filter, then test again.

- Reconnect the pressure gauge to the ramp, start the engine and remove the vacuum pipe (coming from the suction manifold) from the RTD fitting. If the pressure does not change, install a new regulator.

- To make sure that the injectors are working properly, you need to measure and compare two indicators: the pressure on the manifold with the return hose pinched and the maximum pressure created by the pump when connected directly. If the second value is much higher, part of the pressure is lost at the injectors.

If you find problems with loss of pressure on the manifold itself, remove the ramp and check each injector separately. Faulty parts cannot be replaced one by one - you will have to buy and install a complete set.

The easiest way to check injectors for leakage is to test them in operation together with the manifold. Remove the ramp without disconnecting the fuel line, place a rag and turn on the ignition. If the injector valves are worn out and lose their tightness, gasoline will begin to drip from them. The working elements should be checked again - with the return hose crushed.