The design of the fuel system on the VAZ 2107 injector

The VAZ 2107 injector power system has some differences from the classic carburetor.

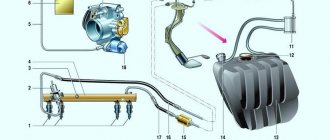

The main distinctive features are caused precisely by the fact that instead of a standard system for supplying the air-fuel mixture to the cylinders, the new VAZ 2107 models use an injector. Accordingly, other elements, such as a pump, filter, etc., differ. In addition to the indicated differences in the fuel system, the VAZ 2107 injection engine has fundamental differences in the ignition system. At the same time, the undeniable advantage of this type of engine is the presence of electronic control of all major systems. It is thanks to it that the efficiency and efficiency of the engine significantly increases. The schematic diagram of the fuel supply system for the VAZ 2107 injector is shown in the following figure.

Here the main elements are indicated by numbers from 1 to 12:

- Air intake tube.

- Filter for air purification.

- Connecting air pipe.

- Damper with built-in idle speed control system.

- Fuel injection system (injector).

- Filter for mechanical fuel purification.

- Pump with electronic fuel volume sensor (installed in the tank).

- Bypass valve.

- Safety valve.

- Tank.

In addition, the power circuit contains a system for cleaning and subsequent saturation of air with gasoline vapor, consisting of a fuel purge valve 8 and an adsorber 12.

As you can see, the power supply system of the VAZ 2107 injector has a number of significant differences, therefore, the procedure for its maintenance has its own characteristics. As for the air filter, everything is exactly the same as in the case of a carburetor. The filter element is replaced during each routine maintenance.

The pump does not require special maintenance, except for cleaning the fuel strainer installed on the suction pipe. This mesh traps mechanical impurities present in gasoline poured into the tank. If the fuel pump fails, it is replaced. To do this, it is necessary to disassemble the tank, remove the entire pump assembly from it, after which the failed element is replaced. The repaired pump is installed in its regular place in the tank.

- mesh filter for rough cleaning from mechanical impurities;

- fuel supply pump;

- electronic sensor for monitoring the fuel level (filled in the tank);

- fuel supply pipe;

- fuel outlet pipe;

- electrical connector;

- float.

The fuel filter is replaced periodically, in accordance with the manufacturer's recommendations. The main element is a special paper insert assembled in a metal case, and it is installed in the supply pipeline between the fuel pump and the injection system. The direction of fuel movement is indicated by an arrow on the body. For example, according to the arrows in the following photo, the pump (fuel tank) should be connected on the right side, and the ramp on the left.

The fuel injection system or fuel rail of the VAZ 2107 engine injector is designed directly to supply the mixture to the engine cylinders.

- fuel injectors;

- feed tube;

- outlet tube;

- ramp;

- spool fitting for pressure control;

- electronic pressure regulator.

One of the main working elements of the VAZ 2107 engine injection system is the injector. It is essentially an electromechanical valve that is controlled by the engine management system. When voltage is applied, the valve opens and the mixture is injected into the cylinder through the nozzle under the pressure created by the pump. During operation, the nozzles become clogged and therefore require periodic cleaning. As a rule, injectors are cleaned during maintenance, but if engine performance deteriorates, they need to be cleaned without waiting for routine maintenance. Injectors are replaced only when they fail.

Another element of the fuel supply system of the VAZ 2107 engine injector is the throttle valve. It is with its help that the engine speed is controlled, the damper regulates the volume of intake air to prepare the combustible mixture. To prevent freezing of the insides of the damper during the cold season, it is connected to the engine cooling system.

- pipe for connecting the adsorber;

- frame;

- flap;

- damper drive;

- pipe for removing crankcase gases;

- pipes for connecting to the cooling system;

- electronic damper position sensor;

- idle speed control element.

Another new element of the VAZ 2107 engine is the adsorber. It is designed to collect gasoline vapors when the car is idle. After starting the engine, the vapors held by the activated carbon are mixed with air, and the resulting mixture is fed through the throttle valve into the cylinders. In this air exchange scheme, among other things, the tank is involved, which is the main supplier of air saturated with fuel vapor.

In general, the nutrition scheme described above is more effective than the classic one. This is also due to the presence of an electronic engine control system, which regulates injection depending on operating mode, temperature and other factors. And if you follow the manufacturer's recommendations regarding routine maintenance, there will never be any problems with your car.

source

The design of the injection engine of the VAZ 2107 car

This design ensures fuel storage, purification from impurities and supply, along with air purified through a filter, into the engine cylinders.

The system consists of several components:

- Gas tank;

- Gasoline pump;

- Fuel lines;

- Fuel rail with injectors;

- Fuel filter;

- Air filter;

- Air supply channels;

- Throttle valve;

- Fuel vapor recovery system.

VAZ 2107 injector

Gas tank and fuel pump

In a VAZ 2107 car, the gas tank is made of two steel parts, lined with lead on the inside, and is located on the right side of the trunk. Fuel is pumped out of the gas tank by a gas pump, which has a filter that does not allow large particles of contaminants to pass through. Next, gasoline enters the fuel filter through the fuel pipe.

Fuel filter and fuel rail

The fuel filter is built into the fuel line between the fuel pump and the rail and consists of a paper filter element and a protective metal housing in the shape of a cylinder. In it, the fuel is finally purified and enters the fuel rail, which is a bar that supplies fuel to four injectors. The ramp is secured with two screws to the intake manifold, into which fuel is injected through the injectors. There is also a valve installed on the ramp that keeps the fuel pressure within normal limits (280-320 kPa), which is necessary for the proper operation of the entire injection engine.

All about model refueling fluids

As mentioned above, the VAZ 2107, like all models of the manufacturer, is equipped with a 39-liter gas tank. This volume is quite enough for long continuous trips. Of course, in recent years, due to a sharp increase in fuel prices, the tank volume has become enough for only 3-4 hours of driving on the highway.

Fuel

Initially, the “seven” was refueled exclusively with A-92 gasoline. However, some of the latest versions of the model implied the use of diesel fuel (VAZ 2107 - diesel). However, diesel modifications of the VAZ 2107 did not gain popularity in Russia due to the high cost of the car and increased fuel consumption.

Engine oil

Another filling fluid for the car is the oil in the power unit. AvtoVAZ engineers recommend that drivers fill the engine with lubricant that meets the minimum requirements of API SG/CD standards . This marking is usually indicated on containers with consumable liquid.

For VAZ 2107 engines, according to the SAE classification, the following oils are recommended:

- Lukoil Lux - 5W40, 10W40, 15W40.

- Lukoil Super - 5W30, 5W40, 10W40, 15W40.

- Novoil-Sint - 5W30.

- Omskoil Lux - 5W30, 5W40, 10W30, 10W40, 15W40, 20W40.

- Norsi Extra - 5W30, 10W30, 5W40, 10W40, 15W40.

- Esso Ultra - 10W40.

- Esso Uniflo - 10W40, 15W40.

- Shell Helix Super - 10W40.

Transmission oil

It is also necessary to maintain an optimal level of lubrication in the gearbox - transmission. For VAZ 2107 with 4 and 5-speed gearboxes, the same types of transmission oils are used.

AvtoVAZ engineers draw the attention of owners that only special gear oil of groups GL-4 or GL-5 should be poured into the gearbox. The viscosity grade must be designated SAE75W90, SAE75W85 or SAE80W85.

It is important not to overdo it with pouring lubricant into the transmission: no more than 1.35 liters of oil can be poured into a four-speed gearbox, and 1.6 liters of oil into a five-speed gearbox.

Injector installation

Let's take a closer look at how to install an injector on a VAZ 2107. First of all, you need to drain some of the coolant, after which the carburetor, intake and exhaust manifolds are removed. An electric air blower is installed under the injector, so if a VAZ 2107 has a forced air blower, it also needs to be removed. The first thing to replace is the crankshaft pulley. To place the sensor on it, the new pulley must have special teeth. Next, the front engine cover and sealing gaskets are replaced.

During installation, you will need a coolant temperature sensor. To install it, you need an underflow located on the tee of the block head. A threaded hole is prepared for the sensor, after which the ebb is installed back. The sensor itself will come in handy after installing new wiring. Then the manifolds are installed with all the equipment attached to them, such as a fuel rail with injectors, a throttle valve and a receiver. The position sensor and idle air valve are bolted to the base of the manifold. The fuel pump and ignition system elements are replaced with plugs, after which the fuel filter is installed in any convenient place.

The gas tank is secured with clamps, and the fuel outlet line is connected to it. If the gas tank is not replaced with a new one, but the same one is installed, it is necessary to wipe it from the inside with a solvent. The electric fuel pump is installed approximately in the place where the gas tank is located, under the bottom of the car. A fuel line is also installed at the inlet to drain gasoline from the system into the gas tank. You can stretch it in any way, but it is important that the line and the gas tank are tightly connected.

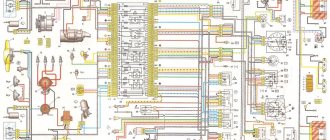

Next, the ramp is attached to the manifold, and new wiring is installed. To install the latter, you need to have a good knowledge of the electrical equipment of the VAZ 2107 car. An on-board computer, wiring harnesses and injection sensors must be installed. The last step is to install the elements of the ignition system, high-voltage wires and the remaining sensors.

Seal the gas tank

So, first of all, we go to a specialized store; to repair the gas tank we will need:

- Fiberglass.

- Epoxy resin.

- Sanding paper.

- Acetone.

It is very important, before starting to repair a gas tank, to thoroughly dry the fuel container and degrease it; the final result depends on this. Next, cut the fiberglass into pieces so that they are larger than the area of damage. Impregnate the fiberglass with epoxy resin.

Place fiberglass cloth on the surface so that there are no bubbles; excess resin should be removed. Pay special attention to the first layer; the final result depends on its quality.

After the repair is completed, let the patch dry, then be sure to putty and paint the gas tank, this will increase the reliability of the repair.

DETAILS: Replacing the fuel filter for BMW X5 E70 diesel

This way you can inexpensively repair your gas tank. However, even this is not a panacea; such a patch will only last for a few years at most, and besides, it, of course, will not stop the corrosion processes of the fuel tank. Therefore, the ideal solution is to purchase a new gas tank. Moreover, on a VAZ 2107 with an injector system this part today costs no more than 3 thousand rubles.

Pros and cons of an injection engine

One of the advantages is that the injector has a much smaller number of disadvantages during operation, which is especially noticeable at low ambient temperatures. Another plus is higher efficiency, meeting European standards.

But there are also disadvantages:

- The injector requires higher quality gasoline than the carburetor;

- Regular washing of the injectors is mandatory, otherwise they will become so clogged that neither flushing nor cleaning will help them;

- New injectors are quite expensive given the current economic conditions.

- In the event of a breakdown, repairs will take longer, and besides, not every car enthusiast will be able to repair the engine themselves

If you are willing to cover possible costs, then an injector will be a more acceptable option compared to a carburetor.

source

When is it necessary to change the gas tank of a VAZ 2107

As stated above, there are two reasons for replacing and repairing the fuel tank:

- Corrosion. Rust particles can get into the engine along with the fuel and damage the mirror-like walls of the cylinders, and through corrosion of the tank leads to fuel leakage, which is very costly and unsafe. A leak can be noticed by the strong smell of gasoline, increased consumption and a drop in fuel level while parked.

- Deformation of the walls, making it difficult to supply fuel to the engine.

It is also useful to periodically remove the VAZ 2107 gas tank to rinse from dirt and drain condensate. It is advisable to carry out this operation once every 3 years. After removing the fuel tank of the VAZ 2107 and washing it, you must thoroughly drain the sediment and rinse it with clean gasoline.

Sometimes it is necessary to remove the fuel tank to gain access to body parts during welding or other body work.

How to detect a leaking gas tank

There is no need to worry about noticing a leaking gas tank. If gasoline escapes from the fuel tank, this will be accompanied by the following symptoms:

- Significant increase in fuel consumption. It’s hard not to notice that gas is running out, even if the car is parked.

- There will be a distinct smell of gasoline inside the car.

- Rainbow spots will remain on the asphalt where your VAZ 2107 was parked.

If at least one of the above signs occurs, most likely, your VAZ 2107 with an injector system actually has a leak in the gas tank. There are several options for action in this situation; we will divide them into emergency and planned.

Emergency gas tank repair

If your car’s gas tank leaks on the highway and you can’t get to the nearest car service center without repairs, you can use a few tricks that will help temporarily return the fuel tank to operation.

The simplest and most effective way: seal the gas tank with rubber or plastic. For this we need:

- Superglue or ordinary glue moment.

- A piece of rubber from a tire or a plastic bottle.

So, the first thing you need to do is find the place where the gas tank is damaged, where fuel is escaping. In the case of the VAZ 2107, the injector system is leaking most likely from below; its cause is a hole or corrosion damage. As soon as the damage is detected, we proceed as follows: cut out a piece of rubber or plastic, lubricate it with glue and press firmly against the damage. After a few minutes you can release the patch, it will finally set in a couple of hours, but in any case you can go. You can easily get to a car service center with such a patch; there are cases when car enthusiasts drove with it for several weeks.

Fuel tank VAZ 2107

Another way to seal a hole is with a regular self-tapping screw. Suitable if the damage is small in diameter and you have a rubber seal for the screw. This is done as follows:

- First you need to find the location of the damage.

- Then install the seal on it (a regular piece of a car inner tube will do).

- Screw a self-tapping screw into the seal so that it fits into the gap in the gas tank and plugs it.

It will be possible to get to a car service center with such a simple repair. Moreover, it is better to stop at the first one you come across; the design is extremely unreliable and can fail at any moment.

Scheduled repair of the gas tank

If you notice a leak and decide to fix it with your own hands, the first thing you need to do is dismantle the VAZ 2107 gas tank; the process is similar for both the carburetor and a car with an injector system.

The procedure for removing the VAZ 2107 tank

First, you need to drain the fuel from the tank to reduce its weight and remove the gas tank trim in the trunk. To do this, you need to unscrew the screws in the upper and lower parts of the casing, as well as from the cover on the spare tire (if there is one).

Next, the removal of the fuel tank begins:

- Remove the sensor wires by first photographing or marking the connection points with a marker. The blue-brown wire is connected to the right terminal of the sensor, pink-brown - to the left.

- Loosen the fuel hose clamp and disconnect it from the fitting.

- Unscrew the bolt of the tank mounting clamp and lower the clamp that prevents removal.

- Loosen the ventilation hose clamp and disconnect the hose.

- Open the gas tank flap, unscrew the fuel filler cap and remove it.

- Using a screwdriver, remove the rubber apron that prevents removal of the tank.

- Unscrew the nuts securing the fuel level sensor and remove the ground wire located under one of the nuts.

- Remove the fuel level sensor.

After the operations have been completed, you can easily remove the VAZ 2107 gas tank by pulling it out of the niche in order to replace or repair it.

Installing the gas tank is done in reverse order.

Important: if the fuel tank of a VAZ 2107 is removed for repairs, it is necessary to wash it with clean gasoline or solvent, and then get rid of flammable vapors. To do this, the tank needs to be “steamed” - rinsed with a stream of hot water. After this, you can carry out repair work without fear of explosion or ignition of gasoline vapors.

Dismantling the gas tank

- So, first we remove the plastic casing under which the gas tank is hidden. It is secured with screws that can be unscrewed with a Phillips screwdriver.

- Now disconnect the power wires from the fuel sensor. You can simply pull them up and remove them from the contacts.

- Next, unscrew the fastening of the fuel hose and pull it out of place using pliers.

- Then unscrew the bolt of the clamping plate securing the VAZ 2107 gas tank with the injector system.

- Now you can unscrew the filler cap and carefully remove the gas tank.

Next, all that remains is to seal the gap in the gas tank. There are many repair methods, from cold welding to sealing the tank with tar. Let's take the simplest and least expensive path.

Fuel pump VAZ 2107 injector

The injection “seven” has a number of fundamental differences from the carburetor version of the car. This difference relates primarily to the fuel supply system. In the design of the VAZ 2107, the injector does not have a carburetor, and the gas pump pumps fuel directly to the injectors: this is reminiscent of the supply system of diesel engines.

Purpose and device

An electric fuel pump, unlike a mechanical one, is responsible not only for delivering fuel from the tank to the combustion chamber, but also for creating high pressure in the fuel system. Fuel injection in injection systems is carried out using nozzles, and gasoline must be supplied to them under high pressure. Only an electric pump can cope with this task; a mechanical one is not suitable here.

The VAZ 2107 fuel pump injector is designed quite simply and thanks to this it has a long service life. Essentially, it is an electric motor with blades located on the front of the shaft, which pump gasoline into the system. The pump inlet pipe is equipped with a coarse fuel filter in the form of a mesh to retain large dirt particles. The design of the electric pump is complemented by a fuel level sensor, which transmits a signal to the instrument panel.

Operating principle

To better understand the principle of operation of the gas pump, you need to have an idea of the injection system as a whole. Such a system consists of:

- Air intake.

- Air filter.

- Air sleeve.

- Throttle valve.

- Ramps with four nozzles.

- Fuel filter.

- Gasoline pump.

- Gravity valve, thanks to which fuel does not spill out of an overturned car.

- A pressure regulator (bypass valve), which is responsible for maintaining the pressure in the system at the required level.

- Safety valve.

- Fuel tank.

- Adsorber.

The VAZ 2107 fuel pump injector starts working after the driver turns the ignition key. At this moment, the electric motor of the pump turns on, and the pressure in the system begins to rise. When the fuel system pressure reaches 2.8–3.2 bar (280–320 kPa), the engine starts. While the engine is running, the gas pump pumps fuel into the system, and the pressure is maintained at the required level. After the engine is turned off, the pressure drops within a few minutes.

Where is

The fuel pump of the VAZ 2107 car, the injector is located inside the fuel tank. If you open the trunk lid, the tank with the pump can be seen on the right. The advantage of this arrangement is the simplification of the fuel system, the disadvantage is difficult access to the fuel pump.

Which fuel pump is better

If we compare an electric and mechanical fuel pump, it should be said that:

- the injection system itself is more reliable due to the fact that it does not have a carburetor, which requires additional maintenance;

- an electric pump is preferable to a mechanical pump, because it: provides direct fuel supply to the injectors;

- can be located inside the fuel tank (i.e., it saves engine compartment space);

- rarely fails due to the simplicity of the design.

Replacing the VAZ 2107 fuel filter (injector): instructions, photos and videos

If your VAZ 2107 suddenly refuses to start, while the starter rotates the engine properly and there is a spark at the spark plugs, there is a high probability that the problem is in the fuel pump. The fuel pump on the VAZ 2107 (injector) is much more reliable than those installed on carburetor models.

However, everything can break. Therefore, you should start by checking the functionality of the fuel pump. Unlike the pump on a carburetor engine, on a VAZ 2107 with an injector the fuel pump works as soon as the ignition key is turned. And it works quite noisily; its operation can be clearly heard when the engine is turned off.

First, let's figure out what the power supply system of the VAZ 2107 injection engine consists of.

VAZ 2107 power supply system (carburetor)

The purpose of the engine power system is to store and purify fuel, mix with air and supply the mixture to the engine. The power system includes:

- Gas tank.

- Fuel pump

- Level sensor.

- Fine fuel filter.

- Coarse fuel filter.

- Fuel lines.

- Fuel rail with injectors.

- Air filter

- Air supply sleeve.

- Throttle valve.

- Fuel vapor recovery system.

A malfunction of any of the elements will cause the engine to stop working.

Checking the VAZ 2107 fuel pump (injector)

The fuel pump on injection VAZ models often stops working due to a malfunction in the power supply circuit. If you can't hear the fuel pump running when the ignition is on, you should start with a simple check of the wiring and pump. In the glove compartment area there are three relays on a special mount. The middle one is responsible for the operation of the fuel pump.

The check should begin with fuse F3, which powers the fuel pump. If the fuse is working, you need to pay attention to the relay, wires and power supply contacts. If not, replace the fuse.

To check the power supply to the fuel pump:

- Remove the relay from the mount.

- Check the presence of a “plus” on the thick pink wire on the fuel pump relay (the ignition must be on).

- If there is a “plus”, connect the pink wire with the gray one going to the fuel pump (relay contacts “30” and “87”).

If, when the gray and pink wires are shorted (if there is a “plus”), the fuel pump does not work, the fault is either in the wiring going to it or in the fuel pump itself. Power connectors located in the trunk especially often fail. This is where you should start checking. There are two of them.

If the fuel pump turns on when the gray and pink wires are shorted, you should check the presence of power at 86 and 85 relay contacts. You also need to check the functionality of the relay. The easiest way to do this is to temporarily install a known working relay.

If the fuel pump makes noise, but does not pump, or does not produce enough pressure, you should try replacing the coarse filter.

The pressure created by the fuel pump in the line can be checked using a conventional pressure gauge. To do this, it is necessary to secure an oil- and gasoline-resistant hose with an internal diameter of 12 mm to the pressure gauge using a clamp and secure the second end of the hose to the fuel pump fitting ramp. Before this, you need to remove the fitting plug and unscrew the spool.

Removing the VAZ 2107 fuel pump (injector), replacing the coarse filter

To replace the filter, you must remove the fuel pump from the car. You will need:

- Key for 7.

- The key is 17.

- Crosshead screwdriver.

- Flathead screwdriver.

- New coarse filter (if necessary),

- New sealing rubber gasket (if necessary).

Installing a fuel pump

Before installing the fuel module (fuel pump with fuel level sensor), you must carefully check the condition of the rubber gasket that ensures the sealing of the connection. At the slightest suspicion, it is better to replace it. It is cheap, but re-installing/removing the fuel pump when a fuel leak occurs is a labor-intensive task.

DETAILS: Headlights for VAZ 2107.Tuning, tinting headlights and taillights Video

When tightening the eight fuel pump mounting nuts, you must be careful not to strip the threads.

Further operations are performed in the reverse order of removing the fuel pump.

After installing the fuel pump and connecting the pipes and power connector to it, you should check the operation of the system. To do this, you need to start the engine and make sure the connections are tight.

semerkavaz.ru

Cases when a VAZ 2107 injector fuel pump needs to be replaced are not that frequent, and its service life depends not only on the quality of the gas pump itself, but also on the condition of the gas tank. The reason I had to change it was because a small speck got into it because the filter came off.

Electric fuel pump device

The design of an injection fuel pump is simple and can be divided into two parts:

- electric motor;

- water pump.

The most important thing is its structure itself. The electric fuel pump itself is hermetically sealed to protect against fuel ingress. The fuel enters the pump through the filter and the intake hole and is supplied to the power system through the outlet hole (sealed from the electric motor).

Here is a diagram you can find. I would like to note that it does not happen that the motor rotor rotates in liquid and even in gasoline. Firstly, a spark forms on the commutator when the engine is running. You understand that this will lead to a fire. Secondly, rotor rotation in liquid is so difficult that gaining speed and creating pressure is simply out of the question.

Therefore, gasoline passes through the engine through a special channel, and the design of the engine itself is hermetically sealed.

Where is the fuel pump on the VAZ 2107 injector?

On carburetor engines, the fuel pump is installed on the right side of the block and is visually accessible. On the injector, it is located in the gas tank and only the output tubes coming from it are visible, and replacement is somewhat more complicated.

Symptoms for replacement

Signs of a malfunction of the VAZ 2107 injector fuel pump appear both when starting the engine and during operation:

- “heavy”, long engine start;

- jerking when moving;

- uneven operation at idle;

- The fuel pump doesn't pump.

Diagnostics

The primary conclusion whether the fuel pump is working or not can be assessed by ear when the ignition is turned on. If you don’t hear a quiet buzzing noise from behind, then you need to check the voltage supply to the gas tank block and then draw a conclusion about its malfunction.

You can check the serviceability of the fuel pump using the MTL-2 pressure gauge; this is the most correct way. You can somewhat roughly estimate the pressure using air pressure gauges to check tire pressure. To do this, screw a rubber hose to the sensor and connect it to the fuel system.

You can do without instruments at all; to do this, unscrew the fuel hose from the filter, place a container and turn on the ignition. In one minute, about 1 liter should be poured into the container.

The pressure of the VAZ 2107 injector fuel pump when the ignition is on should be 4.0 atmospheres, and when the ignition is running 2.8-3.2. In reality, the pump pressure is different and was slightly less, but this may be an error in the pressure gauge.

The carburetor pump is checked by setting the camshaft position by cranking the engine so as to ensure free movement of the pump foot. The hose is unscrewed from the carburetor or filter and the presence of fuel supply is determined by pressing the foot.

How to replace a VAZ injector fuel pump

To replace the fuel pump on an injection vase you will need:

- key to 10;

- 2 keys for 17;

- key to 7;

- crosshead screwdriver;

- a simple screwdriver.

When installing the filter, do not hesitate to give it a good tap, otherwise it may fall off like mine. The fuel pump mesh on the VAZ injector is replaced if the old one is dirty or torn. Its replacement is carried out in the same way. Usually it is sold complete with a fuel pump; if not, you will have to buy it, the price is 25 rubles.

Reassemble in reverse order. We heat the hose again in boiling water; if the mounting location of the old electric fuel pump does not allow the part to be properly secured, then we cut it off.

Check the integrity of the gasket between the flange and the gas tank; if it is torn, there will be a smell of gasoline in the cabin.

Important. When choosing, pay attention to performance and maximum pressure. I had Bosch 0 580 454 456 and replaced it with a close analogue of FR 453-453 from WEBER.

Characteristics:

- OEM part number 21083-1139009-01;

- Installation of VAZ 2108 - 2115;

- Pressure - 580 kPa;

- Productivity - 60 l/min;

- Voltage - 13.5 V.

DETAILS: Nissan Tiida engine oil change

Consumption per 100 km at a speed of 120 is about 8 liters. Very pleased.

A fuel purifier plays a very important role in purifying the fuel that a vehicle runs on. It is necessary to trap all kinds of foreign impurities and protects components and systems from clogging. Refilling a car with fuel offered to domestic consumers makes this procedure extremely important, since it is very often poorly purified.

The need to replace the fuel element is indicated by factors such as deterioration in the traction of the power unit and high fuel consumption. This procedure itself is simple and will not take you more than twenty minutes, but it will save time and money by avoiding a trip to the service station.

Replacement instructions

Filters recommended for replacement in a VAZ 2107 car with a carburetor or injector:

- Alco FF-009;

- DELLO 302010511251G;

- Bosch 0450904058;

- Filtron PS 842131261275;

- Fiaam FT4874.

Signs of a fuel pump malfunction

A faulty fuel pump can be determined by the following symptoms:

- When starting a cold or warm engine, you have to turn it with the starter for a long time. This may be due to the fact that the required pressure does not build up in the system for a long time;

- the car accelerates poorly, the engine has difficulty picking up speed, the response to pressing the gas pedal is delayed, the car moves jerkily;

- a car with a full tank of gasoline starts, but then can stall at any moment;

- extraneous sounds appeared from the fuel pump - hum, crackling or popping sounds;

- Gasoline consumption has increased sharply, etc.

The fuel pump does not pump

If, after turning the ignition key of the injection “seven”, you do not hear the usual sound of the fuel pump running, you need to check the electrical power circuit, as well as the mechanical part of this unit.

Checking the relay and fuse

Troubleshooting begins with the relay and fuse box located in the cabin under the glove compartment. To make it more convenient to work, the block must be removed from the niche by pulling it towards you. The fuel pump fuse is located in the middle of the block (indicated by the number 4 in the figure), the fuel pump relay is located slightly to the right of the fuse (in the figure - 5).

From the connection diagram it can be seen that voltage is supplied to the fuel pump through the fuse and relay. Therefore, first of all, you need to check the integrity of the fuse: this can be done, for example, with a multimeter. If the fuse turns out to be blown, and after replacing it the car runs fine, then you have the easiest emergency of all. If the fuse is intact, then further actions are as follows:

- Turn on the ignition and check for voltage on the pink wire that goes to pin 30 of the relay. The test can be done with the same multimeter. If the device shows 12 V, proceed to the next step.

- We install a jumper between contacts 30 and 87 of the relay. If after this the fuel pump turns on, then most likely the cause of the malfunction was in the relay. To make sure of this, we check the voltage on the relay coil (see figure - REL1 coil contacts). If power comes to the coil, but the fuel pump does not turn on without a jumper, the relay needs to be changed.

If the fuel pump does not turn on, you need to look at the positive voltage not only at the relay, but also at the fuel pump plug. To do this, it is not necessary to turn the ignition on and off: simply place a jumper on the fuel pump relay between contacts 30 and 87, and the control checks the circuit to the fuel pump plug. By the way, the alarms block in the vast majority of cases the fuel pump circuit. It is in the gap of the positive (gray) wire that the contacts of the blocking relay are placed.

Checking the fuel pump motor

If everything is in order with the fuse, relay and wiring, and the fuel pump does not work or works intermittently, you need to check the pump motor. First of all, you should make sure that the electric motor terminals are not oxidized or clogged. After this, you need to connect the clamps of a multimeter or a regular 12 V light bulb to the terminals and turn on the ignition. If the light comes on or the multimeter shows the presence of voltage in the circuit, then there is a problem in the motor. A failed electric fuel pump motor is usually replaced with a new one.

Mechanical check

If the fuel pump receives a voltage of 12 V, the pump motor rotates properly, but fuel is still supplied unevenly to the injectors and interruptions in engine operation continue, you need to check the mechanical components of the unit. First of all, you should measure the pressure in the rail. This is done as follows:

- Remove the fuel pump fuse and start the engine. We wait until the engine stalls after the remaining fuel in the system runs out.

- We attach the pressure gauge to the ramp. The pressure gauge connection point is usually closed with a plug that must be removed. Under the plug there is a special fitting that must be unscrewed carefully, as there may be gasoline residues in the ramp.

- Securely attach the pressure gauge hose to the ramp. The pressure gauge itself is brought out through the edge of the hood onto the windshield.

Low or irregular pressure in the system may be the result of excessive contamination of the fuel pump grid. For preventive purposes, this mesh, which plays the role of a coarse fuel filter, should be cleaned or replaced every 70–100 thousand km. To get to the grid, you will need to remove the fuel pump. We will consider the dismantling procedure below.

Other reasons for insufficient pressure in the system include:

- failure of the regulator, as a result of which the pressure rises and falls uncontrollably;

- contamination of the fuel filter, which needs to be changed every 30–40 thousand kilometers;

- Excessive wear of injector valves. In this case, the engine is “flooded” with fuel.

Stops pumping when hot

Owners of carburetor VAZ 2107 with mechanical fuel pumps sometimes encounter the fact that the pump stops pumping when hot. Most often, in this case, the car drives confidently along the highway, but in city traffic jams it stalls for no apparent reason. Many drivers solve this problem by wetting the fuel pump with a damp cloth or pouring water on it. But in this way only the consequence, and not the cause of the malfunction, is eliminated. The engine stalls due to air locks in the power system when heated.

To get rid of overheating of the fuel pump forever (or for a long time), you need to:

- When replacing the pump, select the correct shims. If the gaskets are chosen correctly, the pusher in the “recessed” position protrudes from the edge of the heat-insulating spacer by 0.8–1.3 mm;

Fuel pump drive

The VAZ 2107 mechanical fuel pump is driven by a pusher and an eccentric. Among drivers, it is customary to call the pusher a rod, although the rod is another part of the fuel pump. The eccentric is located on the intermediate shaft, which operates from the gas distribution mechanism.

The fuel pump drive includes (see figure):

- 1 - pusher;

- 2 — heat-insulating spacer;

- 4 — adjusting gasket;

- 5 - sealing gasket;

- roller (cam).

Device and principle of operation

The operation of the mechanical fuel pump drive is not based on the fact that:

- the oil pump shaft is driven through a timing chain;

- the cam (or eccentric) begins to press cyclically on the pusher;

- The pusher transmits force to the lever and the fuel pump begins to pump fuel.

Drive faults

Problems with the mechanical fuel pump drive lead to interruptions in the operation of the fuel supply system. Actuator malfunctions are most often associated with deformation or excessive wear of the pushrod or cam.

Fuel pump rod bends

The fuel pump pusher is often made of metal that is not strong enough. There are often cases when, after 2–3 thousand kilometers, such a pusher bends and flattens the constant impact of the cam. The length of the pusher should be 82.5 mm. If your fuel pump tappet does not meet this size and is flattened on the cam side, it will need to be replaced.

Fuel pump repair

To dismantle the electric fuel pump you will need:

- Phillips and flathead screwdrivers;

- 7mm tubular socket wrench.

Removing the electric fuel pump

Dismantling the electric fuel pump is performed in the following sequence:

- The negative terminal of the battery is disconnected.

If you need to replace or wash the coarse filter, you need to pry it off with a screwdriver and remove the old mesh. The new filter is installed by pressing tightly.

The fuel pump is installed in reverse order.