When is it necessary to pump the brakes of a VAZ 2107

It is necessary to bleed the brake system in four cases:

- Replacing brake fluid. Brake fluid has a limited service life. Over time, it absorbs moisture from the air, which can cause corrosion of the surface of the brake cylinders and their failure. Water also worsens the main property of brake fluid - it reduces the boiling point.

- The recommended service life of brake fluid on VAZ cars is 2 years, after which it is worth replacing it. This applies to standard glycol-based brake fluid.

- Troubleshooting the brake system. When replacing brake hoses and cylinders, brake fluid leaks and air enters the system. Therefore, after repair work, the VAZ 2107 brakes must be bled.

- Air ingress during operation. This manifests itself in deterioration in braking efficiency, a “soft pedal” or uneven braking of individual wheels.

Problems with the GTZ and vacuum booster

Most often, the pedal fails if the problem lies in the master brake cylinder, due to its destroyed rubber seals. Their destruction may be due to natural wear, or due to the impact of the above-mentioned aggressive fuel fluid. All this contributes to the depressurization of the system. What to do in such a situation? Replace the brake master cylinder.

Now a few words about the vacuum amplifier. It is quite easy to understand that the problem is with this device: while the engine is running, when the brake pedal is pressed, the amplifier makes a sharp hissing sound. It could also experience depressurization due to unusable rubber seals.

So, the brake pedal of the VAZ 2107 fails for the following reasons: the brake system has become airy, there is a problem with the master brake cylinder, there is a lack of brake fluid in the system, the vacuum booster has failed. I wish you success in solving your problem.

What is needed to bleed the brake system

It is almost impossible to bleed the brake system yourself. The work is carried out by two people. One person (“mechanic”) works with the brake system, unscrews the fittings. The second (“partner”) is located inside the car and must press or release the brake pedal on command.

You also need the following tools:

- 8/10 socket wrench;

- a PVC tube or rubber hose, the inner diameter of which corresponds to the diameter of the fitting;

- container for collecting waste liquid.

- Brake fluid is also needed.

How to bleed the brakes on a VAZ 2107

For ease of work and to ensure free access to the brake cylinder fittings, you should use an inspection hole. The design of the front brake mechanisms requires removal of the wheels to bleed the brake system.

Before starting work, it is necessary to fill the brake reservoir to the maximum, and during bleeding, you must ensure that it is constantly filled with brake fluid. If you miss this moment, air will get into the working cylinder and you will have to start work again.

The procedure for each of the 4 working cylinders is as follows:

- Remove the protective cap from the fitting.

- Loosen the fitting using a spanner. If the fitting has not been unscrewed for a long time, significant effort may be required. You must be especially careful not to damage the edges, otherwise the work may become very difficult, even to the point that the brake cylinder will need to be replaced.

- Place the tube on the fitting and lower it into the brake fluid container.

Direct pumping is performed as follows:

- The “partner” sitting in the cabin, at the command of the “mechanic”, presses the pedal all the way.

- The “mechanic” unscrews the fitting half a turn so that the liquid, along with air bubbles, comes out into the container through the inserted tube. The brake pedal “sinks” to the floor.

- The “fitter” tightens the fitting, and the “partner” releases the pedal on command.

The procedure is repeated until no more air bubbles come out of the tube. During bleeding, the end of the tube must be constantly lowered into the brake fluid so that air does not enter the cylinder.

In this way, all four working brake cylinders are pumped. A certain sequence should be followed when bleeding the cylinders. They are pumped “from far to near”:

- Right rear.

- Left back.

- Right front.

- Left front.

After completing bleeding of each cylinder, it is necessary to tighten the fitting and put on the protective cap.

Bleeding the brakes of a VAZ 2107 is quite feasible at home and does not require expensive special tools and devices. No special qualifications are required either. Even a child can release and press the brake pedal at the “locksmith’s” command.

Often, owners upgrade the brake system by installing more efficient, high-quality and expensive parts. However, this does not change the bleeding method in any way and does not eliminate the need for periodic work to replace the brake fluid.

The VAZ 2107 is far from a perfect car; it cannot boast of the reliability of its systems. Including brake mechanisms, on which the safety of driving depends. Sometimes situations arise when the system does not work efficiently or there is a brake fluid leak - in such cases, immediate repairs are required. You can do the work yourself, for which you will need to prepare the necessary tools and read the instructions.

Why does the brake pedal in a car fail?

A serviceable and efficient braking system of a car is a guarantee not only of road safety, but also often the safety of the life of the driver, passengers and pedestrians. And one of the signs of serious problems for the car and its owner is a situation when the brake pedal fails.

This process can occur either slowly or quickly. It happens that a recessed pedal does not return to its place at all. In any case, all of the above signs are a reason for serious diagnostics of the brake system. However, first you should find out what caused the emergency situation.

Why does the brake pedal fail?

One of the elements of the described hydraulic system is a special composition circulating through tubes and other cavities. A special feature of brake fluid is that it cannot be compressed. As a result, the force from pressing the pedal is transferred “unchanged” to the pads, which stop the rotation of the wheel. “Sinking” indicates that the line has become larger in volume or has depressurized. The main causes of the problem are discussed below.

Low quality brake fluid

The composition circulating in the system is quite aggressive. Gradually, bad brake fluid begins to corrode rubber and even metal parts, hoses, and tubes through which it moves. The walls of the latter become thinner to such an extent that they swell when pressure is created. Because of this:

- an excess volume is created into which the brake fluid goes;

- when you add it, the pressure is restored, but the tubes may not be able to withstand it: microcracks form through which the liquid gradually leaves and air enters instead (when the pedal moves in the opposite direction, it is literally sucked in). In the worst situation, the hoses may burst.

Air in the brake system

Its entry into the line is a consequence of depressurization of components and parts of the brake system. A plug may also form due to the fact that the fluid level in the tank has dropped below the existing MIN mark. Another reason is improper bleeding of the brakes when replacing the circulating compound. The danger with air in the system is that, unlike liquid, it is compressed. As a result, the force applied to the pedal goes to waste - in the literal sense of the word.

Master cylinder malfunction

Its main problem is most often related to depressurization. This occurs due to deformation and rupture of seals - cuffs. Their destruction is caused by poor-quality brake fluid or natural aging of the elements. The main brake cylinder becomes leaky even if scratches or wear appear on its walls.

This occurs due to the appearance of foreign particles in the line. They can get inside if the system is carelessly and inaccurately filled. Sometimes “extra” elements are wear and tear products if the car has been in use for a long time.

Repairing a brake cylinder is a difficult task. If you do not have the relevant experience and do not have special tools or devices, it is better to take the part to a workshop or buy a new one.

Problems with the vacuum booster

If it is faulty, then most often this can be determined by the characteristic hissing sound that occurs when you press the brake pedal. This situation may indicate depressurization of the vacuum pump.

The reason may lie in a ruptured diaphragm, seals, or a broken equalizing valve. To solve the problem, purchase a repair kit and replace all rubber parts.

Air can also enter the vacuum booster due to cracks in the underwater pipes: tighten the clamps on them or, if damaged, replace them (in a carburetor car, such a hose fits at the bottom of it).

Incorrect clearances

We are talking about the presence of a gap between the main brake cylinder (its rod) and the pedal. The latter in this case fails and remains in this position. If the clearance is correct, the pedal will initially move smoothly, but at a certain period of travel it will become stiff. If the distance to the GTZ rod is large, resistance to pressing will be felt only at the very end of the stroke.

Unprofessional repair

The reason when the brake pedal fails may lie in the caliper, the fastenings of which are not tightened well enough. Then its vertical axis will be shifted in relation to the brake disc and the pads will not be able to get used to function properly. Also, any unprofessional actions (poor tightening, lack of spring washers where needed, etc.) when repairing or bleeding the brake system will lead to its ineffective operation.

Corrosion

The metal that makes up some of the brake system elements can simply rust. In such cases, the pedal goes down and freezes there, from where it has to be “picked out” with a pry bar or other improvised tool. Corrosion usually succumbs to traction, which just needs to be sanded off.

Brake pad wear

In this situation, an increased gap appears between the disc and the pads. As a result, the pressure created in the system is not enough to brake the wheel. The solution is obvious: replacing the pads.

When not to panic

- If you got behind the wheel, decided to start the engine after a long period of inactivity, pressed the brake and started the engine, and at that moment the pedal “went away,” then there is no need to look for a malfunction: the phenomenon is normal.

The fact is that when the car starts, the hydraulic vacuum booster begins to work: the process involves installing the mechanisms of the unit into the working position. It’s just that there is a difference between the force transmitted to the pedal when the engine is turned off and when the engine is running. - If the brake fails after completing repair work to replace the pads, it also does not always indicate problems.

In this case, the pedal begins to “go away” after bleeding the system, but then functions normally. This is due to the pistons of the working brake cylinders - they “search” for some time for the optimal gap between the disc and the pads.

How to bleed brakes on VAZ cars

This is a procedure performed after repairs, replacement of individual system elements, or when replacing fluid. Pumping needs to be done by two people. But first, check the car's operating instructions, which should indicate the order of actions with the wheels. If there is no such point, start pumping from the rear right and left, then do the same with the front ones. You will also need to prepare:

- a thin hose or plastic tube with a diameter suitable for the bleeder fitting;

- a suitable small transparent container 0.5-1 l;

- key for unscrewing the fitting.

Next, place the car on an inspection hole so that you can get to each wheel from the inside. Have an assistant sit behind the wheel. Further actions:

- Fill the brake fluid reservoir to the maximum level.

- Clean the fitting, put a spanner on it and insert a tube, one end of which is lowered into a container containing brake fluid.

- Have an assistant press the pedal several times and keep it pressed.

- Unscrew the fitting and, holding it with a key, watch the nature of the liquid pouring out. If there are bubbles, tighten the fitting and instruct an assistant to repeat the operation.

- Pumping should be carried out until bubbles stop coming out.

How to bleed the brakes without an assistant is shown in the video below.

If air comes out despite repeating the procedure many times, the reason should be sought in depressurization of the system.

The brake failed at full speed: what to do?

First, try pressing the pedal sharply several times: perhaps its functionality will be partially restored. Next, assess the situation and identify a place where you can gradually turn. Then tighten the handbrake (don't do it too hard) and start shifting (if you have a manual transmission) to a lower gear.

At the same time, when the lever is in “neutral”, press the accelerator (perform “re-throw”) to “prepare” the gearbox gears for emergency operation. As a last resort, choose the lesser of two “evils” - it is better to run into some obstacle near the road (roadside bushes are a good option) than to collide with a car.

Results

To avoid the situation described above, you need to periodically diagnose the condition of the brake system: add fluid, change it, install new pads, check the brake discs, monitor the condition of all components: the hydraulic vacuum booster, the working and master brake cylinders. If you suspect that they are malfunctioning, immediately carry out repairs or contact a service center.

Source: https://djago.ru/tormoznaya-sistem/provalivaetsya-pedal-tormoza-prichiny-i-metody-ustraneniya-neispravnosti/

Malfunctions of the brake system of the VAZ 2107

The safety of driving a VAZ 2107, like any other car, directly depends on the effectiveness of the braking system. If problems arise with it or repairs are carried out, the brakes need to be bled. In order for the system to always be in good condition, you need to know how malfunctions manifest themselves and what causes them.

Soft brake pedal

The normal state of the brake pedal on the “seven” is one in which there are no jerks or dips at the moment it is pressed and there is no need to make any special efforts. However, as the vehicle operates, drivers may encounter a situation where the brake pedal has a different condition: it may be too soft or too tight. Both phenomena are considered unacceptable and indicate problems with the braking system and the need for prompt repairs. Most often, the pedal becomes soft when the system is filled with air. Sometimes this phenomenon is also called a failure. The malfunction is eliminated by bleeding the brakes, as a result of which air is removed from the system, which could enter it for the following reasons:

- There is too little brake fluid in the expansion tank.

- Violation of the tightness of the braking system.

- Malfunction in the main brake cylinder (GTC). The problem is resolved by repairing the mechanism.

Replacing front brake hoses

Replacing the front brake hoses on a VAZ 2107 is not a difficult procedure, and before performing it, you need to pump out the fluid from the expansion tank. To pump it out, it is better to use a rubber bulb or syringe. Before you start doing the work, you will need to grab a tool and get started.

- First, let's start removing the front wheel from the desired side. We remove the front wheel in order to free access to the hose.

- When access to the eyeliner opens, you must first clean the joints with a wire brush, and then treat them with WD-40 or similar lubricant.

- 5-10 minutes after treating the connections with lubricant, you can begin to unscrew the fittings. To do this, use a special 10 mm key with a slot.

- The key has a special stopper in the form of a bolt, which is screwed in after it is put on the metal tube.

- We proceed to loosen the bracket nut, for which you need to hold the fitting with a key “17”.

- As soon as the connecting coupling on the metal tube is loosened, you can remove the special key and continue unscrewing by hand.

- After disconnecting the hose, a rubber boot must be placed on the end of the tube to prevent dust or water from entering the system.

- To release the second end of the fitting from the bracket, you will need to remove the bracket with pliers.

- Using a flathead screwdriver, unscrew the screw that holds the trim bracket to the caliper. After this, you can dismantle the part.

New hose in place - Using a “14” wrench, you need to unscrew the bolt securing the second fitting.

- The copper washers must be replaced, and then proceed to install the new hose on the caliper. It is important to take into account one nuance - the tip of the fitting should be directed downward, not upward.

Read, it may come in handy: How to choose brake pads

After screwing the second fitting, you can begin to perform similar actions, but on the other front wheel. This completes the installation of the front hoses, but do not rush to install the wheels in place, as you will need to perform the procedure of removing air from the system (bleeding the brakes).

Install and screw the locking bracket

What kind of brake fluid should I fill in the VAZ 2107 and how much?

The hydraulic brake system of the VAZ 2107 uses DOT-4 brake fluid. Its volume is 0.382 l. The fluid is topped up or changed not only in case of repairs, but also when the color changes or moisture gets into it. As a rule, on classic Zhiguli cars a complete fluid change is performed every 3 years. The essence of the procedure is to pump fluid through the system.

Procedure for bleeding the brakes

To bleed the brakes on the “seven”, as a rule, 2 people are required: one is under the car and works directly with the brake cylinders, and the second is located inside the car and presses the brake pedal. The following tools are required for work:

- socket wrench 8/10;

- 8/10 open-end wrench or special for brake pipes;

- hose of appropriate diameter;

- container for waste liquid.

Bleeding begins from the furthest wheel from the GTZ, so it is performed in the following sequence:

- Right rear wheel.

- Left rear.

- Right front.

- Left front.

To bleed the brakes of the rear wheels, you need to go under the car. Work on the front brakes is carried out after preliminary dismantling of the wheels. Otherwise the process is the same:

- Remove the protective cap from the fitting of the working brake cylinder.

During pumping, you need to control the liquid level in the expansion tank so that air does not enter the system.

Video: pumping brakes on a VAZ

When should you bleed your brakes?

The need for pumping arises in the following cases:

- The brake master cylinder was repaired.

- The brake pipes were replaced.

- Brake hoses were changed.

- The front brake calipers or rear cylinders were repaired or replaced.

- Scheduled replacement of brake fluid in the system.

When bleeding the brakes on a VAZ-2107, it is necessary to follow a sequence of actions so that subsequently the efficiency of the system is maximized.

All the reasons why pumping is carried out can be called both planned and unplanned. Elements can be replaced both in case of breakdown and when the maximum service life is reached. As for the last point, it is worth talking about separately.

This is the first way to bleed brakes on a VAZ-2107. It is also the main one; you can find it in the official car repair and maintenance manual.

The essence of the procedure is simple:

- Place your assistant in the driver's seat and explain to him what his task is. And it is not very complicated - you need to press the brake pedal all the way at your command. And at your own command, fix the pedal to the floor.

- Fill the reservoir with liquid to the brim.

- You tear off the fitting using a special wrench.

- Place a transparent hose onto the brake bleeder fitting on the rear right wheel. Its second end needs to be lowered into a jar with a small amount of brake fluid.

- Command your assistant to press the pedal 4-5 times and lock it. At this moment, you unscrew the fitting 0.5-1 turns and watch how the liquid comes out. As soon as she stops, you tighten the fitting, and your partner makes a few more pumps.

- Carry out the manipulations from the previous step until air stops flowing through the tube. Add liquid to the expansion tank in a timely manner.

Similar manipulations must be carried out on the remaining brake mechanisms of the car.

Why don't the brakes bleed?

One of the problems that many VAZ 2107 owners face is the inability to bleed the brakes after repairing or replacing the master cylinder. It would seem that a new or repaired part has been installed, bleeding is carried out correctly, but the result is zero. The essence of the problem is that in most cases, when installing a GTZ, tubes and hoses are first connected to it, then brake fluid is poured into the reservoir, and only after that they begin bleeding. However, there is air in the cylinder itself, so you need to bleed it first, and then start working on the brakes.

The fact that there is air in the GTZ is also indicated by the brake pedal, which lies on the floor.

To deal with the problem, you do not need to tighten the fittings on the tubes - just tighten them. After this, pour brake fluid into the reservoir and release the fittings a few turns so that fluid and air flow out of them. Alternatively, to speed up the process, you can wipe the neck of the tank and blow into it to create pressure. After the fluid flows without air, the fittings are clamped and the standard procedure for bleeding the brakes begins.

In addition, a pumping problem can occur when installing a defective cylinder or when a part is incorrectly repaired. If a problematic product is encountered, the fluid is bypassed, which simply flows from the tank to the cylinder and back, i.e. it does not pass further than the GTZ. In this case, the part must be replaced. If the cylinder has been repaired, the procedure will need to be repeated, since, most likely, an error was made during assembly.

In order for the “Seven” brake system to work properly, it is necessary to periodically inspect its elements, monitor the level of brake fluid in the expansion tank, and if it decreases, identify the reason that led to this. Since many problems with the hydraulic brake system require bleeding, you need to know what should be done and in what order - there is nothing complicated in this process.

The VAZ 2107, like all cars, has a hydraulic brake system (with brake fluid), which requires regular maintenance. This diagnostics must be carried out regularly, which will eliminate various malfunctions that can cause accidents on the road. In addition to replacing and repairing related parts, the brake system sometimes needs to be bled to get rid of air bubbles. We'll look at how to bleed the brakes on a VAZ 2107 in the article.

Basic faults

The brake system itself is quite simple, but some of its elements require special attention. Main types of faults:

- The brake fluid leaks, resulting in a drop in pressure in the system. If a preliminary inspection does not find a leak, it is necessary to check the brake master cylinder. We bend the noise-insulating mat located under the brake pedal and inspect for streaks in the area of the rubber seal of the master cylinder. The presence of drips will indicate that the cause has been found and requires disassembling the cylinder and then replacing the cuff. If there is a vacuum booster, the brake master cylinder must be removed and inspected.

- When you release the brake pedal, the car drives sluggishly. Reason: the rear or front pads are jammed. Seized pads are identified by checking the heat of the corresponding wheel. We touch each disk - the hottest one will be jammed. In the case when these are the front wheels, you can, after removing the wheel, move the brake cylinder. If this fails, you will have to replace it with a new one. In the case of rear pads, the brake wheel cylinder will need to be replaced.

- When you press the pedal, braking does not occur, but it does when you press it several times in a row. This may indicate the presence of air in the system. The solution to the problem is to bleed the brakes to remove air.

- Problem with the handbrake. Most often this problem occurs in winter. It manifests itself in the fact that after a long period of parking, when the handbrake is released, the wheels remain locked. The reason is that the parking brake cable is frozen. During its operation, moisture gets there and freezes in winter. If the casing is severely damaged, it will have to be replaced.

Read, it may come in handy: How to raise or lower the suspension. Tuning and modification of the chassis

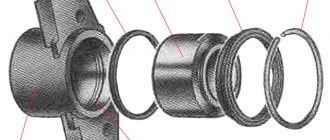

Brake master cylinder diagram

Vibration when braking

This is a fairly common malfunction that is associated solely with critical or uneven wear of the discs or drums, and the repair will consist of replacing them.

Car shifts to the side when braking

The malfunction is due to either a failure of the working (wheel) cylinder or wear of the pads. Replacing them (or repairing them) will solve the problem.

The VAZ 2107 brake pedal fails: the main reasons

The brake system must be sealed and free of air. If the pedal begins to fail, then, with a greater degree of probability, we can say that depressurization has occurred, that is, air has entered the system.

Other reasons:

- rust formation on the pedal linkage;

- failure of the vacuum booster;

- unadjusted distance between the cylinder piston and the pedal itself;

- lack of fuel fluid in the system.

It is also important to remember that brake fluid is an aggressive substance that can destroy thin pipes and even lines. That is why it is important to use only high-quality TZ. Low-quality liquid can form cracks through which it then flows out safely. But the flip side of the coin is that when you press the brake pedal, air leaks through these cracks.

When to bleed the brakes

The brake system on a VAZ 2107 car begins with the pedal and ends with brake pads with discs at the front and drums at the rear. The principle of operation of brakes is based on increasing the pressure of the fluid filling the entire system. The fluid pressure increases due to the displacement of the piston in the design of the master cylinder (by pressing the pedal). Next, the pistons move in the calipers (working cylinders) and they put pressure on the front and rear pads and stop the car. For the brakes to work effectively, all parts must be in good working order and there must be no air in the system.