In my article today I want to talk about brake pedals, namely, what it should ideally be, tight or, on the contrary, soft, how to find this golden mean?

By and large, the brake pedal can have several positions and states.

The first state is the one provided by the manufacturer, when when you press the brake pedal there are no dips or jerks, and no special effort is required. There are also two other unpleasant pedal conditions that can cause driver anxiety.

This refers to the state of the pedal when it is excessively tight or, on the contrary, very soft. Both one and the second phenomenon are equally unacceptable and indicate malfunctions and the need for urgent repairs of the brake system.

A stiff brake pedal can become stiff for several reasons, and they may not necessarily be associated with the traditional “sores” that are typical for all brake models. However, I still propose to consider the most common of them, and I will also try to give practical advice on how to eliminate them.

Most problems that cause the brake pedal to become soft are related to either the vacuum booster or the brake master cylinder.

Reasons why the brake pedal becomes hard:

1. Clogged air filter of the vacuum booster. Treated by replacing the air filter;

2. Sticking of the valve body in the vacuum booster. The vacuum booster needs to be replaced;

3. The vacuum booster diaphragm is damaged. Solved by replacing the vacuum booster;

4. Faulty vacuum booster tip. The tip should be replaced;

5. Sticking or failure of the check valve in the vacuum booster. To eliminate, it is necessary to replace the check valve;

6. The check valve of the vacuum booster is faulty or the seal is broken, resulting in fuel entering the chamber of the vacuum booster. The vacuum booster with check valve should be replaced;

7. Damage to the hose that connects the vacuum booster and the intake manifold, or the hose fastening on the fitting is loose. It can be treated by replacing the hose, or, if possible, by tightening the fastening clamp. The condition of the hose should be regularly monitored, this is especially true in the cold season. As long as the hose is cold, it retains the necessary rigidity - the brakes function normally. However, after several tens of minutes of motor operation, the hose heats up and becomes more elastic. If, for example, during inspection you do not find delamination, the capacity of the hose will decrease, which in turn can cause problems with the brake pedal.

8. The sealing rings in the working wheel cylinders are swollen; this often occurs as a result of fuel and lubricants getting on their surface, or as a result of using low-quality brake fluid. To correct this situation, it is necessary to repair the working brake cylinders and replace the brake fluid

Here are several ways to independently check the performance of the vacuum booster.

First of all, start the engine to allow a vacuum to occur in the system. After this, press the brake pedal; if the pedal is hard, this is a clear sign of a faulty hose or amplifier. Then turn off the engine and wait 5-7 minutes, do not press the brakes.

It is necessary to specify the malfunction; to do this, press the pedal. If it is still hard, most likely the fault lies in the vacuum booster valve.

There is also another test. When the engine is not running, it is necessary to depress the brake pedal several times in order to remove the vacuum in the brake system. After this, without releasing the pedal, you need to start the engine; if the pedal begins to move down a little, the amplifier is in order.

Cause of soft brakes

A soft brake pedal, as a rule, simultaneously indicates several breakdowns in the brake system. More precisely, there are many reasons why the brake pedal can become soft. Sometimes this phenomenon is also called brake pedal failure.

The most common reasons why brakes may become soft are:

Air brake system. Troubleshooting occurs by bleeding the brakes and removing air from the brake system.

Airing can occur for the following reasons:

1. Low level of brake fluid in the expansion tank, depressurization of the brake system;

The brake pedal has become hard: the reason

So, during operation, you can discover that the brake pedal has become hard, medium or too soft. The reasons for a tight pedal, that is, when the brake pedal on a car is too hard, can be either a design feature of a particular car or a malfunction. In other words, a hard brake pedal may be normal for certain car models. If the brakes become hard for another reason, repairs are necessary.

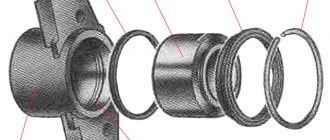

To transfer pressure, brake fluid is poured into the system. The fluid is supplied through steel pipes and rubber hoses from the master cylinder to the brake wheel cylinders. The working cylinders use their piston to transmit pressure to the brake calipers, pressing the brake pads against the brake disc or drum.

The list of main reasons why the brake pedal is hard to press or the brake pedal is not pressed includes problems with the vacuum booster. The following problems should be noted:

- Malfunction of the vacuum brake booster limit switch. Replacing the end switch solves the problem;

- The vacuum booster also has a special check valve. If the valve sticks or does not work, the specified element must be replaced;

- The VUT may also have a dirty air filter, which prevents dirt from entering the system. If the filter is clogged, in a similar situation the brake pedal is also pressed hard;

- The amplifier also has a special check valve. If the VUT valve is stuck, this element must be replaced;

- Often the reason why the brake pedal becomes hard after several presses or the brake pedal is hard after parking is the brake booster diaphragm. The VUT diaphragm breaks or cracks, and the entire amplifier must be replaced;

- At the same time, we note that fuel may enter the booster chamber (often due to a broken check valve), which will also immediately affect the operation of the brake pedal;

- One common cause of a hard brake pedal that won't press down is the hose connecting the intake manifold to the booster. The specified hose wears out and becomes deformed, that is, over time it may require replacement. It also happens that it loosens on the fitting. In this case, a tight fit can solve the problem;

- The list ends with the use of dirty brake fluid that has lost its properties, the ingress of third-party fluids into the brake cylinders, as well as swelling of the sealing rings. To fix the problem, the cuffs and seals need to be replaced (repair of brake cylinders), and the brake fluid must also be replaced. In some cases, entire brake cylinders need to be replaced.

Brake pedal sensor Lada Kalina

Lada Priora Sedan constructor, assemble it yourself Logbook Mileage and clutch replacement

The Kalina brake pedal sensor is a technical device that is used to monitor the degree of impact on the brake pedal. Quite often, car owners of the VAZ line complain about breakdowns or incorrect adjustment settings of the product.

Fortunately, the process of adjusting or replacing a part is not very difficult if certain nuances are observed.

Performance diagnostics

Checking the functionality consists of: 1. Testing the product with a multimeter. 2. Disassembly and visual inspection of the internal components of the part.

3. Replacement sensor is not known to be good.

The first method involves alternately measuring the contacts of the dismantled sensor. The point is to check each contact individually and in pairs (second and third contact). This is quite convenient to do, since at the place where the contact chip is connected, all connectors are numbered.

The second method is used to identify faulty or deformed internal elements of the product (in most cases, damaged springs).

There should be no traces of oxidation or contamination. If there are any, clean them out.

The third method is quite simple and trivial. Install a new part to replace the one whose serviceability you doubt.

When the system is restored to normal operation, the malfunction indicator (check engine) should go out (if it does not disappear within 15 minutes, the error should be reset manually).

Signs of a faulty brake pedal sensor Lada Kalina

In order to understand that the Kalina brake pedal position sensor is the cause of the vehicle’s incorrect operation, pay attention to the following signs:

- presence of error “P-0504” on the dashboard;

- a significant decrease in power and engine responsiveness when pressing the gas pedal;

- increase in engine speed (short-term) when changing gears.

Main causes of sensor failure

In order to identify the reasons that interfere with the normal operation of the device, it is necessary to disassemble it and carry out a thorough inspection to identify deformations and damage. The following defects are most common:

- the internal (small) spring, which is located on the rod, shows signs of deformation or distortion;

- the contact terminals of the product have physical oxidation;

- backlash of the moving contact;

- Quite low quality of factory production (defective, flimsy internal elements of the device).

Adjusting the brake pedal sensor Kalina

If the sensor is in good condition, and incorrect operation of the internal combustion engine continues to bother you, try adjusting the product yourself

Please pay attention to the following features:

- The sensor must be screwed in clockwise until the brake pedal begins to move down. Then you will need to slightly unscrew the product and secure its position using the fastening nut.

- The result should be such that when there is no action on the pedal, the sensor rod is recessed into the housing, and when the pedal is applied, on the contrary, it is completely released from the housing.

- As for the working gap, it is adjusted using two nuts (one at the top, the other at the bottom). The adjustment is carried out using the upper nut, which is tightened, and the lower one, on the contrary, is unscrewed. The entire process is carried out until the button is completely recessed into the body when the brake pedal is applied. However, you should not overdo the adjustment; in other words, you should leave a small gap or travel margin (approximately 2 to 5 millimeters).

Removal and installation

Replacing the brake pedal sensor on Kalina is carried out using an adjustable wrench set to “19”. The sensor itself is located above the brake pedal under the steering column. Conventionally, the removal stages can be divided into 5 steps:

- Before starting electrical work, it is recommended to disconnect the negative wire (terminal) from the battery.

- Then you need to move into the car interior on the driver’s side. For ease of operation, it is advisable to move the driver's seat in the opposite direction from the dashboard.

- Find the location of the sensor. Find a contact chip with wires. Press and hold the 2 plastic fasteners located on both sides of the chip. Pull the connector out of the sensor connector.

- Take the wrench in your hands and loosen the fastening nut. After which the sensor can be unscrewed freely.

- The installation process is similar to the removal procedure, except that you will need to make adjustments (tuning), the process of which is described in detail in the previous section.

If the brake pedal is pressed hard: diagnostics

As you can see, a tight brake pedal is often due to problems with the vacuum booster. At the same time, its operation can be quickly checked on the spot.

To diagnose VUT, you can use two methods. In the first case, you need to start the engine for the vacuum booster to start working. Normally, the pedal is soft; after two or three strong presses on the brake, the engine speed will briefly increase.

Another test involves pressing the brake several times with the engine off. Normally, the pedal should be soft for 2-3 presses, then it becomes hard. After this, you should press the brake and start the engine without releasing the pedal. The pedal should go down after the engine starts. If this does not happen, then you also need to look for a problem with the VUT.

Where is the heater radiator in the Lada Kalina?

The location of the heater radiator in Kalina is so inconvenient that, according to the instructions, to replace it you need to go through almost half of the car: remove the entire front panel, seats, pedals, not to mention the radiator itself and at least two of its pipes . Over the years, from their own experience, drivers have developed alternative ways to change the heater; we will talk about them a little later. Where to look for a stove radiator? Almost directly behind the instrument panel, and this is the root of all the inconvenience associated with replacing it.

Soft brake pedal: reasons

Having figured out why the brake pedal can be hard, you should pay attention to an equally common problem when the brake pedal has become soft. In such a situation, the brakes may be weak and perform poorly, which is no less dangerous than a hard pedal.

In extreme cases, the brake pedal may not rise after being pressed or may sink to the floor when braking. Naturally, in the case of a “cotton” pedal, owners are interested in what is the cause of the malfunction, why the pedal is soft after bleeding the brakes, and also how to make the brake pedal harder.

If bleeding has already been carried out, there is a high probability that mistakes were made, undetected breakdowns, brake fluid leaks, etc. occurred. For example, drivers often encounter a problem when, after replacing the brake pads, the pedal is soft, the brake pedal falls off after replacing the brake fluid, after bleeding the brake pedal fails, but the fluid does not drain, etc.

- One way or another, the main reason is depressurization of the brake system. Pipes fray and crack, problems with brake cylinders are possible, dirty brake fluid damages the cylinder mirror. Jamming of the TC pistons should not be ruled out.

At the same time, it is necessary to inspect the locations of all connections, fittings and other elements, since even a few drops of brake fluid leakage have no effect on the level in the reservoir, but air still enters the system, which is the cause of the soft pedal.

It should also be taken into account that if certain elements of the brake system have been changed (discs, pads, drums, working cylinders, etc.), in this case the braking efficiency will be slightly reduced until the parts are broken in. In this case, over several tens of km. The pedal may also feel softer than usual, or the brake pedal may alternate between being soft and stiff.

If the brake fluid is dirty, old and has lost its properties, it may boil due to heat. This leads to the brake pedal sinking or becoming too soft (“cotton”). This situation is dangerous because the problem may have a so-called “floating” nature. If such symptoms appear, you need to start with a complete replacement of the brake fluid.

Brake pedal sensor Lada Kalina

The Kalina brake pedal sensor is a technical device that is used to monitor the degree of impact on the brake pedal. Quite often, car owners of the VAZ line complain about breakdowns or incorrect adjustment settings of the product.

Fortunately, the process of adjusting or replacing a part is not very difficult if certain nuances are observed.

Performance diagnostics

Checking the functionality consists of: 1. Testing the product with a multimeter. 2. Disassembly and visual inspection of the internal components of the part.

3. Replacement sensor is not known to be good.

The first method involves alternately measuring the contacts of the dismantled sensor. The point is to check each contact individually and in pairs (second and third contact). This is quite convenient to do, since at the place where the contact chip is connected, all connectors are numbered.

The second method is used to identify faulty or deformed internal elements of the product (in most cases, damaged springs).

There should be no traces of oxidation or contamination. If there are any, clean them out.

The third method is quite simple and trivial. Install a new part to replace the one whose serviceability you doubt.

When the system is restored to normal operation, the malfunction indicator (check engine) should go out (if it does not disappear within 15 minutes, the error should be reset manually).

Signs of a faulty brake pedal sensor Lada Kalina

In order to understand that the Kalina brake pedal position sensor is the cause of the vehicle’s incorrect operation, pay attention to the following signs:

- presence of error “P-0504” on the dashboard;

- a significant decrease in power and engine responsiveness when pressing the gas pedal;

- increase in engine speed (short-term) when changing gears.

Main causes of sensor failure

In order to identify the reasons that interfere with the normal operation of the device, it is necessary to disassemble it and carry out a thorough inspection to identify deformations and damage. The following defects are most common:

- the internal (small) spring, which is located on the rod, shows signs of deformation or distortion;

- the contact terminals of the product have physical oxidation;

- backlash of the moving contact;

- Quite low quality of factory production (defective, flimsy internal elements of the device).

Adjusting the brake pedal sensor Kalina

If the sensor is in good condition, and incorrect operation of the internal combustion engine continues to bother you, try adjusting the product yourself

Please pay attention to the following features:

- The sensor must be screwed in clockwise until the brake pedal begins to move down. Then you will need to slightly unscrew the product and secure its position using the fastening nut.

- The result should be such that when there is no action on the pedal, the sensor rod is recessed into the housing, and when the pedal is applied, on the contrary, it is completely released from the housing.

- As for the working gap, it is adjusted using two nuts (one at the top, the other at the bottom). The adjustment is carried out using the upper nut, which is tightened, and the lower one, on the contrary, is unscrewed. The entire process is carried out until the button is completely recessed into the body when the brake pedal is applied. However, you should not overdo the adjustment; in other words, you should leave a small gap or travel margin (approximately 2 to 5 millimeters).

Removal and installation

Replacing the brake pedal sensor on Kalina is carried out using an adjustable wrench set to “19”. The sensor itself is located above the brake pedal under the steering column. Conventionally, the removal stages can be divided into 5 steps:

- Before starting electrical work, it is recommended to disconnect the negative wire (terminal) from the battery.

- Then you need to move into the car interior on the driver’s side. For ease of operation, it is advisable to move the driver's seat in the opposite direction from the dashboard.

- Find the location of the sensor. Find a contact chip with wires. Press and hold the 2 plastic fasteners located on both sides of the chip. Pull the connector out of the sensor connector.

- Take the wrench in your hands and loosen the fastening nut. After which the sensor can be unscrewed freely.

- The installation process is similar to the removal procedure, except that you will need to make adjustments (tuning), the process of which is described in detail in the previous section.

Why is the brake pedal higher than the gas pedal?

Drivers often wonder why on many models all the pedals in the car are not on the same plane. As a rule, on a car with an automatic transmission, the brake pedal is noticeably higher than the gas pedal. On cars with manual transmission, the clutch and gas are also often lower than the brake.

Let us note that there is a lot of debate on this matter and there are a number of conjectures and assumptions. Some car enthusiasts claim that this is inconvenient, others complain that if the pedals were in the same plane, it would be easier to control the car, etc.

Let’s also add that some owners believe that the brake pedal is placed higher in order to increase its travel, and also taking into account the need for more force (lever).

Let's sum it up

Taking into account the above, it becomes clear that any deviations from the norm in the operation of the brake system (either a soft brake pedal, a hard brake pedal, or a combination of problems) require immediate diagnosis. After identifying the malfunction, it is necessary to properly eliminate the problem.

You also need to promptly change the fluid, bleed the brakes, inspect the brake hoses for defects and leaks, install new brake pads, discs or drums in a timely manner, lubricate the brake caliper guides, etc. This approach will allow you to safely operate the car and achieve high-quality performance of the braking system in any conditions.

The brake pedal falls to the floor, the brakes disappear unexpectedly, after replacing the brake fluid, pads, brake discs: the main causes of the malfunction.

Reasons why the engine may stall when you press the brake. The power unit stalls during sudden braking, when the clutch and brake are depressed, etc.

What is engine braking? How to perform this technique correctly. Pros and cons, sleep recommendations. Engine braking on cars with automatic transmission.

How to brake correctly in a car with a manual transmission: types of standard braking on a manual transmission, emergency and emergency braking, tips.

The clutch pedal has fallen: why does this happen? The main reasons why the clutch pedal fails, what should the driver do if the clutch fails.

Driving a vehicle always involves various risks. A high-quality braking system can avoid most of them. Thus, if you find a hard or soft brake pedal, you need to immediately address this problem. If such problems arise, you should not delay; it is better to conduct a thorough diagnosis to find out what exactly is the cause of the problem.

Should I be concerned if the brake pedal is stiff or soft after bleeding?

The manufacturer has ensured that the brake pedal is pressed as easily and conveniently as possible. It is important that there is no need to exert significant effort while pressing, and various dips and jerks are unacceptable. Regardless of whether the brake pedal is soft and does not stop well, or there is a problem of some other kind, it is important not to leave things to chance. In general, if the brake pedal fails, then you urgently need to go to a service station or top up the brake fluid yourself. Most likely there is a leak in the brake system.

Both a tight pedal and too easy its movement are an alarming symptom that can indicate a number of serious problems.

What to do if the brake lights on a VAZ 2110 do not light up and repairs

Advantages of brake lights VAZ-2110

Unlike old VAZ models, where the sensor that turned on the brakes was closed from pressure, liquid or gas directly when the brake pads were activated, on the 2110 model the sensor is located on the brake pedal, and thus the lights come on at the slightest press on the pedal even before braking, giving road users a little advance warning.

Common problems with brake lights

There may be several reasons:

- blown fuse;

- faulty sensor;

- frayed or broken power cord.

The next troubleshooting point is to check the brake light sensor. To do this, you need to check whether voltage is entering and exiting the sensor. In this case, you need to use a control lamp. If the lamp does not light up when connected in front of the sensor, then the problem may be in the wires going to the sensor. If the lamp works before the sensor, but not after, then the problem lies in this part. You can also simply disconnect the input and output of the sensor and close it “directly” using a copper wire; if after these manipulations the lights in the brake lights light up, then the reason is precisely in the sensor. The sensor cannot be repaired, and the only way out is to replace this part with a new one.

The next cause of problems is burnt-out LEDs in the brake light; there have been cases when both burned out at once. To replace the light bulbs, you need to remove the flashlight board by squeezing it from the sides and pulling it slightly towards you. Next, you should visually inspect the light bulbs; perhaps a visual inspection will already answer the question about the reason for the non-working brake light. After this, you should replace the old lamps with new ones.

The brake pedal fails (the brakes are too soft)

It is worth noting that if you feel weak braking when pressing the brake of a VAZ 2109 or any other model, you need to think about the fact that these may be features of a particular vehicle. Perhaps you just moved from another car, so you feel some discomfort while driving a new car.

On the other hand, such a symptom can also occur when air enters the system. It should be noted that in the event of depressurization of the system, the pipeline may completely burst and completely fail. This can be corrected by bleeding the brakes. At the same time, you should diagnose the cylinders, check the level of the brake fluid, as well as its quality (often air gets into the brake system simply because there is too little fluid) and perform a full check of the vehicle (the latter will help determine the presence of hidden problems) ;

If the pedal becomes soft after replacing the brake fluid, then, as a rule, the problem lies in the use of a low-quality mixture. Alternatively, it is possible that air got into the system during replacement - this is also worth paying attention to.

It is also quite common for the pedal to feel soft after bleeding the brakes. First of all, you should bleed the master cylinder. As a rule, this solves a similar problem. Alternatively, there may be problems with the anti-lock braking system (if equipped). In any case, if the brakes are soft after bleeding, you should approach this task responsibly. Perhaps you should contact specialists who can quickly and effectively fix the problem.

Video about the operating principle of the brake master cylinder:

Causes of a hard brake pedal

If the brake pedal is either soft or hard, or the pressure is too tight, there are also several possibilities for the problem. The main reasons here include:

- clogging of the air filter of the vacuum booster. Basically, here you need to replace the filter itself;

- increased sizes of sealing rings in wheel cylinders.

Typically, in this case, the pedal became hard after changing the brake fluid.

You should not use low-quality death; it is better to buy the liquid recommended by the manufacturer. As a result, such a problem will not occur; - presence of mechanical damage on the diaphragm. The element should also be replaced;

- problems with the functioning of the tip in the amplifier. It is necessary to replace it with a working part;

- check valve stuck. These components cannot be repaired, so they should be replaced;

- Vacuum booster valve sticking. You just need to replace this element;

- presence on the hose between the intake manifold and the deformation amplifier or loosening of the fastening. First, try tightening the fastening clamp. If this does not help, you need to change the hose.

We discussed why a soft or hard brake pedal effect occurs. Regardless of the cause of this problem, malfunctions of the braking system are quite serious, so you should take a very responsible approach to diagnosis and repair. If you cannot fix the problem yourself, you should immediately contact a professional - in no case is it recommended to get behind the wheel of a car in which the brakes do not work correctly.