UAZ 3962 “Grey” › Logbook › Installing a winch.

I bought the winch almost immediately after buying the car.

Having studied I-Net, I came to the conclusion, agreeing with many practitioners, that the power of the winch should be twice the maximum permitted weight. I have a UAZ 39625 with a title of 2720 kg * 2 = 5440. A friend recommended the store polniyprivod.ru/, where I bought a winch for 17,000 rubles. Electric Winch 12000 with wired and wireless remote control, 30 m steel cable and 3 connectors (one for the front, one for the rear of the machine and one for the winch). As I later found out, the connectors hold no more than 200A of current, and the consumption of my winch at maximum loads can briefly exceed 400A. There was a need to find the appropriate wiring. Again, many days of searching for information, formulas, etc. Again, I had to rely on the opinion of experts that for every 10A a cross-section of copper wire (core) of 1mm2 is required. Accordingly, I took welding wires of about 40 mm2. The longer the wire, the more the losses in the conductor increase; accordingly, it is necessary to increase the cross-section of the core. The standard wires were short, so I had to disassemble the solenoid block and replace the positive wire with my own. Thanks to the guys, in the workshop they crimped the terminals with a special tool, put on the casings, it turned out no worse than at the factory, but it’s just enough from the bumper through the hole in the tunnel under the speedometer cable to the battery. In the future, I want to replace the battery (battery) with a 90 Ah instead of 60, replace the generator with an appropriate one (I’m still studying the characteristics) and install a winch power cut-off relay from a button on the panel (many complained that it sometimes shorts inside and the winch rewinds without responding to the buttons of the remote control and As a result, it breaks the bumpers, platforms and its own body). Also in winter, on the advice of friends, I will shorten the cable by 10 meters. When winding too long a cable to the side, a heap accumulates at the edge of the drum, which can break the transverse fastenings of the winch if you don’t keep track. So it’s better to interchange with a short cable several times. I would like to share my development for installing a removable winch on a non-lifted UAZ 39625 (loaf, tablet) with standard bumpers. The task was unusual (I set myself the Technical Assignment), install the Electric Winch 12000 winch on a loaf without changing the appearance and without making changes to the design, so as not to register with the Technical Department, not to worry about technical inspections, not to cut the bumper, etc. Moreover, the winch must be removable and installed both front and back for all occasions. The winch platform should not be lower than the edge of the bumper. The rear footrests and standard towbar should be preserved (they are very comfortable). Centering the winch in the middle is recommended, but not required. Inspired by the idea on YouTube:

After much research on the Internet, I decided to make an American towbar: a square pipe is attached to the frame of the car, a square pipe of smaller diameter is inserted into it, welded to the platform with the winch and secured with a pin or a cotter pin. Having told the idea to the specialists (the head of the metalworking shop), they came to the conclusion that the lateral loads of the UAZ require a minimum of 2 square meters. On the Internet I found a picture with the sizes of the holes and the distances between them on the winch platform for the UAZ Patriot on the forum uazpatriot.ru/forum/viewt…pic.php?t=18614&start=210,

They coincided with the drawing in the instructions for the winch and sent it to the workshop. They did it in a week, slowly, but efficiently. The only point is that this platform should immediately be attached to the frame of the Patriot, and on my copy, on the right and left, I cut off the protruding ears with a grinder. We found a rectangular pipe, but there was no smaller diameter! We got out of the situation by taking solid pieces of metal, machined them and welded them to the site. The weight turned out to be the same! All that remains is to attach it to the frame. The hooks must first be removed. They are attached to the frame not with bolts, but with rivets, and are installed “hot”. I spent several hours sawing off the heads of each rivet with a grinder on both sides. I tried to knock it out - it was useless. I had to drill out first with a small drill, then with a large one, and only then was I able to break out the hooks. The left one also turned out to be welded to the frame along with the steering gear mounting spar - but it still broke off! What a pleasure! Next, I measured the width of the frame with a tape measure, estimated the width of the plate, and sent the drawing drawn on my knee to the workshop. Afterwards, the finished plate was attached to the frame, holes were marked on it along the holes from the hooks and again to the metalworking shop. The next time we assembled a ready-made structure.

During final assembly there were many nuances. For example, a piece of rectangular pipe used to grind squares for the winch platform turned out to be from a different batch than the pipes welded to the frame platform. It took a long and tedious time to grind off the excess with a grinder. And inside these pipes there is also a protruding seam! The metal moves slightly when welding, so the squares that had slipped on the site were straightened out with a hefty sledgehammer. In general, they created problems for themselves. When I started cutting holes in the bumper, I realized that they had climbed into the place where the crooked starter was inserted! It was necessary to move the mount by 3 cm...

At the moment, the winch is connected according to a temporary scheme; the wires are simply attached to the battery terminals with nuts. Installation is also easy in 4 minutes. The front grille is removed, a platform with a winch is inserted, it is fixed with 4 pins, which are pinned, the wires are passed to the battery through the hole for the speedometer cable, the grille is returned to its place. In the future, it is necessary to move the solenoid unit into the cabin, remove the sockets from the welding disconnectors (purchased sockets will not be suitable for the current load) in the front and rear. I will route the wiring from welding cables in a corrugated structure along the frame. As soon as I do it, I’ll post it.

Source: www.drive2.ru

Brands of electric winches

“Americans” have proven themselves to be excellent in difficult operating conditions; they turn the cable without any overheating of the housing and gearbox, which is especially important in harsh temporary conditions.

The average cost of COME UP on the Russian market is 30-35,000 rubles, which, along with quality, plays an important role when choosing a buyer. The owners have not identified any disadvantages in using this winch; reviews about it are only positive. However, for many, 30-40k rubles is an amount that exceeds the limit for purchasing a “swan” and then the next option.

UAZ for the hunter: Three winches for one Loaf

You can scold the loaf, you can accuse UAZ of being retrograde, but so far no one in Russia has come up with a way to replace it. For example, take a very good version of the UAZ for a hunter.

We built a car for the specific needs of a specific person and assessed the investment; Hunting takes up quite a lot of time in a customer’s life and is not the least of his interests.

Preparation and correct final product. The air intake is organized through a hole under the roof - a useful solution for fans of “swimming”.

Headlight protection is not a sham, but real steel. Well, it looks evil.

The additional canister on the gate for the spare tire increases the load on the gate, but makes very good use of the space.

In terms of mechanics, the engineers took a classic approach: a 65 mm body lift, Ironman off-road shock absorbers, pneumatic axle locks, a transfer case kit with a 3.3 lowering and higher-torque main pairs (5.2).

To install Simex Jungle Trekker tires mounted on Wheels steel wheels, the arches had to be trimmed. RIF hubs are responsible for disabling the front axle shafts.

To get into the interior of the tall car, a real retractable step was installed.

A house for talking about hunting. Or fishing. Or…

The interior of the off-road bus was divided into cargo and passenger areas.

There is no luxury ahead - only utilitarianism.

The standard front seats have been slightly adjusted to match the car's condition.

In the stowed position, the table folds up and does not get in the way.

The passenger compartment is modest, but not without a certain luxury.

Place for shmurdyak is always a sore subject for travelers by car.

The cargo-passenger version would not fit here without the need for a large trunk.

Moreover, there was room for a spacious shelf above the cargo area.

The trunk can be washed under pressure - everything is sealed and will not get into the cabin.

Special rails are installed for loading the carcass.

Runva 9500 winches are installed in the power bumpers, but in order to find the third winch, you will have to open the trunk.

A small winch for the quad is installed inside and is designed to drag the carcass of a hunted animal into it.

Electric windows made it possible to use the space for installing speakers.

In the stowed position, the canister does not extend beyond the reserve. It is almost impossible to damage it.

The final preparation of Loaf for life in the forest was completed by the Raptor protective coating.

The result was a good bus, capable of traveling along unknown paths of dense forests.

Nothing superfluous, but you will have to climb high for a shovel.

Source: www.uaz.ru

Recommendations for installation and operation

You can install a winch on the UAZ 469 at a specialized automotive center or yourself. An important point is to read the installation instructions. Installation of the UAZ 469 winch must be carried out in strict accordance with the manufacturer’s recommendations.

Platform for installing a winch

The first step is to assemble the site for its installation. First, you need to designate the installation location of the traction equipment - on the front or rear of the car. When working independently, a piece of channel is selected. It should fit perfectly on the frame of the SUV.

Installation work is underway: the platform for the winch on the UAZ 469 is secured with bolts. They must be installed along the edges of the channel. This will prevent distortion when tightening the fasteners.

Note! The main thing is to set the platform level. This is an indispensable condition for further proper operation of the traction mechanism. Another condition for successful installation is pre-prepared drawing and technical documentation

Using it, a platform for the UAZ 469 winch is made. The drawing can be made independently or found on the Internet. They are often found on car forums, or you can use the links posted

Another condition for successful installation is pre-prepared drawing and technical documentation. Using it, a platform for the UAZ 469 winch is made. The drawing can be made independently or found on the Internet. They are often found on car forums, or you can use the links posted.

How to install a winch

A winch, assembled and installed by yourself, will serve every car enthusiast faithfully. With its help, the driver has the opportunity to move the power unit and pull heavy equipment out of the mud. This is an indispensable tool in any road situation.

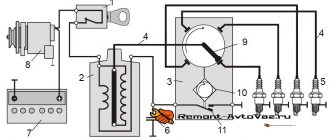

All types of winches operate on the same simple and understandable principle. The steel cable in them is wound onto a drum, which is mounted on an SUV. After installing the platform, the winch itself is placed in the standard holes. The bumper is recessed into the bracket and installed on the frame side members.

The complete washer is placed in the gap between the bumper flange and the corner of the bracket at the hole location. Towing hooks are placed on the bracket and secured with 6 bolts to the frame side member. There are 2 bolts at the bottom. Nut tightening torque: 40-60 Nm. At the last stage of work, it is necessary to connect the power cable to the positive terminal of the battery. The minus is placed on the mass.

We make a winch for a UAZ Bukhanka with our own hands

The question of how a winch is made on a UAZ Bukhanka will certainly be of interest to those owners of an all-Russian SUV who do not yet have this device installed on their car. And it can, under certain conditions, make life much easier for the owner. And for those who are constantly accustomed to traveling off-road, hunting or fishing, a winch is an absolutely irreplaceable thing. As they say, where an ordinary passenger car cannot pass, a Russian SUV will definitely get stuck! But jokes are jokes, but we have to get out. And here an ordinary winch comes to the rescue.

The winch on the UAZ Bukhanka can be installed mechanical, electric, or hydraulic. And there are also hand winches, driven by human physical force using a lever. All of these options have their pros and cons. But let's talk in more detail about each of them.

The device is connected to the shaft. The source of interaction is transmission. The winding speed is controlled by decreasing/increasing engine speed. Other advantages include high stability and traction power (achieved by motor torque). This type of winch is driven by the transfer case of the car. The main disadvantage: the winch directly depends on the serviceability of the motor; for successful operation it requires a properly running motor. If there is a problem with this node, it simply stops functioning.

This kind of device is attached to almost any car that comes with a hydraulic mechanism (UAZ included). The advantages: it works quietly and has small dimensions, powerful and has high performance. Of the minuses: its operation will be directly related to the hydraulic booster (if not, then the device will not function).

For homemade winches, as a rule, starters or generators can be used for loading. The electric winch can also operate on a dedicated electric motor installed in the car. But usually such a winch is mounted on the basis of a converted starter and must operate at sufficiently high speeds, otherwise it will not cope with a heavy machine. Therefore, some install batteries with large power reserves on their cars. Pros: high speed of operation, autonomy (can work regardless of whether the motor is on/off), simplicity of design. Of the minuses: it does not tolerate moisture well, the battery drains quickly.

Since a purchased winch, and even more so its installation, is not always available (most often due to the high cost), craftsmen have gotten used to constructing the structure with their own hands. By the way, this is quite possible to do if you have the necessary tools and certain skills. And yet, our homemade device must have a high torque, otherwise it simply cannot be used for a heavy UAZ (for example, to pull the car out of a mud hole). And most importantly, building a homemade winch will allow you to save a lot of money!

We make the structure itself using a welding machine and an angle grinder from pipes, 5 mm thick sheets of metal for the manufacture of drum discs, a chain with sprockets and a hub. All work is carried out clearly according to pre-drawn drawings. And remember the golden rule: you need to measure repeatedly before cutting.

After the winch structure itself is ready, you can install it on the UAZ Bukhanka. First, we carefully prepare the site. But first we decide: we will install the winch in front or behind. Typically, many people prefer a front location in the central part of the bumper. A channel is usually used as a platform for the device. A piece of it fits well on the car frame.

What components does the winch consist of?

As a rule, the standard electric winch kit for the UAZ 469 includes the following parts:

- The body of the device itself.

- Cable (wound on a drum).

- A metal hook with which cargo and other cars will cling.

- Joystick for easier control of the device.

- Remote control for the winch.

- Lever for switching stroke.

- Solenoid kit.

- Rollers for laying cables (also called sponges).

As a rule, the manufacturer does not include additional components in the kit. So if you absolutely require a corrosive sling or a set of pulleys, you will have to purchase them separately.

When purchasing a winch, it is very important to pay attention to the position of the rollers into which the metal cable will be laid. If the distance between them is greater than the thickness of the cable, then it may “bite” during winding. Of course, you should not purchase a winch with any visual defects.

Carabiners for car winches (pulley hoists)