Design and purpose of the air flow sensor VAZ 2107

The electronic engine control unit receives information about the amount of air entering the combustion chambers of the cylinders. Based on these data, the dosage of gasoline intake is calculated to form the optimal composition of the air-fuel mixture. DMRV VAZ 2107 (injector) is installed between the air filter and the throttle valve. The speed of air flow passing through the sensor is measured by monitoring the temperature of the electrical conductors. The sensor contains two conductive platinum threads. One is blown by passing air, the second serves for control. The passing air cools the first conductor and its resistance decreases. The degree of cooling, and, consequently, the amount of air passed, can be determined by the difference in resistance of the two threads: the larger the volume of air passes, the more the conductor is cooled and the more its resistance decreases. Specific calculations are made by the on-board computer based on algorithms that take into account not only the difference in the resistance of the threads, but also the current temperature of the control conductor.

Checking the electrical part with a multimeter

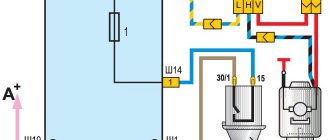

To find out what condition the electrical circuit of the mass air flow sensor is in, you will need to pinout the Siemens VDO contacts. First we check the block on the ECU side. We fix the negative wire of the multimeter to ground and turn on the ignition. We connect the positive wire to contact No. 5 of the block: normal supply voltage is 12 V. Similarly, we check contact No. 4; normal voltage is 5 V. If the values are different, check the ECU or the wiring harness from the mass air flow sensor to the engine control unit.

Important: The reason for the loss of supply voltage may be simple corrosion of the contacts; the operating conditions of the sensor are far from ideal.

How to check the sensor for the correct output signal? Using a diagnostic scanner (ideal) or the same multimeter. The output contact readings show not only the serviceability of the mass air flow sensor, but also the remaining resource.

It is necessary to connect the positive wire to the signal contact of the connector (on the VAZ 2107 this is green No. 3), and the negative wire to ground. The multimeter is set to a measurement range of up to 2 V, the error is up to hundredths of a voltmeter.

After turning on the ignition, the device should display a value of about 1 volt.

- readings from 0.9 V to 1.02 V – the DMF works perfectly;

- from 1.03 V to 1.05 V – service life is coming to an end;

- more than 1.05 V, or absent altogether - the sensor must be replaced.

Note: Repairing the mass air flow sensor is not practical due to the low cost of the device itself and the complexity of the design.

How malfunctions of the VAZ 2107 mass air flow sensor are detected

The first sign by which you can determine whether there is a problem with the sensor is a burning “Check engine” light on the dashboard along with the corresponding error code issued by the on-board computer. In addition, malfunctions of the mass air flow sensor are expressed in the following “symptoms”:

- increased fuel consumption;

- unstable idle speed;

- reduction in vehicle power or dynamics;

- increased or decreased idle speed;

- Difficulty starting the engine (especially when hot).

The above symptoms appear not only when the mass air flow sensor breaks down. However, if they appear, you should check the VAZ 2107 mass air flow sensor. The design of the sensor does not provide for its repair, so if it breaks, it must be replaced.

Tip: one of the reasons for sensor errors is damage to the air duct between the air filter and the throttle valve. Before changing the mass air flow sensor, you need to check its condition.

In some cases, the mass air flow sensor stops working due to contamination of the platinum filament. In this case, you can try to carefully clean it.

How to check the MAF sensor

An accurate check of the sensor's performance is possible only with the help of special equipment - a motor tester. This is an expensive device that only professional service stations have. At home, you can check the performance of the mass air flow sensor in simpler and cheaper ways. 1.Check by disconnecting the sensor. This is the easiest and fastest way to check the operation of the sensor “by eye”. This is done like this:

- disconnect the mass air flow sensor connector;

- start the engine;

- make a test drive.

Under such conditions, the engine ECU will go into emergency mode, ignoring the sensor reading. Accordingly, the composition of the air-fuel mixture will depend only on the readings of the throttle position sensor. If in this case the motor runs more smoothly or acceleration dynamics improve, the mass air flow sensor must be replaced. 2. Checking the operation of the VAZ 2107 mass air flow sensor using a multimeter is performed as follows:

- connect one multimeter probe to ground;

- turn on the ignition; measure the voltage at pin “5”;

- check the power supply circuit of the mass air flow sensor if the voltage is below 12 volts;

- check the voltage at terminal “4” of the mass flow sensor;

- a voltage of less than 5 volts indicates a malfunction of the computer or the sensor power circuit.

If no problems are found in the operation of the ECU and the power supply, it is necessary to replace the mass air flow sensor. 3. Visual inspection of the sensor can be done after removing it from the vehicle. The internal surface of the mass air flow sensor must be clean, free of oil deposits. At the same time, you should check the condition of the air duct from the filter to the throttle. Air leakage is one of the common causes of sensor malfunction. It is also necessary to make sure that the inlet grid of the mass air flow sensor is not oily or covered with dust. If it becomes dirty, it can be cleaned and the sensor will resume operation. Another part that affects the operation of the mass air flow sensor is the o-ring. If it is damaged, air leaks and the sensor stops working correctly.

Symptoms of a malfunctioning mass air flow sensor

Before you start checking the mass air flow sensor, you need to understand from the primary symptoms that it is faulty. The following symptoms may indicate problems with the sensor:

- The “Check Engine” icon is lit on the car’s dashboard;

- The car began to consume more fuel, while its acceleration dynamics decreased;

- Idle speed has changed up or down. The engine idles jerkily;

- The motor does not start.

The above symptoms indicate that air is not supplied to the combustible mixture in the volume required. Moreover, this problem can occur not only when the mass air flow sensor fails. In particular cases, the malfunction may be due to a lack of power supply to the sensor through the electrical wiring or when cracks appear in the connecting hoses.

This is interesting: How to start a car if the battery is dead alone

How to replace the MAF sensor VAZ 2107

To replace the sensor, you must perform the following steps:

- Use a 8mm wrench or a screwdriver to loosen the clamp holding the air duct;

- remove the air duct sleeve from the MAF outlet pipe;

- Using a 10mm wrench, unscrew the bolts securing the sensor to the air filter;

- remove the mass air flow sensor from the car;

- remove the rubber o-ring from the sensor;

- install a new sensor on the air filter, putting the O-ring on it;

- tighten the two sensor mounting bolts;

- put on the air line and tighten the clamp. This completes the replacement of the VAZ 2107 air flow sensor. You can test the operation of the engine.

In the design of sevens with injection-type engines, a mass air flow sensor is installed. The abbreviation stands for mass air flow sensor, which has a direct impact on the quality of engine operation. If the mass air flow sensor on a VAZ 2107 begins to malfunction, the engine will still work, but it is not recommended to operate it for such a long time. If this element breaks down, it should be replaced immediately.

Malfunctions of mass air flow sensor in diesel engines and injection engines

Since the adjustment of mixture formation is based on the readings of the mass air flow sensor, its failure can significantly affect the operation of the engine as a whole. Sometimes symptoms of a malfunction of the mass air flow sensor can be expressed in complete engine failure, seemingly for no apparent reason. There are, however, less alarming, but more eloquent symptoms that the sensor is not working correctly or has failed altogether.

- the engine warning light may come on;

- increase in fuel consumption, not stable, but periodic;

- a decrease in dynamics and loss of power may be observed;

- difficult start-up even under normal conditions;

- unstable idle speed.

Since thermal sensors are also installed in diesel engines, the symptoms may be identical. Exclusively diesel symptoms include characteristic black smoke from the exhaust pipe, but this cannot guarantee an accurate diagnosis. The symptoms are familiar to those who have encountered completely different problems in the operation of the motor, so they alone cannot judge the condition of the sensor. If there are suspicions about the correctness of its readings, the sensor must be checked.

Mass air flow sensor on VAZ 2107

The injection engine is controlled by electronics that receive information from various sensors, adjusting the supply of the fuel-air mixture and ignition. The mass air flow sensor shows the volume of air supplied to the combustion chamber. Against the background of data received by the ECU, the dosage of gasoline is calculated, forming the optimal amount of the fuel-air mixture.

DMRV VAZ 2107 injector is located between the throttle valve and the air filter element (it is mounted in the pipe). The device in question is based on two electrical conductive threads. The principle of operation is based on temperature fluctuations of the first and second threads. To do this, one thread is located directly so that it is blown by the air sucked into the system, and the second is hidden from the influence of the air flow on it.

When air enters the system, the first thread cools, and at the same time the current resistance in the circuit decreases. The more air enters, the stronger the cooling process. The second thread is the control thread, and its resistance does not change. The difference in resistance between the first and second threads is recorded by the ECU, on the basis of which a decision is made on the need to enrich or lean the fuel mixture. If it breaks, the engine will continue to operate, but only in a mode in which the fuel mixture will be mixed in the wrong proportions.

Symptoms of malfunction

The malfunction of this sensor on the VAZ 2107 is indicated by the inclusion of the Check Engine control indicator. However, the absence of an indication does not always indicate the serviceability of the part in question. This is due to the fact that the part very rarely fails completely. Often its malfunction is manifested through incorrect readings. With such readings, the ECU receives a signal from the device, and accordingly makes an appropriate decision on the need to enrich or lean the mixture.

If there is a suspicion that the device in question is malfunctioning, then you need to pay attention to the following symptoms:

- An increase in fuel consumption is detected.

- The idle speed increases, and unstable engine operation is observed at idle.

- The car becomes less pliable by reducing power and dynamics.

- Problems with starting the engine when hot.

The MAF sensor is one of the most expensive spare parts, and if it breaks, it needs to be replaced. It cannot be repaired, but before replacing it, you need to make sure that the sensor is really faulty. If you suspect a device malfunction, you should first check the integrity of the air duct. After all, often the cause of DMRV errors is the intake of air from outside, bypassing the sensor.

Sensor failure may be minor when the surface of the platinum filament becomes dirty. In this case, it can be cleaned. First, let's figure out how to check the device for serviceability.

Checking the mass flow sensor with your own hands

The serviceability of the device in question can be determined with high accuracy only in a car service center that has specialized equipment. However, not every car service center has a special stand, and even if it does, it’s not good to go for diagnostics every time with the above-mentioned symptoms in order to find out the cause. Instructions on how to check the sensor at home include the following steps:

- Disconnect power from the device. To do this, disconnect the terminal from the sensor and start the engine. The engine will operate in emergency mode, relying only on the readings of the throttle position sensor. The operation of the motor is compared with the sensor disconnected. If the motor operates more stably in this mode, then the mass air flow sensor should be replaced.

- Checking the mass air flow sensor with a multimeter. To do this, you will need to connect the black probe of the device to the engine ground, and with the second one touch terminal “5”, having first turned on the ignition. If the device shows a voltage below 12V, then the power circuit needs to be checked. If the voltage is normal, then you should touch one probe to pin number “5”, and connect the second to the third pin of the sensor. If the element is working, the device will show a voltage of up to 1V, and a faulty mass air flow sensor appears if the voltage on the device is higher than 1V.

- Signs of failure of the mass air flow sensor on the seven can be determined by using a known good element. If, after installing a new sensor on a VAZ 21074, stable engine operation is detected, then the malfunction has been successfully detected.

How to check the air flow sensor (3 ways to check)

In some cases, to check the mass air flow sensor, it must be removed from the car. Dismantling procedure:

- Loosen the clamp

- Remove the air pipe,

- Unscrew the screws securing the sensor to the air filter housing.

- Before disconnecting the electrical connector, you must remove the negative terminal from the battery. This must be done so that the electronic engine control unit does not generate an error and the check lamp does not light up.

Method number 1. Visual control

To do this, you need to remove the sensor and carefully inspect it for mechanical damage or foreign objects or debris. It is also worth visually assessing the integrity of the heating filament sensors or heating film.

Such problems can arise due to a leaky air filter housing, or due to a poor-quality air filter.

If visible damage is detected, the sensor must be replaced. And if there is debris or dirt in it, the air flow sensor can be cleaned with special products or a carburetor cleaner (alcohol-based spray). Mass air flow sensors are very fragile, so be careful not to clean them mechanically. The sensor cannot be repaired!

Method number 2. Power off

The easiest way to check the mass air flow sensor is to disconnect power from it. With the engine not running, disconnect the electrical connector on the mass air flow sensor. Then we start the engine.

In this situation, the engine control unit switches to backup mode and replaces the readings of the disabled sensor with those programmed by the manufacturer.

In this case, engine operation should normalize and idle speed should increase. For additional checking, you can drive a car with the MAF connector disconnected - 100-200 meters. If all symptoms of a malfunction of the mass air flow sensor have disappeared, then the sensor is transmitting incorrect data - it is considered inoperative and requires replacement.

When checking the mass air flow sensor in this way, after disconnecting the electrical connector from the sensor, the “Check” engine error lamp will light up on the instrument panel. After completing the check or replacing it, you will need to reset the error! To do this, you can disconnect the negative terminal of the battery for a few minutes (carefully, absolutely all settings will be lost). In some car models, the error can only be reset at a service center using a special scanner connected to the car’s diagnostic connector.

Method number 3. Checking with a multimeter

To check the air flow sensor with a multimeter, you need to know which parameters to measure and from which contacts of the electrical connector. They may differ for each car brand. The location of the sensor wires and terminals can be found in the vehicle's electrical diagram.

For example, on Bosch sensors that are installed on VAZ and GAZ cars, you can check the voltage (V) between the incoming signal and ground at the mass air flow sensor connector. To do this you need:

- Turn on the car ignition, but do not start the engine,

- Connect the red (+) probe of the multimeter to the yellow wire,

- The black (-) probe goes to the green wire of the connector.

- We set the mode switch on the multimeter to measure the minimum direct current.

The voltage at the contacts should be between 1.00-1.04 Volts . If the readings are higher, the sensor requires replacement.

Additionally, you can remove the sensor without disconnecting the electrical connector and apply a stream of air to the sensor from the air filter side. The voltage should increase to 1.3 Volts , in which case the air flow sensor is considered working.

Depending on the sensor design, it is still possible to measure the resistance on the resistors. Moreover, the measurement results at different air temperatures will be different. Accurate data on the optimal values of resistance readings, measurement temperatures and the location of contacts on the connector are usually indicated either in special technical literature or in the car repair instructions.

Check the mass air flow sensor yourself! | Topic author: Lidka

For those who feel sorry for the money for diagnostics... and not every diagnostician looks at this, I’ll tell you how to check the air flow sensor.

We take a regular tester (electronic is required), find the sensor chip and pierce the yellow wire with a needle. Next, take the tester, set it to 20 volts and turn the ignition. the voltage should be from 0.996 to 1.07, if more the sensor is lying, and if 1.1... the sensor is practically dead, but it can be revived. you need a compressor and carburetor cleaner (preferably more expensive). we spray the sensitive element located behind the mesh and blow it dry with air, measure the voltage, if it drops to normal, leave it, if not, do it several times (usually a bottle of cleaner is enough). I wish you all success. 150 rubles is not 1900, but you can try to recover it.

Ps can be checked without diagnostics, and flushing in most cases makes for a better start and more economical and stable operation of the engine. a little secret of car services (you come to them, they say, the sensor gives incorrect readings and you need to replace it. They install your own, the car works like a toy. In most cases, they leave the old one, they wash it, bring the voltages to normal and move on to the next car) and 1800 re and the old (washed to make a new one) sensor in your pocket.

some people advise washing with wd40...the air flow sensor dies almost immediately - I don’t recommend trying it.

the voltage at the output of a working sensor in the out-of-package state is 0.996...1.01 volts. If the voltage falls within the range indicated above, this is the best result of this test. further options are possible:

1.01…1.02 is a completely working sensor, very good.

1.02…1.03 is also acceptable, but the sensor is no longer young.

1.03…1.04 - most of the resource is already behind, you can plan for a quick replacement.

1.04…1.05 - clearly a tired sensor, it has already served its purpose. If your budget allows, feel free to change it.

1.05...and higher are a source of problems, it’s high time to replace them.

Carefully inspect the internal surfaces of both the sensor itself and the corrugation. attention! These surfaces must be dry and clean like... a baby's, without traces of condensation and oil! their contact with the sensitive element of the sensor is the most common cause of its premature death. This happens both because the oil level in the crankcase is too high, and because the oil sump of the crankcase ventilation system is clogged, the outcome is usually the same. If this phenomenon occurs in the intake tract, replacing the sensor is contraindicated! until the causes are eliminated, so that there is no excruciating pain later for wasted money.

dependence of the air temperature sensor resistance on the intake air temperature (permissible error 10%)

The DMRV has a built-in air temperature sensor, the sensitive element of which is a thermistor installed in the air flow. at low temperatures the sensor resistance is high, and at high temperatures it is low (table) if the air temperature sensor is faulty, the computer stores an error code and turns on the warning light, and replaces the readings of the faulty sensor with a fixed air temperature value of 33 °C