Installing power steering on a gazelle.

I'm so tired of driving around yards without power steering.

There was still nowhere to go along the highway, but as soon as you entered narrow courtyards, the fun began. Then I decided to look for power steering installation kits and it turned out that they are sold only in Nizhny Novgorod, although advertisements are posted in Moscow, but delivery comes from Nizhny. Having found a kit that suited me, I contacted the seller and it turned out that their car constantly travels from Nizhny to Moscow and they can send my kit with it. We agreed on the next day. And then my package arrived, which I wanted so badly, but the toad always choked me. By the way, the set cost me 26,300 rubles.

Yes, now many will start writing that this is a Russian set, and not a ZF, which is more reliable and handles better, but with my mileage, this will be enough for me for a long time.

And yes, I’ll tell you even more. I came across a seller who, under the guise of new spare parts, sells refurbished ones. Maybe all sellers do this with these kits, but the fact remains.

The kit contains everything for the complete installation of power steering on a Gazelle. The installation itself is not long, but you will have to hang the engine to install the pump mount.

I struggled with the bipod for a long time, but with the help of a mantle and a sledgehammer it came off.

The Rklevoy shaft stood up like original, but I didn’t change the boot, even though it was included in the kit. Either I was lazy or I really wanted to have a quick ride with the power steering. My boot is in excellent condition, and I kept the new one as a spare.

The oil included was OILWRIGHT and I didn’t dare to pour it into the power steering, but looked around in the garage and found a normal ATF and filled it.

After I installed everything and filled the reservoir with ATF, I started pumping the power steering. I hung up the wheels and, with the engine turned off, began to turn the steering wheel in different directions. Almost all of my barrel was gone and I had to top it up to the level.

Having lowered the car onto the wheels, I felt this ease of rotation of the wheels. Previously, it was even hard to imagine that I would ever turn the steering wheel on this Gazelle with one hand in place. But for some reason, approaching a full turn, the steering wheel becomes stone, although there is still room to turn. But okay, these are minor things.

I am very pleased with the result and now it is much more comfortable to drive this car.

Subscribe to my channel, leave comments and likes!

Source

Refinement of the GAZ 3110 power steering system

The car came stock with power steering... well, it would be better if it wasn’t there at all. The power steering gearbox was installed in the very first production of ShNKF 453465.100.

There were problems with the power steering system from the first day of owning the car... the pump was changed 3 times... the power steering was rebuilt 1 time... looking ahead, I’ll say that this gearbox was not completed before replacement for only 2 weeks and began to leak

There was an idea to buy this power steering kit from Avtodetalservis avtodetal.com/index.php?section=282 Here is a review from a person who bought and installed it for himself www.drive2.ru/cars/gaz/31...376151945221/#replieslist But I have to buy it like this and it failed... if only because of its cost in Ukraine. 5000 hryvnia is not a little, and that’s for Russian parts...

Well, since I couldn’t buy everything at once... I decided to take a more time-consuming and correct path.

I collected a few details like this:

1. I bought a used Volga 31105 power steering gearbox ShNKF 453461.103 link to technical specifications www.agu.by/index.php?module=view_id&vid=1299

2. Power steering pump bracket from the Avtodetalservice kit

3. Power steering pump from a Chevrolet Niva car, part number according to catalog 2123-3407012.

4. I bought a copper tube with a diameter of 13 mm, from which I bent an oil cooler for the power steering system

5. I turned a pulley of the required diameter, since it was not possible to find a ready-made one.

I also additionally bought hoses, metal corrugation, copper washers, adapters, clamps...

The purchased used power steering gearbox from the 105th Volga was sent for modification to the craftsmen at the hydrolab in Moscow (www.gidrolab.ru/price1.shtml). Such modification cost 3,500 rubles. rub. In principle, I have no complaints about them yet, but these guys did not return the bipod and driveshaft that were on the gearbox...

Came like this from Moscow

Stage No. 1 Installation of the power steering radiator: Radiator made of 13mm copper tube. is placed in place of the oil cooler. I bought good quality hoses and laid them in an iron corrugation so that the hoses did not fray or bend. The radiator is placed in the drain line from the gearbox to the expansion tank.

The radiator is fixed, the tubes are connected.

Stage No. 2 Preparing the pump for installation: Here I was faced with a choice for a long time: whether to take it from a Volkswagen, BMW, Audi or Chevrolet Niva

On the left is a pump from an Audi A6 on the right from a Chevrolet Niva... in this photo you can clearly see that they are very similar. There are differences in the angles of the hoses...

Tags: gur

Comments 17

pump from UAZ 469, mount from worthless, steering column from 3110 and belt from groove

it's simple. you take the bracket from UMP and the pump from it! You'll have to look for the pulley. A different trapezoid will be needed. Right now I can’t say for sure about the trapezoid, but there were pivot ones with and without a girder, so you need to look for a pivot one with a girder.

Buy a Volga with 305 configuration and don’t worry, everything is done there from the factory;)

you need to buy a power steering pump for 402 doors. and pump mounting brackets and everything. I converted my s406 to 402 and back. does not touch anything with a trapezoid under 406 doors

on the gearbox with a steering wheel, move the tab that is attached to the trapezoid from a regular gearbox without a steering wheel, if your 3110 is on a ball suspension, then change it anyway, on the 3110 and 105th ball suspension it is an order of magnitude longer, and pay attention to the pendulum, it is also longer , few people attach importance to this, or do not know about it at all, hence the bad and incorrect turning and touching the pallet.

What exactly needs to be changed to make the turn better?

www.drive2.ru/cars/gaz/31/3110/toxa3160/2/ here you will find all the answers to your questions)

On the early 3110, under the 402, there were 3-groove pulleys. It’s difficult to find, expensive, but possible...

nothing went there in the early days, this is where the gur from the factory was there.

You change the gearbox from a regular one to power steering, adapt the pump to 402... Nothing was touched anywhere...

402 will completely die. he doesn't go anyway.

17 seconds to 100 is it going?

If you have straight arms, you can reduce it to 10s

Interesting too. I've been wanting to start a gurg for a long time, but somehow I always give up on it.

I don’t know about the trapezoid, but I couldn’t convert the power steering pump from the 402 engine to the 406 (I never removed the pulley), so it’s lying around and along the trapezoid I have gas 3110 from 402 from the factory, I moved the engine to 406 no problems, just changed the pumps

source

Power steering device gas 3110 repair drawings photo

Any motorist will say that the GAZ 3110 steering mechanism is one of the most important components of the car. Without this it is impossible to drive a car. If there is a problem with the steering mechanism assembly, then operating the GAZ-3110 is strictly prohibited. Even if there is play in the steering wheel, you need to pay attention to it. When a backlash is detected, the driver first goes to a technical inspection station to diagnose the Volga.

Parts for repair of the steering mechanism Gas 3110

When the cause is identified, there are 2 options for solving it. The first is to leave the car to professionals who will make the steering mechanism assembly for a fee, or figure it out yourself and eliminate the cause of the breakdown. In order to know how to fix the problem, you need to have an idea of what the GAZ-3110 steering system consists of:

Device diagram and steering design

- Steering wheel.

- Column.

- Steering gear.

- Hydraulic booster.

- Drive unit.

It would also be very good to consider, or better yet, learn the diagram of what is attached to what and what it looks like.

Device

Both the electric power steering on the Gazelle and the power steering are designed for more comfortable steering. First, let's analyze the power steering device on the Gazelle. We are talking about both the Gazelle Business with the 405 engine and other models in this line.

- Power steering pump. This circuit element ensures optimal circulation of consumables in the system, as well as pressure.

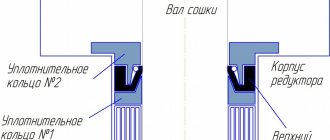

- Steering gearbox with distribution element. This device allows you to provide the air flow necessary to direct the oil into the desired cylinder cavity or back into the tank.

- Another component of the system is the cylinder. With its help, the pressure of the consumable material is converted into the movement of the piston, as well as the rod.

- The consumable material itself, that is, oil. The fluid transmits force from the power steering pump to the cylinder. In addition, the oil provides lubrication of all rubbing elements of the device.

Checking the mechanism

If the driver notices any problems with the steering mechanism. It will be seen and heard. The steering wheel may shake and there may be a drumming sound. When turning, the steering wheel will “wedge” or “knock out”.

Drawing with the names of the elements of the steering column GAZ 3110

You can check the node yourself. To do this you need:

- Put the GAZ-3110 on the handbrake.

- Place supports under the rear wheels.

- Loosen the wheel on the left at the front.

- The front of the car should be raised and placed on supports.

- Remove the wheel.

- After this, remove the protective mudguard.

- In the Volga 3110 interior, completely disconnect the assembly shaft from the mechanism below.

- It is required to mark the position of the control shaft and bipod.

- Remove the bipod from the shaft.

- After removing the bolts, remove the mechanism.

Summing up

As a result, we can say that the steering unit in a car is the main component of the entire mechanism. Do not postpone repair work and diagnostics if any deviations appear. At the slightest incomprehensible sound or vibration, you need to go to a service station and get a diagnosis done.

Installation of a steering column on a Gas car

Because this barely audible sound while the car is moving can turn into a big problem, especially if the Volga is driving at high speed along the highway.

Source

Steering mechanism with hydraulic booster GAZ 3110 Volga

- Repair manuals

- Repair manual for GAZ 3110 (Volga) 1996-2004.

- Power steering mechanism

5.8.1 Power steering mechanism PERFORMANCE ORDER 1. Turn the steering wheel from lock to lock. 2. If the steering wheel rotates easily in one direction and hard in the other, then the power steering mechanism is faulty. 3. If the steering wheel rotates heavily in both directions, it means... 5.8.2 Replacing the steering mechanism PROCEDURE 1. Set the car to the parking brake. 2. Place chocks under the rear wheels. 3. Loosen the front left wheel mounting bolts. 4. Raise the front part of the car and place it on supports. 5. Unscrew the bolts and remove the wheel. ...

5.8.3 Replacing the power steering pump Warning Pumps can be supplied as spare parts with a fitting for the upper hose or without a fitting. If the new pump does not have a fitting, you need to unscrew the fitting from the old one. EXECUTION ORDER 1. Set the car to the parking brake. 2. Place chocks under the rear wheels. 3…

5.8.4 Replacing the fluid PERFORMANCE ORDER 1. Drain the fluid from the power steering system. To do this, unscrew the hose on the pump that goes to the steering mechanism. Reconnect the hose to the pump and tighten its mounting bolt to a torque of 44–62 N·m (4.4–6.2 kgf·m). 2. Unscrew the plastic...

5.8.5 Bleeding the power steering system PERFORMANCE ORDER 1. Turn the steering wheel all the way in one direction. 2. Unscrew the air release valve on the steering gear. 3. Without turning the valve, turn the steering wheel all the way in the other direction. In this case, air should come out of the valve, and then liquid. 4. N...

↓ Comments ↓

1.Operation and Maintenance

1.0 Operation and maintenance 1.1 Interior heating and ventilation 1.2. Running in the car 1.3 Checking the car before leaving 1.4 Frequency of replacing operating fluids and lubricants 1.5 Caring for the paintwork of the body 1.6 Frequency of lubrication of vehicle components

2.0 Engine 2.1. Removal and installation 2.2. Engine of models 402 and 4021 2.3. Lubrication system 2.4. Cooling system 2.5. Exhaust gas system 2.6. Engine power supply system ZMZ-4062 2.7. Power supply system for ZMZ-402 and ZMZ-4021 engines

3.0 Transmission 3.1. Clutch with diaphragm spring 3.2. Clutch with peripheral springs 3.3. Five-speed gearbox 3.4. Four-speed gearbox 3.5. Cardan transmission 3.6. Rear axle 3.7. Axle shafts 3.8. main gear

4. Chassis

4.0 Chassis 4.2. Rear suspension

5. Steering

5.0 Steering 5.1. Steering wheel 5.2. Steering column 5.3. Steering mechanism 5.4. Steering linkage 5.5. Ball joints of the steering linkage 5.6. Pendulum arm 5.7. Ball joint of the pendulum arm 5.8. Power steering mechanism 5.9 Possible steering malfunctions.

6. Brake system

6.0 Brake system 6.1. Brake pedal 6.2. Vacuum booster 6.3. Main brake cylinder 6.4. Front brake mechanism 6.5. Rear brake mechanism 6.6. Pressure regulator 6.7. Parking brake 6.8 Bleeding the brake system 6.9 Possible malfunctions of the brake system.

7.0 Electrical equipment 7.1. Battery 7.2 Fuse block 7.3. Generator 7.4. Generator 9422.3701 or 2502.3771 7.5. Generator 1631.3701 or 192.3771 7.6. Voltage regulator 7.7. Starter 7.9. Sound signal 7.10. Ignition system 7.11 Electrical diagram of a GAZ-3110 car with a ZMZ-4062 engine 7.12 Electrical diagram of a GAZ-3110 car with a ZMZ-402 engine

8.0 Body 8.1. Front buffer 8.2. Rear buffer 8.3. Radiator lining splash guard 8.4. Hood 8.5. Front fender 8.6. Trunk lid 8.7. Front door 8.8. Rear door 8.9 Replacing windshield and rear windows 8.10. External rear view mirror 8.11. Instrument panel 8.12. Windshield wiper 8.13. Front seat 8.14 Rear seat 8.15 Seat belts 8.16 Rear parcel shelf 8.17 Interior attachments 8.18. Heater 8.19 Possible malfunctions of components and body parts.

9.0 Applications 9.1 Weight of units 9.2 Lamps used on the vehicle 9.3 Rolling bearings used on the vehicle 9.4 Cuffs used on the vehicle 9.5 Fuels and lubricants and operating fluids 9.6 Tightening torques of critical threaded connections *

10. Vehicle specifications

10.0 Technical characteristics of vehicles 10.1. Engine

Damage analysis

To identify a malfunction, you need to check the crankcase. If there is a crack or chip on it, then it cannot be repaired; you need a new one.

The bushings look worn out. They also need to be replaced. You can find the crankcase assembly at points of sale of parts.

Worm and roller - if deformation is detected - replace. The bearing should be lubricated and without obvious flaws.

Steering columns removed from the car

If oil leaks occur from time to time, gaskets and seals need to be replaced. Reassembly is carried out in the reverse order, according to the marks made during disassembly.

Actions to replace and repair the pump

You can change this unit yourself. It is even possible to replace a failed bearing. In this case, a power steering pump repair kit will come in handy, which can be purchased at any car store.

Before making a decision to carry out repair work, you need to check the presence of fluid in the tank, as well as its compliance with the brand approved for use on this machine. Often, the cause of signs of malfunction is the appearance of air locks in the system. Therefore, if you suspect this, you need to bleed the hydraulics, removing all air pockets. In this case, the performance of the power steering can be completely restored.

If, when checking the quality of the working fluid, it is discovered that it does not meet the standard, it must be replaced with a fluid of the required brand.

If you decide to repair the power steering pump, you need to prepare a workplace and the necessary tools, as well as materials for the work:

- you need a key for “12”, as well as heads for “14” and “24”;

- you will need a snap ring remover;

- prepare in advance two copper washers, a gasket for the rear casing, two O-rings and an oil seal; they can be replaced by a power steering pump repair kit;

- It is necessary to have a bearing marked “6202” and an outer diameter of 35 mm;

- To pump oil out of the tank you need a large syringe and container;

- clean the workbench and cover it with clean cardboard for disassembling the pump;

- Prepare fine sandpaper and rags for wiping.

Adjusting the steering screw thrust bearings

| 1. Having removed the steering mechanism along with the bipod, remove the universal joint fork from the input shaft of the steering mechanism. | 2. We fix the steering mechanism in a vice with the input shaft up, positioning the screw axis vertically. |

Therefore these gears are also called constant gears. For direct transmission, torque is transferred from the drive shaft directly to the main gear shaft. At point 2, torque transmission is displayed in direct form. When the engine is running and the clutch is disengaged, all transmission gears except the retractable rear wheel and the stationary wheel rotate, even when the transmission is in standby mode. Five-speed fifth gear for speed: straight shot - fourth gear.

The output speeds in fifth gear are higher than the input speeds. The gearboxes on 1, 3 and 4 are straight-line gearboxes 4 Three-way five-speed gearbox. Unlike the pre-3 gearbox, the direct gear is the fourth gear. Fifth gear shifts to speed. Torque is transmitted from the drive shaft through the gears to the front shaft, which rotates at a lower speed than the drive shaft, and from the shaft through its stationary wheel to the free wheel; through the sliding sleeve, which must then be shifted to the right, and its timing unit on the main gearbox.

The force required to turn the input shaft after adjustment should not increase noticeably.