Welcome! Steering gear - it is also popularly called the steering column, thanks to it the wheels of the car rotate, it necessarily consists of a housing and a shaft that comes from it, by the way, depending on the length and thickness of this shaft, as well as depending on the size the parts themselves (For example, from the worm itself, which is located in the gearbox housing) which are located in the gearbox housing, the steering wheel can turn quite easier if all the parts have large shapes (the larger and longer they are, the easier it will be for the car’s steering wheel to rotate), the whole point is that the gearbox facilitates the rotation of the steering wheel and transmits all the torque to turn the wheels of the car, but it, like any other part, wears out over time and mainly after wear it begins to leak, especially if you do not add oil to the gearbox, it becomes so over time It’s hard to turn the steering wheel, this is especially noticeable when driving not at too high a speed, so the gearbox must be repaired (If it can still be repaired) or, if possible, replaced as soon as possible.

Note! In order to change the steering gearbox in a car, you will need tools, namely: A basic set of wrenches, as well as all sorts of other types of wrenches, in addition, we recommend that you use socket heads and a wrench, since it is not always convenient to unscrew the nuts using a wrench key, in addition to this (This no longer applies to tools), you will also need to take an assistant with you, because you will have to carry out this operation together, as it is more convenient!

Where is the steering gear located? It is located in the engine compartment and in the lower part of the car, because of this it is not very convenient to remove it from above, so for such work you need a second person who will take the gearbox itself when you unscrew all the nuts that secure it.

Note! If you want to see the gearbox itself, that is, where it is located, then open the hood of the car and look where on the body (Not on the engine) on the driver’s side, you have a gearbox, which for clarity was shown with a red arrow in the photo below:

When should the steering gear be replaced? Many people recommend immediately going to an auto shop and buying a new gearbox and replacing it with a new one, although it, like any other part, can be repaired (Vit, not everyone has the money to buy a new unit), but as they say, only you can decide here, and We will present the main malfunctions that arise when the steering gear fails, firstly, the oil that is inside it may leak from it (This is either due to the fact that it is rusty and corrosion has corroded it, or the oil seal in it has worn out and requires replacement) , in addition, the steering wheel, due to a worn steering gear, can also turn hard (There are many other components in the steering mechanism that are responsible for steering, so if your steering wheel starts to turn hard, you don’t need to immediately throw all the problems at the steering gear, because this is maybe because of the pendulum arm, but also because of other parts).

Note! In addition to all the above problems, due to wear of the steering gearbox, the steering wheel can simply jam (Won’t spin), and it can also spin but the wheels won’t rotate, so this gearbox plays a very important role in cars and if any of these If you notice any problems with it, we recommend that you replace it with a new one as quickly as possible, or if this is not possible, then simply repair it and after proper repair, it should work for you as before! (For information on how to repair a gearbox, read the article called: “Repairing a steering gearbox on a VAZ”)

How to replace the steering gearbox on a VAZ 2104, VAZ 2105, VAZ 2107?

Removal: 1) At the beginning of the operation, you will need to put the car on a viewing hole, or if you are not afraid, you can lift the front part of it with a jack and place not very thick planks under the front wheels, and then lower the car on them in connection with this it it will become much higher, but it will not be very convenient to work, so as they say here, it’s up to you to decide what to choose.

Note! Be sure if you put planks under the front wheels, we will tell you a couple of practical tips, namely, do not under any circumstances place bricks under the car so that it stands on them, because bricks (no matter how durable they may seem) sometimes cannot withstand the load in this regard, they crack (at best) or break (at worst) and the car falls to the ground, in addition, it is recommended to place something under the rear wheels so that the car will stop in place, and also for greater safety, raise the handbrake of the car and put it on speed so that it stands rigidly and doesn’t roll anywhere!

2) Then, if your car has a distributed injection system (popularly an injector), then you will have to remove the adsorber because it takes up a lot of space and if it is not removed, it will be difficult to remove the steering gear. (For information on how to remove the adsorber, read the article: “Replacing the adsorber on a car”)

- How to remove the gearbox on a VAZ 2107

3) Next, you will need to remove the protective cover of the steering horse (We will not teach you how to remove this cover, because most owners already know this), this cover, as you can see in the photo below, has already been removed, so when you remove it from car, having unscrewed all the screws that secure it, then take two wrenches and with one wrench hold the bolt from turning as shown in the photo below, and with the other wrench completely unscrew the nut of this bolt and then remove the bolt from the hinge.

4) Now you will need to unscrew the two nuts that secure the rods to the bipod of the steering gear (the bipod is indicated by a blue arrow), but before you start unscrewing them, let’s take a little look at what this bipod is, and so it is located on the steering gear itself ( It is screwed to it with a nut), due to this bipod, the forces that come from the steering gearbox are transmitted to the wheels, for example, you turn the steering wheel and all the force that comes from it is fed first to the gearbox itself, then the force goes further and reaches this bipod, which in turn, moves two rods that are connected to it and thereby the wheels rotate either to the left or to the right.

Note! After we have figured out a little about this bipod, we will tell you a few words about where and how both rods are attached to it using nuts, firstly, so that you understand what a rod is, for clarity, one of them is indicated in the photo below with a red arrow, this the rod enters the hole (see photo above and the red arrows that indicate the same holes into which both rods enter) and is attached to it at the very top with a nut, so if you want to remove the rod from this hole, that’s what you basically need will do if you are going to remove the steering gear, then first of all take an extension and a socket and on top of the car crawl under the nuts that secure both rods and then unscrew them as shown in the small photo below:

But before you unscrew the nuts, be sure to remove the cotter pins (Cotter pin - it looks like a small metal twist, it is needed so that the nuts do not come loose and it can be removed easily, you take pliers in your hands and with their help you simply pull it and it comes out hole in which it is installed) otherwise you will not unscrew the nuts! (For clarity, the cotter pins in the photo below are indicated by red arrows)

5) When the nuts are unscrewed, you will need to make sure that both steering rods come out of the bipod, namely at the end of the steering rods there are so-called fingers that go into the holes that are present on this bipod, you will need to knock out both fingers, and you will have to carefully knock out this whole thing using a hammer and small fittings.

Note! By the way, using a special puller, you can also press out both fingers of the steering rods from the bipod. To do this, you need to take the puller and place it as shown in the photo below, where the bipod is indicated by a red arrow, and the steering rod itself is blue, and then tighten the nut that is on top on the pullers, remove the tie rod pin from the hole in the bipod!

Something else you should know, if you decide to knock out the steering rods, then you don’t need to completely unscrew the nut that secures them, otherwise, when the finger comes out of the hole in the bipod, you can still hit it or some other place by inertia, otherwise the finger will not be able to fall completely down because it will be limited by a nut, which you will then unscrew and the finger will come out of the hole in the bipod!

6) And finally, find the bolts at the end of which there are nuts installed (which secure the steering gear), as you can see in the photo below, they are located in the side member of the car on the wheel side, so when these bolts are found, take two keys and unscrew them with their help nuts (and hold the bolts with another wrench) that secure the steering gearbox, and when everything is unscrewed, carefully remove the gearbox, taking out its shaft, which is inserted into the hole and goes into the car interior, if the gearbox is difficult to remove (cannot be removed due to its large size ) then move the bipod (It moves) all the way in any direction and then try to remove the gearbox through the top.

- Replacing the steering gearbox on a VAZ 2104, VAZ 2105, VAZ 2107

Note! If the gearbox does not come out from above (It is unlikely that this will happen), then try removing it from below, and also remove all parts that will interfere with its removal (For example, crankcase protection)!

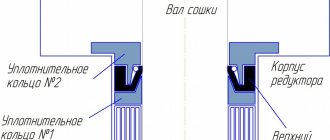

Installation: 1. First you will need to install the steering wheel (Not the wheels themselves, but only the steering wheel) in the direction of straight-line movement, and after aligning the steering wheel, install the steering gear in the reverse order of removal, and when you install everything, make sure that the mark on the shaft (Indicated blue arrow), coincides with the mark that is on the gearbox housing (Indicated by the red arrow) and when these two marks coincide, check that your bipod is exactly in the middle position.

2. In addition, when you put the gearbox in place, do not rush to tighten the bolts that secure it until they stop (just tighten them a little so that they at least somehow hold the gearbox), and also insert both fingers of the steering rods into the bipod and tighten the bolt at the end of which there is a nut , which attaches the steering shaft of the gearbox to the cardan joint in the car interior and when this is done, vigorously turn the steering wheel a couple of times all the way to the right and all the way to the left and then measure the gap in the cabin using a ruler between the brake pedal and the steering gear shaft. will have to be at least 5 mm.

Note! When the gearbox is installed, be sure to check if there is oil in it and, if necessary, add it if it is not there, read about how to do this in the article called: “Changing the oil in the steering gearbox on a VAZ”!

Classic "five"

Owners of "fives" often suffer from a typical problem with "Lada" cars - a kind of steering. On bumps and uneven surfaces, Lada cars have a very unpleasant property of changing the direction of movement. Experienced drivers know about this problem, so they try not to let their guard down. But beginners often find themselves in very dangerous road situations. It is no wonder that many owners decide to modify the VAZ 2105 steering gear or at least configure it correctly in order to increase driving safety and comfort.

Return to contents

Steering device

In terms of its design, the VAZ steering is a fairly simple, but technically sophisticated mechanism. Its most interesting part is the steering linkage, which consists of a very large number of levers and rods. In appearance, the steering mechanism of the VAZ 2105 is quite flimsy, but in fact it can withstand even very difficult road conditions. The design is not so archaic; the VAZ steering column has a special plate, thanks to which the shaft, consisting of several stages, folds in the event of an accident, and the steering wheel does not injure the driver. The worm gear of the VAZ gearbox and the lever system significantly reduce the effort that the driver spends on turning the wheel. Despite this, driving a “five”, or any other “classic”, requires considerable physical strength.

Inside the steering column of the “five” there is a cardan transmission that leads to the gearbox. The VAZ steering shaft crosspiece is used for connection. The entire mechanism is quite reliable and can withstand very long runs. All parts are made from high quality steel and are carefully inspected before assembly or sale. Thanks to this, there are very few accidents of Lada cars due to complete failure of the steering, and repair of load-bearing parts is required only in case of serious damage.

- Repair of steering gearbox on VAZ 2104, VAZ 2105, VAZ 2107

This is the unit

The most complex part of the mechanism is the steering gear, which is based on a worm gear. Since the worm gear is initially characterized by gaps and is subject to wear, a special adjusting bolt is built into the gearbox housing. It presses the bipod shaft, preventing gaps from causing the wheel to wobble.

The steering gear mechanism is in an oil bath, thereby reducing its wear. Regular transmission oil, an analogue of TAD-17, is poured into the gearbox. The steering rods of the “five” are mounted on hinges protected by rubber boots. The steering does not require constant injection and lubrication, but it is necessary to periodically inspect the boots for integrity. To assemble or disassemble the rods, you will need special pullers; you can make them yourself.

Thanks to its simple design, the VAZ 2105 steering control can be repaired with your own hands in a garage.

Return to contents

Unit setup

It should be noted that the problem of “yaw” on the road after hitting an obstacle in a “classic” cannot be completely solved, but through careful adjustment it can be minimized. First of all, it is necessary to adjust the steering gear. It is quite difficult to do, especially if you are not used to it. To carry it out, you need to drive the car onto a level surface, making sure that the wheels are straight.

Adjusting the steering column

Next, you need to use a special puller to press out the fingers and disconnect the bipod. Then everything is very simple - shake the bipod, hold the steering wheel (or vice versa), catch the gap in the worm gear of the VAZ gearbox. According to the instructions, the angle of rotation of the steering wheel when the bipod is clamped should not exceed 30°. If there is play, then unscrew the nut, tighten the clamping screw a little and tighten the nut again.

The most important thing is not to pinch the adjusting screw or break the thread. If the screw is tightened too tightly, the steering will be very tight. There is a special standard for steering wheel force - 25 kgf. The force is controlled when the bipod with rods is installed and the fingers are pressed in. The force is checked using a torque wrench. If it is very large, then the adjusting bolt needs to be loosened a little.

Sometimes adjusting the VAZ gearbox may not give anything. If the mechanism is completely worn out, what can you do? There is no particular point in repairing it, and it will take a lot of time. Therefore, in order not to bother with repairs, the most reasonable solution is to completely replace the VAZ steering gear. Considering that it can be bought for pennies on disassembly, this is the right decision. If you wish, you can purchase a new part; its lifespan will definitely last until the end of the car’s life.

It is preferable to repair the steering gear only when it is necessary to repair an oil leak or perform some other simple procedure. Many owners make steering adjustments by eye without removing the bipod. But in this case, the gap may turn out to be even higher than it was originally.

It is better not to start repairing and adjusting the steering without strictly following the instructions and having the tools.

Return to contents

1.Preparing the tiller outboard motor for connecting the steering control.

If the motor is a tiller motor, then in order to connect a remote steering control to it, it must be converted. Most motor manufacturers offer ready-made kits for converting the PLM into a steering remote control. Often, instead of a ready-made kit, the manufacturer allows the owner of the motor to independently determine the need for components. a mounting plate on the outboard motor , to which the steering rod , which must be purchased, will cling. Next, you need to make sure that there is a place for attaching the cable jacket on the motor. As a rule, outboard motors are equipped with a special pipe located in the area of the clamps that attach the motor to the transom. If there is no such pipe on the motor, then a transom support for the steering cable (it comes in a simple version or complete with a transom pad).

Typical breakdowns

The “Five” can notify its owner of problems with the steering not only by loss of controllability and the appearance of noticeable play, but also by knocking noises that appear when turning the steering wheel or crossing uneven surfaces. Most often, the steering column of the VAZ 2105 knocks, namely one of the worn-out crosspieces. Previously, there were smart people who pressed out the crosspiece and made repairs to it. Today the best solution is to completely replace the steering shaft, along with the cardan. It’s more reliable, faster and smarter. Replacement takes very little time, you literally need to unscrew two bolts. There is no need to worry when purchasing, because the shaft dimensions of the entire “classic” family are the same.

If knocking occurs in several places, then it is best to change the entire control, including the steering gear. Moreover, today they offer better quality spare parts than they cost initially. For example, the new VAZ gearbox has a more convenient system for changing the oil and disconnecting the bipod; there will be much fewer problems with it in the future than with the old one.

If damage to the boots or gaps is detected, the tips must be replaced. To replace them you will also need a special puller. Some owners of the “classic” once every few years redo the steering and measure the wear of the pins and other parts with a caliper. This gives you confidence that the car will not let you down on a long trip.

More serious damage is deformation of levers and rods. They happen when hitting an obstacle, a curb, or a speed bump at high speed. Sometimes it is very difficult to determine whether the tie rod needs to be replaced or not. Deformations are often difficult to see, so you also have to resort to measuring tools. Again, repairs come down to simply replacing deformed or worn parts. There is no point in trying to straighten or restore them.

If, when turning, the control does not knock, but crunches, it means that one of the bearings has crumbled. It can be located either inside the steering column or in the gearbox. In both cases, replacement is a rather complicated operation; disassembly requires incredible effort. The gearbox, of course, should be replaced entirely, but it is better to entrust the repair of the column to a workshop. It is worth remembering that after the steering has been repaired, it is necessary to adjust the camber and toe of the wheels.

Return to contents

VAZ control tuning

Steering unit device

When thinking about modifying the steering, we must not forget that any interventions in this part of the machine are prohibited. Of course, replacing the steering gearbox with a newer modification may not cost anything. But with global changes, it will be impossible to pass a technical inspection. The design of the classics has been well studied; any expert knows it thoroughly. Therefore, it will be impossible to hide this without technical inspection. Nevertheless, for those who decide to do tuning at their own risk, we can advise several directions for creativity.

So, the most common thing is installing a steering column from a more modern VAZ model. The procedure is extremely labor-intensive, but as a result, the VAZ 2105 column gains the ability to adjust in height. For those who like to travel far and have a non-standard build, this is a very convenient option. The new VAZ 2105 column with height adjustment may only require an additional adapter. Such adapters are available in tuning stores.

The main drawback that the vast majority of owners of the “five” would like to eliminate is the heavy steering. It is very difficult and almost impossible to install power steering on a VAZ, but electric power steering is easy. Special kits are sold, even the VAZ 2105 column does not need modification. But electric amplifiers are not always reliable. There are known cases when, after their failure, the car began to be thrown into the oncoming lane, and even at full speed. Therefore, the installation is not very justified. And if you take the ESD from a foreign car, then you may have to install another steering gear and redo half of the car. You may also need to replace the VAZ 2105 steering shaft.

A well-lubricated, adjusted and serviceable steering mechanism of the “five” practically does not require additional strengthening or modifications. But if you want, you can modify it too. It is also possible to legitimize the alteration if you pass tests and receive a certificate from a research institute.

The steering gearbox is a rather old mechanical device that is now used mainly on cars of the classic LADA family. Today you will learn what a steering gearbox is - repair, replacement, adjustment with your own hands.

The steering gearbox is a small mechanism designed to transfer rotational motion to translational motion. This means that the gearbox converts the rotation of the steering wheel into a force that moves the steering rods in the right directions, causing the wheels to turn and change the direction of movement of the car.

The gear used in the gearbox is a reduction gear and consists of two elements - a worm and a gear. In addition, the mechanism has a special lever that moves the steering rods in the right directions.

The steering gearbox of the VAZ 2107 is sealed and filled with oil, which significantly increases its service life and makes it easier to turn the steering wheel, reducing the effort exerted by the driver.

Replacing the steering gear of a VAZ 2107 with your own hands

If uncharacteristic sounds are heard while the “Seven” is moving, oil leaks from the radiator, and considerable effort is required to move the steering wheel, repair or replacement of the VAZ 2107 steering gear is inevitable. The unit transmits force from the steering wheel to the performance mechanisms. The unit itself is quite reliable, it is capable of operating stably for up to 300 thousand kilometers, provided that the operating rules are followed. But there comes a time when the unit fails. Do-it-yourself repairs are quite affordable. Before work, you need to stock up on the necessary spare parts, tools, and familiarize yourself with the design.

Adjusting the VAZ gearbox

Adjustment of the steering gear is carried out to get rid of play in the steering wheel, as well as all kinds of discrepancies when it rotates with the position of the wheels. The car wheels must first be aligned.

To adjust the steering gear, you need to unscrew the lock nut on its cover from above and loosen the special adjusting screw. Ask your partner to sit behind the wheel and rotate the steering wheel in different directions with energetic, but not wide movements, while you gradually tighten the adjusting screw. As soon as the steering wheel begins to rotate tightly and the wheels move with the slightest movement, the locknut is tightened.

This completes the adjustment of the steering gear. As you can see, this procedure is not long at all and can be performed with just a 19-mm wrench and a regular flat-head screwdriver.

Steering cable selection

The steering cable is an important console control element and is located on the right or left side. In ships, 2 cables are required, which are used to regulate the gas and shift the gearbox.

Several types of cables and fastenings have been developed. When selecting a product, it is important to determine the dimensions (length, thickness) and technical characteristics. When calculating the dimensions of the cable, the distance from the central part of the gearbox to the side of the boat, the length of the side and the transom are taken into account. For 90° bends, an additional 100 mm must be taken into account. It is necessary to add 30.5−30.7 cm to the results obtained.

The cable marking is selected in accordance with the gearbox model. For T-67 steering gears with a motor power of 55 hp. a cable marked M58 is required. The fastening is thin, plastic, comfortable to use, inexpensive, but not wear-resistant enough.

For driving the steering T-85 and a motor with a power of 55 hp or more. M66 cable is required. The fastening is strong, wear-resistant, and has a large diameter.

Engines operating at high power require the vessel to be equipped with hydraulic steering systems. The devices support smooth movement and easy change of direction of the craft.

Steering gear reducer design

Before you begin repairing the steering column, you need to familiarize yourself with its structure, as well as its operating principle. The design consists of the following main elements:

- a unit designed to transmit force from turning the steering wheel to actuators;

- steering column, which turns the wheels to the desired angle.

The steering mechanism consists of:

- composite shaft with cardan transmission;

- steering wheel;

- worm type steering gear.

The design has the following components:

- pendulum;

- swing arms;

- steering rods.

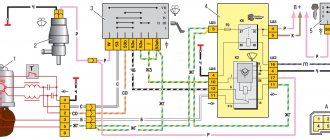

Steering design: 1 - steering gear housing;

2 - shaft seal; 3 - intermediate shaft; 4 - upper shaft; 5 — fixing plate of the front part of the bracket; 6 — bracket for fastening the steering shaft; 7 - upper part of the facing casing; 8 — bearing sleeve; 9 — bearing; 10 — steering wheel; 11 — lower part of the facing casing; 12 — bracket fastening parts Since the outer rods have two parts, this makes it possible to adjust the toe angle. The steering functions as follows:

- The driver operates the steering wheel.

- Through universal joints, the worm shaft is driven, through which the number of revolutions is reduced.

- The worm rotates, which helps move the double-ridge roller.

- The secondary shaft of the gearbox turns.

- A bipod is mounted on the secondary shaft, which rotates and carries the steering rods with it.

- Through these parts, force is applied to the levers, thereby turning the front wheels to the angle desired by the driver.

The bipod is a rod that connects the steering gearbox to the steering linkage.

Signs of a gearbox malfunction

As the vehicle is used, the steering column may develop problems that require repair. The most common of them are:

- oil leak from the gearbox;

- extraneous sounds in the mechanism;

- It takes a lot of effort to turn the steering wheel.

Table: VAZ 2107 steering faults and ways to solve them

| Malfunctions | Elimination method |

| Increased free play of the steering wheel | |

| Loosening the steering gear mounting bolts. | Tighten the nuts. |

| Loosening the tie rod ball pin nuts. | Check and tighten the nuts. |

| Increased clearance in the ball joints of the steering rods. | Replace tie rod ends or tie rods. |

| Increased clearance in the front wheel hub bearings. | Adjust the gap. |

| Increased clearance in the engagement of the roller with the worm. | Adjust the gap. |

| There is too much clearance between the swingarm shaft and the bushings. | Replace the bushings or bracket assembly. |

| Increased clearance in the worm bearings. | Adjust the gap. |

| Stiff steering wheel rotation | |

| Deformation of steering gear parts. | Replace deformed parts. |

| Incorrect alignment of the front wheel angles. | Check the wheel alignment angles and adjust. |

| The gap in the engagement of the roller with the worm is broken. | Adjust the gap. |

| The adjusting nut of the pendulum arm axis is overtightened. | Adjust the tightening of the nut. |

| Low pressure in the front tires. | Set the pressure to normal. |

| Damage to ball joint parts. | Check and replace damaged parts. |

| There is no oil in the steering gear housing | Check and top up. Replace the oil seal if necessary. |

| Damage to upper steering shaft bearings | Replace bearings. |

| Noise (knocking) in the steering | |

| Increased clearance in the front wheel hub bearings. | Adjust the gap. |

| Loosening the tie rod ball pin nuts. | Check and tighten the nuts. |

| Increased clearance between the pendulum arm axis and the bushings. | Replace the bushings or bracket assembly. |

| The adjusting nut of the pendulum arm axis is loose. | Adjust the tightening of the nut. |

| The clearance in the engagement of the roller with the worm or in the worm bearings is broken. | Adjust the gap. |

| Increased clearance in the ball joints of the steering rods. | Replace tie rod ends or tie rods. |

| Loosening of the steering gear mounting bolts or the swing arm bracket. | Check and tighten the bolt nuts. |

| Loosening the nuts securing the swing arms. | Tighten the nuts. |

| Loosening the steering intermediate shaft bolts. | Tighten the bolt nuts. |

| Self-excited angular oscillation of the front wheels | |

| Tire pressure is not correct. | Check and set normal pressure. |

| 2. The alignment angles of the front wheels are incorrect. | Check and adjust wheel alignment angles. |

| 3. Increased clearance in the front wheel hub bearings. | Adjust the gap. |

| 4. Wheel imbalance. | Balance the wheels. |

| 5. Loosening the tie rod ball pin nuts. | Check and tighten the nuts. |

| 6. Loosening the bolts securing the steering mechanism or the pendulum arm bracket. | Check and tighten the bolt nuts. |

| 7. The gap in the engagement of the roller with the worm is broken. | Adjust the gap. |

| Steering the vehicle away from straight-line motion in one direction | |

| Uneven tire pressure. | Check and set normal pressure. |

| The alignment angles of the front wheels are incorrect. | Check and adjust wheel alignment angles. |

| Different draft of front suspension springs. | Replace unsuitable springs. |

| Steering knuckles or suspension arms are deformed. | Check the fists and levers, replace unsuitable parts. |

| Incomplete release of the brakes on one or more wheels. | Check the condition of the brake system. |

| Vehicle instability | |

| The alignment angles of the front wheels are incorrect. | Check and adjust wheel alignment angles. |

| Increased clearance in front wheel bearings. | Adjust the gap. |

| Loosening the tie rod ball pin nuts. | Check and tighten the nuts. |

| There is too much play in the tie rod ball joints. | Replace tie rod ends or tie rods. |

| Loosening of the steering gear mounting bolts or the swing arm bracket. | Check and tighten the bolt nuts. |

| Increased clearance in the engagement of the roller and worm. | Adjust the gap. |

| Steering knuckles or suspension arms are deformed. | Check the knuckles and levers; replace deformed parts. |

| Oil leak from crankcase | |

| Wear of the bipod or worm shaft seal. | Replace the seal. |

| Loosening the bolts securing the steering gear housing covers. | Tighten the bolts. |

| Damage to sealing gaskets. | Replace gaskets. |

Where is the gearbox located?

The steering gearbox on the VAZ 2107 is located in the engine compartment on the left side under the vacuum brake booster. If you have insufficient experience, you may not find it at first glance, since it is usually covered with a layer of dirt.

Operating principle and installation

The remote control system consists of:

1) Steering remote control

The remote control for an outboard motor consists of several different devices: a steering wheel, a gearbox, a steering cable and a tie rod. These elements, by fastening them together, form a control system.

When choosing a steering remote control for a boat, consider, first of all, the power of its motor. A competent combination of motor power and a certain type of remote control gearbox provides the best results and ensures the most efficient operation.

The single-cable remote control system is currently the most common system and is installed on imported units. Control is carried out using the steering wheel (steering wheel), which is mounted on the steering gear shaft. The rotational movement of the steering wheel through the steering gearbox is converted into a reciprocating movement of the steering cable, at the end of which the steering lever is attached (it is attached to a special rack at the bottom of the outboard motor tray).

A distinctive feature of this system is the operating principle of the steering gear, this is the so-called “gear” transmission. A cable tip with teeth is inserted into this gearbox, and the shell is screwed to the gearbox body, creating a stop. When you turn the steering wheel, the cable exits/enters from the second hole into a special protective cover, which is usually filled with lubricant. A complete shift of the steering wheel is usually carried out in two and a half turns. The other end of the steering cable is connected to the engine. The cable jacket again serves as a stop, and the cable itself pushes/pulls the engine, turning it left and right using a rod and a tie rod, which is connected to the support plate. The support for the shirt can be done in several ways, depending on the type of boat and engine model - to the motor clamp or to the transom. There is a steering rod on the steering arm, thanks to which you can change the angle of application of force when turning and tilt the engine. The steering lever and the support plate under it are installed individually for each motor, this eliminates all interference with the stroke of the rod and ensures the maximum angle of rotation of the motor.

2) Remote control of reverse and throttle.

To remotely control gear shifting and the throttle valve of a boat motor, it is necessary to additionally lay two gas reverse cables in the boat, one of which controls the throttle valve, and the second serves to change gears of the engine gearbox. Control is carried out using special remote controls or, as they are called differently, commanders and gas reverse machines. The most convenient and well-functioning gas reverse machine is the one that is purchased together with the engine (branded).

Typical breakdowns

The “Five” can notify its owner of problems with the steering not only by loss of controllability and the appearance of noticeable play, but also by knocking noises that appear when turning the steering wheel or crossing uneven surfaces. Most often, the steering column of the VAZ 2105 knocks, namely one of the worn-out crosspieces. Previously, there were smart people who pressed out the crosspiece and made repairs to it. Today the best solution is to completely replace the steering shaft, along with the cardan. It’s more reliable, faster and smarter. Replacement takes very little time, you literally need to unscrew two bolts. There is no need to worry when purchasing, because the shaft dimensions of the entire “classic” family are the same.

If knocking occurs in several places, then it is best to change the entire control, including the steering gear. Moreover, today they offer better quality spare parts than they cost initially. For example, the new VAZ gearbox has a more convenient system for changing the oil and disconnecting the bipod; there will be much fewer problems with it in the future than with the old one.

If damage to the boots or gaps is detected, the tips must be replaced. To replace them you will also need a special puller. Some owners of the “classic” once every few years redo the steering and measure the wear of the pins and other parts with a caliper. This gives you confidence that the car will not let you down on a long trip.

More serious damage is deformation of levers and rods. They happen when hitting an obstacle, a curb, or a speed bump at high speed. Sometimes it is very difficult to determine whether the tie rod needs to be replaced or not. Deformations are often difficult to see, so you also have to resort to measuring tools. Again, repairs come down to simply replacing deformed or worn parts. There is no point in trying to straighten or restore them.

If, when turning, the control does not knock, but crunches, it means that one of the bearings has crumbled. It can be located either inside the steering column or in the gearbox. In both cases, replacement is a rather complicated operation; disassembly requires incredible effort. The gearbox, of course, should be replaced entirely, but it is better to entrust the repair of the column to a workshop. It is worth remembering that after the steering has been repaired, it is necessary to adjust the camber and toe of the wheels.

Gearbox installation

All gearboxes require the use of a special installation kit. It contains a bracket for attaching the gearbox to the control panel, a decorative casing, mounting bolts, nuts and washers, a key and a steering wheel fixation nut. Thanks to the installation kit, the gearbox can be easily mounted on the console of your boat (you just need to drill the holes). We can only dwell on some of the subtleties of the process.

- When marking the space for the gearbox, take into account the size of the steering wheel so that it does not touch the levers and interfere with the control of the boat as a whole.

- When purchasing a cable, calculate not only the distance from the steering wheel to the motor along the side, but also make allowances of 0.5 m for each bend

- Balance the power of the gearbox and the strength of the console. You may need to purchase a separate rack to install the remote control if your console is, for example, made of plastic

- Do not try to “disguise” the gearbox so that it cannot be reached later - sometimes it is recommended to remove it for maintenance

Our tips are simple and not difficult to apply, but by following them, you will avoid a lot of problems and modifications during operation. Enjoy your holiday and seven feet under the keel!

Repair and maintenance

Over the years of operation it has been proven that the steering on VAZ 2107 vehicles has impressive reliability. However, this does not take away the fact that the machine requires periodic inspection and repair.

- When performing maintenance, it is important to check for increased play as well as increased wear on the ball joints. To do this, you need to turn the steering wheel from one side to the other. If the wheels do not respond when the steering wheel is turned 5 degrees from its original position, this indicates severe wear. Here you will need to repair the steering column on a VAZ 2107.

- To avoid the need for urgent and rather expensive repairs of the steering gear on a VAZ 2107, it is necessary to change the oil in the worm gear housing. This is done at intervals of 60 thousand kilometers. Leaks may occur through the seals, so they are carefully checked 2-3 times a year. This is one of the weak points of the system.

- The swing arm should be inspected by slowly rotating the steering wheel from side to side. If the parts move in a vertical plane, then surgical intervention is required.

2.Determine the method of connecting the steering control.

After we have equipped the boat motor with all the missing components, it is necessary to determine how to connect the steering control on the boat.

Note! The name or brand of the PLM is not a criterion for choosing a steering cable connection!

Steering connection options.

Standard steering cable connection via tie rod

Non-standard steering cable connection via transom support and adapter

Non-standard steering cable connection via side transom support and adapter

Standard steering connection.

Any steering connection using a tie rod is standard. With this method, the end of the steering cable jacket is attached to a pipe or transom support installed under the engine using a nut. The rod passes through the pipe and comes out on the opposite side. The boat motor is connected to the eye at the end of the steering cable through the steering rod. In the remote motor, everything is ready for a standard connection; we complete the tiller motor with everything necessary from the previous point.

Non-standard steering connection.

A non-standard type of connecting a steering remote control includes laying the steering cable through the hull of the boat (boat) or using a transom support installed on the side of the motor. In this case, the steering rod is removed from the steering gear connection kit as unnecessary. Instead, an adapter for connecting the steering cable . To many, the adapter may seem unnecessary, since you can connect the steering cable directly to the motor. It is important to understand that when the outboard motor is rotated relative to the central position, the angle of supply of the cable to the suspension changes. A very important property of the adapter is that it gives a degree of freedom to the steering cable and prevents the rod from breaking!

Kit for non-standard connection of steering cable:

In order for everything to work like a charm, it is important not to make a mistake in choosing the transom support and be sure to install an adapter for connecting the steering cable!

So, everything is ready on the motor side. What's left to do?