Main characteristics of the Bosch model

The VAZ 2110 gasoline pump has a performance in the range of 3-3.8 bar.

For each type of fuel system, the manufacturer produces a separate device. Many car enthusiasts replace a broken mechanism with a Bosch model with high pressure. The pressure of the VAZ 2110 fuel pump does not affect consumption, because the cars are equipped with a return line and excess fuel is returned to the tank. There is also a fuel pressure regulator. Fuel consumption may increase if the rail is not at optimal pressure. After which the nozzles do not spray, but pour gasoline, which does not have time to burn.

Parameters of the Bosch model 0580453453

If you are interested in a VAZ 2110 Bosch fuel pump, the characteristics of the models will differ in the length and sometimes in the diameter of the body. The diameter of the body is adjusted using a gasket made of gas-resistant rubber. Also, devices may differ in pressure, placement of chips on the terminals. The device grid does not differ in the number of seats, but may vary in shape. You can remake the chip for a terminal or install it from a VAZ car. The length of the fuel pump determines its performance when the volume of fuel in the tank is low. If it is located in a module, then compliance is required to install it. The length of the Bosch model 0580453453 is 105 mm, 0580453449 is 65 mm, and for Bosch 0580453465 this figure is 90 mm. The pump is located in the car tank, it is immersed in fuel. It contains an electric motor that drives the pumping element. A combination of these components supplies fuel under high pressure. As a result, the fuel pump is noisy and needs cooling. Therefore, the equipment is immersed in a tank of fuel, as it serves as a coolant and noise-insulating compound.

How to buy a quality device?

The price for a VAZ 2110 fuel pump in market conditions will be 2 times lower than in a specialized store. The equipment is in durable and sealed packaging. Inside the package is purified gasoline. If you smell gasoline, then the seal of the packaging is broken and there is a possibility of corrosion forming inside the gasoline pump. Submerged equipment is lubricated and cooled by fuel. When using low-quality additives and gasoline, internal electrical mechanisms are corroded. If additional substances are not used in the operation of the device (dry), then the brushes wear off and it overheats. The service life of the equipment is longer. Some car owners are planning to replace the VAZ 2110 Bosch fuel pump, the characteristics and pressure of which are not normal only due to long-term use. Its pressure can be 6-7 atmospheres. It was amazing to hear from an experienced driver his method for testing the fuel pump. To do this, he took a jar of water, turned it on on the battery, and by the flow of liquid he realized that the power of the gas pump had decreased.

The fuel pump (VAZ-2110) is the main structural element of the fuel system of a gasoline internal combustion engine, which functions to supply fuel to the injectors or carburetor under high pressure. Depending on the type of drive, electronic and mechanical units are available. And now we will look at the structure of this part using the example of an element installed on a VAZ 10-ku.

Mechanical fuel pump VAZ-2110 - properties and design

This type of mechanism is used only on cars with carburetor engines. This VAZ-2110 fuel pump has its own mechanical drive from the camshaft, and it is located on the internal combustion engine.

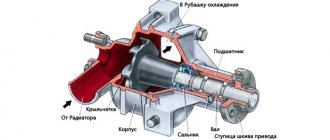

According to its design, this element is one of the types of piston and contains the following parts:

The drive of this device, as we said earlier, is carried out from the camshaft eccentric. When this element rotates, the part moves the rod with the diaphragm down, and the spring force is overcome. The volume of space above it increases, and gasoline, due to the resulting vacuum, seeps into the pump through a separate valve from the gas tank. The discharge valve is still closed.

The main operating mechanism of the pump is the diaphragm. It consists of two membranes, between each of which there is its own gasket. The diaphragm is connected to the rod. The latter interacts with the mechanical drive parts. There are various pump drive schemes. For example, on Russian “10s” a design is used that consists of a pusher and a lever with a balancer. On imported cars, they use their own design with a two-arm “rocker arm”.

Fuel pump for VAZ-2110 - properties

The main properties of this device are the pressure level and housing dimensions. The most popular units today are German-made Bosch units. The pressure of the VAZ-2110 fuel pump is about 2.8-3.8 Bar. The very feature of the fuel pump is sometimes determined by the diameter of the body; in most cases, it is the length.

The dimensions of this part can be very different. Depending on the model and brand of the manufacturer, this parameter is 65, 90 or 105 mm. And these are not all the sizes of VAZ fuel pumps.

Apart from the length, these devices differ in the location of the terminal chips. The mesh itself, in terms of its seats, actually does not differ by brand. By the way, the quality of its operation when the level of fuel in the tank is low depends on the length of the gasoline pump itself. In other words, when choosing, you need to pay attention to longer elements. By the way, the diameter of the housing can be varied using a gasket made of gas-resistant rubber.

Tips and tricks

If it is necessary to replace the VAZ 2110 pump or after removing the pump for preventative replacement/cleaning of the mesh, after completing the reassembly and installation of the pump, do not immediately install the rear sofa and the pump cover.

Additional verification will be required before doing this. To do this, you need to turn on the ignition and determine whether gasoline is leaking from the fuel pipes. Also, the smell of gasoline in the car interior, etc. is not allowed. If this is the case, then you need to determine the cause of the leak and replace the problematic elements, tighten the tube nuts, etc.

To make the selection accurate, the existing module must be removed from the car and purchased a similar one. Also, when choosing, you need to take into account the type of engine, since the pumps are different. Before purchasing, the fuel pump itself should also be inspected, its housing should be checked (cracks, dents, and defects are not allowed).

Electronic analogues

What is special about the fuel pump? The VAZ-2110 (injector) is equipped with specifically such devices in the fuel system. The electronic pump is used on gasoline engines with distributed fuel injection. In turbodiesel and diesel engines, this element is used in the low-pressure circuit for the preparatory passage of fuel to the high-pressure pump. By the way, electronic pumps on gasoline engines with direct injection of Common Rail fuel operate on the same principle. The electronic mechanism makes the pressure about 0.3 MPa (in power plants with direct injection - about 0.7 MPa). The use of mechanical pumps in such systems is not recommended due to the low pressure when supplying gasoline.

Troubleshooting

The main symptoms of a malfunction of the VAZ 2110 fuel pump are engine interruptions in various operating modes, lack of pressure in the fuel system, loss of acceleration dynamics, increased fuel consumption, or complete failure when trying to start the engine.

The first step is to check the functionality of the pump. When you turn on the ignition, you should hear a slight whirring sound from the pump under the rear seat for a few seconds.

If the engine is running, it is necessary to check the fuel supply pressure using a pressure gauge; the fuel supply pressure to the injector should be 3.5 - 4 atmospheres. If the sound of the fuel pump is not heard, if you have an electrical tester, you can check whether power is being supplied to the pump.

To do this, you need to remove the back seat of the VAZ 2110, the decorative cover, and the terminal from the fuel pump housing, turn on the key to crank the starter, if the tester does not receive power, you need to check the relay, fuse or wiring trace for a break! If there is power, the fuel pump needs to be replaced.

The serviceability of the relay can be checked by replacing it with a working one from the fuse box, for example the high beam headlight relay. When replacing a new relay, you need to pay attention to the manufacturer and the recommendations of a spare parts specialist in the store; it is better not to save on the cost of the relay.

Where is he located?

This device is located in the fuel line or in the fuel tank. Thanks to this placement, the risk of losses is significantly reduced due to the absence of absorbing mains.

The design of the electronic pump implies the presence of the following parts:

- Electric motor.

- Pump housed in an iron casing.

In other words, this device consists of an electric drive and a pump part. All its components are in direct contact with the fuel. In addition to the parts listed above, the module of this device also includes a fuel flow sensor, a fuel intake and a strainer.

And the part we are considering operates thanks to the presence of two valves - a reversible valve and a pressure reducing valve. The first one locks the system when the internal combustion engine stops. The second one performs the function of maintaining pressure in the system, while part of the fuel is bypassed to the rear inlet.

By design, there are a number of types of electric pumps:

- Roller.

- Gear.

- Centrifugal.

Centrifugal

Due to their own design features, these two pumps are installed directly in the fuel line. Current injection devices use centrifugal type mechanisms. Such pumps provide a uniform supply of gasoline and virtually do not make any noise. But they have their limitations in terms of pressure and performance.

Here's the thing - the car won't start. Unfortunately, this problem is often present among drivers of the VAZ 2110. And this is connected with nothing other than the fuel pump. Today, replacing a VAZ 2110 fuel pump is the most common type of repair. And a fuel pump replacement for a VAZ 2110, as this type of repair is called in auto repair shops, can be easily carried out on your own.

Electric type fuel pump

The fuel pump for VAZ 2110 is an electric injector and is installed in cars with an adjustable injection system. The “tens” electric fuel pump is located in the fuel pipeline system in the vehicle’s gas tank. This dislocation of the element greatly reduces the possibility of fuel loss due to the use of a scheme without the participation of pipelines that work to suck in fuel.

This element of the fuel supply system includes:

- EDH;

- a pump, the body of which is made of metal;

- fuel level sensor;

- fuel intake component;

- filter mesh;

- check valves and pressure reducing valves.

The valve of the reverse principle of action stops the fuel distribution complex when the power plant is stopped. A pressure-reducing element controls pressure by acting as a bypass valve.

The designs of electric fuel pumps are:

- roller type;

- gear type;

- centrifugal type.

An electric roller pump sucks in fuel and drives it through the functionality of the rotor element and the movement of special purpose rollers. The gear electric pump sucks in fuel and drives it through and is pumped by moving an internal gear relative to the stator element, which plays the role of an external gear. When a rotational type rotor moves, the side elements of the tooth create a chamber in their segments that changes the degree of rarefaction, with the help of which the effect of suction and supply of fuel is created.

At the same time, a centrifugal type fuel pump is mounted directly in the fuel line. Such elements make it possible to ensure an even supply of fuel and operate almost silently. They have one significant feature - a limit on pressure parameters and functionality.

The fuel pump is the most important part

Let us first determine what the functions of the fuel pump are, its structure and types. This will help to more accurately understand the philosophy of replacement, its internal reasons, so to speak.

Reasons for failure

Often, due to a naturally faulty system, a person receives extreme stress. Yes, and this is not a joke. Imagine a situation where a driver in a hurry runs to his car, tries to start it, but all in vain. What is the reason? It turns out that if a car has “plowed” more than 90 thousand kilometers, failure of the fuel pump suggests itself and experienced drivers know this. Whether this part is electrical or mechanical, it will become difficult to supply fuel and will eventually need to be replaced.

Note. Time is not the only reason for fuel pump failure. Another, no less common reason is low car engine power. In addition, if the car suddenly stops running, this will also affect the normal operation of the fuel conductor.

Although manufacturers promise that their gasoline pumps will supposedly last for 12 thousand hours, which is approximately 700 thousand mileage, these data do not come true in practice. Whether it depends on climatic conditions, driving style, company and much more does not matter so much. The part fails and needs either repair or full replacement. If you present the reasons for the failure of the fuel pump in the form of a list, it will look like this:

- frequent driving on an empty tank;

- filthy ;

- frequent sudden engine stops;

- low engine performance and power;

- dirty fuel.

The first two reasons are the most dangerous. Indeed, making it a rule to always drive with a tank that is at least half full guarantees a long service life of the gas pump. And it is simply necessary to change the mesh filter of this part from time to time, since not only the fuel pump itself can “fly” from a dirty filter, but also the car engine, which will constantly receive dirt, dust and other harmful components.

Types of fuel pump

The purpose of the fuel pump is to supply fuel. It would seem that the function is not so complicated. But the whole point is that the car’s engine and gas tank are located far from each other, which is already a problem.

Note. On some older car models, there is no fuel pump at all and the role of a fuel supplier is played by an ordinary hose. But this is very inconvenient and smacks of old age and rigidity.

Today, thanks to the genius of the engineers and designers who came up with these parts, two types of gasoline pumps are known: mechanical and electronic. One of them is installed on cars with fuel injection, the other on cars with a conventional engine. The mechanical fuel pump is a classic. The part is mounted outside the fuel tank, while the electric version is always inside the tank (this is partly due to the fact that this type of fuel pump is very noisy). One of these types of fuel pump operates at low pressure, but with large volumes of fuel (mechanical), and the other vice versa (electronic). The operating principle of the mechanical version is quite simple: the part sucks fuel from the tank. And a mechanical fuel pump is capable of operating at low pressure, since the distance between the carburetor and it is small.

Note. Both the first type of fuel pump and the second can be installed on the VAZ 2110.

As for the electric fuel pump, this one always operates under the strict control of the entire electronic system of the car, which takes into account several factors simultaneously:

- throttle position;

- exhaust content;

- air to fuel ratio, etc.

As mentioned above, the electric fuel supply pump always operates under pressure, which is why noise cannot be avoided. It is precisely for the purpose of muffling the sound that it is installed deep into the tank of the car, and the fuel itself acts as a cooler and muffler. The fuel pump is started by an electric motor. At the same time, when the ignition switch is turned on, it sends a signal to the pump, which begins to supply fuel. In some cases, an electric charge is supplied to the fuel pump, which causes the motor to rotate for several minutes, setting the pressure in the fuel system.

Note. Interestingly, if after three seconds the computer does not inform the electric fuel pump to start working, it will automatically turn off. It is because of this that the operation of the pump motor can be heard only in the first seconds of operation. After this, the fuel enters the fuel pump through a tube and exits through a specific one-way valve.

Replacing the fuel pump, especially on older versions of the VAZ 2110, will not be difficult. It is located on the top of the engine and is fairly easy to get to. You should only be armed with a screwdriver and a wrench of the required size.

Note. If the fuel pump is mechanical, then in all domestic models, including the VAZ 2110, it is dismountable, which allows it to be repaired rather than replaced.

Types of fuel pumps

Nowadays, car manufacturers equip their products with mechanical or electric fuel pumps. The former are used in carburetor-type cars. In them, fuel under conditions of reduced pressure ends up in the carburetor. Electric fuel pumps, on the other hand, deliver fuel to the engine when exposed to high pressure.

Nowadays, fuel pumps do not break down very often. As a rule, careless car drivers are to blame for this.

Main causes of breakdowns:

- clogged fuel filters;

- driving with empty gas tanks.

If these reasons exist, the Bosch fuel pump operates at its full capacity, which means it wears out much faster.

Drivers must comply with the following requirements:

- ensure that the gas tank is at least half filled;

- Monitor the serviceability of fuel filters.

Mechanical fuel pumps ensure that fuel moves from the fuel tank to the engine. They do not require high pressure because they are located close to each other.

Replacing the fuel pump VAZ 2110 (electronic)

We begin the process of replacing the electric fuel pump:

- de-energize the battery;

- unscrew the fuel pump cover;

- remove the connector from the fuel pump;

- loosen the clamp located on the fuel hose;

- unscrew both hoses supplying fuel;

- dismantle the gaskets;

- the fuel pump is held on by eight bolts, which we unscrew;

- remove the sealing ring;

- The fuel pump comes out with the float.

The replacement process is not complete yet. You also need to remove the rubber seal and then install a new fuel pump in place if the old one cannot be repaired. The entire procedure for replacing a fuel pump with your own hands takes only twenty minutes. If necessary, you can watch the corresponding video or photo materials. The main thing is to follow the step-by-step instructions and not invent anything. As you know, the price of repairs or similar replacement of parts in car services is high, and therefore learning to do it yourself is profitable.

The fuel pump failed, only about thirty percent of these statements are true. The thing is that such malfunctions are quite difficult to diagnose without appropriate testing, since they are very similar to damage to other components. And yet, many try to do this, as they say, “offhand,” often without even having sufficient experience. But there is no need to despair and count losses when going to a car service center, since you can check the performance of the fuel pump yourself, in a garage.

Replacement

Replacing a fuel pump with a new one requires careful selection of the manufacturer; each pump has its own performance. The absolute leader in this area is BOSCH.

To replace or remove for repair the VAZ 2110 fuel pump we will need: a 17mm wrench, depending on the modification, a 10mm socket, pliers, a flat screwdriver. We remove the rear seat, it is advisable to unscrew the gas tank cap to relieve excess pressure in the system. Disconnect the plastic pump power terminal.

Depending on the modification, we remove the fuel supply and return hoses, or, by pressing the spring clip and pulling the hose, disconnect it from the fuel pump housing. In the second option, use a 17mm wrench to unscrew both fittings and disconnect the tubes.

width=”500″ height=”281″ frameborder=”0″ allowfullscreen=”allowfullscreen”>

In both cases, it is necessary to disconnect carefully, since the system is under pressure and when disconnected, the pressure will be released from the injector and a small amount of fuel will leak. If the performance of the old fuel pump is small, there will be no pressure in the system.

Unscrew the 8 nuts from the studs using a 10mm socket and remove the retaining ring with the seal. Carefully pull out the VAZ 2110 fuel pump housing at a slight angle so as not to damage the fuel level sensor; repairing it is unlikely. Using a screwdriver and pliers, remove the lower part of the fuel pump housing and remove the connectors and hoses from the pump. We dismantle the pump.

Assembly is carried out in reverse order. By the way, the original BOSCH fuel pump comes with a mesh. The new fuel pump has high performance, so after replacing it, when you turn on the ignition several times, there will be extraneous sounds when the system is pumped.

Fuel pump malfunctions: symptoms

It is quite natural that the desire to check the performance of the fuel pump does not arise out of nowhere. Most often, this is preceded by systematically recurring following symptoms:

- The car does not start or starts with great difficulty;

- Unstable engine operation at idle;

- The situation is the opposite of the previous one, i.e. the car runs normally at idle, but when you try to move off, what is called “does not pull”;

- Interruptions in engine operation under load at high speeds;

- It is difficult to start the engine after long periods of parking.

Each of these symptoms is quite typical for any element of the nutritional system, and not only it. Even poor quality gasoline cannot be ruled out. Therefore, in this case you need to act from simple to complex. That is, before checking the fuel pump, you need to exclude smaller and simpler faults. Let us also use this principle and move on to consider the simplest case.

Causes of malfunction

The main causes of malfunctions of the VAZ 2110 fuel pump are the low quality of the fuel being filled, low fuel supply pressure, the regular presence of a small amount of gasoline (less than 5 liters) in the fuel tank and improper operation when starting the engine - before starting the engine, you must wait after turning on the ignition 2-4 seconds to pump fuel into the engine power system.

It is also possible that the fuel pump as a part will naturally fail, depending on the mileage of 150 - 200 thousand km. or for a period of 4-5 years, but again this malfunction depends on the operating conditions of the car itself. Usually the factory fuel pump is replaced with a BOSCH one.

There are secondary malfunctions of the VAZ 2110 fuel pump failure - failure of the relay, blown power fuse, they are located in the fuse mounting block either under the hood or in the lower left part of the dashboard, front console, depending on the engine modification, and contamination of the fine filter mesh fuel cleaning (located directly on the fuel pump).

Mechanical fuel pump

Even domestic manufacturers stopped producing carburetor engines in the last decade. What can we say about the world's auto giants? But for a long time to come, cars with a mechanical fuel pump will drive across the vast territory of our country, the performance of which will have to be checked more and more often over time.

Fortunately, this is not difficult to do and will not take much time. The main problem with a mechanical fuel pump is a decrease in performance. This occurs due to wear of the rod that drives the fuel pump. If the car behaves quite normally at idle and low engine speeds, but fails at high speeds, and sometimes cannot reach them at all, be sure it is the rod. It is not difficult to check this by measuring the amount of gasoline pumped by the gas pump over a certain time. To do this, you simply disconnect the fuel hose from the carburetor inlet fitting and insert it into a one and a half liter plastic bottle. It is necessary to take all measures to prevent him from jumping out, even to the point of using the help of an assistant.

Now you need to start the engine. Naturally, with the hose removed, its performance will be very limited. But we only need to time half a minute. The gasoline previously pumped into the carburetor float chamber is enough for this.

So, we time it for 30 seconds, after which we turn off the engine. To assess the performance of the gas pump, we measure the amount of fuel in the bottle. If it is less than 500 ml, the performance of the fuel pump is insufficient and the rod needs to be changed.

There is another common malfunction, known to any owner of a classic. When the engine gets too hot, the fuel pump stops working. This happens especially often when stuck in traffic jams for a long time in the summer. In this case, the engine stalls and refuses to start until it cools down a little. The reason for this is the pump valve. They wear out and, when overheated, are unable to close the increased gaps in the seats. This cannot but affect the performance of the fuel pump. It simply stops pumping fuel until the engine cools down.

The fuel pump valves are included in its repair kit. But experts are extremely skeptical about their replacement. This operation is quite labor-intensive and painstaking, and the functionality of the fuel pump is restored at best for several months, after which the malfunction recurs. In addition, it is not uncommon for the fuel pump valves from the repair kit to simply not fit in the seats. Therefore, it is better not to waste time and money, even if not a lot, but to immediately change the entire fuel pump. At the time of writing, the average price was 650 rubles. Not that expensive considering the importance of this unit.

Fuel pump of an injection engine: checking serviceability

For those who may still be unaware, the fuel injection pump is electric and is usually installed in the car's tank. All this imposes its own characteristics on checking its performance. Namely:

- There may be malfunctions of both the electrical and mechanical parts of the fuel pump;

- The inaccessibility of the installation site of the fuel pump and its rather high price complicate the performance check by replacing it with a known good one;

- To objectively assess whether the fuel pump is working or not, you can no longer get by with a plastic bottle; you will need special instruments.

But not everything is as scary as it might seem at first glance. However, first things first.

Checking the fuel rail pressure

An injection engine, by definition, involves supplying a combustible mixture to the cylinders under pressure. It is created by the fuel pump and should not be less than a certain value. Otherwise, you can’t count on normal engine operation. Thus, by checking the pressure in the fuel system, you can draw objective conclusions about the performance of the fuel pump.

But where and how to measure this pressure. After all, you wouldn’t want to rupture the fuel line and connect a special device there. Of course not. The designers have already taken care of this. The best and most convenient place to measure pressure in the fuel line is the fuel rail. What it is. The ramp is a hollow metal tube that connects all the injectors. Thus, it turns out that it is located directly in front of the engine cylinders, after the fuel filter and gas line. Therefore, it is on the ramp that you can measure the actual pressure in the fuel line, and thus check the performance of the fuel pump. On most cars there is a special fitting for this, closed with a cap.

So, now we’ve sorted out how to measure the pressure in the fuel rail. First of all, you need a pressure gauge. There are probably ready-made ones designed specifically for this purpose, but most car enthusiasts make it themselves. This is more practical, given that you don’t have to use it very often.

In order to make a pressure gauge for measuring pressure in a ramp, you will need a device with a measurement limit of at least 6 atmospheres, a piece of hose whose internal diameter must correspond to the diameter of the ramp, and two clamps.

As for the pressure gauge itself, car enthusiasts most often use the device to check tire pressure, but if possible, it is better to choose another liquid one. Using a separate pressure gauge will eliminate the need to disassemble the device after each pressure check.

So, we take a piece of hose about 50 centimeters long and insert a pressure gauge on one side of it, which is fixed with a clamp. The entire device is ready, it would seem that you can start measuring and some do so, but no, it’s too early.

The fact is that if the fuel pump is working properly, the pressure in the rail is maintained even when the engine is turned off and any attempt to unscrew the cap will lead to splashing of gasoline, which is of course unacceptable from a fire safety point of view. Therefore, before checking the operation of the fuel pump, you need to relieve the pressure in the fuel system. How to do it. There are several ways, but perhaps the simplest and most painless is to remove the fuel pump fuse. The whole difficulty here is to correctly determine which fuse goes to the fuel pump. The easiest way to find out is the inscriptions on the fuse box or its cover. Below is a table of fuel pump fuses for VAZ cars. You just need to take into account that it is usually located in the additional fuse box.

So, we pull out the fuel pump fuse and try to start the car. As a rule, rotating the starter for 3-4 seconds is enough to relieve pressure in the car’s fuel system.

Now you can install a pressure gauge hose on the ramp instead of the cap. We fix it with a clamp. Replace the fuse. All preparatory activities are completed, you can proceed to checking the functionality of the fuel pump.

To do this, the car engine starts. Do not forget that there is no pressure in the system, so it is better to first turn on the ignition, wait until the fuel pump works, and then turn off the ignition. Now the operation needs to be repeated and the engine can easily start.

First of all, we check the tightness of all connections. If everything is fine, look at the pressure gauge readings. At idle speed, for VAZ cars, the pressure in the fuel rail should be within 2.8-3.4 atmospheres. As the speed increases, the pressure in the system should also increase. If at idle the pressure gauge reading is significantly lower than 2.8, and increases with rpm, the fuel filter most likely needs to be replaced. If the pressure in the system does not change, or even drops, the fuel pump is faulty.

But that is not all. Now you need to turn off the engine and see what happens to the pressure gauge needle. Ideally, his readings should not change. If the pressure in the rail drops, what is called “before our eyes”, the check valve of the fuel pump does not hold. Here is the reason for poor starting after a long stay.

This, in general, is all that concerns checking the mechanical part of the fuel pump. We remove the pressure gauge from the ramp, not forgetting to relieve the pressure in the system, replace the protective cap, and if doubts about the pump’s performance remain, we check its electrical part.

Checking the electrical circuits of the fuel pump

The operation of the electric motor of the fuel pump can be assessed, as they say, “by ear”. We turn the ignition key and within a few seconds we hear a characteristic buzzing sound. This is true for all cars. Perhaps, except for premium cars, it is unlikely that their owners will independently check the performance of the fuel pump. But let's not get distracted.

So, what should you do if you can’t hear the fuel pump running when you turn on the ignition? Naturally, the first thing to do is check the corresponding fuse. To do this, we determine which fuse goes to the fuel pump and pull it out of the connector. A blown fuse can most often be identified visually. But even if it gives the impression of being whole, you must definitely verify this with a multimeter. If the fuel pump fuse is faulty, you need to replace it with a new one. You shouldn’t get fancy with various jumpers and “bugs”; in the end it will cost you more.

If after replacement the fuse burns out again, but it corresponds to the nominal value, then there is a short circuit in the fuel pump circuit, and this is a topic for another discussion. But more often it happens that the fuse is intact, but the fuel pump still does not work. In this case, we pull out the fuse again and check the presence of voltage at its “sockets”. This can be done using a regular light bulb, with a current consumption of no more than 0.25A. But it is more convenient, for this purpose, to use a special probe, the price of which in any auto store does not exceed 100 rubles. Its purchase will greatly simplify the diagnosis of electrical wiring faults.

So, we connect one contact of the light bulb or probe to ground, and with the wire of the other we touch the fuse terminals one by one. Naturally, the car's ignition must be turned on. If there is no voltage at the connector, the problem is bad, the ECU or the wiring from it to the fuse is faulty. In any case, there is no need to try to fix this without sufficient skills; it is better to contact specialists. It's another matter if there is voltage on the contacts. Let's go ahead and check the fuel pump control relay.

Probably everyone has noticed a click, after which the buzzing of the electric motor stops. This clicks the fuel pump relay. Its necessity is explained by the rather high power of the pump, which excludes its power supply directly from the circuits of the electronic control unit. That is, the ECU controls the relay, and it supplies power to the fuel pump. It must be said right away that the clicking of a relay does not mean at all that it is operational. Its contacts may “burn” or even “stick”. Therefore, the simplest, most objective and effective way to check a relay is to replace it with a known good one.

To do this, first of all you need to find the fuel pump relay. As a rule, it is located next to the corresponding fuse. The relay has been found, remove it from the circuit board and insert another one. We turn on the ignition, the fuel pump works - the old relay is in a landfill. You can check the pump relay without replacing it, but this will require some skills in electrical engineering, at least minimal - the ability to read electrical diagrams.

Any relay consists of a winding and working contacts. The winding is controlled by the ECU; voltage is supplied to the electric motor through the contacts. As a rule, the electrical circuit of the relay is printed on its body. This allows you to find out which relay outputs go to the winding and which to the contacts. For example, you can consider the VAZ fuel pump relay.

As can be seen from the figure, pins “80” and “85” are windings, and “30” and “87” are working contacts. Contact “30” goes directly to the fuse, and “87” is connected to the fuel pump winding. We turn on the control lamp or indicator at terminals “80” and “85” and turn on the ignition. If the lamp is on, then the relay control circuits are working. Now you can briefly short-circuit terminals “30” and “87” and turn on the ignition. The fuel pump should work. Attention: before performing this procedure, you need to make sure that these pins are indeed normally open relay contacts, otherwise a short circuit cannot be avoided.

So, if the fuel pump starts working, the relay is faulty. If the treasured buzzing sound is not heard again, then you need to check the presence of voltage at contact “30”. To do this, you will have to become a test lamp between it and the “ground”. The glow of the light bulb will indicate not only that there is voltage, but also that the fuel pump itself or the wiring from it to the relay is faulty. The absence of voltage at pin “30” when the ignition is on indicates a fault in the wiring between it and the fuse, of course, provided that the latter is definitely in good working order.

The topic is open to those who are looking on the Internet for information about the technical characteristics of the Bosch fuel pump for the VAZ 2110. If you were looking for information about the fuel pumps for the VAZ 2110 Bosch, then this is an incorrect request.

Fuel pumps most often mean high-pressure fuel pumps, also known as injection pumps, and this is closer to diesel fuel systems. Gasoline engines have fuel pumps - mechanical and electric.

On the VAZ 2110, the Bosch electric fuel pump is probably the most popular fuel pump, because it has a relatively low price and universal dimensions, as well as availability in most stores.

Let's look at the following topics:

Fuel pump VAZ 2110 Bosch performance/pressure

Characteristics of Bosch fuel pumps and specifically the Bosch fuel pump 0580453453

Electric fuel pump

The Bosch electric fuel pump uses higher pressure than the mechanical one. High pressure allows fuel to be pushed directly into the engine. In previous generations of car models, the fuel pump operated continuously. In modern gasoline pumps, the speed of its operation is determined only by the requirements of the device. The operation of this type of fuel pump is controlled by the vehicle's electronic system. It automatically calculates the throttle position, exhaust composition and the proportion of fuel in the air mixture.

Please note that electric fuel pumps are loud and hot because the engine is supplied with fuel under pressure. Therefore, such pumps are located in the gas tank, which makes it possible to cool the fuel pump using fuel. Additionally, it can be noted that this arrangement of the fuel pump makes its operation almost silent.

The electric pump is controlled by a signal from the electric motor. After setting the ignition switch to the on mode, the car computer gives a signal that the fuel pump is started and a charge of electricity is supplied to it. The engine, which is located inside the fuel pump, rotates for some time, increasing the pressure in the fuel system. If there is no signal from the computer to start the engine for more than two seconds, the fuel pump is instantly turned off for safety reasons.

It is in the first seconds after the engine starts running that the driver hears the pump running. Next, the fuel enters the fuel pump through a special tube, after which it enters the gas filter, which cleans the fuel mixture of contaminants. It is for this purpose that the fuel filter needs to be changed periodically. This allows for effective fuel purification. At the next stage, pre-purified fuel enters the engine. The fuel pump runs until the engine is switched off.

Bosch fuel pump performance - from 3 to 3.8 bar

The manufacturer Bosch produces its own fuel pump for each type of fuel system. Why, after the original fuel pump fails, do people install a Bosch fuel pump from a VAZ 2110? How does the pressure and performance of the fuel pump compare with the original one? If you put it with high pressure, will the flow rate increase?

Consumption does not increase due to the performance of the fuel pump, since on cars the return line is activated and excess fuel is returned to the tank, there is also a fuel pressure regulator, from the name it is clear, I think what function it performs.

Consequently, there was a 2.8 bar pump, they installed a Bosch VAZ 2110 fuel pump with 3.8 bar and it will only get better. Fuel consumption may increase if the fuel pump does not create sufficient pressure in the rail and the injectors begin to pour gasoline, which does not burn, rather than spray.

Malfunctions and repairs

The fuel pump fails for various reasons. Often - low quality gasoline. It is important to remember: before removing the pump, check the condition of the filter and the supply voltage at the terminals. Pump malfunctions are varied: failure of the electric motor, breakdown of the impeller, etc. The diagnostic and repair process includes the following steps:

- the rear seat and carpet are removed and the iron hatch comes off (the pump is located under it) - use a 12mm wrench and remove it from its seat with a slotted screwdriver;

- after dismantling, use a screwdriver to unscrew a pair of side screws - they hold the fuel pressure sensor in place (the float must be in good working order);

- two blocks are disconnected (supplying power) - one is connected to the bracket, the second to the motor (before disconnecting, the clamps should be released);

- the coarse filter is removed (looks like a fine mesh) - just pry it off with a screwdriver and move the lock washer;

- the electric motor is pulled out of the plastic housing - just press the plastic down (there are springs inside) and pull out the cotter pin;

- unscrew 2 screws securing the cover - after which it can be removed along with the rubber bushing;

Read also: Car battery socket

When all of the above operations are completed, you can remove the engine itself from the housing and install another module. It is important to remember: if the rubber bushing installed in the housing is deformed or partially destroyed, it must be replaced.

Characteristics of the Bosch fuel pump 0580453453

Especially for my readers, I got confused and measured the fuel pump that is on my display case. In fact, the characteristics of Bosch gasoline pumps differ in the length and very rarely in the diameter of the body. Why?

The diameter of the body can be adjusted using a gasket made of petrol-resistant rubber.

Most often, the characteristics of fuel pumps (not only Bosch, but also from other manufacturers) may differ in length, pressure, location of terminal chips and that’s it :). The fuel pump mesh does not differ in seating, but it may differ in shape.

The chip for the terminal can be remade or supplied from the same VAZ. The length of the fuel pump is important, since its operation depends on this when the fuel level in the tank is low, and if it is in the module, then you need a match to install it.

Fuel pump length:

- Bosch fuel pump 0580453453 - 105 mm

- Bosch fuel pump 0580453449 - 65 mm

- Bosch fuel pump 0580453465 - 90 mm