It is fair to say that various kinds of extraneous sounds appear on a car mainly as it reaches a significant mileage. But if you violate operating rules and force the machine to work within its limits, this will manifest itself much earlier.

Squeaks and grinding noises are part of everyday vehicle use. And in most cases, uncharacteristic sounds are a clear sign of malfunctions and breakdowns. Just in which node they arose is a question that remains to be answered.

Practice shows that creaks and other extraneous noises indicate the beginning of the development of malfunctions, the incorrect operation of a particular mechanism. Moreover, they can only be heard when certain conditions are created. A striking example is turning the steering wheel while moving or standing still.

Why do you hear a rubber squeak when you turn the steering wheel? 8 reasons

Many motorists are familiar with the question of why a rubber squeak is heard when turning the steering wheel. This problem is not unique. It can be found on a variety of car modifications. This does not depend on the brand or model. Any person can encounter a similar phenomenon. The reason may be completely harmless, but it may also be a sign of impending steering failure. Therefore, it is extremely important to promptly diagnose and identify the cause. Your safety may depend on this. The diagnostic principles are approximately the same for different models. Only a few little things differ, based on design features.

Steering rack – a peculiar crunch and appears infrequently

Some BMW models in the late 90s had a certain technical subtlety - their steering racks sometimes crunched. It’s not even a breakdown, it’s just that the rack had such a design feature. However, the Bavarians never had a good relationship with slats. But this node is not the only one that causes certain problems.

Problems with the steering rack occur in almost all cars; this unit lasts no more than 250-300 thousand kilometers. With such a resource, almost every car has to deal with rack problems. Moreover, in some cases the mechanism can fail much faster. The main signs of a broken steering rack are:

- The crunch may occur during the entire stroke of the steering wheel or at certain intervals during rotation;

- knocks are heard not just under the hood of the car, but directly in the steering wheel, vibration is felt in the hands;

- with the engine turned off, when checking the free play of the steering wheel, a knock is heard in the extreme positions;

- the characteristics of the steering change, stiffness appears or, conversely, excessive ease in turning the steering wheel;

- There are problems in driving; the car does not always react to turning the steering wheel as expected.

If such problems exist in your car, you should work on the steering rack. Unfortunately, the design of the steering mechanism on modern cars is such that in most cases the rack will have to be replaced. This is an important point that should be applied almost always. Steering rack repair is short-lived, so it may not be economically viable and not very pleasant for further use.

New Lada: Comparison of Daewoo Nexia and Lada Kalina. What's better?

How to diagnose?

Why do you hear a rubber squeak when you turn the steering wheel? To answer this question, you need to check all possible reasons. It can squeak anywhere. Therefore, when carrying out diagnostic actions, be sure to clarify where the sound is coming from. This will make it easier to find the breakdown. But even after identifying the reason, check all other details. They may also be damaged. To identify the source of the squeak, you need to drive the car into an inspection hole. The assistant turns the steering wheel, and you listen to where the sound is coming from.

Wheel alignment angles

. If the squeak comes from the rubber, and only when driving while the car is stationary. The reason is most likely due to incorrect wheel installation. Visit a service where there are specialists in such adjustments. Do not delay in eliminating the cause. An incorrect installation angle leads to uneven tire wear. Moreover, they can become completely unusable quite quickly.

Steering column

. It is easy to establish that the creaking comes from it. The sound will be superficial, and you will often feel vibration and impacts in the steering wheel. The column coupling may creak. Just lubricate it and everything will be back to normal. Often the cause of a squeak is a bent steering column. The problem arises after accidents and unsuccessful repairs. This can only be eliminated by replacement. But this does not affect the driving performance. If the noise is not strong, then you can drive without fear.

Steering rack

. It rarely creaks. But this still happens. The creaking can be produced by the articulation of the rack and column. This happens due to wear or simply poor adjustment. First, try adjusting the mechanism. But this is not possible on all car models. Therefore, start by studying the manuals on this issue.

Tie Rod Ends

. These parts creak if the boot is damaged. In this case, dirt and sand get into the finger. This is what causes the creaking. Moreover, this sound can appear not only when driving, but also when driving over uneven roads. The problem is identified visually by inspecting the tips. It is recommended to change these parts on both sides at the same time.

Silent blocks

. These suspension elements usually begin to creak in extreme heat. And this is not always a sign of their malfunction. This is the first symptom of a future malfunction. Typically, this manifests itself on parts made of rubber. It dries at high temperatures and shrinks slightly in size. This is why there may be a squeaking sound.

To avoid this, it is recommended to install polyurethane parts. If such a squeak appears, carefully inspect the silent blocks. If there is no visible damage to the part, you can continue driving. As the temperature drops, this unpleasant symptom will go away.

Bearing problems

. The bearing in the steering knuckle will squeak. This also occurs when turning the steering wheel. A squeak appears when there is a lack of lubrication or grains of sand get into it. At the same time, the bearing may heat up, but this is not necessary. Add lubricant and adjust it.

Plastic

. The steering column of a modern car is located in a plastic, decorative casing. On budget models, the plastic is prone to crickets. Therefore, when you turn the steering wheel, various sounds may appear. This can be eliminated in various ways. It all depends on the car model.

Other sound sources

. In rare cases, the power steering belt may sound. The problem appears when there is a lot of wear and tear. Brake pads can squeak when sand gets under them. This sound occurs regardless of the position of the steering wheel or the operation of the brake. Usually, this phenomenon goes away on its own, and relatively quickly.

Conclusion

. Most suspension and steering problems manifest themselves through various sounds. Thanks to this, you can quickly and timely eliminate the source of the problem. Therefore, many car enthusiasts are interested in why a rubber squeak is heard when turning the steering wheel. There are several reasons for this behavior. Knowing the main faults that lead to such a sound, you can easily identify the fault. Accordingly, you can quickly eliminate it.

First signs

The presence or absence of extraneous sounds is a purely subjective concept. An owner who knows his car thoroughly will easily identify a newly formed knock. A beginner, as a rule, concentrates his attention on the road and on his own manipulations. However, there are certain signs of malfunctions that manifest themselves precisely when turning the steering wheel, and the reason does not always lie in the steering.

Let us divide the symptoms of the problem into two categories:

- A knocking sound is heard when driving over bumps with the wheels turned up;

- A knocking noise is heard when turning the steering wheel even when the car is stationary.

Often audible knocks are accompanied by very noticeable shocks to the steering wheel. It is almost impossible to make a correct diagnosis unambiguously. Some malfunctions are not such, and knocking noises are caused by design flaws or poor-quality assembly of the unit. However, the operation of the suspension and steering directly affects driving safety, so the signs that appear cannot be ignored.

Creak when turning the steering wheel Niva Chevrolet

| Forge |

| Rating: 15 / -8 PM mention |

I'm sinning with leverage.

balls seem to be ok

The car is relatively new.. therefore, I don’t think anything is fundamentally wrong..

who can take a look and improve all this equipment, preferably tomorrow afternoon

Well, I’ll be glad if you recommend something and I can do it myself)))

Thanks in advance everyone!

quote: Originally posted by Antoshka92:

most likely ball

| Antoshka92 |

| Rating: 85 / -37 PM mention |

| alex-auto |

| Rating: 41 / -11 PM mention |

| aroma757 |

| Rating: 124 / -57 PM mention |

| -Axis- |

| Rating: 77 / -16 PM mention |

| Forge |

| Rating: 15 / -8 PM mention |

| how to check the ball joint? Yesterday I changed the pads, started jacking up the car and started squeaking, the same as when driving over bumps. I rocked the car, the front of the car... nothing creaks.

The interior is just quiet after 35 thousand mileage. and the interior of the shniva is not creaky. verified) how to check the ball joint? Yesterday I changed the pads, started jacking up the car and there was a creaking sound just like when driving over uneven surfaces. I rocked the car, in front of the car.. nothing creaks. | ||

| Forge | ||

| Rating: 15 / -8 PM mention |

- List of forumsAuto - EquipmentTechnical section Lada 4x4 NivaGeneral technical

- Search

- Links

- Unanswered topics

- Active topics

- Search

Creaking and grinding noises under the steering wheel, in the area of the steering column switch.

Creaking and grinding noises under the steering wheel, in the area of the steering column switch.

Posted by al-awast » 05 Mar 2021, 05:41

Re: Creaking, grinding noise under the steering wheel, in the area under the steering switch.

Post by Roman elektrik » Mar 05, 2021, 08:00

Re: Creaking, grinding noise under the steering wheel, in the area under the steering switch.

Post by Dmytryk » March 05, 2021, 08:02

Re: Creaking, grinding noise under the steering wheel, in the area under the steering switch.

Posted by al-awast » Mar 05, 2021, 12:03 pm

Re: Creaking, grinding noise under the steering wheel, in the area under the steering switch.

Post by Dmytryk » 05 Mar 2021, 14:58

Re: Creaking, grinding noise under the steering wheel, in the area under the steering switch.

Posted by al-awast » 07 Mar 2021, 13:46

avtoexperts.ru

Crunching sounds when turning the steering wheel are not a common malfunction, so they can confuse car owners - many simply do not have experience in dealing with this scourge due to its rarity. Meanwhile, the phenomenon is very insidious. It is very dangerous to let the situation with the steering take its course, so when the first oddities (including sound ones) appear in its operation, you need to react. The problem is that the crunching has one obvious reason and many unobvious ones. It’s good if the problem can be fixed in an obvious way, because otherwise the cause of the squeak can take a long time to find.

Crunching noise when turning the steering wheel while driving

A striking feature of the “steering” crunch is whether it is heard only while driving or is heard while standing still. This classification allows you to choose the desired search direction. If a crunching sound is heard during turns and maneuvers in motion, then with a high degree of probability the problem is in the CV joint. Constant velocity joints allow you to shift the plane of torque transmission. Usually in a front-wheel drive car there are two pairs of them - the internal ones are located near the exit from the gearbox, and the external ones are located directly near the wheel and allow torque to be transmitted even when the wheels are turned out. It is when the steering wheel is turned at speed that a sharp sound appears, the frequency depending on the rotation of the wheels. It is difficult to confuse it with something else; drivers whose CV joints have started to creak at least once can easily recognize the breakdown the second time.

In general, the CV joint is a fairly simple and reliable design. Very rarely they die from natural wear and tear, and if this happens, it happens over very long runs, at least several hundred thousand kilometers. However, CV joints can fail at any mileage, even very little, the cause will be problems with the anthers.

A kind of rubber covers, designed to protect CV joints from dirt and water, either break due to contact with sharp stones, nails, wire and other debris scattered on the road, or fly off the mount. How long does a protected hinge last and how little does a hinge that gets dirt and water get into? Usually, it takes a little time from damage to the anther to a crunch. In theory, if you notice damage to the boot, but the CV joint has not yet crackled, then you can wash the assembly, lubricate it and cover it with a new boot, but rarely does anyone inspect the car at least weekly from a pit or a lift, so damage to the boot usually becomes obvious after The CV joint crunched. In the vast majority of cases, problems arise with external CV joints.

If it comes to crunching, then the hinge needs to be changed . Depending on the design of the car, the situation may develop differently. The best option is if the design of the car requires a separate replacement of the CV joint, then everything is simple - buy it and replace it, the complexity of the replacement also depends on the specific car model, the most difficult thing is usually to remove the joint from the drive.

But it also happens that the design of the car does not allow changing CV joints separately, the drives are not dismountable, then it is necessary to replace the assembled drive. In terms of labor intensity, this is much simpler; even a not very experienced car enthusiast can handle the replacement, but the price of the complete drive assembly is always higher than a separate joint would cost, so by saving on service, we significantly overpay for the spare part. Alas, modern trends in car design lead to the use of large non-separable elements, which are cheaper to manufacture but create difficulties during repair.

CV joint malfunctions are the most likely cause of a crunching sound when turning the steering wheel while driving. But if checking all the hinges does not show any problems, you can still pay attention to the wheel bearing . The service life of this spare part greatly depends on the make of the car; in some cars, the bearing may fail even at low mileage simply due to an unsuccessful design.

Strictly speaking, the sound that a broken bearing makes can be called more of a howl than a crunch, but you never know, in matters of breakdowns it is difficult to be unambiguous, and all people classify sounds differently. If there is a suspicion of a wheel bearing, it is not difficult to diagnose. It is enough to hang up the front wheels one by one, spin them and listen carefully for any extraneous sounds. Everything should be obvious here - it crunches or doesn’t crunch.

Crunching sound when turning the steering wheel in place

If unpleasant sounds when turning the steering wheel appear when the car is standing still, then the CV joint and wheel bearing can be left alone, the reason is elsewhere. There are many possible options, and among them there is no clear leader in the frequency of problems that arise.

1. Steering wheel friction . On some cars, due to wear or improper installation, the steering wheel may touch the plastic of the steering column lining when turning and make unpleasant sounds. On some cars, there is a special metal part on the steering wheel for the electrical circuit of the horn; it can move a little and start walking in a path not intended for it. Usually, breakdowns of this type are easy to fix - having localized the source of the extraneous sound, remove the steering wheel and install it correctly so that it does not rub or touch anything.

Why does the CV joint start to crunch?

Constant velocity joints, both internal and external, are quite reliable mechanisms, and with proper care their service life can be calculated in years.

In some cases, it is even comparable to the service life of the entire car. However, this circumstance directly depends on the care and operating conditions of CV joints. One of the reasons why joints fail prematurely is an aggressive driving style and/or poor road surface on which the car is driven. As mentioned above, CV joints experience maximum load during sharp turns and high torque from the engine (in other words, when the driver enters a turn “with gas”).

As for bad roads, they can damage not only the car’s suspension, but also the CV joint, since a similar situation is created here. For example, the driver accelerates the car through the CV joint, and at this time the wheel oscillates significantly in the vertical plane. Accordingly, under such conditions the hinge also experiences increased load.

Torn CV boot and lubricant splashed from it

The second reason why the CV joint starts to crunch is damage to its boot. This is especially true for the outer CV joint, since it is located in close proximity to the wheel, and accordingly, a significant amount of dust and dirt gets on its body. Under the boot there is a lubricant, which, when moisture and dirt gets into it, immediately turns into an abrasive compound that begins to destroy the surfaces of the internal joint components.

This should under no circumstances be allowed. It is necessary to regularly check the condition of the boot in the inspection hole, as well as the presence of lubricant in it. Also check if there is any grease on the wheel rims and parts close to it, because often when the boot is torn, it simply splashes onto the mentioned surfaces.

The third reason why the “grenade” crunches when turning is the natural wear of its internal components under normal operating conditions. This is especially true for cheap Chinese or domestic CV joints. If the mechanism is made of “raw” or low-quality metal, then the service life of such a unit will be short.

In the outer hinge, at the point of contact between the balls and the cage, a groove gradually begins to appear. As a result, the designated balls roll very freely, along grooves having a larger diameter than the balls themselves. This rolling is perceived by the human ear as a kind of crunch.

Detecting play on the CV joint

An additional sign of partial failure of the CV joint is the appearance of play on the shaft or axle shaft. It is quite easy to detect it by driving the car into the inspection hole and tugging at the corresponding parts with your hand.

Creak when turning the steering wheel Niva Chevrolet

When you turn the steering wheel to the right, you can clearly hear a disgusting creaking sound, like an old creaky door. The creaking only happens when you turn the steering wheel to the right. Noticed while rotating in place, I haven’t had a chance to test it at speed yet. Where to look for a problem first and how to check what?

Reg.: 03/18/2008 Messages: 37 From: Magnitogorsk Age: 36 Car: 21213 2002.

Reg.: 12.12.2008 Threads / Messages: 2 / 4250 From: Omsk Age: 48 Car: VAZ-1118, 2008

Reg.: 03/30/2008 Threads / Messages: 11 / 2618 From: Surgut Age: 34 Car: VAZ 21310i 2012 October

In general, the report: after the last message, it seems that the noise has stopped, before that I tightened the hub nut, but in the City a periodic creaking appeared like an old stroller, slowly, slowly (60 km.h) I drove home (in advance, having bought wheel bearings + 2 oil seals for a total of 440 rubles ). In the city, even in front of the store, I vigorously shook the wheel for play - I found nothing, I came home and jacked it up, and there was HORROR! It was so loose that my heart skipped a beat: it was a MIRACLE how I got home that the wheel didn’t fall off. In general, I got to the outer bearing, and it turned out that it had crumbled, only after complete removal did I see that the holding “strips” had completely dissolved, I couldn’t take a photo, my hands were covered in fuel oil... but here’s a schematic explanation:

that is, there were 2 such stripes left, then I looked there, both the caliper and the disc itself were all hot, it turned out that with these 2-3 times daily tightening of the hub nut, I brought it to the point that (I simply drowned the disc) the brake disc became “there” brake caliper and “ate” it by 3-4 cm, having pretty much worn itself out, I don’t have money for a disc at my own peril and risk, I left this one for now.

Such a problem. After warming up, at a standstill, or when cruising at neutral low speeds, a creaking noise is heard from somewhere in front, even with the slightest turns of the steering wheel. The sound is similar to squeaking rubber.

Disassembling the steering rack and repairing it when jammed

If steering rack repair is required, it begins with disassembling it. During repairs, a steering rack repair kit is used. Disassembly is carried out in a certain order. First, the adjusting nut is unscrewed, which sometimes requires considerable effort. Then the thrust bushing is removed.

If it is difficult to remove, you can use a mallet to lightly hit the rack body. The side plugs and boot are removed after cutting off the plastic fasteners. For preventative purposes, it is recommended to replace the boot with a new one in any case. The shaft is removed from the rack housing by hitting the body with a mallet.

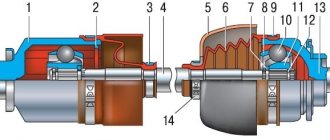

Steering rack parts: 1 – rack bushing ring; 2 – rack support sleeve; 3 – steering gear housing; 4 – roller bearing; 5 – drive gear; 6 – ball bearing; 7 – retaining ring; 8 – protective washer; 9 – sealing ring; 10 – bearing nut; 11 – lock washer; 12 – boot; 13 – rack; 14 – protective cap; 15 – rack stop; 16 – sealing ring; 17 – retaining ring; 18 – stop nut; 19 – clamp; 20 – protective cover; 21 – inner tie rod end; 22 – connecting plate; 23 – locking plate; 24 – bolt securing the rod to the rack; A - mark on the boot; B - mark on the crankcase

Inside the freed cavity of the housing, a plastic sleeve will become noticeable, which can be removed using a screwdriver. It must be replaced with a new one from the repair kit. All old grease is removed from the cavity of the steering rack housing; the surface is thoroughly cleaned, washed and blown.

New lubricant is applied both inside and outside the housing. Litol is used for this purpose.

Particular attention should be paid to lubricating the gearing areas. All rack parts are inspected and, if necessary, replaced with new ones from the repair kit.

If the steering wheel is jammed, it must be removed. This operation for Lada Kalina is carried out as follows.

First, the airbags are disconnected from the battery, their locks and clamps are loosened. The cushions are released and moved to the side. The two horn wires are disconnected. On the steering wheel mounting shaft, in the place marked with an arrow, a mark is made on the location of the steering wheel before it is removed.

The steering wheel nut is loosened (but not completely unscrewed). When the steering wheel swings from side to side, it is tightened until it stops against the nut. Then you should align the car's wheels and ensure that the steering wheel is straight. The pin is removed and inserted into the switch block below the steering wheel.

Every Lada Kalina car owner will sooner or later be faced with the problem of steering rack failure and repair. Of course, experts and auto mechanics recommend changing this element, but not everyone can buy this element, so repair is the way out.

Video about steering rack repair on Lada Kalina:

Causes of failure in the steering column

Usually, squeaks when turning the steering wheel while driving occur in several cases, but most often this occurs due to a broken steering column. Also, unwanted sounds and vibrations can be caused by problems with the chassis, brake system, or suspension problem. In any case, these problems require attention, since neglect of such minor breakdowns can lead to costly replacement of parts and components.

Steering wheel turns hard

There may be several reasons for this:

Excessive tightening. Large forces applied to the adjusting screws of angular contact tapered bearings can result in significant forces on the steering wheel. To avoid this, it is necessary to tighten the adjusting screws until the first stresses appear.

Insufficient performance of a vane pump can be caused by loose drive belt tension, air entering the system, poor-quality oil, fluid leakage, pump failure, and so on. The problem is eliminated after identifying the source of the malfunction using one of the above methods.

A crackling sound when turning the steering wheel is typical for older models of the VAZ family. After repairing or replacing steering elements, the alignment of the steering shaft and the mating spline may be disrupted. The malfunction is eliminated by installing gaskets between the body side members and the steering assembly housing.

Hello all knowledgeable forum members

Attention question. I turn the steering wheel to the right or to the left all the way, and there is some kind of whistle, what is it?

And how to treat it. THANK YOU.

It's your power steering belt that's loose. tighten it, or better yet, replace it and you will be happy.

to ArturA: check the belt tension. Whistle on a cold engine or constantly?

to ArturA: You don’t need to hold it firmly, the oil whistles in the bypass valve. If you are exhausted, you will lose your pump. Is there oil in the reservoir? And if the steering wheel doesn’t whistle when you turn it, then don’t worry, just ride for now.

But for the future, I recommend that you don’t turn the steering wheel all the way, always leave at least 1 cm, it’s just that when you stop, the hydraulics develop a maximum force that you don’t need (up to 60 atmospheres). hence the collapsed seals and leaks.

to Nissanovod: Thank you for your feedback. healthy.

to ArturA: Well, they already said about belts. About turning it all the way too. The whistle may also be due to the fact that the fluid level in the power steering reservoir is low. It sucks in liquid along with air bubbles. That's where he whistles with bubbles. I'm serious!

Same bullshit. Liquid in the barrel is maximum.

to Sokol: Don’t touch anything, what the heck is the belt. Do you people even know how the hydrach works? The belt has nothing to do with it at all, it should “whistle” on all cars if you press it all the way. The bypass valve is whistling, read some books or something. And a normal pump presses up to 90 atm.

On one car there was a “whistle” only when you turned it to the left, but if you turned it to the right there was silence. So the car was pulling to the right, so I had to adjust it. I set the valve to the middle point, it stopped pulling to the right. And you check just by the angle of rotation of the steering wheel and until the whistle.

DO NOT INTERFER THE MECHANISM TO WORK AND IT WILL NOT FAIL.

to NICK67:

Of course, thank you, but this didn’t happen before.

to NICK67: Brother, don’t panic, you’re not the only one smart here. Talk about a whistling sound. This means that we can assume that the whistle is like this: like a generator belt whistling. And if the belt is loosely tensioned, then when the steering wheel is turned to the extreme right or left, the pressure increases, and accordingly, the weakly tensioned belt begins to whistle.

to nikolaewalilia: I support.

to NICK67: And I completely agree with you! Because there is no point in turning the steering wheel all the way and holding it.

If the belt is tensioned properly and everything whistles evenly in extreme positions, then this is normal, it whistled on all my cars except Mitsu, I drove it and never bothered, everything worked and works perfectly

to Dimon-811: And I started whistling after replacing the timing chain, it was removed, and after assembly it was loosely tightened. I tightened the belt, the whistling stopped, well, I mean hysterical, and only the one that was made by the bypass valve remained.

to nikolaewalilia: It will work, it will get used to it.

Eliminate valve noise. Replacement. Report.

to nikolaewalilia: Valve whistling is not a defect.

But avoid turning the steering wheel to extreme positions.

I start to whistle when I start to turn the steering wheel slightly, I drive a little and it goes away, if I turn it enough it whistles loudly, what should I do? (fluid reservoir is full)

Read the reviews above.

Causes of creaking rack and steering column

If the steering column is not working properly, you will hear a slight knock and noticeable vibration when driving. The cause of this malfunction is a strong mechanical impact on the steering wheel, during sudden braking or a collision during an accident. Such signs indicate deformation of the steering column. Also, strange sounds may come from the coupling.

Of course, the best way to eliminate a squeaking or knocking sound when moving and turning the steering column is to simply replace the non-functioning element with a new part. Unfortunately, the steering column is expensive, which means you need to look for ways to repair the old part. Vibration and noise can be eliminated using lubricant. Lubricating the driveshaft with a small amount of grease can eliminate unwanted noise, but this will only mask the symptoms. It is important to seek help from professionals who can fix the broken part before it completely fails.

Disassembling the steering mechanism

Crunching sound when turning the steering wheel.

Remove the steering rod support. We insert the bit into the groove of the crankcase pipe mounting nut.

We unscrew the nut, striking the beard (right-hand thread).

. and remove the crankcase pipe.

Use a screwdriver to press out the two clamps of the bushing located inside the pipe.

. and remove the bushing.

Remove the two rubber O-rings from the bushing.

Steering rack bushing (arrows indicate bushing clamps)

.

If it is necessary to replace the nut, use pliers to remove the locking rings. . and remove the retaining ring.. Remove the pipe securing nut.

Remove the rubber plug from the rack stop adjusting nut. Using a scraper, remove the jammed metal in the locking areas of the stop adjusting nut.

Using a special 24mm wrench with an external octagonal head, unscrew the stop nut.

We take out the stop spring. Prying it with a screwdriver.

. remove the sealing ring.

By hitting the crankcase against a wooden block, we knock out the rack stop. Prying it with a screwdriver.

. remove the liner from the stop.

A rubber sealing ring is installed in the groove of the stop.

Remove the rubber ring from the crankcase that seals the hole for the steering mechanism on the front panel.

Remove the boot from the gear shaft.

Use a 6mm hex to unscrew the two screws.

. and remove the crankcase cover.

Remove the separator with the thrust bearing rollers.

Remove the sealing ring of the cover.

We remove the rack from the crankcase.

We press out the gear shaft by holding the shaft in a vice with soft metal jaw linings and pressing the crankcase upward with the mounting blade.

We remove the gear shaft with bearing from the crankcase. We pry it off with a screwdriver..

. remove the bushing retaining ring.

We take out the gear shaft bushing assembled with the support plate.

If it is necessary to replace the needle bearing with a drill d=4 mm, we drill two diametrically located holes in the crankcase so that they extend to the end of the outer ring of the needle bearing.

Through the drilled holes, using a rod of the appropriate diameter, we knock out the outer ring of the bearing from the crankcase.

Using a puller, we press the ball bearing of the gear shaft with the inner ring of the roller thrust bearing.

Use a puller to press the inner ring of the needle bearing off the shaft.

Using a screwdriver, pry and remove the gear shaft oil seal from the crankcase cover. If it is necessary to replace the outer race of the roller thrust bearing.

. Using a scraper, remove the extruded metal in four places and take out the ring. We generously lubricate the bearings, rack and pinion teeth, and the plastic rack bushing with Fiol-1 lubricant. We assemble the steering mechanism in the reverse order. We press the outer ring of the needle bearing into the crankcase using a mandrel of suitable diameter. To seal holes in the crankcase, you can use “fast steel” or “cold welding”. We press the gear shaft with the ball bearing into the crankcase using a piece of pipe of a suitable diameter or a high head, applying force to the outer ring of the bearing. You can press the gear shaft into the crankcase, resting the outer ring of the bearing on the jaws of a vice.

Then we put the crankcase on the bearing.

. and press the crankcase with light blows of a hammer through a wooden block.

We press the gear shaft seal into the cover through a mandrel or head flush with the end of the cover. We insert the rack into the steering gear housing. Install the pipe. Turn the gear shaft so that the flat on it is located on the right side. We move the rack so that the steering rod support mounted on the rack is located in the middle of the pipe groove. We insert the rack stop, the stop spring and tighten the stop nut. It is recommended to replace the stop nut with a new one. By adjusting the gap in the engagement of the gear with the rack (see “Description of design”).

Repair and diagnostics of control racks

The control rack (control gearbox) transmits force from the steering wheel to the wheels through rods. The steering rod is one of the main parts of the steering control. There are three types of control racks:

- Electronic, used in city cars, because Under heavy loads, the electric motor often fails.

- Mechanical ones are used less and less in cars.

- Hydraulic, these racks have a hydraulic pump installed on them, which makes it easier to turn the steering wheel.

Malfunctions associated with the steering rack may be indicated by knocking noises when turning, and the force required to turn the steering wheel also increases.

Checking the condition of the steering rack is quite problematic due to its inaccessibility. To check the control rack, you have to disassemble the entire control mechanism.

Problems with the steering rack

The main reason for annoying squeaking noises when turning the steering wheel is a faulty steering rack. Such a squeak can be annoying, and untimely repairs can damage the parts. Unwanted squeaking can occur due to simple wear of the mechanisms, damage to the rack box or wear of the steering tips, which can rub against the rods. In addition, damaged anthers can accumulate dirt and debris, which makes a nasty sound when the mechanism operates.

Also, the cause of an unwanted squeak may be an incorrect setting between the steering rack and the column. It is extremely difficult to make such an adjustment, since all machines have an individual adjustment system, and it is better to trust a specialist.

From personal experience

Above, only some standard situations in which knocking is observed were considered. However, this list is far from complete. Owners on forums share valuable information that they receive from personal experience. Some tips may be very useful.

- The cause of the sound when turning the steering wheel may be loose silent blocks of the lower or upper control arm.

- The installation of non-standard crankcase protection is often accompanied by the fact that the steering rod clings to it.

- The connection between the steering column and the side member may be loose.

- The installation of the front section (pants) of the muffler is also a reason, since the bipod begins to cling to it.

Steering wheel creaks in place

Interestingly, squeaking when turning the steering wheel in place, just like with the steering rack, can occur due to damaged steering rod boots. It is the debris and dirt in the protection that can contribute to squeaking when turning the steering wheel. This sound can be heard both while driving and while parked. All you need to do is clean the components from dust and dirt with the familiar WD-40 product, and replace the worn boots with a new and high-quality product. But it’s better not to start everything up, and not to wait until the steering wheel squeaks again, but to periodically check the condition of the boots and, if necessary, replace them.

Important! If the steering wheel not only makes a grinding noise when turning, but also wobbles a little and vibrates, the problem is not only in the steering rod, but also in the steering joint. Such a hinge may wear out over time and require replacement. If you do not replace the part in time, the hinge itself may jam, and you need to be reminded what will happen if the steering wheel starts to jam while driving and turns poorly.

Another reason for squeaking when making turns is an insufficient amount of fluid in the power steering. Typically, such a squeak will only be heard when the steering wheel is turned while the car is stopped. The first thing to do is try to replenish the fluid in the power steering reservoir. If this method does not help, you need to carry out a full diagnosis and, if necessary, repair the pump and other power steering elements. These elements are quite complex to repair at home, so it is better to contact a service station.

Incorrect wheel alignment can also cause a crunching sound every time you turn the steering wheel. Diagnostics and debugging are carried out only in car services, using computer diagnostics. The service will set the exact angle of the wheels, which will not only get rid of squeaking, but also help avoid severe wear of the tire rubber.

Also, a crunching or rubbery squeak when turning the steering wheel may indicate that the ball joints are worn out. If such problems are detected, urgent diagnostics must be carried out. In the event of a breakdown, it is necessary to replace the broken part with a new support. If you can't find a new ball joint, you can use lubricant. This repair will be temporary and will need to be replaced in the future. If you do not replace the ball joint in time, there is a possibility that the wheel will come off at high speed. In this type of accident, it is rare for anyone to escape without injury.

Having learned about a malfunction in the steering part, there is no need to hesitate. It is important to remember under what circumstances the noise occurs and contact a car service center. With correct diagnostics and skillful hands, the car will be on the road again. The steering part is one of the most important parts of the car, so you should not carry out repair work yourself. Finding a quality car service is not easy, but the Uremont.com website makes the search much easier. You just need to submit a request for car diagnostics and select a suitable car service from the list. Thus, you can quickly and easily repair your car thanks to our service.

What to do if you hear a grinding noise near the wheels on a VAZ-2114 when you turn the steering wheel

A similar grinding noise can be heard when there is a fault in the support bearings of the steering column.

It happens that the source of noise is in the wheels. In this case, there may be various reasons for the problem. Here are the most likely ones:

- Due to the rubber being torn, stones or crushed stones got into the outboard bearing of the cardan.

- This sound may occur due to friction of the brake pads against the discs.

- A loose retaining ring can be another possible cause of grinding noise.

- In cold weather, noise may occur if there is insufficient lubrication. If you add it additionally, the problem will disappear.

Not only the above reasons are possible here, but also other reasons.

Adviсe

If the sound you hear from the front of the car resembles a gurgling noise, the most likely cause is high wear on the tie rod ends. In this situation, it is not recommended to continue driving. Otherwise, there is a possibility that the steering control system will be damaged in this way.

Both of these tips are changed at the same time, and this entails significant financial expenses. After the repair, it will be necessary to adjust the wheel alignment.

Sometimes when driving there is a muffled knocking sound. In this case, it can be argued that the bearing is worn out and needs to be replaced.

Tie Rod Ends

Recommendations

When you hear a grinding sound from the front wheels, you need to try to more accurately determine the nature of the sound. One possible source could be a damaged plastic fender liner. Although the grinding noise may be loud, it is not dangerous and can be easily fixed.

You need to pay attention to exactly when the noise appears. If it started after the car overcame the hole, then it may be a problem with the shock absorber spring. It is recommended to replace this part. If the spring is welded together, it will not be as strong as before.