Leaning of the fuel-air mixture: causes and symptoms of a lean mixture

At the very beginning, you need to clearly understand what a lean mixture means. It should be recalled that in the combustion chamber the fuel charge not only consists of fuel, but also contains part of the air. These components are mixed in certain proportions in relation to different operating modes of the internal combustion engine.

Without going into too much detail, the optimal ratio is considered to be 1 kg of gasoline per 15 kg of incoming air. This mixture is called stoichiometric, that is, it has a ratio of 1:14.7. This ratio allows the engine to develop sufficient power while also maintaining acceptable fuel consumption.

If the amount of air is reduced, for example, to 13 kg, then the proportion of gasoline in the mixture will naturally increase. The engine will begin to produce even more power, while efficiency will deteriorate, that is, consumption will increase. Reducing the amount of air even more will cause the mixture to become too rich.

Ultimately, such enrichment will mean that the charge loses its ability to ignite, the spark plugs flood, and the cylinders do not work. With a ratio of 1:5, the over-rich mixture in the cylinders is no longer ignited by a spark.

This process can also occur in the reverse order, that is, the proportion of air in the mixture increases. In this case we are talking about charge depletion. With a lean mixture, fuel consumption is lower, and engine power is also noticeably reduced.

The ratio of gasoline to air 1:21 is the value when a very lean mixture, similar to an over-enriched one, stops igniting. Taking into account this information, it becomes clear that for different operating modes of the internal combustion engine, the composition of the mixture has to be changed.

This allows you to best balance engine power and fuel consumption. For example, with minimal engine loads, there is no point in supplying a stoichiometric or rich “power” mixture to the cylinders all the time.

If the loads increase, then there is no talk of saving fuel by depletion, since in loaded modes the unit requires normal or even maximum performance.

So let's get back to our problem. As already mentioned, a too lean mixture on gas or gasoline can appear on both carburetor and injection engines. It is quite obvious that the main reasons for this impoverishment are:

- insufficient fuel supply;

- intake of excess air;

The main signs of a lean mixture are that the engine starts poorly and runs unstably at idle, the engine stalls immediately after attempts to start moving, while driving the driver presses the gas pedal hard, but the car does not accelerate, the power unit “does not pull” under load , twitches, chokes, etc.

Note that the symptoms of a lean mixture may resemble individual problems with the ignition system or POP failures. On carburetor engines, the engine “sneezes” into the carburetor when running on a lean mixture. The injector may experience popping noises in the intake manifold. Moreover, if the elements and settings of the ignition system are in perfect order (spark plugs, spark plug high-voltage armored wires, etc.), then you need to move on to diagnosing the intake system and power supply system.

Let us add that in some cases it is possible to unscrew the spark plugs from the engine, after which the initial diagnosis is further carried out by the color of the carbon deposits on the spark plugs. Brown light soot will indicate that there are no obvious problems with mixture formation, that is, the mixture burns normally in the engine.

We also recommend reading the article on how to determine the condition of the engine by the color of the spark plugs. From this article you will learn in detail about what the different colors of spark plugs indicate and what possible faults should be looked for in a given case.

Black soot is a sign of excessive enrichment of the mixture. Grayish light or whitish soot indicates that the engine is running on a lean mixture, is overheating, etc. We also note that carbon deposits and its color can be considered an accurate sign only if the engine is in full working order, the ignition is adjusted and working normally, and there are no problems with the spark plugs.

Gas equipment malfunctions: “lean mixture” error on gas

You need to understand that HBO is a separate power system. For this reason, to check the lean mixture when driving on gas, only some of the operations will be the same as in the case of determining the cause of lean mixture on a conventional carburetor or injection engine.

At the initial stage, you should check how the car behaves on gasoline. In some cases, it happens that when switching to gasoline, the car works normally, no errors occur. However, after switching to gas, misfires begin, the check light comes on, etc.

If no air leaks are detected anywhere, and the electronic sensors are also in perfect order, then special attention should be paid to the following points:

- correct installation and configuration of gas equipment;

- cleanliness of gas filters and gas supply channels;

- condition and settings of the gas reducer;

- gas injectors, their performance and quality;

Taking into account the fact that there are many generations of HBO, various malfunctions occur on such systems. So in some cases it is necessary to diagnose certain installed elements.

For example, the first generations of gas installations (GBO-I, GBO-II) were characterized by such a problem when the performance (power) of the installed gearbox could simply be insufficient, as a result of which when operating in loaded modes there is not enough gas, the mixture becomes lean, the engine does not pull , errors appear, etc.

Also, the gas injectors themselves can be a common cause of a lean mixture, regardless of the generation of gas equipment. It is enough to imagine a situation where the electronic unit opens all the injectors for the same time, but one of them closes earlier. As a result, the mixture will become lean in only one of the cylinders.

Signs of a lean mixture

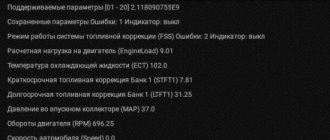

The error is displayed on the BC screen. This suggests that the amount of fuel in the air-fuel mixture is significantly less than air.

The presence of a lean mixture manifests itself in the form of misfires or a delay when sharply pressing the gas pedal. In other cases, the engine may stall or completely stop working at idle speed. In addition, when accelerating, the vehicle jerks, and the sound of the engine is completely different and different from the sound of the engine during normal operation. The operation of the power unit when using a lean mixture is not at all stable.

Lean value

A lean fuel mixture will be indicated by error p0171. Signs of a poor fuel-air mixture include a drop in engine power (the car accelerates slowly), the engine is unstable at idle, and the car responds poorly to the gas pedal.

What is a lean mixture, and what happens in this case? With a lean mixture, the amount of air in the cylinders increases significantly and exceeds more than 15 kg of air per 1 kg of gasoline. At the same time, the fuel combustion process becomes worse, and if the indicators exceed more than 22-25 kg of air per 1 kg of fuel, the engine may stop.

Mixture indicator standards and possible consequences

For cars with the Euro-2 standard and higher, a special sensor was installed on the engines - a lambda probe. He controls the quality of the mixture produced. According to the standard, it is established that for one part of fuel there are 14 parts of air. If there is a minimum deviation of 0.25, the on-board computer will generate an error about a lean mixture. When an over-lean mixture enters the engine, not only failures in operation occur, but also the possibility of engine overheating. The rev speed is quite low. In addition, if you do not carry out high-quality diagnostics and do not eliminate the cause of the formation of a lean mixture, the consequences will become much worse:

- overheating of the power unit;

- burnout of piston rings;

- valve burnout;

- low engine thrust;

- burnout of pistons;

- increased fuel and coolant consumption.

Why does a rich mixture appear?

You can find out that your engine has too rich an air-fuel mixture (error p0172) by measuring CO (carbon monoxide) and CH (soot) during a technical inspection or when diagnosing the engine during scheduled maintenance. You can find out about the occurrence of a problem during operation if you notice that black smoke is pouring out of the exhaust pipe and the engine is shooting into the muffler.

There may be several reasons for the appearance of a rich air-fuel mixture:

1. Problems with the intake system.

In general, an enriched fuel-air mixture is either a lot of gasoline or very little air. Based on this, it is necessary to check the engine systems. The appearance of more gasoline is a more difficult problem to diagnose. One of the simplest solutions is to check the condition of the air filter (if it is dirty, replace it), check the functionality and position of the air and throttle valves in the intake manifold. If the dampers are not fully open, a small amount of air will enter the cylinders, which will lead to an over-enrichment of the mixture. Examine them. If necessary, adjust or reconfigure them. Also pay attention to the condition of the mass air flow sensor or air pressure sensor in the intake manifold.

2. Problems with the fuel system.

Solving the problem with injectors is more complex and requires appropriate equipment. To check the fuel consumption through a calibrated hole, the completeness of the injector closure (so that it does not leak), the operation of the cut-off valve (so that it does not freeze), the injector is checked on a stand: what pressure it can withstand, how the electromagnetic control unit works. Malfunctions may include incorrect operation of the ramp pressure reducing valve. Because of this, increased pressure is created in it, which can lead to incorrect operation of the injector. If these problems occur, repair or replacement of the nozzle or components is necessary.

If your car is equipped with a lambda probe, then do not forget to check it, because the signals that adjust the mixture composition depend on the quality of the device.

Why does a lean mixture occur?

The causes of a lean fuel mixture will be the same sensors and engine systems that we discussed above.

Signs of a lean mixture are popping noises in the intake manifold. Popping can occur for the following reasons:

1. Due to the slow combustion of the mixture in the cylinder during the working stroke, the intake valve has time to open during the ventilation stroke of the cylinder, because of this, the ignited fuel mixture is combined with the fuel going into the adjacent cylinder during the intake stroke.

2. Shift in valve timing due to a violation of the timing drive tension adjustment or partial destruction of the timing drive (cutting teeth from the belt).

3. Early ignition. Also, signs of deterioration in the quality of the fuel mixture will be engine overheating (the combustion process lasts longer and heats up a larger number of parts and cylinder areas). Significant reduction in engine power.

To eliminate the “lean mixture” error and the above problems, pay attention to the following reasons:

1. Problems with the intake system.

A lean fuel mixture is when there is a lot of air and not enough gasoline. To eliminate these problems in the air supply system, the operation of the throttle valve must be checked.

It should correspond to the position of the gas pedal. When the pedal is released, it should be completely closed, and when the pedal is pressed, it should open smoothly and evenly until the air channel is completely open. If equipped with an automatic choke, please note that its position must correspond to the engine temperature. On a hot (warmed up to operating condition) engine, the air damper must be fully open. On a cold engine, depending on the outside air temperature, it should be turned to a certain degree. If it is in the open position, then your air damper opening control system is faulty. One of the reasons for a lean air-fuel mixture may also be damage to the gaskets on the intake manifold and air leaks. To fix this problem, you need to tighten the intake manifold and, if necessary, change the gaskets. Check the condition of the mass air flow sensor or the air pressure sensor in the intake manifold. Check the condition of the terminal connectors to ensure correct transmission of information to the computer from these sensors. 2. Problems with the fuel system.

Here the problems are exactly the opposite when the mixture is too rich. To eliminate these problems, injector testing must be carried out using appropriate equipment. In this case, you should check how much fuel passes through the nozzle. It may be clogged with mechanical impurities that have passed through the filter. In this case, the sprayer or nozzle must be washed. In addition, check the electromagnetic unit: how well and completely does it raise the needle.

We recommend: Transmission oils from different manufacturers: is it possible to mix with each other?

Attention! Do not forget to make sure that the electronic unit is securely connected to the engine ECU: whether the actuator signals are fully transmitted. You also need to check the operation of the fuel pump (how much fuel it supplies to the rack) and the condition of the pressure reducing valve (whether it maintains operating pressure in the rack). If one of the listed problems is detected, the injector or components will need to be repaired or replaced.

3. Problems with the condition of the gas distribution mechanism.

If you don't regularly check the condition of your car's timing system, problems may arise with one of the main engine systems. To ensure that the timing system does not affect the appearance of a lean mixture, it must be checked and, if necessary, adjusted. If a timing fault is detected, the faulty part must be repaired or replaced. When checking the timing belt, pay attention to the condition of the drive belt tension roller, the absence of delamination, cord bulging, cracking of the belt body, or destruction of teeth. If the motor has a drive chain, make sure that the chain tensioner and its dampers are in good condition. At the same time, check whether the chain is stretched. If there are any malfunctions, repair or replace parts.

Did you know? Problems with lean and rich mixture can cause a fire in your car.

Technical description and interpretation of error P2187

This diagnostic trouble code (DTC) is a generic powertrain code. Trouble code P2187 is considered a common code because it applies to all makes and models of vehicles. Although the specific repair steps may vary slightly depending on the model.

This code is ambiguous; it is not always possible to notice it, since the Check engine indicator may not be displayed. Therefore, if you do not have a diagnostic scanner, you may not know about it. This code is difficult to crack without a diagnostic strategy. A problem with the idle fuel mixture is usually determined when other errors are read by the scanner.

The error code means that the fuel mixture is too lean (too much air and not enough fuel) at idle. If you have a 4 cylinder engine, the "Bank 1" information is meaningless to you. However, if you have a 6 or 8 cylinder engine, then Bank 1 indicates a problem on the number one cylinder side. Code P2189 is the same code, but for bank 2.

There is an extensive list of components that can cause this error scenario. But moreover, the diagnostic procedure is not complicated, but simply takes a lot of time. A bug-hunting strategy requires that problems be observed and noted. The check then starts with the most frequently occurring ones and moves forward.

When error signal P0172 is triggered

In order for the ECU to show this error, if present, the engine must be started and an oxygen sensor must be installed - a lambda probe. Also, the error of the engine coolant temperature sensor, intake air temperature sensor (IATV), absolute pressure sensor (MAP-sensor), throttle position sensor (TPS), mass air flow sensor DFID, camshaft position sensor (error P0021) should not be displayed. and crankshaft position sensor (CPS).

Reasons for enriching the mixture:

- the fuel does not burn completely due to inconsistent spark supply to the spark plugs (or the problem is in the spark plugs, or the ignition coil, or in the high-voltage wires);

- Excessive amount of oxygen is supplied due to improper operation of the oxygen sensor or injectors;

- the required amount of oxygen is not supplied.

More often, problems with the fuel mixture are caused by a lack of air, and an excess of air is less common. When supplying air to form a combustible mixture, a lambda probe and a MAP sensor are involved.

The reason for the enrichment may be associated not only with improper operation of the sensors, but also due to a violation of tightness, low cylinder compression, and malfunction of the gas distribution mechanism.

Signs of engine operation on a rich mixture:

- Bad dynamics. Pressing the gas pedal does not accelerate the engine speed.

- Increased fuel consumption.

- Exhaust gases are black.

- Popping sounds from the muffler due to the fact that the fuel does not have time to burn in the working combustion chamber of the cylinder and burns out in the exhaust system. They are clearly audible when releasing the gas.

- The spark plugs have a black velvety residue.

To determine the cause of error P0172, you must do the following:

- Start the engine and bring it to the mode when error 0172 appears.

- Analyze the error from a scanner, for example OBD2.

- Inspect the components of the power unit, check the connections; if air is sucking in, it will be noticeable.

Poor fuel assembly: concepts

A lean fuel mixture

is a fuel assembly with a reduced content of gasoline and an increased content of air.

The error code assigned to this error by the on-board computer is P0171. Literally, this code stands for very poor fuel supply. Sometimes poor FA is called low-calorie.

A poor fuel mixture shows itself with the following signs: very poor traction, especially noticeable on steep climbs, engine overheating, the injector makes popping sounds, and white or gray smoke comes out of the exhaust pipe.

Reasons for preparing a lean fuel assembly: fuel pump malfunction, use of gasoline with water or other impurities, fuel sensor malfunction, vacuum hoses or intake manifold malfunction, injectors supply too little gasoline, pressure sensor malfunction.

Signs of a rich mixture

The formation of a rich fuel mixture occurs with a chic set of manifestations.

- The first and most important sign: the malfunction indicator issued by the car’s on-board computer lights up. Error code: P0172.

- The car muffler makes a loud popping noise. This happens due to a lack of air in the engine cylinders and, as a result, the air burns out in the exhaust pipe.

- Exhaust gases are black or gray. This occurs due to the fact that the fuel assembly burns not in the engine, but in the exhaust pipe; the exhaust gas does not undergo any purification by filters; when burning in the pipe, the amount of atmospheric air sharply increases.

- The car is less dynamic, less powerful. This is explained by the slow combustion rate of the fuel mixture. As a result of slow fuel combustion, power failures occur. If the mixture is over-enriched, it is even possible that the car simply will not move.

- Fuel consumption has increased sharply. It is explained by the inefficiency of using the fuel mixture: it tries to cover the low combustion rate with additional injection of liquid fuel.

When the mixture becomes rich

Deviations in mixture preparation appear as a result of certain failures of vehicle systems. The injector is responsible for the process of creating fuel. It prepares mixtures with a certain percentage of oxygen. It is this ability of the presented engine element that allows the engine to operate in different modes.

If necessary, the driver can, thanks to such a device, increase speed, cope with inclines, overtake, etc.

The rich mixture at the injector is determined by a mathematical formula. The normal ratio is 14.7 kg of oxygen per 1 kg of liquid fuel. If for some reason the amount of oxygen in this formula increases, this composition is called poor. If the amount of fuel in the mixture rises, the mixture acquires the status of rich.

The car owner can independently adjust the level of oxygen supply to the fuel mixture. Errors made in this process lead to breakdowns and improper operation of the vehicle. A rich mixture - VAZ, UAZ, BMW, Audi and other existing car brands - can manifest itself in a wide range of deviations in the operation of the car. If such violations occur, it is necessary to urgently find out the reason for this condition of the engine.

In vehicles in which an auto scanner is installed, when the presented deviations occur, the indicator lights up with the corresponding error code (P0172). In this case, the muffler may make loud popping noises. This occurs due to the combustion of air in the exhaust pipe. This is one of the first signs of violations.

In this case, you can notice the appearance of black and gray shades in the exhaust gases. This is also due to the inappropriate way the fuel burns. The exhaust does not undergo any cleaning.

There is a large amount of atmospheric oxygen in the pipe. Therefore, the exhaust gas acquires a characteristic dirty hue.

Causes and how to determine them

The reasons for a poor air-fuel mixture (injector) are quite simple and lie in the operation of the car. They can be determined using engine diagnostics. First of all, its presence is visible from deposits on the spark plugs.

Also, the causes of a lean mixture on the injector are associated with malfunctions in the fuel injection system. It is responsible not only for supplying fuel to the power unit, but also for the correct preparation of the air-fuel mixture. In this case, the problem may be related to the fuel or air supply settings. Because of this, the mixture becomes leaner. To solve the problem, the car owner should seek help from specialists, since a failure of the injection system can include faulty sensors and incorrect adjustment of the throttle valve angles. It also happens that part of the firmware on the electronic engine control unit fails. It is worth remembering that the composition of the mixture may change by some values only for a minimally short time. Otherwise, you need to look for the problem and fix it.

Fuel system malfunction

Other causes of a lean mixture on the injector are due to improper operation of the vehicle's fuel system. As a rule, operational disruptions occur due to low-quality fuel, which is filled at little-known gas stations. One of the options for unstable engine operation and the formation of a lean mixture is clogged fuel cells of the car. In such cases, there is a misfire in the engine. As a result, the car may jerk. To prevent this from happening, it is necessary to purchase fuel only from trusted gas stations. Both fuel elements should also be replaced in a timely manner. Remember that one filter is presented on the injector in the form of a mesh and is installed directly into the fuel pump. The second element is most often located near the tank on the bottom of the car, less often in the engine compartment. To avoid over-leaning the mixture, it is necessary to change them at least once every 40,000 km. Sometimes this figure may be lower, since it all depends on the quality of gasoline.

What to do if there is an error

The causes of a lean mixture on the injector (including VAZ 2110), if detected, can be eliminated independently, but the best solution would be to take the vehicle to a specialized workshop, where auto mechanics will carry out high-quality diagnostics and will be able to detect other malfunctions in the operation of the vehicle. It is also worth contacting a service station because most drivers simply do not know how to control and adjust the composition of the air-fuel mixture being created. As a rule, on injection engines and carburetor engines, the car owner has this opportunity. An example is adjusting the throttle opening angle. To do this, it is enough to change the position of the locking ring, alternately moving it along the special grooves of the damper.

First aid for a car [error p0172]

If error P0172 “mixture too rich” appears, first reset the fuel trim to 0%! To perform this operation, you must find a sensor (node) that provides incorrect information. To detect it, use a tester or multimeter. Check the mass air flow sensor, intake manifold air pressure sensor, lambda probe, coolant sensor. Their readings must comply with the manufacturer's instructions. Make sure that the intake and exhaust manifolds are securely fastened and the gaskets underneath them are in good condition.

By following these recommendations, you will most likely solve the problem of incorrect operation of your car’s engine.

Subscribe to our feeds on social networks such as Facebook, Vkontakte, Instagram, Pinterest, Yandex Zen, Twitter and Telegram: all the most interesting automotive events collected in one place.

Checking and eliminating causes

General diagnostics begins with the ECM sensors. Typically, the P0171 code occurs due to a malfunction of the MAF sensor (mass air flow sensor). The fact is that the specified sensor ceases to respond in a timely manner to changes that relate to air flow. The cause is usually an accumulation of contaminants.

Contamination of the MAF sensor can occur due to the ingress of fuel vapors that penetrate through the intake and throttle assembly at times when the engine is not running. As a result, a layer of paraffin forms on the sensor, as well as on its wiring, which causes the sensor to send an incorrect signal to the ECU about the lack of air to prepare the mixture.

In this case, the control unit automatically reduces the fuel supply so that the amount of air increases. The result is a lean mixture at different operating modes of the power plant. After this, error P0171 occurs; in parallel, error P0100 or P0102 can be detected. Such codes usually indicate problems and malfunctions in the mass air flow sensor.

To eliminate the causes, the sensor must be removed, after which it is cleaned. You can use carburetor cleaner as a cleaner. The device must be cleaned carefully so as not to damage the sensitive element. If cleaning does not help, then the sensor needs to be replaced.

If the mass air flow sensor is in working condition, then further checking is to determine possible depressurization and air leaks. Defects may occur in the inlet pipe area, in the throttle body area.

- It is necessary to separately check all connections of the vacuum hoses, the mounting location of the intake manifold, the throttle body gasket, the intake gaskets

- nogo collector, etc.

- Also, cracking or other damage to the crankcase ventilation system pipes, fuel vapor recovery system hoses, and plugs on the intake manifold is not allowed.

- The exhaust system must be completely sealed (without corrugations, etc.), since defects near the installation site of the oxygen sensor will also lead to mixture formation failures.

As for the EGR system differential pressure sensor, if present, this sensor can also cause the P0171 code to appear if it fails or malfunctions. The specified sensor is located on the engine, connected to the main pipe for supplying exhaust gases to the USR using two separate pipes. The sensor controls the exhaust recirculation valve.

Contamination of the differential pressure sensor affects its sensitivity, causing the sensor to signal that not enough exhaust gas is entering the system, thereby forcing the EGR valve to open for a long time. This discovery leads to more air in the mixture and depletion occurs.

Now let's move on to checking the fuel system, since reducing the volume of fuel supplied in some cases does not allow the mixture to be enriched, leaving it lean. Fuel supply diagnostics involves the following steps:

- First of all, you should make sure that the fuel filters allow the fuel to flow in the proper volume.

- Then you will need to measure the fuel pressure in the fuel rail, and also make sure that the pressure regulator is working.

- At the same time, you may need to check the fuel pump and its performance.

- Another operation will be diagnosing the injectors (preferably on a bench), as well as cleaning them if necessary.

Having a professional car scanner or a compact device that connects to the OBD II diagnostic connector allows you to evaluate a number of parameters without disassembling the engine and removing equipment. If error P0171 appears with some frequency, then the cause may be an unreliable connection or damaged electrical contacts. In this case, the wiring of the sensors, wiring harnesses to the controller, and ground are checked.

Self-adjustment

Most drivers are very glad that they know how to adjust the throttle angle, as they are completely confident that this will help regulate fuel consumption. In addition, some resort to flashing the vehicle's electronic control unit. In order not to damage some units or ECUs, it is worth seeking help from qualified technicians who can, using special programs, without affecting the quality of the mixture, improve some of the car’s performance. Otherwise, the risk of “killing” the engine of your vehicle increases. Thus, a lean mixture is formed on the injector, the reasons (2114 is no exception) for which lie in the independent adjustment of the angles or the intervention of an inexperienced car owner in the operation of the engine system.

How to save gasoline using an injector in simple ways

The simplest and often very effective way to reduce fuel consumption is to clean the injector, since contamination disrupts the correct shape of the spray pattern. At the same time, due to the delay in gear shifting, the dynamic acceleration characteristics of the vehicle also change.

Similar preventive measures include cleaning a clogged air filter. It affects the reliability of the data transmitted to the electronic control unit and indirectly affects the calculation of specific gasoline consumption at a given load.

Malfunctions in the operation of the catalyst lead to the fact that it resists the release of exhaust gases. This leads to insufficient discharge in the exhaust manifold, and this, in turn, leads to the transmission of distorted information about the increased load. The system, reacting to the supposedly increased load, increases the fuel supply, excessively enriching the air-fuel mixture. Failure of the catalyst is caused by using gasoline of worse quality than recommended by the manufacturer. Therefore, the advice to comply with fuel quality requirements is one of the first and most widespread.

While the vehicle is moving, the Pilot records the operation of the oxygen sensor and air flow sensor. At the same time, you can see on the computer monitor in real time which mixture is lean or rich.

Content

Driving a car

A mixture that is too rich also appears when driving. Almost any driver will immediately notice this. The car becomes less dynamic. Engine power decreases sharply. Since the combustion process in the engine chamber occurs more slowly, the mechanism is not able to work at full strength.

In some cases, the car may not even move. But this is with very serious deviations in the ratio of fuel and air in the combustion chamber.

When driving a car, the owner may notice that fuel consumption has increased. This is also a characteristic sign of engine malfunction due to running with a rich mixture. This violation can be explained simply. The engine does not operate efficiently under such conditions. The fuel mixture is not being used correctly. To prevent a low combustion rate, the motor begins to inject more liquid fuel into the chamber.

Consequences of running the engine on a lean mixture

Overall there are not many consequences. The engine will choke when idling. There is also a serious risk of overheating - the fuel mixture burns much more slowly than necessary. The engine will have difficulty revving up under load. In the most serious situations, when a lean mixture is supplied for a long time, the engine overheats greatly, which in most cases leads to burnout of the valves. And these are serious repair costs.

Also among the consequences can be identified huge fuel consumption. It increases due to difficulties in the process of gaining momentum. Therefore, owners of cars with such problems are recommended to drive in low gears.

List of reasons for a lean mixture on the injector. What needs to be checked and how to do it?

Before studying the reasons for a lean mixture on an injector, it is probably worth understanding what a lean mixture means (in the very concept), and how this, in principle, threatens the car. However, it is worth knowing the signs of excessive impoverishment, identifying the reasons (unless this was not intended) and being able to deal with them, if in your immediate plans the first item is not a serious repair of the car or even replacing it.

The reasons, by the way, are not so varied, and eliminating them is often quite simple. The main thing is to understand what is happening to your car and take action before it gets offended at you and completely refuses to drive, and your nerves become completely unusable.

Reasons for preparing a lean mixture

There are several typical reasons why the fuel mixture is not prepared correctly. All these reasons can be divided into a large volume of air and a small amount of fuel.

Lean mixture errors can often occur with a large air supply. In this case, it is recommended to check the fuel consumption sensor - very often the sensor channels become dirty. The second reason is a vacuum leak. The third is the EGR valve, which sucks in additional air. The valve may be broken or not closing tightly. If a lean mixture enters the cylinders, the reasons are the injector, ignition, fuel system, malfunction of the gas distribution system.

The process of mixture formation in car engines

In an internal combustion engine, the combustible mixture of the required composition is prepared in carburetors or, in the case of an injection power system, it is calculated electronically. A mixture where 15 kg of air is used per 1 kg of gasoline or other fuel is considered normal. In this mode, the engine operates quite economically, while its power is at a high level. To save money, the amount of air in the mixture is increased. So, a lean mixture is when up to 15-17 kg of air is used per 1 liter of gasoline. Fuel consumption becomes minimal, and power loss is only 8-10%. A lean mixture is when there is more than 17 kg of air per 1 liter of gasoline. With this composition, the engine operates unstably, a large amount of fuel is consumed, and power decreases. This is harmful to the power unit. In addition, this phenomenon often leads to misfires in the ignition system and delays when pressing the accelerator pedal.

Also, the motor may change the sound of its operation and will work unstably. In injection units that comply with Euro2, a lambda probe is installed. It controls the quality of the fuel mixture supplied to the combustion chambers.

How to resolve the error

How to prepare a fuel mixture for a two-stroke engine

Regardless of the cause of error P0172, you should not delay repairs; a rich mixture will shorten the life of the catalyst. The most likely sources of problems are checked and eliminated first:

- Examine the candles. Check by the presence of black soot that the mixture is over-rich.

- On vehicles with a return line, remove the hose from the regulator and try to bleed it to ensure it is not pinched anywhere along the way to the gas tank.

- Find out the correct fuel pressure values for your car. For a VAZ with a drain ramp it is 3 bar, with a drainless one - 4. Please note that the pressure on the drain ramp is measured with the vacuum pipe removed from the regulator, otherwise the readings at idle will be 0.6-0.5 bar lower! The pressure gauge itself for measurement can be inexpensively purchased or borrowed.

- Connect the tester to the signal wire of the lambda probe in voltage measurement mode. It is more convenient to use pointer instruments - they do not have the same inertia as digital ones; on a working lambda probe, you can see the needle oscillate from 0.25 to 0.75 V.

- Measure the voltage at the output of the mass air flow sensor with the engine turned off, comparing it with the standard one, if it is possible to find it out. For example, for VAZ sensors it should not be higher than 1.03 V (Bosch) and 0.04 V (Siemens).

- Check the level and condition of the engine oil.

- Without “catching” the source of the problem, contact the service - for a qualified diagnostician there will be no problems here.

Video: P0172 Rich mixture

Seal

In this article we will tell you what a lean or rich mixture of gasoline and air is. What proportions are optimal for engine operation?

Mixture formation in engines

In internal combustion engines, a combustible mixture of the required composition is prepared from fuel and air in a special device (carburetor, injection system), and then supplied in the required quantity inside the engine. A mixture in which 1 kg of gasoline contains 15 kg of air (with a standard oxygen content) is usually called normal.

. To be precise, a mixture of gasoline and air in a ratio of 1:14.7 is called stoichiometric. These are the basic proportions for any engine, but there are variations.

Let's reduce the air intake to 12.5 - 13 kg. The mixture will be enriched (with gasoline) - it will become powerful

, because, burning in the cylinders most quickly, it creates maximum pressure on the pistons, which means high power. True, efficiency deteriorates by 15-20%. If the combustion of 1 kg of gasoline consumes from 13 to 15 kg of air, the mixture is called enriched

, if less than 13 kg of air -

rich

.

Further enrichment of 5-6 kg of air per 1 kg of fuel leads to the fact that the ignition ability of the mixture deteriorates so much that the engine may stop. If the ratio of gasoline and air becomes 1:5, then the mixture will not ignite.

If you strive for efficiency, you should add a little air to the mixture - up to 15-17 kg per 1 kg of gasoline. This mixture is called lean

. Gasoline consumption becomes minimal, although the loss of power is up to 8-10% compared to “power”. If there is more than 17 kg of air, the mixture of this composition is called lean

. The mixture with a ratio of gasoline and air of 1:21 or more does not ignite.

You cannot deplete the mixture indefinitely: when there is more than 20 kg of air per 1 kg of gasoline, ignition from a spark will become unreliable and may stop. As long as it runs on a lean mixture, there is no reason to expect sufficient power and, oddly enough, efficiency. After all, the traction characteristics of the car deteriorate so much that the driver is forced to “spur it up” by switching to a lower gear where he could easily drive in a higher gear.

If the mixture is too rich, engine power is significantly reduced and gasoline consumption increases. This means that a rich or, worse, over-enriched mixture means an excess of gasoline or a lack of air.

How to remove error P0172

The test must be done from simple to complex. That is, the simplest thing is to check whether there is air leakage on the intake and exhaust manifolds, then check the spark plugs, spark plug wires (there are often broken wires) and the ignition coil. For a complete check, you also need to check the lambda probe, MAF, and DTOZH sensors with a multimeter. Then check the ignition marks and fuel pressure with a pressure gauge.

After eliminating the found cause, you need to reset the fuel supply adjustment. Typically, P0172 errors are resolved by flushing or replacing the mass air flow sensor and oxygen sensor.

Video

Causes of mixture being too rich. P0171 - lean mixture, P0172 - rich.

Methods for eliminating lean and rich mixtures on injection engines.

Lean Burn Codes

Do not think that if a “lean mixture” error appears, only one code indicates the reasons for this. For example, P0171 is standard, but for Ford vehicles this code indicates problems in the first cylinder. Some Honda models may display error P0172, which indicates a lean mixture.

On the popular Chevrolet Captiva, the problem with the mixture is indicated differently - P2177. But to eliminate it you need to use universal methods. On a Japanese Mazda-6, code 2178 appears, which also indicates a lean mixture. All this is determined by computer diagnostics.

Expert advice

If the mixture in the fuel tank is too rich, the first thing experienced auto mechanics recommend doing is resetting the additional settings for the injector. If the owner independently adjusted the fuel control system, he could make serious mistakes. A rich fuel mixture will lead to inevitable engine failure very soon.

If the cause of the deviation is related to the injector system, this can be determined visually. With such a malfunction, traces of fuel combustion appear on the outside of the injector.

Burnt and soot can also be found on one side of the copper O-ring. Such deviations are caused by incorrect installation of the injector. If the O-ring is not in its place, similar malfunctions are also possible.

How to return the mixture to normal

If the problem is similar to those described above, you should contact a competent diagnostician. Sometimes the cause of a rich mixture can be eliminated by adjusting the throttle valve or injector. In other cases, replacement of “flying” sensors is required. Therefore, a specialist is needed who has the knowledge, experience and equipment to conduct a comprehensive diagnosis.

Chip tuning can eliminate problems with the oxygen sensor (lambda) - this is one of its functions. When choosing this solution, trust the professionals to reprogram the control unit (ECU).

Get chip tuning from ADACT partners

Map of ADACT partner services

We recommend watching

17 ratings, average: 4.47 out of 5

Let's sum it up

As you can see, there are quite a lot of reasons that lead to disturbances in mixture formation towards an excess amount of air in the fuel-air mixture, that is, depletion occurs.

Please note that on injection internal combustion engines, interference with the standard ECU firmware as part of engine chip tuning, removal of the catalyst, or during the installation of LPG can lead to subsequent disruption of mixture formation and a lean mixture.

Such manipulations with the controller often come down to programmatically disabling certain sensors, changing the throttle opening angle, correcting and shifting the ignition timing, making certain changes to fuel maps, etc.

Many drivers try to save fuel using chip tuning, choosing so-called “economy” versions from modified ECU firmware. At the same time, a reduction in consumption in many cases is achieved by leaning the mixture at different engine operating modes.

It should be remembered that low-quality third-party firmware can lead to serious problems during the operation of the internal combustion engine, and at the initial stage the driver practically does not notice external signs. The “check” does not light up on the dashboard, in normal modes the unit operates stably, etc.

However, the problem of a lean mixture can appear when the load on the engine increases above average. In such a situation, the right decision would be to immediately carry out computer diagnostics of the car. If it is known that the ECU firmware has changed, then you should definitely inform specialists about this.

Remember, operating the engine with a mixture that is too lean will lead to serious problems in the future. Most often, there is a need to repair the cylinder head, as valves burn out, cracks appear in the head, and problems with the pistons and piston rings may be found.

Sources

- https://KrutiMotor.ru/bednaya-smes-karbyurator-inzhektor-gaz/

- https://FB.ru/article/274748/prichinyi-bednoy-smesi-na-injektore-razbiraemsya-v-probleme

- https://scart-avto.ru/remont/oshibka-p0171-slishkom-bednaya-smes-prichiny-diagnostika/

- https://autostuk.ru/oshibka-r0172.html

- https://autodont.ru/system-of-injection/prigotovlenie-smesi

- https://FB.ru/article/283131/slishkom-bogataya-smes-prichinyi-i-sposobyi-ustraneniya-ot-professionalov

- https://FB.ru/article/272476/bednaya-smes—chto-eto-takoe-prichinyi-obrazovaniya-posledstviya