The ball joint is the assembly that connects the hub

on the steering wheel and the suspension arm. Its task is to provide the ability to rotate the hub with the initial position of the wheel horizontally during vertical movement.

The design of the ball joint is very simple

. It is a cone-shaped finger with a mushroom-shaped or spherical tip, which is capable of rotating and, at the same time, swinging at angles in the support body. The housing is pressed onto the lever or bolted. In this case, the ball joint is usually changed along with the suspension arm.

In modern newly introduced units, a non-dismountable design is mainly used. In it, after installing the finger, the body tends to roll. Plastic or other types of inserts are placed between the body and the finger. They work like a sliding bearing and provide rotation with little effort. For domestic, older car models, other ball joints are also supplied, which are called collapsible. Backlashes in them are eliminated by tightening the cover.

Auxiliary electrical equipment

Classification of auxiliary electrical machines Asynchronous phase splitter NB-455A Asynchronous electric motor AS-82-4 Asynchronous electric motor AE-92-4 Asynchronous electric motor for fan VE6-M2 Maintenance of auxiliary AC machines in operation Malfunctions of asynchronous three-phase electric machines and methods for eliminating them Electric pumps ECT- 63/10, 4TT-63/10 DC electric motors P-11M, DMK-1 Maintenance of DC electric motors Fan motor MV-75 Malfunctions of DC motors and methods for eliminating them Electric oven PET-2B Electric heater

Malfunctions and their symptoms

The main malfunctions of the suspension of the VAZ Oka car are:

- Wear and damage to rubber elements (silent blocks, bushings, support washers);

- Leakage of working fluid from the shock absorber;

- Wear of the ball joint;

- Spring damage;

- Wear of the upper support;

The front suspension has a direct impact on the car's handling, so any malfunctions in it negatively affect the car's behavior on the road.

The condition of the rear suspension, although it affects handling to a lesser extent, its technical condition is also important

Symptoms of problems are:

- Knocking in the front suspension, squeaks (when driving through an area with uneven surfaces);

- Incontinence of the rut (when driving on a straight section, it is necessary to steer in order to maintain the trajectory);

- Deterioration in controllability;

- Uneven tire wear;

- Steering wheel vibration when braking;

There are also more specific signs, for example, a clearly noticeable misalignment of the car, which happens in the case of a broken spring.

Note that some symptoms may indicate malfunctions in other components of the chassis - wheel hubs, steering, brake system. Therefore, to more accurately determine the cause, diagnostics of these nodes is necessary. After this, the chassis is repaired, which involves disassembling its components, troubleshooting and installing new spare parts to replace worn ones.

Wear and tear of consumables is the most common reason for the need for suspension repairs. Silent blocks, bushings, washers provide vibration damping during suspension operation. But these parts are made of rubber, which is subject to “aging” and delamination. As a result, their work efficiency decreases. In addition to the environment, the condition of rubber components is also affected by the operating conditions of the vehicle.

The shock absorbers are also not highly reliable, and due to their excessive “softness,” the performance of these components on the Oka leaves much to be desired. Their most common failure is the appearance of a leak of working fluid. Such a malfunction leads to a malfunction of the part. Damage to the shock absorber rod or housing is less common.

The ball joint is the lower support point of the suspension, so it does not bear quite heavy loads either. Over time, this joint wears out, which leads to knocking noises (when hitting bumps) and deterioration in handling. This spare part is also non-repairable and must be replaced when critical wear occurs.

Springs do not cause any particular problems for Oka owners. But in rare cases, their destruction is possible. Due to the burst spring, the strut is unable to support the body, causing it to warp. Naturally, the performance of the suspension is completely impaired and it is almost impossible to operate the car with such damage.

The second problem associated with the spring is the loss of its elasticity - it “shrinks”. This type of malfunction manifests itself through vehicle subsidence, often uneven, and “bounces” (strong knocks) of the suspension when driving even over minor uneven surfaces.

The upper support also fails over time. Its “weak points” are the bearing and the rubber layer. The malfunction of this unit manifests itself in the form of creaks, grinding noises when turning, and knocking on potholes. The support cannot be repaired and requires replacement if worn.

And of course - Driving style!

What Russian doesn't like driving fast? Would a normal guy spare a couple of bucks on suspension repairs for the sake of getting adrenaline??? More speed means fewer holes (and at the same time fewer parts in the suspension). There are a great many such sayings and sayings. It is unlikely that I will be mistaken in saying that everyone has experienced them on themselves. And the more often the driver listens to the voice of his heart rather than his mind, the more often he repairs the suspension and steering. And it makes all the more sense to use the service for restoring ball joints , because a well-restored ball joint runs no worse than the original spare part, and costs several times less. And the company's full guarantee is a guarantee of this.

By using it, you receive

a Full Guarantee . And for the restored suspension arms, and for the work of installing and removing them. That is, by restoring a ball joint or making a polyurethane silent block with removal and installation from us, if a warranty case occurs, you do not need to pay additionally for the removal and installation of the part.

Come back directly by car, we will fix everything at our own expense. Analysis and prompt elimination of errors is one of the main lines of the strategy. to the page “Ball Restoration” =>

Share this post

- Related Posts

- Ball joint device

- Adjustable Hinge Technology

- Restoring ball joints

- Pre-sale preparation of suspension

- Restoration of ball joints using SJR technology

Ball joint: how it works and how it works

Let's start with the fact that there is a certain set of strict requirements regarding the position of the wheels relative to the road surface

As for the steering wheels, it is also extremely important to ensure the ability to maneuver

Simply put, the wheels must be securely secured while steering must be easy and efficient. In this case, it is the ball joint that allows the wheels to turn and connects the hub of the steered wheel to the suspension arms.

If we consider the history of creation, ball joints were created as an alternative solution to replace the pivot mechanism. Initially, such supports became elements of the front suspension to ensure wheel rotation around a vertical axis.

At the same time, the design of the ball joint, after a number of modifications, remains unchanged for quite a long time. While the first versions were two stamped body parts that were joined by spot welding, a cast mount with a threaded cap was developed next. Also, balls can be serviced or not serviced.

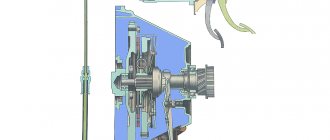

Today, the most common design is a maintenance-free ball joint. This solution includes:

- finger with ball;

- thread;

- housings with a spherical recess;

- anther;

The boot is designed to protect against moisture and dirt, is put on the finger and prevents water and abrasive from getting inside the ball housing, which is filled with a special lubricant. Functionally, ball joints provide a fixed position in the horizontal plane at the moment of vertical movement of the wheel.

This is possible due to the fact that the ball pin can rotate in the body and swing at certain angles. It turns out that a ball is a part that, in the mounting plane, provides both linear and rotational movements of the finger.

Taking into account the load and characteristics of the work, balls are made of steel. Also, to reduce friction of the working surfaces, the spherical recess of the housing has a special coating made of plastic or polymer.

However, there are ball joints where there is no such coating (mainly on old imported cars, as well as the domestic auto industry). The reason is that if the model has collapsible ball joints, the play in them can be eliminated by tightening the cover.

According to the method of fastening balls, two types can be distinguished:

- the ball is bolted to the lever;

- the ball is pressed into the lever or is integral with the assembly;

In the first case, if the ball fails, the part secured with bolts is replaced with a new one. In this case, fixation is carried out with the same bolts. In the second case, it is necessary to replace the suspension arm with ball joint assembly.

Of course, the second option is more expensive, since in addition to the ball ones, which quickly fail, you also have to change the lever itself (often in good condition). This design is more typical for German and Japanese cars.

In practice, balls pressed into the lever last longer than removable ones, but we cannot talk about a significant increase in service life. The fact is that the ball is under heavy loads (the mass of the car rests on a small surface area of the ball).

If you add passengers, cargo and shocks while driving, the load increases significantly. For this reason, if you need a ball joint for a particular car model, when choosing, it is better to give preference only to an expensive original or solutions that are similar in quality. This means that you should immediately discard cheap offers and analogues.

Purpose and design of ball joints

A ball joint is a joint that is one of the fundamental parts of the front suspension of a car. In a car's design, these elements are designed to allow the front wheels to move left and right. The hinge is subject to heavy loads, so it has a short service life, which means it needs to be replaced often.

Ball joints on domestic cars began to be used relatively recently, and before that the ability to move the front wheels in a horizontal plane was realized through king pins. The pivots need frequent lubrication, and the slightest lack of lubrication reduces the mobility of the joints, which means the controllability of the vehicle deteriorates. In the design of the VAZ-2107 car, kingpins are not used, but instead, ball joints are used, which are structurally simpler and 10 times smaller.

The design of the ball joint is as follows:

- Body or base.

- The ball pin is a movable element of the part.

- Boot or protective cover - prevents water and dust from penetrating into the connection.

- Plastic liner inside the case. It is located between the ball part of the pin and the base of the part.

To ensure the mobility of the finger inside the housing, a lubricant is used, which not only improves the mobility of the part, but also protects the internal parts from corrosion and increases service life. The front suspension of the VAZ 2107 has two ball joints per wheel. These are upper and lower devices that differ in design. The upper devices have a poured design inside the housing, and the lower ones consist of metal-ceramic liners. This was done for a reason, but for the reason that the upper and lower ball joints experience different degrees of load.

Signs indicating a ball problem on the seven

Driving a car with faulty ball joints is extremely dangerous, since at any moment when turning the steering wheel the part can fall apart, which will lead to an emergency. It is for this reason that owners of all vehicles need to check the serviceability of the part. You can determine the malfunction of the SB on a VAZ 2107 by characteristic signs:

- When driving the car, extraneous sounds appear in the form of knocking and grinding. The sound is especially pronounced when driving on uneven roads, as well as at a speed of about 30-40 km/h. Knocks and grinding noises indicate that the part has signs of damage to its integrity.

- Failure of ball joints can be diagnosed by vibration of the wheels. A faulty part causes the wheel to have play in the vertical plane, which, when moving at high speed, causes the car to become unstable on the road. The faulty part must be replaced, and urgently, since in the future the amount of play will only increase.

- When the steering wheel is turned to the sides, a metal grinding noise occurs, which is the reason for the lack of lubricant inside the steering wheel.

- When driving, the car may periodically be pulled to the side, due to play in the ball joint, the position of the wheel changes.

- If the parts in question fail, uneven wear of the rubber also occurs. Even if the wheel alignment has been replaced, then after that you need to set the wheel alignment, otherwise tire wear will continue to increase.

All these signs of a malfunction of the SHO are indirect, therefore, to clarify the need for replacement, you will need to diagnose the VAZ 2107 suspension.

Self-diagnosis of ball joints on a VAZ 2107

Grinding and squeaking of a car can occur not only when there is a malfunction of the ball joint, so you should not immediately start replacing the ball joints until a diagnosis has been made. Diagnostic manipulations will allow us to say with 100% certainty that this part needs to be changed.

Ball joints belong to the category of non-repairable parts, therefore, if they malfunction, they must be replaced with new ones.

Diagnostic procedures for determining a malfunction of the shutter on a VAZ 2107 consist of the following manipulations:

- First of all, a simple check is performed, which is based on the fact that two people stand near the front wheels and press alternately on the hood. If a creaking or grinding noise occurs when pressing, then we can say with 100% certainty that there is a faulty part in the suspension design.

- Diagnostics of ball joints continues, which is based on identifying play. To do this, you need to jack up the part of the car that is suspected of having a faulty part. There is no need to remove the wheel; it just needs to be suspended. To prevent the wheel from moving forward and backward, you need to fix the brake pedal in the depressed state, then grab the wheel with your hands from above and below and begin trying to swing it towards and away from you. Repeat the procedure, holding hands on the left and right. The presence of even a slight play indicates a malfunction of the shock absorber, which cannot be repaired, but only replaced. Please note that play can also be caused by a loose wheel bearing.

- The boot of the VAZ 2107 ball joint is inspected, which should be in good condition. If it is torn or has microcracks on the surface, then there is a high probability that water and dust have gotten inside, which means that the process of corrosion destruction will soon or has already begun. If the boot is faulty, the part should also be replaced, otherwise it will soon fail, which will entail the need for emergency repairs of the front suspension.

- Checking the stroke of the ball pin. If the finger moves freely on the removed part, this indicates that the ball part has severe wear and therefore further operation is impossible. The ball pin must move with force and is difficult to move manually.

When buying new supports, you need to pay attention to the manufacturer so as not to fall for a fake. It is also worth remembering that a good ball joint will never be cheap, so buy only original models that with 100% certainty will last at least 20-30 thousand kilometers. We recommend reading the article about replacing the ball.

Is it possible to drive with a broken ball joint?

Many car enthusiasts who are faced with a similar problem for the first time are interested in the question: if the ball joint is knocking, is it possible to drive with such a breakdown? The answer depends on the degree of wear and damage of the specified unit. If the knocking noise from the ball joint while driving has just appeared and the car is not yet “driving” on the road, it does not knock when turning, that is, there are only early signs, then you can still drive such a car. However, make sure that the driving speed is not high, and also try to avoid potholes and uneven surfaces. And, of course, you still need to think about the upcoming renovation. After all, the sooner it is done, the cheaper it will be, firstly, and secondly, the car can be operated safely!

If the breakdown of the ball joint has already reached such an extent that the car “fidgets” on the road and the knock of the ball joint while driving is clearly audible, then it is better to refuse to operate such a car until repairs are carried out. As a last resort, you can drive it at low speed and following the rules of safe driving to a car service center or garage, where you will have to replace it (usually the ball joint cannot be repaired and is only replaced with a new one).

Also often asked about:

- What are the signs of a faulty ball joint on a VAZ 2114?

- Causes of ball failures on Lada Kalina

Replacement of ball joints VAZ 2107

Ball joints on the VAZ 2107 cannot be repaired. On the first “sevens”, collapsible ball joints were installed, from which a worn ball pin could be removed and replaced. Modern supports cannot be disassembled. Moreover, even if we allow for the possibility of disassembly, it will still not be possible to repair the SHO, since ball pins for the VAZ 2107 have long been discontinued.

To replace the SHO you will need:

- a set of new ball joints;

- jack;

- a device for squeezing supports out of the eyes;

- set of open-end and socket wrenches;

- hammer;

- flat blade screwdriver.

Procedure for replacing ball joints

Replacing ball joints on a VAZ 2107 is carried out as follows.

- The wheel on which it is planned to replace the wheel is jacked up and removed.

- Using a 22mm open-end wrench, unscrew the nut securing the upper ball pin.

Video: replacing the ball joint of a VAZ 2107

Thus, technically replacing ball joints on a VAZ 2107 is quite simple. However, in practice, squeezing the ball pins out of the lugs will require considerable physical strength. Therefore, any car owner should realistically assess their capabilities before starting work on replacing the car.

About other manufacturers

As mentioned above, the production of high-quality ball joints requires serious costs. And this cannot but affect the final cost of the product. Therefore, there are only four large manufacturers of supports for the VAZ 2107, and all of them are listed above. Of course, there are smaller companies that offer car enthusiasts ball joints at almost half the price. But any sane person understands: if a ball joint costs half as much, it means that the manufacturer saved on something during its manufacture. Most often, savings are made either on ultrasonic analysis of rod blanks or on heat treatment. Neither the first nor the second bodes well for the buyer of the support.

Cheap ball joints have a very short service lifeAnd if the car owner is of sound mind, then he will not react to a temptingly low price and save on a detail on which his life literally depends. It is for this reason that little-known manufacturers of cheap supports will not be considered in this article.

Here we should mention another unpleasant thing: fakes. Recently, ball joints from well-known brands have begun to appear on the shelves of car dealerships, costing suspiciously cheaply. Upon closer examination, the vast majority of them turn out to be fake, and often the fakes are made so well that only a specialist can recognize them. For an ordinary car enthusiast, the criterion for selecting supports is still the same: price. It should be approximately the same as indicated above. And if a ball joint from a well-known brand costs half as much, then buying such a part is categorically not recommended.

Tuning and improvements

As already, the front suspension on the Oka leaves much to be desired, so many small car owners are interested in how to strengthen the suspension and improve its performance. Suspension tuning helps a lot in this matter.

Conventionally, tuning of this component on the VAZ-1111 can be divided into two categories - with minimal impact on geometric parameters and serious alteration.

In the first case, reworking the suspension comes down to replacing the shock absorber and installing rubber elements with improved characteristics. The front suspension spring does not change in this case.

On the Oka, in addition to factory shock absorbers, you can install similar parts from other cars, but here it is important to take into account their dimensional parameters, in particular the length. The front shock absorbers of the Chevrolet Niva, VW Jetta/Golf 2 are similar to the front of the VAZ-1111, for example.

But the former, when fully extended, are 1 cm shorter than the “original” ones from Oka, and the VW shock absorbers, on the contrary, are 3 cm longer. Therefore, their installation will entail a change in ground clearance. But as an option, the rod on the Jetta 2 parts can be ground down by 3 cm and a thread can be cut on it, thereby adjusting the part to the required dimensions

The front shock absorbers of the VAZ-1111, for example, are similar to the front shock absorbers from the Chevrolet Niva, VW Jetta/Golf 2. But the former, when fully extended, are 1 cm shorter than the “original” ones from Oka, and the shock absorbers from VW, on the contrary, are longer by 3 cm. Therefore, their installation will entail a change in ground clearance. But as an option, the rod on the Jetta 2 parts can be ground down by 3 cm and a thread can be cut on it, thereby adjusting the part to the required dimensions.

In both cases, replacing the shock absorber with a stiffer one will have a positive effect on the car’s handling and will reduce the “rolliness” of the car, and at the same time, the alteration will have virtually no effect on the geometry of the entire unit.

As for the serious modification of the suspension, everything here depends on what the owner wants to get as a result. For example, some “Okovody” make a kind of crossover out of a small car. And for this, a suspension lift is performed, which boils down to adding spacers to the strut design, while the shock absorbers are also replaced with higher ones. As a result, the car is significantly “lifted” - its ground clearance increases.

In general, there are many modification options and they are, by and large, limited only by the imagination of the car owner. Some only strengthen the suspension, others modify it using components from other cars, and others practically develop it from scratch, adapting it to certain operating conditions of the car.

Methods for diagnosing ball joints

To do this you need a pit or a lift. After hanging the wheels, insert a pry bar between the suspension arm and the steering knuckle. We are trying to shake up these two parts of the suspension and chassis. I told you how to properly diagnose all elements of the front suspension yourself in a previous article. If play is visible, even if it is not large, this is a sign of wear on the ball joint liner. The video shows how to do this.

The second method is to measure the gap between the ball and the inner joint liner. This method allows if the design has a hole in the lower part of the body.

For example, on a VAZ classic, there is a hole in the lower ball joints with a threaded plug. To diagnose, you should unscrew it and use a caliper with a bore gauge to measure the distance from the edge of the body to the ball. It should be no more than 11.8 millimeters.

Is it wise to “not sweat the small stuff”?

If the first clicks in the ball joints (ball joints of the suspension arms, ball joints of the steering tips, ball joints of the steering linkages and rods, stabilizer struts) are not paid attention in time, the wear of the ball joint progresses. Over time, the sound develops into a sharp metallic knock. Now the ball pin, having “eaten” the polymer liner, hammers on the metal of the ball joint housing, unbending the flaring of the plug or gnawing a hole in the upper part of the ball joint housing. One fine day, the sphere of the ball pin will make its way and even jump out of the ball joint housing. Have you heard the expression: “tore out the ball joint”?

Causes of ball failure

There are a number of typical reasons why a ball joint becomes unusable. Among them:

Natural wear and tear. On average, a ball joint can last from 20 to 150 thousand kilometers. However, if the part is of more or less high quality, then problems with it may begin after about 100 thousand kilometers of the car. Wear is influenced by many factors - the quality of the part, operating conditions, care of the part, the presence of lubrication, the integrity of the boot, driving at high speed on uneven roads, sudden temperature changes, off-road driving, and so on.

- Torn boot. This part of the ball joint, roughly speaking, is considered a consumable item, so it is advisable for the car owner to periodically monitor its condition, in particular, its integrity. If the boot is damaged, then moisture, sand, dirt, and small debris will probably get inside the ball joint while driving. All these elements will form an abrasive material that will naturally wear out the insides of the support. Therefore, torn anthers must be replaced in a timely manner using the appropriate lubricant.

- Increased loads. This primarily applies to driving a car at high speed on uneven roads. In such conditions, impacts occur on various suspension elements, including the ball joint. Naturally, this leads to wear and damage. Another situation is overloading a vehicle, that is, transporting cargo with the maximum permissible weight or even exceeding the permissible weight. A particularly difficult option is driving fast on a rough road with a significantly loaded car.

Lubrication production. It is removed from the ball for natural reasons - drying out, evaporation. As mentioned above, if the boot is damaged, the lubricant can be removed very quickly due to natural causes, which will lead to increased wear of the ball joint. Accordingly, it is useful to periodically add lubricant to the ball, including when installing a new unit, since manufacturers often do not leave as much lubricant on new bearings as required by the automaker’s instructions. There are special devices for adding lubricant to the ball. And as a lubricant you can use lithium greases (for example, “Litol”), ShRB-4 and others.

Remember that the causes of ball joint failures do not appear overnight. The only exception may be an initially defective part (for example, with a crack in the body), but the likelihood of this is quite low. Therefore, it is necessary to diagnose the ball at the initial stage of failure. And when buying, it’s also better not to skimp and pay a little more, because the more expensive the part, the more wear-resistant it will be (in most cases). Their main difference is the quality of the material, the type and amount of lubricant used, as well as tensile strength.

Causes of ball joint failure

During operation, these supports experience severe loads. Depending on the location of their installation and the design of the suspension, the supports carry most of the total weight of the car, and also withstand constant systematic impacts when driving on uneven roads.

The main reason for the disruption of the correct operation of the ball joint is wear of the contacting surfaces; it leads to an increased gap in the gap from the body to the pin. As a result, the finger begins not only to rotate, but also to dangle in the body.

If the wear is too severe, the loads on the support may cause the pin to break out of the housing. As a consequence of all this, it turns out that the support is not able to hold the wheel, and the car collapses onto the asphalt.

An increase in the gap occurs due to the following factors:

natural wear and tear combined with obsolete materials,

dynamic loads increase while driving at high speeds on uneven roads,

the protective cover or boot breaks, as a result of this, water and all kinds of dirt get into the gap, and they in their time increase corrosion, and even abrasive wear,

lack of lubricant in the hinge (if necessary).

Here are a few main signs of wear on ball joints:

When you drive on an uneven road at low speed and you hear a knocking sound.

If the force on the steering wheel is increased, and when you turn it, you hear a creaking noise from the front of the car.

Because the front wheels are wobbling, your car is moving unsteadily in a straight line.

The tires on the wheels are worn unevenly.

Symptoms of malfunction

| Symptoms of ball failure | Description of symptoms and causes |

| Wheel knocking while driving | Extraneous sounds will appear at any speed and are clearly noticeable when hitting an uneven surface, a hole, etc. It is both one-time and recurring in nature. |

| Changing wheel alignment | The wheel with a faulty ball joint suffers the most. Increased tire wear at the edges is possible. |

| The car swerves along the road | There is play in the ball joint, which causes the wheel to wobble when driving. |

| Creaks during maneuvers | Creaks can come from the steering wheel or rear wheels; you should listen specifically to the front ones during maneuvers. |

| Changing the braking trajectory | The car will drift in the direction with the faulty ball joint. |

Purpose of ball joints VAZ 2107

A ball joint (BJ) is an ordinary hinge built into the VAZ 2107 suspension and allows the wheel to move only in a horizontal plane. At the same time, it limits the possibility of wheel movement in the vertical direction.

Ball joints of the VAZ 2107 are very short-lived, so they have to be changed often.

Design of ball joints VAZ 2107

Previously, passenger cars did not have ball joints. They were replaced by bulky king pins that had to be lubricated frequently. The mobility of such compounds left much to be desired. This, in turn, negatively affected the car's handling. The designers of the VAZ 2107 abandoned the kingpins and installed ball joints. The first SHO consisted of:

- housings;

- ball pin;

- springs;

- anther

The finger was pressed into a fixed eye, fixed with a powerful spring and covered with a boot. This structure also needed to be lubricated periodically, but quite rarely (about twice a year). The lubricant on the pins had to be changed every week.

Subsequently, the VAZ 2107 SHO was constantly improved:

- the spring disappeared from the structure;

- the steel boot was replaced with a plastic one;

- the fixed eyelet in which the finger was fixed became more compact and received a plastic external finish;

- SHOs have become non-separable, that is, practically disposable.

One driver I know assured me that he had found a great way to extend the life of plastic boots. Before installing new ball joints, he always applied a thick layer of silicone ointment to the boots, which car owners use to prevent the rubber bands on car doors from freezing in winter. From his words, it turned out that the anthers after such a procedure become practically “indestructible.” When I asked how an ointment intended for rubber could improve the quality of plastic, I was recommended to just try it and see for myself. Unfortunately, we never got around to it. So I leave it to the reader to check this driver’s find.

Reasons for failure of VAZ 2107 ball joints

The main reasons for SHO failure are as follows:

- Alternating shock load. As a result, the ball pin pressed into the suspension eye is destroyed. The support is designed in such a way that the shock loads on the pin ball are very high. When the quality of roads is poor, these loads increase manifold. In such conditions, even a high-quality SHO will not be able to fully exhaust its resource.

- Lack of lubrication. Under the influence of shock loads, the lubricant is gradually squeezed out of the SHO. In addition, over time, the lubricant loses its original properties.

- Anther destruction. The boot protects the hinge joint from dirt. If a crack appears in it, the dirt that gets into the joint turns into an abrasive material and grinds down the surface of the ball pin.

Signs of malfunction of VAZ 2107 ball joints

The main symptoms of a VAZ 2107 SHO malfunction include:

- Extraneous sounds. While driving, a knocking or grinding noise begins to be heard from the wheel. This is especially pronounced on uneven roads at a speed of about 30 km/h and is usually a consequence of partial destruction of the ball on the support pin.

- Wheel rocking. When accelerating, the wheel begins to sway slightly in different directions. This happens due to the backlash that occurs in the SHO due to its wear. The situation is quite dangerous, and the backlash must be eliminated quickly. Otherwise, the wheel may turn at a right angle to the body at speed.

Video text

Video showing how you can easily and quickly restore a ball joint in a garage. A LITTLE BELOW ADDITIONAL. RESTORATION INFORMATION. Of course, buying a new ball is the most ideal option. But from the point of view of saving and extending the life of this unit, someone will find this useful for themselves.

ALL EXTRAS INFORMATION ON RESTORING THE BALL AND ITS SERVICE LIFE: IT IS RECOMMENDED TO RESTOR ONLY ORIGINAL BALLS, BECAUSE THEY HAVE BETTER QUALITY MATERIALS

ATTENTION. NON-ORIGINAL WILL RUN LESS AND WITH POOR-QUALITY REPAIRS, THE BALL POSSIBLE TO PULL OUT AFTER A SEVERAL HUNDRED KM

THE FIRST SIGN OF AN URGENT REPLACEMENT OF A RESTORED PART IS THE APPEARANCE OF A WEAK KNOCKING. BY THIS TIME THE NEW BALL SHOULD BE READY. MORE THAN 15 THOUSAND HAVE BEEN DONE ON THIS BALL JOINT. KM (CLOSER TO 20 THOUSAND KM.) DIDN'T DETECT IT DEFINITELY. AFTER MINOR KNOCKING APPEARANCE, I REPLACED IT WITH A NEW ONE. I WOULD HAVE WENT LONGER IF IT WERE NOT FOR THE ROAD TO THE HOUSE WHICH WAS VERY BROKEN ABOUT 2 KM. WHICH I WAS NOT DRIVING ESPECIALLY SLOWLY - I WAS ALREADY WAITING FOR IT TO KNOCK AND PRACTICALLY FINISHED IT MYSELF. BUT SHE STILL DIDN’T KNOCK - GOOD MATERIALS OF MANUFACTURE. AFTER THE KNOCKING APPEARED, I REPLACED IT. GOOD LUCK IN REPAIRING AND GOOD VEHICLES TO EVERYONE!

REPAIRING BENDEX - EASILY WITH YOUR OWN HANDS. HERE: https://www.youtube.com/watch?v=vdeFs.

Good luck to everyone with the renovation! ===================================================== ==== Optimization (not for reading. ): how, easy, restore, ball joint, oleg vinokurov, vaz, ball joint, support, ball joint, fret, suspension, ball repair, steering end, tip repair, car repair , car repair, ball removal, ball, steering rod, VAZ support, ball replacement, front arm, Mercedes, Toyota, Volkswagen, repair, auto repair, car, Lada, test drive, avto, ball support, toyota, replace ball, remove ball joint, cars, replacement, chassis repair, restoration of ball joints and levers, restoration of a ball joint, do it yourself, how to restore a ball joint, how to restore a ball joint, how to restore a ball joint, restore a ball joint, how to restore a ball joint yourself, suspension repair, yourself , restoration, ball joint restoration, ball joint repair, aker mechanic, anton krainikov, nemagiya, auto blogger, akermehanik, simonov, main road, webasto instructions, launch, from, webasto, at, -50ºc, and, registration, for, rally, pole of cold 2021, restoration of ball joints with your own hands, restoration of ball joints, levers, machine for restoring ball joints, restoration of a ball joint, ball joint, support, ball joint, how it works, device, what is needed, how to repair, repair, replacement, h100, hyundai, hyundai h100, ball joint, ball, suspension, chassis, car, car suspension, ball diagnostics, lever diagnostics, Matiz ball diagnostics, ball play, chassis diagnostics, lever diagnostics, lower ball joint VAZ 2101, ball joint VAZ fake, fake when it's time to change the ball, causes of ball failure, broken ball, ball knocking, ball replacement, ball repair, ball repair video, ball video, ball failure video

The ball joints carry the load of the front end of the vehicle, including the weight of the engine. At the same time, when moving, they receive constant impacts from the wheels in any direction. No matter what durable material these parts are made of, their service life is limited. It’s good that in many cases restoration with your own hands is possible.

Video

This video shows in detail the design of the ball, what it is used for, etc.

Here you can clearly see how a ball joint works in motion.

How to diagnose the suspension yourself.

Diagnostics of steering tips and balls.

This video shows how to check the suspension.

Checking and replacing the ball joint on a FORD FOCUS 2 / FORD FOCUS 2 car.

The suspension of any car consists of many different parts that have different functions. One of these parts is a ball joint, which is a connecting part that allows the front wheels to rotate in different directions. If a part malfunctions, serious consequences can arise, so we will figure out how to check the ball joint of a VAZ 2107, and what may be needed for this.

How to check a ball joint

If you experience symptoms of a ball joint malfunction, you should use the services of a service or conduct an independent check. True, you can’t do without a lift or jack.

- Inspection. The visual condition can say a lot about the position of the spare part: cracks in the boot are a clear sign of a clogged unit.

- Wiggle. If no visual defects are found, you should grab the edges of the wheel and swing it vertically. It should be noted that the breakdown will only appear in a certain position, so it is better if someone turns the steering wheel. Again, backlash may indicate other problems.

- Check with a mount. The flat end of the mount is inserted into the gap between the lever and the pivot pin: if you press on the handle, you can check for play or clicks, which are easily transmitted to the handle.

Some models have diagnostic holes for this purpose, through which it is easy to measure wear. Still, it is worth noting that the final diagnosis can be made when the support is removed. It is enough to move the tip to the sides and make sure there is play

Timely diagnosis of supports is very important, as this can protect against accidents on the road

Towing a car without the driver present

If you actually find out that the car has been towed, then you should do the following:

- First of all, find out where the car was towed to. Where to call for this? The telephone number depends on your geographical location. So, for the city of Moscow there is a “Moscow Parking” service, a hotline, for St. Petersburg - +7 812 004 (can be dialed from cell phones);

- If you don’t have the number at hand, then simply contact the police duty station - 02, where you explain the situation: “... I came - there is no car. I don’t know: theft or evacuation? Where to call?". You should not be refused information;

- The 21st century has given us the opportunity to access the Internet from any more or less modern device. On the Moscow Parking website you can search for a car by impound lot using the appropriate service. The prudent creators of the site provided all the necessary information to the driver whose car was towed.