This part in the clutch system plays a fairly important role as the final link in the distribution of hydraulic load. In the classic VAZ clutch system, the master cylinder is located, respectively, in the engine compartment near the gearbox and has a fairly convenient outlet for repairing the VAZ 2106 clutch slave cylinder. The part consists of several main parts, which together form a single small but important unit:

- The piston directly serves to squeeze out the fluid located in the main tank (as usual, special brake fluid is poured there). When the clutch pedal is pressed, it is the piston that activates the hydraulic pressure mechanism and applies forceful pressure to the fork in the clutch.

- The case is the fundamental part in which the entire mechanism is enclosed. The outer part in modern versions is made of durable plastic. In early models on old Soviet designs, a metal body is sometimes found, but this design is less reliable not only due to age, but also due to the likelihood of corrosion.

- The rod is driven by a piston and acts as a pusher both when the pedal is pressed and after it is released. When pressed, this part pushes liquid into the system, and then closes the housing for liquid.

- The protective cap serves to maintain integrity inside the system when liquid enters. Otherwise, it is simply called a cover that covers the housing parts from excessive contact of substances with the mechanical parts of the unit.

- The spring acts as a single unit together with the piston when the gas pedal is pressed and actually “serves” the unit during the return action. One of the main reasons for system failure is often the wear of the spring, which causes the cylinder to not close properly and the fluid to escape beyond the closed circuit.

- A valve for bleeding air, which is also a common cause of failure of the entire part due to its inoperability. This part is designed to remove excess air during piston operation. Excess air, if present in the system and liquid penetrating inside, leads to the disappearance of the clutch, which can lead to an emergency. It is the valve that serves to remove the formed air, but for some reasons this unit can wear out and fail. Moreover, despite its simple design, such a part can rarely be repaired and most often must be completely replaced, not only because of the impossibility of the repair itself, but mostly because of the low cost of both the complete assembly and its individual parts.

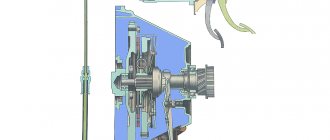

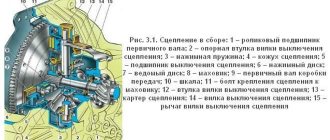

Clutch drive device VAZ 2107

We dealt with the clutch mechanism of the classic VAZ 2101-2107 not so long ago. There is nothing complicated there either and you can refresh your knowledge here. In all rear-wheel drive VAZ cars, the clutch release drive is hydraulic. The clutch master cylinder is installed in the engine compartment on the shield, the cylinder is located coaxially with the clutch pedal rod. A pusher is attached to the pedal itself through a hinge, which presses directly on the master cylinder piston. The VAZ clutch drive diagram is presented below.

Clutch drive diagram VAZ 2101-2107

Thus, the rod, through the pusher piston, acts on the incompressible brake fluid in the master cylinder, which transmits force to the piston of the working cylinder, already installed on the gearbox housing through the hydraulic hoses.

Bleeding the system

The design of the VAZ-2106 clutch master cylinder is approximately the same as on a similar element of the brake system. Pumping is done in the same way:

- The entire system is assembled, threaded connections are tightened.

- Liquid is poured into the expansion tank to an average level.

- A tube is put on the bleeder fitting and lowered into a small container with brake fluid.

- An assistant presses the clutch pedal several times and then locks it in the pressed position.

- At this time, unscrew the bleeder fitting a little so that the air comes out.

Repeat the last two steps several times until air stops escaping from the system. Be sure to monitor the brake fluid level. Otherwise, the mechanism will run dry, and it may be necessary to disassemble the VAZ-2106 clutch master cylinder for repair.

Operating principle and replacement of the clutch master cylinder

The clutch master cylinder itself serves to transmit the maximum fluid pressure from the foot pedal of this mechanism to the VAZ 2106 clutch slave cylinder, forcing it to move within the required limits in its plane. As has already been noted, the transmission of the pressure force of the foot drive through the clutch master cylinder entails an increase in the pressure parameters in the hydraulics of this complex.

Next, the system pressure is transmitted to the clutch slave cylinder, which drives the vehicle’s transmission. However, there are defects that require repair and replacement of the GCS and RCS. This can be determined if the following signs are present:

- The drive unit of the system does not completely disengage (the clutch “drives”).

- Leakage of working fluid from the components of the unit, incl. from hydraulic pipes and their connections.

- “Wedging” of the clutch master cylinder when the foot drive is in the lowest (recessed) state.

Timely replacement of the VAZ 2106 clutch cylinder is done in the following sequence:

- Use a bulb or other device to pump out the working fluid from the clutch hydraulic reservoir.

- Having loosened the fastener in the form of a crimp clamp, disconnect the hydraulic hose from the drive fitting.

- Unscrew the pipeline drive fitting using a “13” wrench.

- Unscrew the 2 nuts of the studs securing the foot clutch drive using a socket set to “13”.

- Carefully remove the GCS.

- When installing an updated product, assembly is carried out in reverse order.

- We pour special fluid into the hydraulic tank and pump the hydraulic system.

- We remove from the end part the cap for the protective function of the VAZ 2106 clutch cylinder, the price of which is low, which protects this spare part from mechanical deformation.

- Use a screwdriver with a thin blade or an awl to remove the lock washer-gasket and dismantle the fitting device with the seal.

- Having installed the clutch master cylinder in a vice on a bench, use a 22mm wrench to unscrew the plug.

- We take out the retaining ring and the remaining elements of the GCS.

- We inspect in detail the components of the GCS: the “mirror” of the product and the piston outer surface must be smooth, without burrs. The return element must have the necessary rigidity, otherwise it will need to be replaced. The sealing o-rings must be replaced with updated products, as well as the protective cap. If the lock washer of the fitting device is defective, it must also be replaced.

- We wash all the elements of the GCS with a degreaser solution, after which we assemble the product into a single whole.

in this video I change the clutch master cylinder

for

VAZ

2107. similarly,

the master cylinder is replaced

...

Operating principle and replacement of the clutch slave cylinder

If a car owner is replacing the clutch slave cylinder of a VAZ 2106, then it is necessary not only to prepare a set of plumbing tools, cleaning and degreasing products. It is required to have sufficient skills in plumbing, to imagine the structure of the product being dismantled and to have the desire to make such a replacement.

Dismantling the clutch slave cylinder is carried out according to the following algorithm:

- Starting the dismantling process, it is necessary to slightly loosen the screw securing the rubber hydraulic tube, which leads to the connection with the clutch slave cylinder of the “six”.

- We remove the spring mount that pulls back the clutch fork, and then dismantle it.

- We fix the location of the pusher element of the clutch working cylinder, and then remove the cotter pin.

- Remove the bolted connections of the clutch slave cylinder to the vehicle's clutch housing.

- Remove the spring-type pull-out bracket and remove the pusher element from the mechanism fork.

- The next stage is the removal of the clutch pipeline from the control center, this requires fixing the front tip from rotation, while using a circular motion we dismember the connecting element from the control center.

- Then we remove the sealing washer, which during further assembly of the product must be replaced with an updated product, because its reuse is unacceptable.

- After this, we substitute an empty tank to place the liquid in it, which circulates in the hydraulic drive of the mechanism.

Removing and installing the clutch slave cylinder on a VAZ 2106

Remove the slave cylinder from the VAZ 2106 car for replacement or repair if the clutch is not completely disengaged caused by a fluid leak. To remove the clutch slave cylinder from a VAZ 2106, you will need: keys “13”, “17”, pliers.

1. Loosen the hydraulic hose on the clutch slave cylinder.

2. Disconnect the release spring from the clutch release fork and remove the spring.

3. Remove the cotter pin from the hole in the clutch slave cylinder pusher.

4. Remove the two bolts securing the slave cylinder to the clutch housing.

5. Remove the release spring bracket.

6. Remove the slave cylinder pusher from the clutch release fork.

7. While holding the hose tip from turning and rotating the clutch cylinder, separate them.

WARNING Be careful not to lose the sealing washer.

8. Drain the fluid from the drive and working cylinder into a prepared container. 9. Install the new clutch slave cylinder on the vehicle in the reverse order of removal. 10. Bleed the clutch hydraulic drive

Device location

To find the clutch slave cylinder on a VAZ classic, you need to look for it directly in the area where the gearbox is located. The device is attached with two bolts to the gearbox housing.

The mechanism can only be seen from below or in the very depths of the engine compartment on the driver’s side. Repair work related to dismantling and replacing the clutch slave cylinder can be carried out “from under the hood,” but it is much more convenient from an inspection hole or on an overpass. The video below shows the location of this unit. What function does this product perform and is it possible to do without it? We'll find out more about this later.

Features of operation

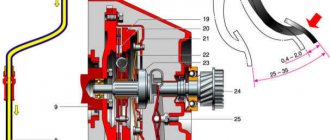

The operating principle is very simple. Below is a diagram where the slave cylinder is indicated by a green arrow.

According to this diagram, we can say that the RCS performs an important function, or rather, it activates the fork, which is connected to the clutch drum. The main element of the RCS, or rather the piston, is activated by the resulting fluid pressure coming from the main cylinder through the hose when the clutch pedal is pressed. The brake fluid pushes the piston, which in turn drives the fork, which acts on the drum, pushing the disc away from the flywheel. Many people wonder why brake fluid is used in the system? The reason is that brake fluid is incompressible, which is why it is used in such important systems as brakes and clutches.

When to replace the RCS

During the use of the unit, which happens very often, the product tends to fail. The main causes of breakdowns are chafing and wear of the cuffs, the appearance of cracks in them, which entails the leakage of liquid. Significant loss of fluid will cause the clutch system to malfunction. It is possible to repair a DCS that has become unusable, but it is easier and more efficient to replace it with a new one.

In order not to wait until the pressure in the clutch pedal disappears, you need to periodically inspect the unit. If there is a leak in the fuel fluid, it is necessary to immediately carry out the appropriate repairs on the VAZ 2107. Before carrying out repairs, you need to make sure that this particular element is faulty, since the main circulation system may also fail. The main signs of failure of the RCS are:

- decrease in the level of fuel fluid in the tank;

- visible brake fluid leaks from the device body or from under the rubber boot;

- “failures” of the clutch pedal, which can be periodic or constant;

- difficulty changing gears.

But most often the malfunction is determined by detecting a brake fluid leak.

Features of replacing the RCS

Replacing the VAZ 2107 clutch slave cylinder begins with the need to remove all fluid from the reservoir. Further actions are carried out in order:

- First you need to loosen the fastening nut that connects the hose to the cylinder. There is no need to unscrew the nut completely, just loosen it at this stage.

- Using pliers, you need to remove the tension spring.

- After this, you should unclench the cotter pin and remove it from the tip of the pusher.

- Using a key set to “12”, you need to unscrew the two bolts that secure the product to the gearbox housing.

- After unscrewing the bolts, you can disconnect the bracket from the cylinder, which is intended to secure the spring.

- Holding the working cylinder body, you should dismantle it. During dismantling, pay attention to the pusher, which is located in the fork.

- After disconnecting the product from the crankcase, you can continue unscrewing the nut connecting the hose to the device. After unscrewing the nut, brake fluid will begin to flow out of the hose, so you should prepare a special container in advance.

After the device is dismantled, it should be replaced with a new one, since repairing it is irrational. The cost of the product is insignificant, so it is easier to replace it with a new one than to try to carry out repairs. Installation of the product is carried out in the reverse order of removal. After installation, it is necessary to carry out the system bleeding procedure. In conclusion, it should be recalled that regular car maintenance helps prevent various unforeseen consequences along the way, such as the “disappearance” of the clutch.

Installing the clutch master cylinder repair kit

It is not difficult to determine when it is necessary to repair the master cylinder; the main signs of its malfunction are:

- Insufficient clutch release (clutch drives)

- Any type of leakage, whether from under the nuts securing the hose and tubes, or from the end from under the rubber seals

- Master cylinder stuck in pressed position

In my situation, the main leak was due to a worn out sealing ring, in other words, fluid flowed down the clutch pedal into the passenger compartment.

I started the repair by dismantling the reservoir hose, unscrewed the clamp on the main cylinder and quickly removed it from the main cylinder, turned it up and pinched it behind the reservoir cap so that the liquid did not flow out of the reservoir. Next, I unscrewed the tube that goes to the working cylinder, I did this with a special key, it’s a pity there is no photo, but you can buy one without any problems at any auto store. All that remains is to unscrew the main one itself, it is secured with two 13 nuts and remove it from under the hood.

The boot was removed and it was noticeable that fluid was flowing from here.

Having picked up the boot with a screwdriver, I saw exactly where the liquid was flowing from; the assumption was absolutely correct.

Next, you need to wipe the cylinder, remove dirt and rust.

Attention. Do not use gasoline or similar liquids for washing, as they will very quickly ruin the new rubber bands. To flush the clutch and brake elements, use clean brake fluid.

After cleaning the dirt, you can begin disassembling. To do this you will need an awl or similar object.

Next, you need to carefully remove the insides, keeping in mind that the piston is under the action of a spring.

This is what it looks like

Next, you need to clean the master cylinder body, you cannot scrape the parts with a screwdriver, sandpaper, etc., this is just in case, I use a rag with brake fluid. In repair manuals, I often came across such expressions that if rips, scratches, etc. appeared on the parts, then it is unusable. But despite all this, practice shows that despite all the risks, provided that a high-quality repair kit is installed, the master cylinder works without problems. I used this kit:

Repair kit for clutch master cylinder VAZ

We remove the old rings, clean all the grooves and holes. There should be no dust or debris there.

The ring is removed, clean the piston, install a new one

Thanks for subscribing!

And by the way, here is the reason for the clutch cylinder leaking:

The ring is not worn evenly

After cleaning and replacing the rings, you can assemble the cylinder, below is a photo of what should be there and how:

Here is a photo not cleaned, I added it here to show the correct assembly

Having assembled the cylinder, install the corkscrew ring

Bleeding the clutch on a VAZ 2106

After the repair has been made, it is necessary to bleed the clutch. In all repair manuals you can find standard instructions for bleeding the clutch, but it may not always help.

- The first bleeding option is standard; it consists of filling the tank with liquid, unscrewing the bleeding fitting, putting a hose on the fitting, and lowering the other end into a container with clean liquid. Then, by pressing the pedal, we monitor when the air stops being released, and also do not forget to control the level in the tank.

- The second method is to use an assistant - one person presses the pedal 4-6 times and keeps it pressed to the floor. The second unscrews the bleeder fitting; air bubbles should come out of the fitting; as soon as they stop coming out, you need to screw the fitting in and then release the pedal. And so on until normal operation of the pedal is restored and air bubbles stop coming out.

- There is also the simplest method of pumping, but which does not always work - to implement it you just need to pour liquid into the reservoir and unscrew the fitting on the working cylinder. The liquid will flow by gravity through the entire system and when it begins to flow steadily out of the fitting, it can be closed and the pumping can be considered complete.

Selection of GVC for VAZ 2107

The best option for replacement is to purchase a GCS designed specifically for classic VAZ models. Clutch master cylinders from UAZ, GAZ and AZLK vehicles are not suitable. The same applies to foreign analogues - foreign cars with rear-wheel drive are equipped with GVCs, which only highly qualified specialists can adapt to the VAZ 2107 (different sizes, different threads for pipelines, different pipe configurations). However, you can easily replace the original cylinder with a GCS from a VAZ 2121 and from a Niva-Chevrolet.

Manufacturer's choice

When purchasing a new GVC, you should focus on products from trusted Russian manufacturers (AvtoVAZ JSC, Brik LLC, Kedr LLC), the Belarusian company Fenox, which is adapted to our conditions and is affordable. The average cost of GVC is 600–800 rubles.

Table: comparative characteristics of GVCs from different manufacturers

| Manufacturer, country | Trademark | Cost, rub. | Reviews |

| Russia, Tolyatti | AvtoVAZ | 625 | Original GVCs are made with high quality and are more expensive than analogues |

| Belarus | Fenox | 510 | Original GVCs are inexpensive, made with high quality, and are popular among drivers |

| Russia, Miass | Brick Basalt | 490 | Improved design: the absence of a technological plug at the end of the cylinder and the presence of an anti-vacuum cuff increases the reliability of the product |

| Germany | AND THOSE | 1740 | The originals are of the highest quality. The price is tied to the EURO exchange rate |

| Germany | HORT | 1680 | Original GCS are reliable and durable in operation. The price is tied to the EURO exchange rate |

| Russia, Miass | Cedar | 540 | The original GVCs do not cause any particular complaints |

Monitoring the brake fluid

One of the main signs of failure of the clutch slave cylinder in VAZ 2106, 2101, 2107 cars is partial or complete failure of the pedal inside the car when pressed. This indicates a lack of tightness in the system - gradually the amount of brake fluid decreases, and the harder and more often you press the pedal, the more fluid will leave at a time.

This will cause the clutch to stop working and changing gears will be difficult or impossible. If you do not monitor the level of brake fluid in the reservoir and do not eliminate leaks in a timely manner, then consequences may arise - the clutch basket and release bearing will fail, not to mention the creation of emergency situations.

To eliminate the cause of the breakdown or completely replace the working cylinder, depending on the nature of the breakdown, you will need a new working cylinder, brake fluid and a standard set of tools. It is best to replace the working cylinder in a VAZ 2106, 2101, 2107 car from an inspection hole or on a lift. Before starting work, it is necessary to drain the brake fluid that is in the clutch system. Having all the necessary tools at hand, the procedure for removing the cylinder is very easy.

The first step is to pull out the pusher clamp, then remove the tension spring. Next, slowly unscrew the nut on the hose with the liquid, after placing a container to collect it. Then proceed to unscrew the cylinder mounting bolts, after first pulling out the pusher with the clutch fork. Move the fork with the pusher so that it does not interfere with you. Between the working cylinder and the rubber hose there is a rubber gasket with a sealing washer. It is very important not to lose it, because it is not included in the repair kit.

Replace the clutch slave cylinder and proceed with reassembly in reverse order. If necessary, you can adjust the depth of pedal pressing on the cylinder fitting. After completing all the work, fill the brake fluid into the clutch reservoir. Filling will help to completely flush the entire hydraulic clutch system of a VAZ car. Bleeding is performed to clear your system of air that is in the brake fluid.

Pedal dips

A dip in the pedal is one of the main signs that the VAZ-2106 clutch mechanism has become unusable. The clutch master cylinder may have lost its seal. But you shouldn’t blame it right away; you need to carefully examine all the elements of the system. The pipes connecting the cylinders must not have brake fluid leaks. There should also be no traces of it on the cylinder bodies themselves. If the pedal fails, the clutch will not work normally.

The following problems may occur:

- Difficulty changing gears.

- Drop in fluid level in the expansion tank.

- When used for a long time in this mode, the release bearing, basket, and disk fail.

If you notice a pedal failing, try to carry out repairs as quickly as possible, since with each press the fluid will come out of the system.

Why do you need to change the clutch?

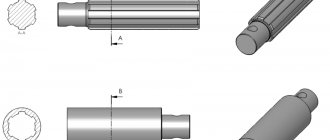

To replace the clutch you will need to stock up on: A 13mm wrench, and in addition to all this you will also need to take two different types of screwdrivers (Flat and Phillips in this case), and you also need to stock up on a mandrel for centering the clutch disc which in a car store it costs literally 100 rubles! (You can see what this mandrel looks like, which is discussed in the article, just below in the section: “For beginners!”)

When should you change the clutch?

During operation, the clutch of any car wears out over time, and the first signs of a worn clutch that a car will show are:

- Increased noise that begins to appear very clearly when changing gears in the car.

- Jerks can also occur when starting a car, and they can also occur while driving when you depress the clutch pedal, then engage a gear, and then when you release the pedal, the car jerks forward slightly.

- In addition to all this, if the clutch malfunctions, the effect that the clutch “slips” may occur. This is when you are driving a car and at the same time you press the gas pedal, let’s say to the floor, and your car does not accelerate, but the engine speed increases sharply and even reaches the red zone, this effect is popularly called the clutch “Slipping”.

- And in conclusion, we note one more effect, called the “Leads” clutch. The first signs of this effect are as follows: let’s say you engage first gear and at this time the clutch pedal is still fully depressed, but even despite this the car starts to roll. This effect is called the “Leads” clutch.

How to repair a VAZ hydraulic drive

The main thing to remember is that in all cases of such repairs, after it has been carried out, it will most likely be necessary to pump the hydraulic system. It must be done according to the instructions for this car model.

So, to replace the clutch master cylinder in a VAZ 2107 we will need:

- wrenches;

- syringe, container;

- screwdriver, pliers.

- Use a syringe to pump out the fluid from the master cylinder reservoir.

- Having loosened the clamp, pull the tube off the tank and drain the liquid from it into a substitute container.

- We unscrew the fastenings of the pipe connecting the first and second hydraulic drive units.

- By pressing the pedal, we remove the broken link of the system.

- We install the new spare part in the reverse order.

- Add the missing liquid to the reservoir.

Changing the master cylinder of a VAZ 2106 is carried out in the same way. But the work of replacing the working cylinder of a VAZ 2107 will have to be carried out using a slightly different method. True, we’ll take the same tools.

Product location

The master cylinder on a VAZ 2107 is located under the hood, directly on the wall separating the interior from the hood, near the driver’s feet. Directly above it is the expansion tank, and next to it are the vacuum booster and the brake master cylinder. Usually, simply looking at the product is enough to determine the problem. The presence of a leak indicates that the part is faulty and requires repair or replacement.

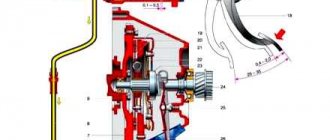

Purpose of the device

Cars are equipped with clutch master and slave cylinders, without which the operation of the mechanism is impossible. The VAZ 2107 clutch master cylinder is designed to push out brake fluid. Below is a diagram from which you can visually find out the operating features of the unit.

When you press the clutch pedal, the piston moves in the device in question, thereby pushing out the brake fluid. This liquid enters the working cylinder through a tube, where the reverse process is observed (the liquid pushes out the piston). Brake fluid drives a piston, which is connected by a fork to the clutch disc. As a result, the clutch disc and flywheel are separated, allowing you to change gear. The GCS is also called the main one, since it is with its help that force is supplied from the pedal when it is pressed.

The need to replace the device: when required

Like all parts of any car, the GVC tends to wear out, resulting in the need for repair or replacement. The simplest breakdown of a product is wear of the boot, which can be determined by the characteristic signs of a fluid leak.

To identify a cylinder malfunction, an initial visual inspection is required. It is possible to repair a failed main circulation system on a VAZ 2107; for this you can look for repair kits, but this is not always rational due to the quality of modern spare parts, so it is easier and faster to replace it entirely. The malfunction can also be determined by the characteristic loss of pressure in the system, which is determined by pressing the pedal. Let’s take a closer look at how to change a faulty VAZ 2107 mechanism.

We change it ourselves

Replacing the VAZ 2107 clutch master cylinder begins with the need to pump out the brake fluid from the hydraulic reservoir. This can be done using a syringe or a rubber bulb. Together with this socket or a 10mm wrench, unscrew the bracket securing the expansion tank and move it to the side to gain access to the cylinder.

The next step involves removing the clutch expansion tank hose. To do this, you need to loosen the hose clamp, then disconnect the hose and position it so that it does not interfere with further work. If you want to remove the tank completely, this is done very simply.

Further actions are performed in the following sequence:

- Using a “10” wrench, you need to unscrew the pipeline securing nut to the device. Once the nut is unscrewed, the tube can be moved to the side.

- There is a hose nearby near the steel pipeline, which also needs to be disconnected from the main device. This can be done by loosening the fixing clamp.

- The GCS is fixed to the body using two fastening nuts. To unscrew them, you will need to use a wrench with an extension and a “13” socket. After unscrewing the two nuts, you can remove the product and drain the remaining brake fluid from it. If it is not possible to dismantle the unit, you can press the clutch pedal, as a result of which it will move.

- But repairs are usually not rational, so after removing the old one, a new unit is installed in its place. Installation is carried out in the reverse order of removal. After installation, it is necessary to carry out the process of pumping the hydraulic drive, first pouring fuel fluid into the tank. You can find out how the system is pumped from the relevant material on the website.

Repair

In order to repair the clutch cylinder, it must be removed from the VAZ 2106. This is done using a 8-mm wrench. Next, secure the part in a vice and release the air from it by unscrewing the special fitting.

Removing the protective boot

The next step is to rotate the part 90 degrees without removing it from the vice. Remove the protective cap, and then the pusher located under it. Next, use a screwdriver to pull out the piston. There will be a spring and a support ring on it. They also need to be removed.

Once the spring and ring are removed, remove the rings. Now that all the parts of the clutch slave cylinder have been removed, they need to be cleaned with gasoline and wiped dry with a rag. Next, reassemble all the parts in reverse order and test it in action. If the symptoms recur, repair will no longer help and a complete replacement of the part will be required. After this, your VAZ 2106 will definitely get a second life, and the problems with the cylinder will disappear.

Repair of the clutch slave cylinder on a VAZ 2106 car

To repair the clutch slave cylinder on a VAZ 2106, you will need: an 8-point wrench and a screwdriver. 1. Remove the slave cylinder from the vehicle. 2. Having installed the clutch slave cylinder in a vice, unscrew the air release fitting.

3. Change the position of the cylinder in the vise. Carefully pry up the protective cap with a screwdriver and remove it along with the pusher.

4. Place the clutch cylinder horizontally in the vise again. Using a thin screwdriver, move the piston until it comes out of the cylinder and remove the piston.

5. Use a screwdriver to pry up the retaining ring on the piston and remove it, holding the spring.

6. Remove the spring from the piston.

7. Remove the washer and first o-ring from the piston.

8. Remove the second o-ring from the piston by carefully prying it off with a screwdriver. 9. Remove the protective cap from the pusher.

NOTES Remove the plug only if absolutely necessary (to replace the gasket under it if a brake fluid leak is detected). Pay attention to the markings on the clutch slave cylinder housing - this will help you make your choice when purchasing auto parts.

10. Clean the holes in the cylinder and air outlet fitting. 11. The clutch slave cylinder mirror and the outer surface of the piston must not be damaged or scratched. 12. Inspect the spring. If there is mechanical damage, replace it. 13. Replace the O-rings. 14. Inspect the protective cap. If there is mechanical damage and signs of rubber aging, replace it. 15. Assemble the clutch slave cylinder in the reverse order of disassembly.

NOTE: Before assembly, wash all parts with clean brake fluid. Contact of mineral oil, kerosene, gasoline or diesel fuel is not allowed on the parts (to avoid swelling of the rubber parts).