Purpose of the mechanism

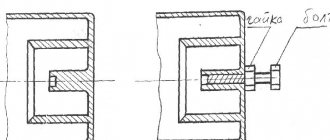

Front suspension elements: 1 – protective cap; 2 – limiter of the compression stroke of the support; 3-upper rack support; 4 – upper support bearing; 5 – upper spring cup; 6 – front suspension spring; 7 – adjusting bolt; 8 – eccentric washer; 9 – protective casing; 10 – compression progress buffer

The task of both front and rear shock absorber struts is to dampen the vibrations of the car as it moves on an uneven road, as well as to ensure maximum adhesion of the car’s wheels to the road surface . In addition, the A-pillars enhance the smooth handling of the vehicle. In general, struts are the most important suspension component of a car. They are attached to the front and rear axles and can be seen by removing the car wheels.

Front strut assembly VAZ 2110

Let's sum it up

Today you can find many interesting options for shock absorbers for the VAZ 2110. The car is transformed, receives really many useful characteristics and is one of the most interesting options for a buyer in the budget class on the secondary market. Today, stock “Tens” are asking very little money, because the owners of these cars are trying to purchase more expensive vehicles of foreign origin or exchange their 2110 for a newer AvtoVAZ invention. But for novice drivers or for a work trip, the car is quite interesting, reliable and of high quality.

By installing good shock absorbers on a VAZ 2110, you will feel how the car has changed in movement and has become unique in all its characteristics. The vehicle will receive many new sensations when traveling and will become closer to your understanding of the ideal car. However, shock absorbers do not change the fact that the car has a lot of childhood problems that will have to be solved additionally. But the VAZ 2110, with which they actively worked to eliminate factory deficiencies, is truly one of the best purchases in this segment on the secondary market. What racks would you put on the “Ten”?

Reasons for replacing with a VAZ 2110

Like any other suspension part, shock absorber struts have a limited service life. You can find it in your car's owner's manual. In particular, the service life of VAZ 2110 struts can vary from 30,000 to 40,000 km. After it expires, the car owner begins to have problems listed below:

- There is a strong vibration in the steering wheel.

- When driving on an uneven road, the car vibrates strongly, and the vibration is felt more strongly from the side of the failed strut.

- A characteristic knocking sound appears in the area of one of the struts (which indicates that the shock absorber valves are not working correctly).

- The braking distance of the car becomes longer (and this is extremely dangerous, as it can lead to an accident).

- At the moment of a sharp turn, the skid trajectory becomes uneven.

- When leaving the parking lot, stains of leaked oil are visible on the asphalt.

The role of the front pillar in the VAZ 2112 car

The main suspension component of any car is the shock absorber struts. Their main purpose is to dampen car body vibrations and ensure sufficient traction of the wheels with the road surface when driving. The manufacturer offers a service life for each machine component. The instructions recommend replacing the front shock absorber strut after an average of 30 - 40 thousand kilometers. What indicates the need to replace the front struts:

- From the side of the damaged rack, the vibration of the body on the “comb” increases.

- Steering wheel wobble appears.

- The car is moving away from straightness.

- When turning, the car inexplicably skids.

- The braking distance increases.

- Abnormal operation of the shock absorber strut valves is indicated by a knocking sound.

- Oil may leak out and its characteristic smudges may appear.

All these faults must be eliminated; further operation of the suspension is not advisable. This can lead to negative consequences:

- Failure of the front support bearing struts.

- Increased uneven tire wear. The wheels “jump” when the car moves, which breaks the hub bearings, the price of which is quite high.

- An increase in braking distance, which is associated with the safety of using a car, when a split second decides a person’s fate.

- Reduced service life of brake pads, which affects vehicle safety and increases the cost of frequent replacement of parts.

Tip: The driver needs to regularly listen to how the suspension works. The appearance of a knock indicates that the car has a fault in the front pillar, which requires urgent replacement or repair.

Types of shock absorber struts

The type of road surface and its quality determines the use of different racks. The style with which the car is driven also plays a role. So:

Comfortable movement in the city and beyond is ensured by hydraulic or oil front struts of the VAZ 2112 - the cheapest and with small dimensions. Although they have sufficient advantages, they have a number of disadvantages:

The presence of an air mixture in the chambers for compensation: if the level is low, the shock absorber efficiency is zero. Creates unreliability of devices and excess air; Frequent and sudden movement of the piston when the car is moving on a dirt road can provoke the formation of cavitation bubbles, which leads to foaming of the oil; Poor heat dissipation.

- Gas front struts have greater rigidity when driving at high speeds and under increased load. But, the increased shock load reduces the comfort of movement for the driver and passengers. For the VAZ 2112, the front gas strut differs and has an increased cost.

- Double-pipe gas-filled struts are a compromise between gas and oil devices. They have sufficient softness and perform well when driving over rough terrain at high speed. With low pressure, the gas pressure prevents oil from boiling and effectively dampens vibrations. This type is the most reliable and durable device.

Removing and replacing the front shock absorber strut VAZ 2110, 2111, 2112

Various problems with the suspension are the most common reason for calling the service for diagnostics and repairs. Alas, Russian roads in some places of our Motherland are more like a tank training ground, or something that remains of a road in the usual sense of the word. In any case, you have to drive on any roads, which results in a number of suspension problems that any car owner faces.

In this article we will analyze in detail the removal and replacement of the front shock absorber strut on a VAZ 2110, 2111, 2112 with our own hands. The instructions include a step-by-step guide for repairing this suspension unit.

Typically, struts are changed at a mileage of 50-60 thousand km, but from experience we can say that these figures may not correspond to the realities in which the car is used. It’s one thing if the owner constantly drives on high-quality asphalt to and from work. And it’s a completely different matter when the car is used on different roads, most of which cannot be called roads. In the latter case, the suspension elements, including the front shock absorber strut of the VAZ 2110, 2111, 2112, become unusable at 30 thousand kilometers or earlier. Therefore, everything is individual. Carry out diagnostics periodically if you notice a deterioration in handling and overall suspension performance.

Rear pillar replacement instructions

If you take a closer look at the structure of the front and rear struts, you will see that this is a nodal mount - a kind of device for the interaction of springs and shock absorbers in a bilateral form. Replacing the rear struts on a VAZ-2112 with your own hands is not a very complicated process, but you must carry out a number of steps, as well as have special keys and everything necessary for the work.

Manipulations for removing the rear pillar:

- In the area of the stern fastening arches, dismantle the spare parts.

- Prepare the car seat located at the rear for removal, remove all fasteners and belts.

- Use a special key to unscrew the rod fasteners.

- Raise the car on a lift.

- Remove the lower mount.

- Remove the stand from the mounting socket.

When you have finished removing the necessary elements and removed the desired part, proceed to the next replacement step. Now you need to generate a stroke compression buffer system, remove the protective cover, bushing, support washer, spring and shock absorbers.

Which front struts are best?

There are different types of racks: gas, oil and gas-oil. They all differ in design and price. Oil elements are installed. They are the most comfortable and provide a very smooth ride. However, such a car does not have the best handling. For those who want greater maneuverability and stability on the road, Kayaba sports struts are suitable. They are gas-filled and have high rigidity. What is the price for these VAZ-2110 front struts? The set can be purchased for 5-5.5 thousand rubles. This manufacturer also makes oil struts. Their cost is about 4 thousand rubles.

Another manufacturer of sports stands is Kony. They have quite positive reviews. But these are the most expensive front struts on the VAZ-2110. The price for the set is 7-9 thousand rubles. As for other manufacturers, motorists speak well of the following:

We will talk about these racks separately. This product is made in Samara. It is highly popular among motorists.

Choosing the best front strut

The best front struts for the VAZ 2112 are produced by the Japanese company Kayaba. By installing Kayaba front struts on a VAZ 2112, the car enthusiast provides himself with maximum comfort and low vehicle noise when driving at low speeds. Even at high speeds, optimal shock absorption and a high level of safety are ensured. The best front struts for the VAZ 2112 do not create any problems when replacing parts. The strut can be changed easily and quickly, which reduces the time required to repair the shock absorber. Very often, the quality of shock absorbers can be improved if a stretcher is installed on the front struts on the VAZ 2112. In this case:

- Increases accuracy when driving a car when cornering.

- The machine's stability increases when moving in a straight line.

- Deformation of the body is reduced when the car is driven on dirt roads and on turns, which leads to a reduction in the appearance of cracks on the body.

If you do all the work efficiently and without haste, then you won’t have to redo it for a long time. Also on our resource you can find out how to replace the rear struts.

Choosing which ones to buy

It is impossible to say unequivocally which front struts are best to choose for the VAZ 2110. Some choose factory ones because they are not rigid enough for them, others prefer analogues for their softer and more comfortable behavior.

Some people even want to install a sports version of struts , since they are the stiffest and the springs are the thickest.

Sports

The choice is between oil and gas (gas-oil, actually). The former are more affordable from a financial point of view, but they do not have such a wide temperature range, which is why the shock absorbers become stiffer in winter.

Gas analogues have a more complex design, a high price, but an excellent “tenacity” indicator.

Among the manufacturers, in addition to CC20, the following manufacturing companies can be distinguished:

All of them have approximately the same devices, so there should be no problems with selecting suitable parts.

Instructions for replacing the front struts of a VAZ 2110

The car is placed on a level surface, secured with wheel chocks, and the handbrake is applied. Then jack up the car and remove the desired wheel. For safety reasons, we place the removed wheel with the bars under the car body and slightly loosen the jack so that the car sits tightly on the bars. We remove the front strut in the sequence as shown in the photo below:

- To slightly loosen the M19 nut of the shock absorber rod, remove the cup cap. Then loosen the three upper M14 nuts securing the rack

Preparing for dismantling, loosening the nuts securing the stand to the glass

- The shock absorber rod at the upper end can be slotted or square. We hold the rod either with a screwdriver or a wrench and slightly unscrew (“undermine”) the nut securing it

Loosening the shock absorber rod nut

- To avoid damage, remove the brake hose together with the holder from the bracket on the rack

Removing the brake hose

- Next, unscrew the nuts securing the strut to the steering knuckle

Preparing the rack for disconnection from the swing arm

- It is necessary to remove the cotter pin on the nut securing the steering joint to the strut

Unscrewing the steering joint nut

- Having unscrewed the nut securing the tip, use a special press to remove the tip from the conical socket

Pressing out the steering joint

- Using a special bronze drift, we knock out the bolts securing the strut to the steering knuckle, and then remove it from the cheeks of the strut downwards

Disconnection of the strut from the steering knuckle

- The three nuts securing the shock-absorbing strut to the glass, slightly loosened before disassembly, are now fully released and the strut is brought out through the wheel arch as shown in the photo at the beginning of the article.

Replacing the front struts of a VAZ 2110 with your own hands

The average price for replacing the front struts of a VAZ 2110 in a specialized car service is approximately from 1200 to 1500 rubles per piece, in total - within 3000 rubles. “Private” car mechanics charge a little less: from 800 to 1000 rubles, but this is still quite significant for the family budget. In principle, if you prepare all the necessary keys in advance and involve one assistant, even if he is not particularly versed in the nuances of this process, you can replace the front struts of the VAZ 2110 yourself, i.e. with your own hands.

Without knowing how, you can “dismantle” the racks anyway

What will be needed for this:

- Firstly, the usual standard set of keys from M10 to M27, which a normal car enthusiast should always have in his car;

- Secondly, it is necessary to have a sufficiently level area so that the jacked-up vehicle in front of the car does not fall anywhere, even when fixed using the removed wheels placed, as usual, under the body with spacer wooden bars or a set of planks, 20-30 mm thick, and slightly longer than the full one. wheel diameter.

Additional recommendations

Before you begin assembling all the components of the VAZ-2112, you should perform several additional manipulations:

- treat all insert elements with kerosene;

- Before direct installation, carefully inspect each element, even a new one, to ensure its integrity and quality;

- The final fixation of the mounting bolts should be carried out after the jack has been removed;

- After assembling all components, it is recommended to carry out a special wheel alignment check.

We recommend: Ford Focus 2 do-it-yourself front hub replacement

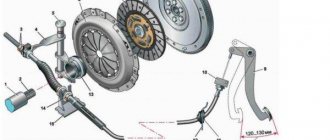

Replacing front struts, springs and supports with bearings on a VAZ 2110

If you hear knocking noises from the suspension while driving, and you are sure that the reason for this is worn out shock absorber struts, then they need to be replaced. Since you will have to completely remove the entire front suspension module of the VAZ 2110, the best option would be a full check of all components and elements, including supports, support bearings, and springs. If diagnostics reveal problems, the necessary parts must be replaced.

You can carry out this repair yourself in a garage, spending no more than 3-4 hours on the work, but it is worth keeping in mind that you will need a certain tool, which you simply cannot do without in this case.

What happens if you don't change the racks?

If you continue driving without replacing the struts, you will have to repair the entire suspension

Below we will describe to you several reasons that directly indicate what will happen to the car if the front struts are not repaired in time:

- During the first 2-3 thousand kilometers with faulty shock absorbers, the support bearings on the front struts can be broken.

- When the struts are faulty, wheel balancing is also disrupted over time and tires begin to wear unevenly, and hub bearings break.

Progress of work on replacing struts, supports, support bearings and springs on a VAZ 2110

First, you need to open the hood of the car and slightly unscrew the nut securing the support to the strut, while using a 9 key to hold the rod so that it does not rotate:

After this, we remove the front wheel of the car, having first lifted the front part of the VAZ 2110 with a jack. Next, you need to apply penetrating lubricant to the nuts securing the front drain to the steering knuckle. After this, unscrew the nut securing the steering tip to the steering arm of the strut, and using a hammer and pry bar, remove the pin from the lever:

Then you can proceed further and unscrew the two nuts securing the rack from below, as is clearly shown in the photo:

Now we move the front suspension module to the side so that it is free from the steering knuckle, and then unscrew the fastening of the support to the body shell:

When you unscrew the last bolt, you need to hold the stand from the inside so that it does not fall. And now you can remove the module assembly, resulting in the following picture:

Next, we will need spring ties to disassemble this element. Having pulled the springs to the required level, completely unscrew the nut securing the support to the rack and remove the support:

The result is shown below:

Also, take out the support bearing with the cup and rubber band:

Then you need to remove the bumper and boot. When you have completed the disassembly, you can begin the reverse process. Having determined which parts of the VAZ 2110 suspension need to be replaced, we buy new ones and install them in the reverse order.

First, we assemble the support, support bearing and cup with elastic band:

We put the new spring on the strut, having first tightened it to the desired moment and put the support on top. If the tightening is sufficient, the rod should protrude outward so that the nut can be tightened:

Replacing the support bearing on VAZ-2110, 2111, 2112

Support bearings are designed to reduce body loads transmitted from the vehicle wheels through the shock absorber struts.

They are components of the upper supports of the front shock absorbers. The support bearings are located in the upper inner surface of the “cups” located in the engine compartment above each of the wheels.

The design of the standard support bearing of the VAZ 2110 consists of the bearing itself (a thick rubber separator with steel balls built into it) and two protective rubber gaskets.

Basic faults

When a support bearing fails, a knock resembling dull blows appears in the front part of the car in the area of the pillars. Most often, such symptoms are observed when driving over uneven surfaces.

A knock indicates that the bearing has ceased to cope with its duties due to a violation of its integrity. This is caused by the destruction of its structure due to:

- exceeding the recommended resource;

- excessive dynamic loads;

- dirt and moisture getting inside the bearing.

However, knocking in the area of the racks may have other causes. To check the bearings and make sure that they are the ones knocking, lift the hood of the car, remove the cover of the supposed “glass”, and place your palm on the upper shock absorber support.

Rock the car up and down. If at the same time you hear the same knock and feel the corresponding vibration with your hand, immediately replace the bearing.

We determine that the element did not fire

There are several signs by which a malfunction can be identified:

- The body is amplified by vibrating on the ridge on the side of the damaged shock absorber;

- Feels in the steering wheel;

- The braking distance becomes longer;

- When turning, the car enters;

- Traces of oil stains;

- When driving in a straight line, the car drifts away;

- There is a knocking and extraneous noise in the rack.

Device diagram

If you do not repair the front struts at a service station on time or with your own hands, this can lead to dire consequences:

- The supporting bearings will collapse;

- Tires will wear unevenly, jump, and form bumps on the rubber surface;

- The supporting bearings will not pass;

- The braking distance will be longer, which is dangerous on any part of the road;

- The brake pads will be damaged and their service life will be significantly reduced.

There are two main ways to test items to see if they are faulty. One is a professional, the other is a craft, but also quite effective.

- Special table for shaking. It is driven by the car and the computer calculates the efficiency of the shock absorbers. It should be noted that new racks may show a result of about 75%!, but this is quite normal. If the percentage is less than 50, then it's time to change the part.

- Manual rotation. You need to take the front part of the car, behind its wing, and start swinging. Try to achieve the maximum amplitude that allows you to bear your body weight. In any case, ask a friend to help. The point is that after swinging, suddenly remove your hands and look at the car. If it immediately returns to its original position and does not wobble anymore, then everything will be fine. If you detect even a slight hesitation, you can assume that the struts should preferably be replaced in the near future.

Replacing front struts, supports and springs VAZ 2110, 2112, Lada Kalina, Granta, Priora, 2109 Video guide on how to independently replace front struts, supports and springs on front-wheel drive cars.

Replacing front struts, supports and springs VAZ 2110, 2112, Lada Kalina, Granta, Priora, 2109 Video guide on how to independently replace front struts, supports and springs on front-wheel drive cars.

When to change

The service life of standard bearings for the VAZ 2110 is 100 thousand km, but given the state of our roads, it is better not to take risks and change the bearings after no more than 50 thousand km or 2-3 years of operation, especially if they are no longer factory.

Also, support bearings must be immediately replaced when their malfunction is diagnosed. Otherwise, in addition to the body, the supports themselves and the shock absorber struts will suffer.

It is recommended to replace two support bearings at once.

The cheapest support for the “ten” costs about 300 rubles . A good alternative to the original bearing models are products from other manufacturers, such as SS-20, ASOMI, TRACK or FENOX ( up to 800 rubles per piece ). They may have a modified design designed to meet certain consumer requirements.

You can also buy the entire upper support assembly. This will cost approximately 1200-3000 rubles per unit .

The cost of replacing one prop at a service station is about 500 rubles.

Replacement

It is not necessary to overpay for the work of replacing support bearings. Having the necessary tools at hand, you can do this yourself.

Tools and tools:

- wheel wrench;

- car jack;

- a special puller for steering tips (as a last resort, a hammer and a small pry bar);

- wrenches 9, 13, 19;

- pliers;

- two spring ties.

Work order

- Park the machine on level ground. Jack up the body on the desired side. Remove the corresponding wheel.

- Unscrew the nut securing the steering tip (pliers) and unscrew it (19mm wrench).

- Using a special tip puller, press out the pin. If you don’t have such a tool, knock out the finger by carefully tapping it with a hammer from below and prying it up with a small pry bar from above. Be careful not to damage the threads on the finger.

- Unscrew the two nuts securing the lower part of the strut in the steering knuckle (19mm wrench). If you cannot unscrew them, treat the connections with anti-rust liquid.

- Under the hood there are three nuts securing the upper support to the body. Unscrew them (key 13).

- Remove the entire shock absorber.

- Using two spring ties, tighten the spring enough to relieve the load on the support.

- Unscrew the nut of the central fastening of the support to the rack (wrenches 9 and 22). Remove the support and disassemble it.

- Replace the support bearing in it with a new one.

- Carry out work on assembling the rack and installing it to the body and suspension in the reverse order. Replacing the second bearing is carried out in the same way.

Disassembly and assembly of the unit

Replacement of the rear pillars of the VAZ 2110 is carried out on any flat area on the street or in the garage; an inspection hole is not needed here. To disassemble the unit, you need to prepare the following tools and devices:

- jack;

- wooden stand of the required height;

- curved spanner wrench size 19 mm for unscrewing the rod;

- a set of open-end wrenches of standard sizes;

- standard plumbing tools (pliers, hammers, screwdrivers);

- wheel key;

- aerosol lubricant WD-40;

- gloves, rags.

It is better to carry out assembly and disassembly work with gloves to avoid minor injuries when loosening or tightening threaded connections. Replacing the rear struts 2110 begins with disassembling the luggage compartment side of the car. It is necessary to remove the rear seat fasteners and unscrew the seat belts, as well as dismantle all interfering decorative panels. Stuck threaded connections are sprayed with universal lubricant WD-40. The further sequence of work looks like this:

- The upper support of the rear pillar is unscrewed. To do this, unscrew the nut using a 19 mm curved spanner wrench, and hold the rod with a special or open-end wrench. In VAZ 2112 cars it is possible to unscrew the nut with a 19 mm open-end wrench.

- The wheel bolts are loosened, the car is jacked up and the wheel is removed. Don’t forget to secure the car with available anti-roll bars.

- A wooden support is placed under the bottom of the VAZ, and the jack is released and installed under the rear wheel hub.

- Using 17 and 19 mm wrenches, the lower support of the rear pillar is unscrewed, the bolt is removed and it is removed together with the spring.