Device

In order for the car to move, it is necessary to transfer the rotation of the engine to the wheels. But the engine speed is too high, and in order to correctly distribute the torque, a mechanism is needed that changes the gear ratio. Due to the gearbox and different engine speeds, the speed of movement changes, and the main pair of the rear axle takes over the rotation and transmits it to the wheels through gears.

- flange, it is fixed on the drive gear (shank) of the RZM, and is an intermediate link between the driveshaft and this gear;

- the shank of the main pair, at one end of which there are splines for pressing the flange, at the other end there is a bevel gear with a small number of teeth;

- driven gear (planet gear), it is in mesh with the drive gear, and it is with it that it forms the main gear;

- center differential, allowing the rear wheels to spin at different angular speeds.

The differential design is very simple - the mechanism consists of two axle gears, two satellites and a satellite pin. From the gearbox, the movement is transmitted to the axle shafts, on which the wheels are mounted.

Differences in VAZ rear axle gearboxes

RZMs differ in the gear ratio of the main pair; in total, there are four types of gearboxes on the VAZ classic:

The slowest one is the RZM 2102, its drive gear has 9 teeth, and the driven gear has 40 teeth. To calculate the gear ratio, you need to divide the number of planetary gear teeth by the number of teeth on the drive shaft; for the VAZ 2102 the drive gear is equal to 4.44.

The “penny” gearbox (2101) accordingly has the number of teeth on the gears 10/43, so its IF is 4.3. The next, faster one is RZM 2103 - it has a ratio of 1041, which means the gear ratio is 4.1. And finally, the “fastest” will be the 2106 gearbox, with the number of teeth 11/43 and an inverter frequency of 3.9, respectively.

Many VAZ 2101-07 owners strive to install the fastest gearbox, but this is not always necessary. If the car often carries cargo, that is, the car is a “workhorse”, high speed is of no use, but high-torque power will be very useful. It should be noted that RZM 2102 was not supplied as spare parts; it was installed only on station wagons.

Design and technical characteristics of the gearbox

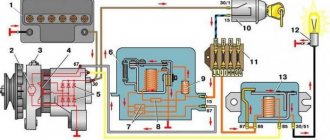

The rear gearbox of the VAZ 2107 car consists of a massive steel casing with a shank, a driveshaft flange, two main gears mounted at right angles to each other and a self-locking differential.

The main elements of the gearbox are the housing, the main pair of gears and the differential with satellites

Rear gear ratio

The main characteristic of any gear transmission is its gear ratio. It is the ratio of the number of teeth on the driven gear to the number of teeth on the drive gear. The driven gear of the VAZ 2107 rear gearbox has 43 teeth. And the drive gear has 11 teeth. Dividing 43 by 11 we get 3.9. This is the gear ratio on the VAZ 2107 gearbox.

Another important point should be noted here. VAZ 2107 was produced for many years. And over the years, gearboxes with different gear ratios were installed on it. For example, the earliest models of the “seven” were equipped with gearboxes from the VAZ 2103, the gear ratio of which was 4.1, that is, the tooth ratio was 41/10. On later “sevens” the gear ratio changed again and was already 4.3 (43/10) and only in the newest “sevens” this number is 3.9. Due to the above reasons, the driver often has to independently determine the gear ratio of his car. Here's how it's done:

- the car is set to neutral gear;

- The rear of the car is raised using two jacks. One of the rear wheels is securely fixed;

- After this, the driver manually begins to turn the driveshaft of the car. It is necessary to make 10 revolutions;

- By rotating the driveshaft, you need to calculate how many revolutions the unfixed rear wheel will make. The number of wheel revolutions should be divided by 10. The resulting number is the gear ratio of the rear gearbox.

Bearings

The rotation of all gears of the gearbox is ensured by bearings. In the rear gearboxes of the VAZ 2107, single-row roller bearings are used on the differential, and the rollers there have a conical shape. Bearing marking is 7707, catalog number is 45–22408936. The price of a bearing on the market today starts from 700 rubles.

- How to remove the gearbox on a VAZ 2107

All rear gear bearings of the “seven” are roller, single-row, tapered

Another bearing is installed in the gearbox shank (i.e., in the part that connects to the cardan). This is also a tapered roller bearing marked 7805 and catalog number 6–78117U. Standard VAZ shank bearings today cost from 600 rubles and more.

Planetary pair

The main purpose of the planetary pair in the rear gearbox of the VAZ 2107 is to reduce engine speed. The pair reduces the crankshaft speed by about 4 times, that is, if the engine crankshaft rotates at a speed of 8 thousand rpm, then the rear wheels will rotate at a speed of 2 thousand rpm. The gears in the planetary pair of the VAZ 2107 are helical. This solution was not chosen by chance: a helical gear is almost twice as quiet as a spur gear.

The planetary pair has a helical gear to reduce noise levels

But helical planetary pairs also have a disadvantage: the gears can move along their axes as they wear out. However, this problem is relevant for racing cars, the rear axles of which have exclusively spur gears. And for all the years of production of this car, the VAZ 2107 had exclusively helical planetary pairs.

Replacing the rear axle gearbox of VAZ 2106, 2107

The main disease of REM is increased noise (hum), and the gearbox can hum for various reasons:

- there is insufficient oil in the bridge, or it is completely missing;

- the gap between the gears of the main pair is not adjusted;

- the gears are worn out, they have chips and other damage;

- the main pair has a manufacturing defect, the gears are not ground in from the factory;

- the shank nut has become unscrewed or loosened;

- bearings are worn out.

The main malfunction of the center differential is the wear of the gears of the axle shafts and satellites, when the surfaces of the parts are heavily worn, play forms between the differential gears, but the rear axle usually does not make noise due to wear of the differential gears.

ZM gearboxes on VAZ classics can be repaired, but only if there is no wear on the gears. If the mechanism can no longer be repaired, it needs to be replaced. We replace the rear axle gearbox of a VAZ 2106 on a “seven” as follows:

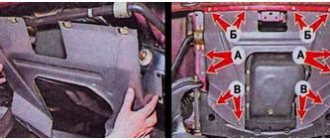

- we install the car on a pit or a car lift; changing the gearbox on the ground is extremely inconvenient;

- if the car is installed on a pit, it is necessary to jack up both sides; in any case, the rear wheels must be removed. If the work is not done on a lift, you should install stops under each side of the car (in the rear);

- unscrew the drain plug in the REM, drain the transmission oil, having previously prepared a container for it;

- remove the rear brake drums (two guide bolts on each side), after first removing the car from the handbrake. The drums can be difficult to remove; they are dismantled by tapping them from behind with a hammer through a wooden block. You cannot hit the drum with a metal hammer; the drum may break;

- remove the brake pads;

- unscrew the fastenings of the rear axle axle shafts on each side, each axle shaft is secured with four nuts;

- we press out the axle shafts, for this you will need a special puller, you can also make a homemade device;

- remove the driveshaft by unscrewing the four bolts and nuts. If the same REM is installed, the cardan with the shank must be marked; this is done in order to put the shaft back in the same position. If you install the cardan incorrectly according to the marks, the shaft may begin to vibrate;

- unscrew the eight bolts securing the rear gearbox (key 13), remove the assembly.

At this point, the removal of the gearbox can be considered complete; now all that remains is to either repair the mechanism or install a new one instead.

Repair of VAZ 2106 gearbox

| EXECUTION ORDER | |

| We use a core to make marks on the bed and the corresponding bearing cover so that during assembly we can install the covers in their places. |

| Using a 14mm wrench, unscrew the bolts securing the bearing caps. |

| Remove the outer bearing rings and adjusting nuts from the differential housing. |

If we do not change the bearings, then we mark the outer rings so as not to mix them up during installation, because The bearings are individually worn in and it is not advisable to disassemble them.

| We check the absence of radial play in the axle gears. |

| Use a puller to compress the inner rings of the tapered bearings. |

| Using a 17mm wrench, unscrew the eight bolts securing the driven gear to the differential housing and remove it. |

| We use a beard to knock out the satellite axis. |

| We turn the axle gears and remove the satellite gears. |

| We take out the axle gears with adjusting washers, marking their position. |

| We remove the drive gear and the deformed spacer from the crankcase. When assembling the gearbox, we replace it with a new one. |

| Using a soft metal drift, knock the inner ring of the tapered bearing off the drive gear shaft. |

| An adjusting ring is installed under the bearing to ensure the correct relative position of the main gear gears. |

| Use a suitable tool to knock out the outer rings of the tapered bearings from the crankcase. |

| We weld a plate 80 mm long and trim it to a size of 50–0.02 mm relative to the plane for the bearing. The serial number and size deviation are engraved on the conical part of the shaft. |

| We set the crankcase to a horizontal position and level. |

| We place a round, even rod (an extension from a set of socket heads) in the bearing bed and use a flat feeler gauge to determine the size of the gap between it and the device plate. |

| We install an adjusting ring of the required thickness on the shaft and, using a piece of pipe of a suitable size, press on the inner ring of the bearing. |

We insert the shaft into the crankcase. We install a new spacer, front bearing inner race, collar and drive gear flange.

| Gradually tighten the nut with a torque wrench to a torque of 12 kgf.m. |

| We determine the moment of rotation of the drive gear shaft. |

| We install the differential housing together with the bearings into the crankcase and tighten the bolts of the bearing caps. |

If axial play is detected in the axle gears, then during assembly we install new, thicker support adjusting rings. The side gears should fit tightly into the differential housing, but can be turned by hand.

| We make a wrench from a steel sheet 2.5–3 mm thick for tightening the adjusting nuts. |

| Using a caliper we measure the distance between the covers; |

| Slowly turn the driven gear three turns and at the same time feel the play in the meshing of each pair of teeth. |

The VAZ 2107 is equipped with rear-wheel drive. This technical solution has both advantages and disadvantages. The key element of the “seven” drive is the rear axle gearbox. It is this device that can cause the car owner a lot of problems due to poor adjustment or due to simple physical wear and tear. The motorist can fix problems with the gearbox himself. Let's figure out how this is done.

Adjusting the VAZ rear axle gearbox

If the main pair in the gearbox is worn out, it must be replaced. But you can’t just put the gears back in place; the gaps in them must be adjusted. In total, two types of basic adjustments are made:

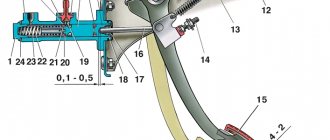

- The thickness of the adjusting sleeve (washer) is selected for the shank (drive gear). The washer can have a thickness from 2.6 mm to 3.5 mm;

- The gap between the gears of the main pair is adjusted using two adjusting nuts of the differential housing.

The washer for the shank is selected in such a way that the shaft with the drive bevel gear rotates in the gearbox housing without backlash with a force by hand (0.3-0.4 kg). In this case, the shank nut should be tightened with a force of 12 to 26 kg, usually 18-19 kg are tightened.

After installing the shank, the differential housing with the planetary gear attached to it is put in place. The housing is secured with two covers (4 bolts, a knob with a 17mm head). The adjusting nuts are tightened from the sides of the bearings, the differential is installed so that there is play between the gears of the main pair, and the planetary gear should not be clamped. By moving the adjusting nuts to the right and left, the shank gear is brought to the planetary gear. By adjusting, you select the moment when the gap between the gears practically disappears.

The last stage is to adjust the preload of the differential bearings; the adjusting nuts are tightened from the sides. This work must be done with an indicator; the device should show from 0.14 to 0.18 mm, the gap between the gears should be within 0.08-0.13 mm. After the operation, the adjusting nuts are fixed with plates so that they do not turn.

It should be noted that adjusting the VAZ rear axle gearbox is a very difficult matter, and it is better to trust it to professionals.

Differential device

The planetary gear is mounted on the differential housing. The differential consists of two axle gears, two satellites and a pin. The main, most common differential malfunctions are wear of the pinion pin (play) and wear of the splines on the axle gears.

On a car, the play of the pin of the satellites can be determined by turning the driveshaft by a quarter or more; if there is no play, then the shaft practically remains in place when you try to turn it in one direction or another.

It's also worth noting that there is never any noise coming from the differential. When moving forward (in a straight line), the differential rotates as one unit and it turns out that there is simply nothing to make noise there.

The cause of noise from the rear axle gearbox when gas is added and the noise disappears after releasing gas is (almost 99.9%) wear of the teeth of the main pair. This is clearly visible on the removed gearbox. The forward side of the teeth has significant wear, while the reverse side shows little wear.

If, after disassembling and troubleshooting the parts of the main pair, wear of the teeth is detected, then no repair will help and it will simply be a waste of time and money. Only the main pair needs to be replaced.

Home-couple

The gears of the main pair are selected at the factory based on contact patch, noise and other parameters and are marked. For example, on the planetary gears it is stamped - VAZ 2103 (model), 10 41 (gear ratio), 4091 (pair number). The main pair number 4091 is also marked on the bevel gear.

After marking these parts, they became the “main pair” and are not installed one without the other, that is, “family”. “- 6” is also marked on the “tip”; this is an amendment for assembling the main pair in the gearbox. When troubleshooting a differential, its bearings are also checked for wear and, if necessary, replaced. Bearing wear is often caused by unprofessional replacement of the gearbox seal.

For example, after replacing the oil seal, tighten the shank nut without observing the tightening torque (pull as much as possible) and the force is transferred not to the spacer sleeve, but to the differential bearings.

As a result, after a short run after replacing the shank oil seal, noise from the gearbox appears. Only in this case, the “hum” noise in the gearbox is constant and unlike the noise from worn teeth of the main gear. In this case, the hum is constant, regardless of whether gas is added or released.

Rear axle gearbox assembly video

During assembly, the gearbox is adjusted according to 4 parameters:

1. Selection of the adjusting ring

Parameters from 2.6 to 3.5. The ring serves to adjust the depth of engagement of the teeth of the “tip” and “planetary gear”, which is strictly specified. This is where the “correction -6” is needed for this main pair, which was mentioned above. Of course, this amendment will be individual for each main couple.

In this video, the main pair will be adjusted using a special device. It is clear that the vast majority of motorists do not have such a device and this is just a clear example of adjusting the engagement depth parameter. An option will also be given for adjustment without a “device”.

A “device” with a micrometer is also installed on the device, simulating the gear of the main pair. The indicator shows zero. Then the indicator leg is transferred to the bearing bed and in this case the indicator shows a value of 3.25, which is not good, since it should be within the range of 3.0. On the second landing plane it turned out to be 3.45. The arithmetic mean is 3.3. To adjust, we will use the correction at the “tip” - “-6”. In this case (– 3.3) + (-6) = 3.36. The thickness of the adjusting washer required is 3.36 mm. Using a micrometer, select the washer of the required thickness.

Note. When the shank bearing wears out, it begins to rotate on the “tip” body. As a result, the bearing end, adjusting washer and shank gear bodies wear out. It turns out that when replacing the shank oil seal, even with the correct tightening torque, the adjustment of the depth of engagement of the teeth of the gears of the main pair is lost and the “howl” of the pair is ensured, as is its early failure.

2. Adjusting the preload of the shank bearings

The shank bearing sits on the “tip” and a NEW spacer sleeve MUST be installed. The video clearly shows that the new bushing is smooth without any deformation, while the previously installed one is deformed. What happens is this: When the shank nut is tightened to the prescribed torque (from 12 to 26 kgf), the bushing takes on the tightening force and, when deformed, works like a spring, creating tension. The tightening force for the VAZ 2107 gearbox nut is significant and the shank must be secured against turning.

In the video we see what kind of “device” the master uses. It is necessary to tighten the shank nut until there is no play. When the nut is tightened correctly, the shank should rotate with a resistance force of 0.3-0.4 kg, therefore, the bearing preload is correct. This assembly rule applies to old (used) bearings.

The differential with bearings is installed and secured with covers (tightening torque is about 8 kgf) and the adjusting nuts of the differential bearings are tightened.

3 and 4. Simultaneous adjustment of the thermal clearance of the main pair and the preload of the differential bearings

For these purposes, another “device” with two indicators is needed. Using the adjusting nuts in the video and everything is shown well, we move the planetary gear towards the teeth of the “cone” to achieve the required clearance. Factory clearance adjustment data is from 0.08 to 0.12 mm. However, such a gap is provided for the new main pair (“tips” and “planets”). The gap is checked in 4 planes by turning the gear. The gap for the working main pair after adjustment is 0.13-0.14 mm.

Repair or replacement, which is better?

Car owners of VAZ classics often cannot decide what is best to do - buy a complete ready-made REM assembled or purchase individual parts and repair the gearbox. It’s really difficult to decide here - the price of a new gearbox, of course, is higher, but the owner of the car is freed from the headache of adjustment. The thing is that it’s not so easy to find a good specialist in VAZ gearboxes, and there is no guarantee that the new main pair will not hum.

If a car owner buys a new gearbox, but it hums, the part can be exchanged under warranty, but the car owner loses money on removing and installing the gearbox. If you purchase a defective main pair, the repair itself will be more expensive - you will have to pay a technician for a secondary overhaul of the gearbox.

VAZ rear axle gearbox locking

On VAZ 2101-07 vehicles, the factory does not provide locking of the center differential, but the industry already produces both differentials with locks and fully assembled 3M gearboxes. The most common today are REMs with screw locking; in them, the differential gears are locked depending on the load. In such rear axle gearboxes, a preload clutch is installed, it connects the wheel axle shafts with a certain force, and acts as a blocker.

Locking the VAZ rear axle gearbox provides the following advantages:

- increases cross-country ability, allows the vehicle to avoid slipping on difficult road sections;

- allows the car to accelerate faster at the start;

- The car corners more confidently.

But ZM gearboxes with screw locking also have their disadvantages:

- Fuel consumption increases slightly;

- when accelerating, the car handles worse;

- The differential and assembled gearbox with locking are much more expensive than standard parts (the price is approximately 2-2.5 times higher).

VAZ 2101-07 car owners should know that after installing the RZM with blocking, the car will not become an SUV, and it will not be able to move on severe off-road conditions.

Malfunctions of the rear axle of VAZ 2101, 2102, 2103, 2104, 2105, 2106, 2107 cars

Increased noise from the rear wheels

— The wheel mounting bolts are loose

The bolts need to be tightened.

— Wear or destruction of the axle bearing

The axle bearing needs to be replaced.

Constant increased noise from the rear axle

— The rear axle beam is deformed

Replace the rear axle stockings or the entire axle.

We replace bent axle shafts with new ones.

— Wear of splines on axle shafts

— The rear axle gearbox is incorrectly adjusted, its gears or bearings are damaged or worn

The gearbox needs to be repaired or replaced.

— Not enough oil in the rear axle

Bring the level to normal, eliminate leakage.

Noise when accelerating a car

— Shock absorbers are faulty

Check and replace shock absorbers.

— Incorrectly adjusted gearing of the main gears after gearbox repair

Adjust the engagement by selecting the drive gear adjusting ring.

— Damaged axle bearing

— Not enough oil in the rear axle

Bring the level up to normal.

Noise when the car engine brakes

— Incorrect lateral clearance in the mesh between the final drive gears

Disassemble the gearbox and set the gap to 0.08 - 0.13 mm.

— Increased clearance in the drive gear bearings due to loosening of the flange nut or wear of the bearings

It is necessary to check the technical condition and moment of resistance to rotation of the drive gear.

Noise when accelerating and braking the car engine

— Wear or destruction of drive gear bearings

They need to be replaced.

— There is no lateral clearance between the teeth of the main gear gears

Disassemble the gearbox and set the gap between the teeth to 0.08 - 0.13 mm.

Noise when cornering

— Tight rotation of the satellites on the axis

Disassemble the differential, replace damaged and deformed parts.

What is an axle reducer?

The rear axle gearbox is a set of mechanisms designed to transmit the torque of the propeller shaft to the axles of the rear wheels. To understand that it requires a gearbox, you need to know how the engine energy is transferred to the wheels of the car.

During operation, the rotation of the engine crankshaft is transmitted to the vehicle's clutch disc, and then to the input shaft of the gearbox. The gear selected by the driver transmits rotation to the output shaft of the gearbox, and then to the crosspiece of the driveshaft, which extends under the car to the rear axle gearbox. The rear axle gearbox distributes torque from the driveshaft to the axle shafts, which, in turn, drive the wheels. Thus, the rear axle gearbox is designed to convert the torque of the propeller shaft to the two axle shafts of the rear wheels of the car.

Where is the gearbox located?

On the "sevens", as on all representatives of the rear-wheel drive family, the gearbox is located at the rear, under the bottom of the car. It connects the cardan to the VAZ 2107 axle and causes the wheels of the car to rotate. Rotation occurs thanks to axle shafts engaged in the gearbox, which, due to the technical features of the rear axle of the VAZ 2107, will have to be removed later. If the car is lifted, or when viewed from a garage pit, the gearbox is simply impossible not to notice.

Signs and malfunctions of the classic rear axle gearbox

Replacing a gearbox with your own hands is a labor-intensive process, which includes not only the purchase of a new unit (quite expensive), but also time costs. Therefore, before you start, you need to make sure that the gearbox is faulty. You can define the signs like this:

- gradually accelerating the car, listen carefully and remember at what moment the noise appears;

- while driving, start engine braking (remove your foot from the gas pedal at speed), at this time listen to the gearbox and note the moment the noise appears;

- accelerate the "seven" to hundreds, switch to neutral and turn off the engine - listen to how the gearbox behaves while coasting.

“If the bridge is noisy both in neutral and at speeds, the gearbox has nothing to do with it. If the hum occurs only at speed (regardless of the number), repairs, or, as a last resort, replacement of the gearbox are inevitable.”

When the signs are identified, it is necessary to carry out another check:

- park the car, secure the front wheels with shoes;

- jack up the rear so that the bridge hangs over (it is necessary that the wheels come off the surface);

- start the engine and accelerate the “seven” to the point at which noise occurs, while the wheels should spin without load.

Diagnostics and causes of malfunctions

The fact that the gearbox is in a faulty condition is indicated by the appearance of a characteristic noise (hum) when the vehicle is moving. To accurately determine the gearbox malfunction, there is the following experiment.

You need to accelerate the car to 25 kilometers per hour and gradually pick up speed, starting from this mark. If suspicious hums appear, be sure to record the speed at which you hear them.

Once you reach the desired speed, slowly release the gas pedal and apply engine braking. Again, listen for extraneous noises and pay attention to the speed at which they appear or disappear.

Certain noises should appear and disappear at the same speed. If this happens, it means that the rear axle gearbox is in a faulty condition. However, to be 100 percent sure, be sure to put the car on the parking brake, put the gear in neutral and try to gain speed, if the noise appears again, then the problem is not in the rear axle gearbox, and if there is no noise, then you can be sure that it is rear axle gearbox.

The cause of malfunctions, most often, lies in the use of low-quality oil, loss of its viscosity, as well as its complete absence. In addition, the gearbox may fail due to failure of oil seals, bearings and special gears. Sometimes, the cause of a rear axle gearbox failure is a broken axle shaft.

When is it necessary to replace the VAZ 2107 axle bearing?

Constant loads and driving on uneven roads contribute to rapid wear of the device. In this mode, the rear axle bearing of the VAZ 2107 can fail at any time.

In this case, the signs of its malfunction are as follows:

- Extraneous noise appears while driving a car. It is very difficult not to notice unnecessary sounds - they tend to intensify during acceleration;

- the product jams and stops rotating;

- the bearing is damaged (deformed) and several balls fall out of it.

In the cases mentioned above, it may be necessary to replace the bearing of the VAZ 2107 axle shaft, and sometimes the axle shaft assembly itself.

How to repair a gearbox on a VAZ 2107

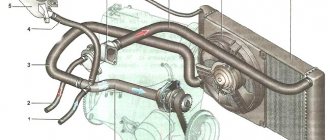

If you decide to carry out repair work, you must remove the gearbox from the car. To do this, first of all, drain the oil from the gearbox: unscrew the drain plug at the bottom of the gearbox and place an empty container. At the end, the oil will need to be replaced with new one.

Now you need to unscrew all the screws that secure the gearbox shank to the driveshaft flange. Then lift the rear of the car and remove both wheels. Remove the brake drums and unscrew the bolts that secure the axle shafts. Pull out the axle shafts, thus completely freeing the gearbox. There will be 4 gearbox mounting bolts left, which also need to be unscrewed. After this, you can safely remove the gearbox.

To repair the gearbox, it must be disassembled. To do this, unscrew all the nuts that secure the shank, pull out the flange, gear with special adjusting rings, rubber seal and inner ring of the bearing. Then press out the outer bearing races and then disassemble the differential and drive gear. Once you have completely disassembled the gearbox, discard the locking spacer.

As you understand, the spacer sleeve needs to be changed in any case. This part is disposable and cannot be reused. Also, if the condition is unsatisfactory, it is recommended to change the bearings and the main pair. The pair allocates a gear ratio, and the larger it is, the higher the power of the gearbox. A small gear ratio increases the speed characteristics of the gearbox. What to choose is up to you. The selection of the gear ratio is precisely the adjustment of the gearbox.

After selecting the gear ratio, change all the oil seals and seals and reassemble in the reverse order.

If the gearbox is in very unsatisfactory condition, it is recommended to completely replace it with a new one. This is a good saving on the work of car service specialists.

Installation of a new or repaired gearbox is carried out in the reverse order. First, install the gearbox itself, tighten the fastening bolts and insert the axle shafts and secure them. After this, install the cardan to the shank and fill the gearbox with new oil.

Dismantling and assembling the rear axle Chevrolet Niva

The rear axle can be completely disassembled directly on the car.

However, if it is necessary to replace the axle housing, it is more convenient to perform the work on a removed axle. You will need: keys “8”, “10”, “12”, “13”, “17”, socket heads “12”, “17”, extension, wrench, screwdriver, wrench for nuts brake pipes, drain plug wrench, oil drain container.

1. Place the vehicle on a viewing ditch or lift.

2. Set the parking brake lever to the down position.

3. Loosen the rear wheel nuts, lift the rear of the vehicle, remove the wheel nuts and remove the rear wheels.

4. Drain the oil from the rear axle housing.

5. Remove the brake drums.

7. Unscrew the bolts securing the shell tip to the brake shield.

8. Using a screwdriver, disconnect the parking brake cable end from the release lever.

9. Unscrew the nuts and disconnect the brake lines from the working cylinders.

10. Plug the holes in the pipelines to prevent brake fluid from leaking out of the brake hydraulic drive.

11. Remove the brake assembly.

12. Disconnect the rear propeller shaft from the drive gear flange of the rear axle reducer.

13. Remove the rear axle gearbox.

14. Clean the mating surfaces of the rear axle housing and gearbox flanges from gasket residues.

15. Clean the internal surfaces of the beam and gearbox housing, as well as other components and parts of the rear axle from dust, dirt and oil.

16. Assemble the rear axle in the reverse order of disassembly. Before installing the axle shafts, lubricate the working surfaces of the oil seals with transmission oil.

Source

VAZ 2107: replacing the rear axle gearbox

VAZ 2107, the last representative of the classics, which was equipped with rear-wheel drive. It had the same structure as its predecessors: gearbox, cardan drive, rear axle, etc. On newer models, VAZ 2108, 2109, 2110, instead of a gearbox, so-called CV joints were installed, which, over a long period of operation, proved to be less durable.

In general, the gearbox is considered one of the strongest mechanisms in a car. But, as they say, nothing lasts forever, and sooner or later, this mechanism will need to be repaired or replaced. So, let's look at the procedure for replacing a VAZ 2107 gearbox with your own hands.

Adjustment and installation of the VAZ 2107 gearbox

Main pair engagement depth adjustments

In this case, it is necessary to select the thickness of the adjusting washer.

So: Instead of the device, we install the “original” shank and tighten the nut until it stops lightly, leaving a gap. The differential with planetary gear assembly, bearing caps are installed and their mounting bolts are tightened.

When replacing the shank oil seal, a number of incorrect actions are allowed, which ultimately lead to premature failure of the gearbox. Before releasing the shank nut, according to the technology for performing the work of replacing the oil seal, it is necessary to remove the axle shafts (which is almost never done, since the amount of work will increase many times). Although according to the price list, the removal of the axle shafts will most likely be included in the list and a fee will be charged for this, since this is required by the plant’s technology for replacing the oil seal. This is a necessary condition, since the axle shaft will create resistance when tightened and correct adjustment will simply be impossible to achieve.

Before releasing the shank nut, it must be secured against turning and the tightening force of the nut must be checked with a torque wrench, around 12 kgf. Before installing the oil seal, if its outer surface is not rubberized, then you need to use a sealant to guarantee it. Thus, a mark of 0.15 mm on the gearbox stocking will be sufficient to pass oil through the outer surface of the oil seal.

Back to assembly...

The adjusting nuts are installed, and the gap on the main pair is pre-selected (the final working gap is 0.08 to 0.12 mm). Then paint is applied to the teeth of the planetary gear from an aerosol can and, using a shank, it is necessary to make several movements in different directions in order to fix the contact spots in the paint.

Read, it may come in handy: How to check the condition of the VAZ-2107 steering on your own

Now, having turned the planet gear back, you can clearly see the contact patch on its teeth with the teeth of the pin. The contact patch (in this case) shows that the adjusting washer on the shank is thicker than the required thickness. We slightly tighten the shank nut, thereby moving its bearing, which makes it possible to move the gear teeth towards each other, that is, as if “reducing” the thickness of the adjusting washer. Using the differential bearing adjusting nuts, we set the approximate gap (reducing it slightly).

Then we again apply paint to the teeth of the planetary gear and again begin to rotate the shank (or gear) in different directions to print the contact patch between the teeth. It can be seen that the contact patch has risen a little, but still not enough and it is necessary to tighten the shank nut a little again. Similar actions with paint and turning the gear must be carried out until the contact patch is located exactly in the middle of the teeth, and the sound of the turning teeth becomes quieter.

After correct (final) adjustment, the sound will be almost inaudible.

Remember to tighten the differential bearing adjusting nuts every time you tighten the shank nut. As a result, the contact patch was located exactly over the entire surface of the teeth. It should be noted that this is the condition for the location of the contact patch for old (working) pairs. For new main pairs, the contact patch, as mentioned above, should be located in the center of the teeth.

Further. The planetary gear mounting covers are released and the differential is removed. The shank nut is unscrewed and removed. Since the shank was installed only with a bearing without an adjusting washer, there was a gap between the bearing and the shank gear where the washer would fit. This gap is measured with a set of feeler gauges, thereby calculating the required thickness of the adjusting washer.

It turns out, as in the case of using instruments and accessories, the size for the required adjusting washer was also 3.36 mm. The shank bearing is removed, an adjusting washer (3.36mm) is installed, the bearing is put in place and the gearbox is assembled. The shank is installed, the shank nut is tightened, min. 12 kgf. The differential with planetary gear is installed, the covers and bolts are tightened, but not completely.

By the way, the lids should not be mixed up. The adjusting nuts of the differential bearings are installed and the gap on the main pair is pre-set. Then the differential cover bolts are finally tightened. The gap in the main pair is finally adjusted and the adjusting nuts are secured.

The gearbox parts are assembled in the reverse order of disassembly. You can press in the bearing rings using a hammer and a special tool (a socket wrench head will do).

Adjusting the VAZ 2107 gearbox

Device

The gearbox is one of the main mechanisms included in the design of the rear axle. It is responsible for transmitting torque from the gearbox to the drive wheels. His device includes:

- Two main gears: drive and driven;

- An axis with satellites located on it;

- Axle gear;

- Locking plate;

- Differential box;

- Adjustment screw;

- Carter;

- Gearbox housing.

It is worth noting that all the parts of this mechanism are basically in constant motion and are subject to heating. It is for this reason that they require special equipment and operating conditions, otherwise you will need to replace this unit very immediately.

Disassembling the gearbox and replacing satellites

The satellites are additional gears installed in the differential gearbox. Their purpose is to transmit torque to the axle shafts of the rear wheels. Like any other part, pinion gears are subject to wear. After this, they will have to be changed, since this part cannot be repaired. To restore worn teeth, the car owner has neither the necessary skills nor the necessary equipment. In addition, any gear in a car undergoes a special heat treatment - carburization, which is carried out in a nitrogen atmosphere and strengthens the surface of the teeth to a certain depth, saturating this surface with carbon. An ordinary car enthusiast cannot do anything like this in his garage. Therefore, there is only one solution: purchase a repair kit for the rear axle gearbox. It costs about 1500 rubles. Here's what it includes:

- a pair of gears for axle shafts;

- a pair of satellites for the differential;

- satellite axis;

- support washer.

In addition to the repair kit for gearboxes, you will also need a set of regular open-end wrenches, a screwdriver and a hammer.

Sequence of operations

To disassemble the gearbox, it is best to use a regular bench vice. Then the work will go much faster.

- The gearbox removed from the machine is clamped in a vice in a vertical position.

- A pair of adjusting locking bolts are unscrewed from it, under which the locking plates are located.

So, an ordinary car owner is quite capable of removing the gearbox from the rear axle of the “Seven”, disassembling it and replacing its worn parts. There is nothing complicated about this. Certain difficulties may arise only at the stage of adjusting the new gearbox. But you can also deal with them by carefully reading the above recommendations.