Many drivers do not even realize that high-voltage wires are one of the main ones in the car’s ignition system. Reliable operation of the power unit largely depends on their correct choice. They must provide the following tasks during engine operation:

- Provide voltage transmission of 40 thousand volts;

- The transmission of high-voltage pulses must be carried out with minimal losses;

- Help minimize interference to radio-electronic devices;

- The insulation of the wires must ensure that current does not leak;

- The operability of the wires must be in a wide temperature range from minus 30 to plus 100 degrees or more.

The first samples of such products were produced with minimal internal resistance to ensure impulse transmission to engine spark plugs. After the appearance of radio receiving devices inside cars, problems arose in their reception of signals from transmitting centers due to interference from ignition systems. Therefore, significant modernization of these products was carried out to ensure reliable operation of radio-electronic devices.

The picture shows one type of such wires. They also began to use armored wires in power units.

How to choose a high voltage wire kit

High-voltage wires used in automotive ignition systems are gradually being forced out of the market. The fact is that automakers are actively promoting ignition technology without the use of wires, in which the ignition coil is placed directly on the spark plug. Nevertheless, such conductors have shown themselves to perform well: they are extremely resistant to external influences, durable, and easy to manufacture. A significant number of cars on the roads are equipped with just such wires. Let's figure out how to use them and choose the right ones.

High voltage wires for spark plugs

Every car enthusiast, even one who is far from the intricacies of auto mechanics, knows that not a single engine can operate without an ignition system. In this case, the main elements of the ignition system are a switch (or distributor), a coil and spark plugs. However, in this article we will talk about another, no less important component of the ignition system - high-voltage wires. VAZ high-voltage ignition wires, like high-voltage wires in a car from any other manufacturer, are designed to transmit high voltage to the spark plugs.

Absolutely all spark plug wires are classified depending on their design features. In particular, all wires are divided depending on the material from which the conductor is made, as well as the material from which the insulation is made. Let's look at the types of wires in more detail.

Classification by conductor type

According to the type of conductor, spark plug wires can be:

- With copper conductor. Such cables are considered classic and have a very low resistance - about 0.2 Ohm/m. The main disadvantage is the significant level of interference that occurs during the operation of the ignition system.

- With conductor made of non-metallic material. Structurally, such a wire is made of linen thread, Kevlar, fiberglass with graphite impregnation. In this case, the core is enclosed in a special shell made of electrically conductive plastic. The distributed resistance is about 2 kOhm/m. Such cables should only be used with interference suppression devices.

- With a non-metallic conductive core, they are structurally made almost identically to the wire described above. A distinctive feature is a higher distributed resistance - about 40 kOhm/m. Such cables can be used without interference suppression devices.

Ignition wires

Classification by insulation material

As mentioned above, spark plug wires are classified depending on the material from which the insulation is made. In budget cables, the insulation is most often made of polyvinyl chloride material. Such insulation can withstand temperatures ranging from -20 to +120 degrees.

Insulation made from the so-called elastomer is considered to be of higher quality. The main distinctive feature of cables with such insulation is their high resistance to the negative effects of chemically aggressive substances. The temperature range at which the elastomer does not lose its qualities lies within -30 - +180 degrees.

Silicone insulated cable has the highest characteristics. Silicone insulation can withstand temperatures ranging from -50 to +250 degrees and has the greatest durability compared to other types of insulation. It is wires with such insulation that are recommended by many automakers, including domestic ones.

What should be the resistance of high-voltage ignition wires?

Many car enthusiasts believe that the lower the resistance of the ignition wires, the lower the level of losses will be, and the more efficient the ignition system will function. Are such statements really justified and true?

It is recognized that the lower the resistance of the conductor, the higher the negative impact of electromagnetic interference on the operation of the vehicle’s power plant. In this regard, it is very important that the set of high-voltage cables meet the established standards in terms of noise suppression. If we take cars of the VAZ family as an example, their technical manuals state that, depending on the length, the wire resistance should be in the range of 3.5-10 kOhm.

At the same time, the lower the resistance of the entire ignition line, the more efficient the car’s power unit will operate. It’s not for nothing that sports cars use wires with almost zero resistance. If we remember about interference, then the resistance of the candle is quite enough.

High voltage ignition wires

Signs of malfunction of high-voltage ignition wires

Evidence that the ignition cables have become unusable are the following signs:

- difficulty starting the engine, especially in wet weather;

- At medium and high speeds, unstable engine operation is noted;

- the engine does not develop full power;

- increased fuel consumption is observed.

As a rule, when there is severe wear on the wire insulation, many microcracks appear, due to which current leakage occurs. As a result, the wire is not able to transmit to the spark plug a current that is sufficient in magnitude for its normal operation. This significantly increases the spark generation time and interferes with the correct operation of the engine cylinders.

Quite often there are cases when wires are damaged as a result of contact with any engine elements. Situations of loss of cap tightness are also possible, and as a result - oxidation of contacts and current leakage. Regular cleaning of contacts is a mandatory procedure, especially when operating a vehicle in difficult climatic conditions.

How can a car owner check the wires for leaks? In fact, everything is very simple: in a dark garage, open the hood and start the engine. Leak areas will glow quite brightly in blue. There is a slightly different method: instead of a spark plug, a spark gap is installed (two electrodes in one housing) and the energy supplied to the spark plug is controlled using it.

In order to increase the durability of the insulation, it is recommended to monitor and constantly keep it clean. The contacts between the spark plugs and each wire are also subject to constant checking and cleaning.

High voltage wires

How to check spark plug wires with a multimeter

First of all, any diagnosis begins with a detailed external examination. Very often, just a visual inspection is enough to identify a worn cable. The presence of significant defects in the form of, for example, cracks and fractures in the insulation already confirms the need to replace the wire.

If a visual inspection shows that the insulation is in good condition and there are reasonable doubts about the serviceability of the conductor, you can check with a multimeter.

In order to check the high-voltage cable, you will need a pointer or digital multimeter. The testing process itself is very simple: set the measuring device to resistance measurement mode, disconnect the wire from the spark plug and ignition coil and measure its resistance. Of course, the resistance measurement must be made in relation to all wires.

During operation, it is worth remembering that the difference between the readings should not be more than 2 kOhm. If the difference between the readings is higher than this value, this indicates the need to replace the wire.

Separately, we should remember another method of verification. To do the job you will need a fairly long piece of wire with bare ends. We connect one end to the negative terminal of the battery (to ground), and gradually pass the other end along the high-voltage cable. In places of damage, if present, a spark will jump.

We emphasize that if, for example, after checking the high-voltage ignition wires with a multimeter, only one wire was found to be unusable, then the entire set must be replaced. The thing is that only installing a new kit can guarantee equally stable operation of each cylinder of the power unit. For the same reason, it is highly not recommended to make any repairs to the caps and/or insulation of the high-voltage cable.

As many years of experience show, the main reason for the rapid failure of ignition system cables is their low quality. Remember that savings in this case are not justified.

It is much more profitable to buy a high-quality product once than to buy a low-quality, but cheap one every month.

Place of wires in automotive ignition systems

Today, a high-voltage wire is used in conjunction with a distributor or an electronic control unit. The first option is often called simply mechanical, and the second - static power distribution system. Here's how it works:

- Distributor system

. Using the ignition coil, the energy from the 12-volt battery is converted into several thousand volts, which are distributed using a mechanical distributor. There is always one wire from the coil to the distributor and the number of wires that corresponds to the number of spark plugs; - System with ECU

. The modified system is equipped with candles, each of which has a coil. The number of wires is dictated by how many coils will be supplied with voltage from the control unit. We only note that the coil can provide operation of one spark plug or two at once, as is the case in dual-spark DIS systems.

Only one fact remains unchanged: the high-voltage wire must supply voltage from the coil to the spark plug. In accordance with this, wires with specified characteristics are selected. Let's try to explain.

Conductor Specifications

When making a wire, most attention is paid to the core and insulation. The core can be copper, a special graphite thread, a thread made of flax or fiberglass. Non-metal conductors perform well, since they do not require additional resistors.

Insulation is almost always multi-layered. The outer protective layer makes the entire wire resistant to mechanical and chemical influences, the middle of the wire is made of dielectric, and the braiding of the conductor is deliberately made quite rigid. As a result, we get an extremely durable and not too flexible wire. It is not afraid of temperature, exposure to automotive chemicals, dust and moisture. According to standard

, the insulation must cope with a voltage of 40,000 V.

NGK wires: main features

The popular company offers customers a considerable number of different products that meet established requirements. The wires will last as long as possible because they are durable and reliable.

High voltage wires NGK

In addition, the following points are characteristic of such products:

- the original versions do not differ in their design;

- wires made of copper are supplemented with lugs that suppress interference;

- the products can be used immediately after their purchase;

- the wires are not afraid of exposure to engine oil and fuel;

- The products are suitable for operation if the voltage in the ignition system has sharply increased.

If we talk about the disadvantages, it can be noted that the length of the wires is the same. Sometimes this causes inconvenience during their operation.

More about zero resistance wires

On old cars you can often find high-voltage copper wires of zero resistance. They have a number of disadvantages:

- Electromagnetic interference

. We have already talked about the fact that modern spark plugs can require up to 35,000 V. When the system operates, the so-called skin effect and energy distribution in the space around the conductor are observed. Of course, the energy losses are not too great, but they are enough for the same radio to start working with interference. The problem is partially solved by installing additional resistors to suppress interference; - Impact on insulation

. Unfortunately, the insulation quality of a zero-resistance wire deteriorates too much as it is used. You cannot turn a blind eye to this for a number of reasons, one of which is the deterioration of the spark plug. The result: dirty exhaust, loss of power due to incomplete combustion of the fuel mixture.

However, these shortcomings do not always manifest themselves fully. Simply, wires with nylon or cotton threads impregnated with soot, replacing the “zero” ones, turn out to be noticeably better. The most modern wires have glass fiber inside, on which graphite is sprayed.

SIGNS OF MALFUNCTION OF HV WIRES

Any problems with the ignition of the fourteenth may indicate that something is wrong with the high-voltage wires.

. The main sign of breakdown of high-voltage equipment is the absence of sparks on the spark plugs due to the fact that the current does not reach the spark plugs themselves, or it does, but in insufficient quantities.

Signs of malfunction of high voltage wires are as follows:

- Mechanical damage is visible on the surface;

- Cracks have formed on the insulation of the wires;

- The conductive copper wire located inside the insulating coating has broken;

- The contacts have oxidized at the points where the GDP is connected to the spark plugs and the coil;

- High-voltage wires constantly overheat due to incorrectly selected resistance.

Any of these malfunctions causes the engine number fourteen to malfunction - it will twitch or stall even at idle speed. This happens due to the fact that when the cylinders are damaged, an insufficiently powerful spark plug is supplied to the cylinders, due to which the fuel in the cylinders ignites late or every other time.

A broken high voltage wire is one of the most common and, at the same time, most unpleasant problems. When a wire is torn, an internal spark (electric charge) is formed, which occurs at opposite ends of the explosive wire. The resulting internal spark is a parasitic impulse that circulates throughout the vehicle's wiring. Because of this, the sensors of the fourteenth function incorrectly or fail.

Advantages and disadvantages of each type

Now let's try to summarize the information about each type of wire:

- Copper

. They may have additional internal resistance, or they may be created without it. If their internal resistance is zero, i.e. Inside there is a regular core made of copper wire, the installation of additional resistances is required; - With distributed resistance

. Consist of several layers. They themselves are difficult to manufacture, but they have improved insulation (there is a complex inner and outer layer) and core. In European wires, the distributed resistance is 9-25 kOhm/m. As a result, radio and television interference is not created at all. We installed the wire and off we went; - With inductive reactance

. A very interesting solution. A so-called pulsating magnetic field appears in the wire. The ignition coil accumulates energy during operation and then releases it. As a result, the inductive voltage in the cable can increase. In such wires, the resistance is a variable value, which depends on the frequency at which the motor operates. The most modern solution, but, alas, expensive.

More information about high-voltage wire terminals

The terminal is needed for high-quality and durable contact. Since the junction of the wire with the energy-consuming device can be called weak, it is covered with a special cap. As a result, the system will work reliably even in hostile environments. Automotive terminals are usually protected with silicone caps. This material is not afraid of water, dust, or auto chemicals.

The following connectors for automotive spark plugs

: SCREW/VRUT, M4, SAE, DIN, D4. As a rule, in modern cars the terminals are removable, so there is a SAE connector for a latch and an M4 for a thread.

Finding out when to replace wires

Please note that there are no regulations for replacing explosive wires. You need to navigate along the way. There is a lot to consider:

- The engine began to “trouble” and run rough, and fuel consumption increased. Most likely the wire has broken. The engine freezes at high speeds, since the electromagnetic pulse in the ignition system has decreased and the spark is either weak or absent at all;

- The wire began to spark and glow. You can observe this phenomenon if you look under the hood of a running car. The problem is insulation or contacts. This wire is only

for replacement; - Inspection revealed the presence of external damage. The easiest way is to simply replace the wire with a new one.

As a rule, high-voltage wires fail without anyone’s intervention, although sometimes they are “killed” by a master who is careless

removes the spark plug. You can accurately determine their malfunction by observing the engine at idle speed, as well as using a tester. If it shows an open circuit (resistance is infinity), the wire will need to be changed.

We also note that unknowing people confuse wiring faults with those of a spark plug. Yes, the high voltage wire determines the operation of the spark plug. However, without “experiment” it will not be possible to determine the broken part. Since checking spark plugs is a very troublesome task, it is more advisable to remove the wire and check it with a multimeter, setting the measurement limit to 20,000 Ohms.

Failure of ignition wires

Reduced cable conductivity or other problems in the ignition system lead to incomplete combustion of fuel, increased gasoline consumption and increased exhaust toxicity. If signs of breakdown appear, you need to test with a multimeter.

Causes of malfunctions

The causes of wire breakdowns are:

- insulation violation;

- poor quality conductive or protective layer;

- core detachment;

- corrosion;

- damage to the cap, wire or contacts.

Signs of breakdown

Symptoms of problems with high-voltage cables include:

- slow ignition;

- problems starting the engine;

- ozone smell under the hood;

- increased fuel consumption;

- “triple” of the engine, stopping operation at high speeds;

- the machine moves jerkily;

- appearance of an open spark.

Checking elements

Procedure for checking ignition wires:

- Open the hood and visually assess the condition of the system while the engine is running. In a dark room, strong current surges can be seen without special equipment. Do not touch the cables while the motor is running.

- Turn off the engine. Prepare a multimeter, rubber gloves, small pieces of paper with marks for marking cables.

- Disconnect the wires from the cylinders in the sequence “1-3-4-2”, remove them from the distributors. Clean off dirt and oil.

- Inspect the surface and contacts. If there is no visible damage, connect the multimeter probes to the contacts and measure the resistance. A value above 10 kOhm indicates a malfunction.

You can ring the wires by holding them close to the car body.

Understanding the choice

You probably already guessed that the high-voltage wire kit includes the conductor itself of a certain length and equipped with a certain terminal with additional protection. So you will have to choose based either on the VIN code of the vehicle, or on the instructions for the car, or on its technical parameters. The new wires should be the same length and connector type as the old ones.

In order not to increase the wear of old wires, it is worth changing everything at once. This will reduce the risk of one of the spark plugs failing. If you have a new car, you will have to use the most expensive and modern wires. The fact is that spark plugs in new vehicle models consume up to 35,000 V, which means they have high requirements for the quality of conductor insulation. Typically, under the hood of foreign cars there are wires with distributed resistance with silicone insulation.

Armored wires for VAZ 2114 which are better

High-voltage automotive armored wires are a fairly simple element of the ignition system. In this case, the high-voltage wire performs the most important function in the operation of this system. Using high-voltage automotive wires from the ignition coil, electric current is transmitted to the spark plugs to form a spark and timely ignite the fuel-air mixture in the engine cylinders.

The efficiency of ignition of the mixture directly depends on the quality of the high-voltage wires, which means stable engine operation in different modes. A malfunction of the high-voltage ignition wire or several wires can lead to engine stalling, increased fuel consumption, loss of power, etc. The simplicity of the design and location of automobile armored wires allows you to accurately and quickly independently check them with your own hands.

Common malfunctions of high-voltage armored wires

Failure of a high-voltage wire is accompanied by symptoms that are similar to malfunctions during spark plug operation. Often the engine starts to run unstably, jerks when you press the gas pedal, and idles at idle. The electric current may not be supplied to the spark plug at all or may not reach the spark plug completely. In the second case, there is usually a breakdown of the high-voltage ignition wire.

If the ignition armored wire is pierced, then the engine begins to work with noticeable interruptions. The main reasons for the failure of high-voltage automotive wires are:

- malfunction of the high-voltage wire contacts at the junction with the spark plugs or ignition coil;

- The conductor of the pulse supply wire is damaged;

- destruction of the insulation of a high-voltage automotive ignition wire, which leads to current breakdown and leaks;

- increased resistance of high-voltage armored wires;

In the event that a break occurs in the main core, then a spark is formed inside the high-voltage wire at the site of such a break. The formation of an electrical discharge between the two ends of a high-voltage armored wire broken under the insulation leads to a voltage drop and causes an unwanted electromagnetic pulse. Such an impulse has a negative impact on the automotive sensors of the electronic engine control system (ECM), and the correctness of their readings is disrupted.

As a result, it is the damaged high-voltage wire that causes vibrations and malfunctions in the internal combustion engine, since ignition in the cylinder occurs untimely, with skips and delays. The synchronous operation of the cylinders is disrupted, the engine begins to trip and vibrate at idle, as well as under load.

In some cases, when the cylinder fails completely, fuel consumption may noticeably increase and the color of the exhaust may change. This happens due to unburnt fuel entering the exhaust system from the combustion chamber.

Self-check of automotive high-voltage spark plug wires of the ignition system

It is necessary to begin diagnostics with an external inspection of high-voltage wires. During such an external examination, the presence of noticeable defects in the form of cracks, fractures, etc. is not allowed.

- The easiest way to check is to use a known good spare ignition wire. It is necessary to disconnect each armored wire one by one, replacing it with a spare one. Stabilization of engine operation after replacing one of the wires will indicate a faulty element.

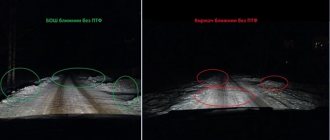

- To identify a possible breakdown of the ignition armored wire, you must wait until it gets dark. When darkness falls, you will need to open the hood and start the engine. If there is a breakdown, then during engine operation an electric spark on the damaged high-voltage wire becomes clearly visible.

- Also, checking high-voltage automotive ignition wires can be done by using an additional insulated wire. To check, the ends of such a wire are stripped (exposed). Then one end is shorted to ground, and the other end should be passed along the highest voltage wire, connections, bends, caps, etc. If there is a breakdown in a certain place, then an electric spark will appear between the breakdown area and the end of the tester wire.

- Checking the resistance of high-voltage car wires is carried out using a multimeter. To check, the multimeter must be switched to operating mode as an ohmmeter. The next step is to remove the wire from the spark plug on the first cylinder, after which the specified wire is also disconnected from the ignition coil. Then the contacts of the multimeter are connected to the ends of the wire, after which the obtained data is evaluated.

Serviceable ignition wires should have a resistance value that ranges from 3.5 to 10 kOhm. This variation will depend on the specific type of high-voltage wires installed on the vehicle. Reference information regarding the resistance of certain ignition armored wires is usually applied on top of the insulation.

In a similar way, you should check the remaining high-voltage ignition wires. It should be taken into account that the spread in readings between all wires should not be higher than 2 or maximum 4 kOhm. Exceeding this threshold will indicate the need to replace high-voltage automotive ignition wires.

It should be added that if a faulty wire is detected, replacing only one defective element is not recommended, since it is a temporary measure. It is optimal to replace high-voltage armored ignition wires in a car as a set. This approach allows for the most efficient operation of the ignition system and smooth engine operation in all modes. For the same reason, it is highly not recommended to repair high-voltage wires for further operation without replacement.

Didn't find the information you are looking for? on our forum.

If you find an error, please select a piece of text and press Ctrl+Enter.

Practical recommendations

In order to buy the best wiring, you should not forget about some things. In the selection process, you should always focus not even on the recommendations of the car manufacturer, but on the recommendations of the engine manufacturer. It would also be appropriate:

- Study the packaging. It contains very important information: manufacturer data, engine and car models. Also, a separate sticker indicates the product’s compliance with the ISO 3808

, if it is a wire from a foreign factory, or

GOST 28827-90

, if from a domestic one. Specified operating temperature range: -40°C to 200°C; - Check to see if it's a fake. Making a fake wire is not very profitable, but the same cannot be said about caps and terminals. If both are of disgusting quality, the transmission of the discharge can deteriorate by one and a half times. Although only a specialist can tell you in detail about some elements of the wire, in order not to buy a fake, you should get a general impression of the product: the terminals should not be skewed, have traces of rust, and the caps should not seem “oaky” to the touch;

- Check insulation. Long-term storage and low suitability of the product are indicated by cracks appearing on it and uneven color of the insulation.

If you decide to switch to a different type of wire, you will have to measure the resistance parameter

I. There is another, more crude and extremely inaccurate method: if, after replacing the wires, the car radio began to work with interference, you selected a product with a small additional resistance.

High voltage wires. Test

29.09.2012

Many car enthusiasts are interested in the question: “which high-voltage wires are better?” And few of them find the correct answer. In this article we will try to find out the answer to this question and find out the results of the high-voltage wire test.

One well-known auto magazine has already conducted a similar test, but this test is focused on carburetor cars. Do not forget that injection and carburetor engines have different requirements, for example, carburetor wires have a lot of radiation, which will interfere with the electrics of the injection engine. In this article we will test high-voltage ignition wires for injection engines, which are equipped in most of our cars.

Let us remember the Soviet-era GOST for high-voltage wires (GOST 14867-79). Here are the main points of the content of the standard:

Terms of Use:

- climatic version O according to GOST 15150-69;

- operating temperature from minus 60 to 110°C;

- The wire is resistant to oil, gasoline, ozone, mold, and does not propagate fire.

Let us immediately note that the conditions and situation in the world have changed greatly since 1979.

Reliability of wires according to the following criteria:

- Active resistance.

- Breakdown voltage (at least 40 kV according to GOST).

- Electromagnetic field level.

- Price.

The test involves complex and inaccessible equipment:

- multimeter MY68;

- universal breakdown installation UPU-1M;

- electromagnetic radiation level meter P3-31.

Our test involves high-voltage (HV) wires from the following companies:

- Slon.

- Ween.

- Cezar.

- Horse.

- Tesla.

- Finwhale.

Let's take a closer look at the candidates:

High voltage wires

SLON

According to our information, SLON high-voltage wires have been installed from the factory on domestic cars for three years now. Salespeople in auto parts stores say the same thing. Resistance from wires 1 to 4 is: 4.24-4.74-5.19-7.60. Passed the breakdown test at 40 kV.

The price for high-voltage SLON wires is approximately 480 rubles.

Ween

Country of origin: Belgium. They have resistance from cylinders 1 to 4: 6.17-6.57-7.52-9.89 kOhm. The breakdown occurred at around 35 kV.

The price for Ween high-voltage wires is approximately 260 rubles.

Cezar

Country of origin: Russia. Resistance from cylinders 1 to 4 is: 3.10-3.53-4.23-5.34 kOhm. Passed the breakdown test at 40 kV.

Estimated cost: 450 rubles.

Tesla

Country of origin: Czech Republic. Tesla high-voltage wires have a resistance from cylinders 1 to 4 of 3.27-4.16-5.02-6.26 kOhm. Passed the breakdown test up to 50 kV.

The cost of Tesla high-voltage wires is 450 rubles.

Horse

Country of origin: Russia. The wire resistance is 3.15-3.90-4.09-6.24 kOhm. The breakdown test passed up to 40 kV.

The price for Horse high-voltage wires is approximately 360 rubles.

Finwhale

Country of origin: Germany. The resistance of wires of this brand is: 1.95-2.18-2.60-3.42 kOhm. The breakdown test has been passed (50 kV).

The price for Finwhale high-voltage wires is 570 rubles.

Absolutely all the wires we examined are suitable for operation in Russian realities:

- all wires are silicone;

- soft;

- withstand temperature changes from -40 to +100 degrees Celsius;

- as for electromagnetic radiation, all wires are within the permissible limits;

Let's summarize a little and enter the data into the table. Based on the table, you can find out how much high-voltage wires cost and what characteristics they have.

Comparison table of high voltage wires

Do not forget that each engine is designed for certain wires, and not every wire will ensure its normal operation. Choose your GDP wisely!

Useful articles:

Brand tour

OEM wires based on the VIN code of your car.

, which satisfy all parameters.

As for alternative spare parts, things are going well with him. Those manufacturers that supply quality spark plugs also supply excellent high voltage wire. We can note Magneti Marelli from Italy, as well as the German company Beru and the French Valeo.

The most popular among motorists are the German Bosch, the Czech Tesla and the well-known Japanese NGK. From budget solutions, we choose products from the Danish company JP Group and the Czech company Profit.

Conclusion

In the case of high-voltage wires, there is no problem of choice as such. Firstly, you can always buy the original or an analogue. Secondly, almost at home you can create a car wire according to instructions on the Internet, and you can also save a lot of money. However, we do not recommend that you engage in such experiments, especially if your vehicle is a new foreign car. The high-voltage wire is not so expensive that you can skimp on it and risk breaking other components of the ignition system.

Testing high-voltage ignition wires behind the wheel

Here is an article from the experts at “Behind the Wheel”

EXAMINATION: high-voltage wires. The Path of Thunder Authors: Mikhail Kolodochkin, Alexander Shabanov Most smart textbooks avoid this topic. Like, the ignition system is mainly spark plugs and coils. True, there are still some high-voltage wires between them. But there seems to be nothing to say about them: wire is just wire in Africa.

Are they all the same, and also problem-free? To figure this out, we purchased sixteen sets of wires for carburetor Samaras in Moscow stores.

Looking ahead, we note that this examination surpassed even spark plugs in terms of complexity and volume of work!

The motor is there, “Behind the glass”...

The average consumer's requirements for high-voltage wires are simple - let them conduct current properly and not fall off on their own. The ideal would be a thick copper wire with zero resistance - that’s all science...

The specialist will nod respectfully: they say, everything is correct, but... The resistance of the wires should not be zero - otherwise the level of interference from the ignition systems will become such that even flying saucers will stall. Yes, the discharge will become weaker, but you have to put up with it. We must also not forget that the wires must be “all-weather” - complaints about Russian frost and engine compartment heat are not considered. And, of course, the parameters of wires from one set should be as close as possible - this is understandable.

The examination of the wires was divided into two parts - non-motorized and motorized. After a visual inspection, we assessed the length of the wires and their resistance, then determined the force of tearing the wire off the spark plug, and then sent everyone to the refrigerator. As for motor tests, with each kit installed on the engine, measurements of power, fuel consumption and exhaust gas toxicity were carried out. And the final quality indicator was determined using a point system. During each test, the result of the best set was equal to 5 points, and the worst - to zero, the rest were located in between.

PERCENTAGES, JOULES AND LEAKS

The influence of wires on the life of the engine is reflected, naturally, through the energy of the discharge - there is simply nowhere else. But how much of this discharge reaches the spark plug electrodes? First, the gaps in the contacts of the ignition distributor cap interfere, then leaks through the wire insulation will steal something. Have you seen how flashes of electrical discharges rush around the wires in the dark in humid weather? These are the same leaks that steal joules from the candles. Then again there is a gap in the contact between the wire and the spark plug tip. And the worse the wire, the greater these losses.

What does this mean? Firstly, the combustion rate decreases, hence the gluttony, dullness of the engine, and “tasteless” toxic exhaust. Secondly, the moment of combustion begins shifts towards late ignition. After all, in order for the discharge to pass through the gap of the spark plug, it takes some more time - under the influence of high voltage, the initially non-conducting air with fuel vapor must be ionized. And the lower the voltage on the electrodes, the more the ignition delay increases. We may be talking about milliseconds, but at high revs they translate into actual degrees of crankshaft angle.

And one moment. Almost all of our “under investigation” wires have distributed resistance. Moreover, depending on the length, the resistance of the ignition lines of the first and, say, fourth cylinders could differ by almost two times!

How big is the influence of wires on the operation of the motor - is it about “catching fleas” or about a real difference in percentages, grams and watts? This is exactly what we want to find out.

The length of the central wires for all sets is almost the same. But the rest are quite different: for example, the shortest are those of the VAZ and JanMor. Their owners may have problems putting the wires on, and they may “break.” The longest wires are with the HORS kit (especially the first and second cylinders). In addition to ease of installation, this ensures a certain equalization of resistance along the ignition lines of all spark plugs.

The SenTech kit has the lowest distributed resistance (it does not exceed 0.5 kOhm). For B-Tech it is over 10 kOhm. The best indicators for uniformity of linear resistance are found in the SenTech, Champion and Tesla kits (range 3–4%), the worst are in Wego, Ween, JanMor and Master Sport (20–33%).

You can fit onto a candle in different ways... A normal cap fits tightly, but the “Master Sport” cap fits only halfway.

Remember the jokes about machine guns with a crooked barrel? Which option seems better to you?

When assessing the force of tearing the wire from the spark plug, the “work” of both the tip and the cap, worn to the maximum possible level, was assessed. Naturally, the winners were products with spring-loaded tips - Champion, NGK, Tesla, HORS. As for the obvious outsiders, spark plugs fall out of VAZ tips even under the influence of their own weight! Pliers in hand and off you go?

When cooling, the VAZ set completely lost its functionality, the tips and wires lost their elasticity, their installation and dismantling became almost impossible.

The only successful “number” of these wires emerged during motor tests. However, resistor spark plugs, tests at a reduced supply voltage, and then a test to stop sparking again threw them to the bottom of the table - large losses in the contacts of the tips affected them. The best were Champion, NGK, SenTech and HORS.

In terms of electromagnetic radiation, NGK, Caesar and SenTech were ahead. To be fair, we note that the absolute leader of Champion’s expertise in this category, to put it mildly, did not shine.

In terms of increasing power, improving efficiency and reducing toxicity, the worst and best wire sets found a difference in power and fuel consumption of up to about 3-5%, and in toxicity - up to 8-10%! Which, in fact, was what needed to be proven... For the curious, we present in the table data on the quantitative change in engine power and efficiency when replacing one set of wires with another. At the same time, all sets of wires, in general, are functional: the main differences will appear in difficult conditions - in winter, in rainy weather, when the battery is dead, etc.

Change in engine power and efficiency depending on the type of high-voltage wires

SO WHERE IS THE ANSWER?

So what wires do we recommend to our readers? If you love your car at least a little above average, then it’s better to choose from at least the first dozen wires. If money does not have a decisive vote, then take “Champion”, if you want to “support your own” - pay attention to HORSE. If you want to save money, be content with the Belgian Ween, but do not approach it with “champion” standards.

Have you chosen? Then – good luck to you and your ignition system along the “Path of Thunder”...

WITH OR WITHOUT RESISTORS?

During the tests, two types of spark plugs were used - with and without resistors. Let us note at the same time: NOT ONE wire manufacturer indicates which spark plugs it considers preferable - with or without resistors. In the same way, candle makers are silent about which additional resistances in the wire circuit they prefer. It seems that the manufacturers of these critical components had a fight in the sandbox in childhood and have not spoken to each other since then. This applies even to those companies that simultaneously produce both! Taking this into account, motor tests were carried out with two variants of spark plugs - A17DVM and A17DVRM: for all occasions. The exceptions were measurements of magnetic and electric fields - here resistorless spark plugs were used, as well as tests at reduced power - here, on the contrary, plugs with resistances were involved. The reasons are clear - in both cases, obviously worse operating conditions were simulated. To eliminate the random factor, resistor spark plugs were chosen with passion - the resistance of each of them is 3.1 kOhm.