Fuel system

If it is below -20 degrees outside the window, it is possible that condensation has formed in the tank. The presence of water in gasoline is a bad sign. Moreover, it is not necessary that it be “diluted” at the gas stations themselves. Due to the temperature difference, condensation forms on the walls of the tank. At low temperatures it freezes. As a result, the VAZ-2115 (injector, 8 valves) does not start. Frozen water can be both in the fuel lines and in the filter itself. There is no point in trying to turn the starter with the hope that the car is about to start. You'll just drain the battery. The only solution to the problem is to warm up the car. It's better if it's in a garage with this problem. By installing an oil or induction heater there, you will quickly warm up the air temperature in the room. And the car will start successfully.

The engine stalled while driving and the reasons for the VAZ 2115 do not start

- Registration

- Entrance

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

VAZ 2115 injector .. the problem is that as soon as the mileage hit 35,000 km and the warranty ended, the car stalled on the move and would not start again :)

the starter turns .. at first it stalled and immediately stalled, and later it stopped stalling. It seems that when you turn the key the gas is not pumped.

Do you really have to change the fuel pump?

Fuel pressure, CV position sensor, Timing belt, Ignition module.

The HF position sensor has been changed - it's a good one

The filter was changed within 2 weeks. back. Timing belt - seems early..

gasoline is not pumped (cannot be heard)..

I'll go look at the fuse and relay.

hmm.. how should I look at this relay?

because how to understand that it is not working properly? replace with a new one?

it is also possible that the mesh is clogged

mesh - what kind of animal is this?

If after parking it does not start at all, you need to look at the electrician.

what if it starts?

Source

Ignition problems

Most often, the reason lies precisely in one component of the ignition system. Weaknesses that are the first to come under suspicion are:

- egnition lock;

- induction coils;

- starter and ignition relay;

- lack of voltage at the battery terminals.

Most often, the problem lies in a banal lack of voltage at the ignition switch contacts. It is supplied directly from the battery to the starter.

If, after turning the key, the dashboard goes out or does not light up at all, it may be a problem with the cylinder.

Checking the functionality of the ignition switch is relatively simple:

- it is necessary to dismantle the larva;

- Using a multimeter, the contacts are called in different positions.

If there is no contact, then you should simply purchase a new lock. It simply doesn't make sense to repair it.

You need to pay attention to the behavior of the car immediately after turning the key. If there is no characteristic clicking sound from the side of the door from under the panel, the relay has probably failed. It is located above the clutch pedal.

Like the ignition switch, it simply does not make sense to repair such a relay. You need to purchase a new one and install it in place. You also need to check the ignition coils. Often the spark on the spark plugs disappears due to their failure. The test must be carried out by removing the coil and connecting it to the tester. You should ring the windings - a break in one may be the cause of the malfunction.

If you have problems starting the engine in cold weather, you should make sure that the battery is working properly. Often it simply fails.

It is not difficult to check the condition of the battery using a conventional tester - you need to switch it to the constant voltage measurement mode and set it to the 20 V limit.

The voltage between the terminals should be 12.6 V. It would also be a good idea to measure the density of the electrolyte using a hydrometer.

VESKO-TRANS.RU

Content

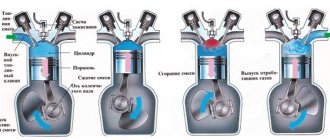

Obstacles to starting a car engine are divided into two main groups, depending on the degree of engine heating.

Since the engine has been shut down for less than 6 hours at an ambient temperature of 20°C for at least 3 hours at a temperature of -20°C, the engine crankcase oil temperature is the same as the ambient temperature. The methods for starting an engine with a fuel injection system are the same at any ambient temperature.

1. Open the hood by personally pulling the drive handle, locking it.

4. Use the dipstick to determine the oil level. This is required between the "MAX" and "MIN" characters.

3. Check the brake level.

4. and coolants.

5. Carefully inspect the engine and engine compartment. Carefully inspect for gasoline, oil, brake and coolant stains. Check wiring integrity. Check the suitability of the high-voltage wires in the ignition module connectors and on the spark plugs.

6. Turn on the ignition by turning the ignition key to position “I”. The gasoline pump will turn on. Do not close the hood (if the hood is covered with rain or snow), walk away. Start the engine.

It is better to close the hood if the engine starts running. Before doing this, it is better to inspect the engine again to make sure that fuel, oil, antifreeze and other sounds are leaking.

If the engine does not start, there are three main conditions:

The engine is warm, as they call it hot

Don't turn the starter, don't turn the key, VAZ 2115, 2114

The oil temperature in the crankcase is higher than the ambient temperature.

To begin, simply turn on the starter without touching the accelerator pedal. The engine management system will unassistedly set the fuel and ignition parameters required for starting.

If for any reason the spark plugs are "primed" during a failed test, use the cylinder "bleed" mode. To do this, fully depress the accelerator pedal and turn on the starter. There is no fuel supply, excess gas is removed from the cylinders by a stream of fresh air, and the spark plugs are dried. After cleaning, try rebooting as always.

If the engine does not start, there are three main conditions:

Troubleshooting to start accounting (software)

Malfunctions in the starter system occur when the starter is not operating properly. There are 5 main starter defects:

1. The starter is not cut. The reason is a violation of contact connections, shutdown due to another short circuit in the starter switching circuit, or a malfunction of the traction relay.

4.5. When the starter is turned on, the clicking noise is repeated. The reason is a failure of the holding winding of the traction relay, the battery is severely discharged, and the contacts in the starter circuit are weak.

3. The starter is cut, but its armature either does not rotate or rotates slowly. The reason is that the battery is discharged, the contacts are broken, the traction relay contacts are burnt, the commutator is dirty or the brushes are worn out, switching, which is called a short circuit in the windings.

4. The starter is cut off, its armature rotates, unfortunately, the flywheel remains motionless. The reason is the weakening of the starter to the clutch housing, damage to the flywheel or drive gears, slipping of the drive flywheel, breakage of the lever, drive ring on another buffer spring of the starter drive.

5. After starting the engine, the starter will not turn off. The reason is a malfunction of the freewheel mechanism, sintering of the contacts of the traction relay. If such a malfunction occurs, stop the engine immediately!

These faults require qualified intervention at a service station in different ways after arriving at the garage (see Chapter 9 “Electrical”). Previously, you could only check the degree of discharge of the battery using a voltmeter in the instrument cluster and the tightness of the contacts in the starter circuit.

Testing the ability to keep records (software) of ignition

Your vehicle is equipped with a Microprocessor Based Maximum Power Z (MPSZ) ignition system. A voltage of about 40,000 V is supplied to the high-voltage wires; of course, with a small current this is not life-threatening; a possible electric shock when checking the ignition system leads to lingering consequences. If you handle high voltage ignition wire, use thick rubber gloves or, in the latter case, insulated-handled pliers.

Phillips slots and screwdrivers, insulated pliers and tester.

Before checking the ignition timing set, place the shift lever in neutral and apply the parking brake.

1. When turning off the ignition, check the integrity and compliance of the high-voltage wires in the ignition module.

3.5. Disconnect the harness connector from the ignition module low voltage circuit block.

3. And check if the tester is turned on in low current (mA) mode, the low voltage circuit of the module is open by connecting test leads to terminals C and B of the unit.

4. If the ignition module low circuit is operating, to check the operation of the module high circuit and high voltage wires, check for spark at the spark plugs. Remove the high voltage wire from any spark plug. Insert the spark plug into the tip of the wire and press it with the iron part against the ground of the car. Turn the engine starter crankshaft.

5. If there is no spark, replace the high voltage wires with new ones. Of course, for testing you should not install a new one, unfortunately tested, “from a running machine”.

6. If spark does not appear after replacing the wires, replace the ignition module (see Chapter 9, Electrical Equipment). If there are sparks, unfortunately the engine will not start, replace the spark plugs with new ones. You can also try installing a new one, unfortunately tested "from a running machine" in the past.

7. If the engine does not start later, check the functionality of the complex engine management accounting programs (see “Troubleshooting complex fuel injection accounting programs”).

Clogged filters

This problem can occur in both summer and winter. And this applies not only to the fuel filter, but also to the air filter. The latter is in a special plastic case. On VAZ 15th model cars it looks like this.

After moving the latches, lift the air filter housing cover and remove the cleaning element itself. If it is dirty, the part needs to be replaced. Filters are consumables and cannot be restored at home. Moreover, they cost pennies. As for the fuel filter, it is located under the bottom of the car. The element looks like in the photo below.

If the car has driven more than 30 thousand kilometers, the filter should be replaced. You will not be able to visually determine the degree of contamination as you can in the air. The part is located in a closed, non-separable case. It has porous paper inside. It is capable of passing particles smaller than 10 microns. Over time, the pores of the paper become clogged, and the filter is not able to pass the required amount of fuel through itself. So that the problem does not take you by surprise, change this part in advance.

A characteristic sign of failure is jerking when moving (as if the fuel supply to the cylinders had stopped for some time). This means that the submersible pump is not able to supply the required amount of fuel through the paper pores. As for the air filter, it is changed every 6 months or every 10 thousand kilometers. By following the regulations, you will protect yourself from such problems.

The starter turns but does not start: injector

When the starter turns, but the VAZ 2114 does not start, it has 8 or 16 valves (also relevant for similar car models). The problem is searched for in the following systems:

- fuel supply;

- ignition;

- electronics;

- injector.

Fuel system

Pump

A common problem when injection vehicles fail to start is a breakdown of the fuel pump. When you turn the key in the ignition switch, a characteristic hum should be heard from the tank, accompanied by pumping gasoline into the line. If it is absent, the corresponding relay and fuse are checked. If the inserts are in good condition, it is necessary to diagnose the pump itself (located inside the tank, under the rear seats). It is also necessary to check the integrity of the fuel lines and the working condition of the coarse and fine filters.

Gasoline quality

There is a widespread belief that a properly tuned engine can operate even on surrogate gasoline without causing problems - this is fundamentally not true. If the starter turns but the Priora or a similar car does not start some time after the last refueling, the problem may be with bad fuel. This mixture must be drained and filled with new fuel as quickly as possible.

Injectors clogged

In 90% of cases, the problem arises as a consequence of a previous incident. The nozzle nozzle has a minimum diameter. The smallest specks can clog the passage inside the part, which causes failure of the power unit or tripping.

You can check it like this. After 2-3 unsuccessful attempts to start the engine, you need to unscrew the spark plugs. If the electrodes are wet, the injectors work.

Note! Fuel injectors do not fail at the same time. A secondary sign of device failure is that the car is running rough before starting problems.

Repairs and thorough diagnostics of parts are carried out on a special stand.

No pressure inside the fuel rail

The starter turns, but the 2114 VAZ or Priora does not start - the reason may be due to insufficient operating pressure of the injector fuel rail. If the fuel pump is operating adequately, it is necessary to check the mass air flow sensor. A faulty unit may send incorrect information to the ECU, which prevents the combustion mixture from forming correctly. In some cases (5-6%), the launch is affected by the failure of the TPS. However, this is unlikely.

Electronics and ignition

Initially, spark plugs are diagnosed using the standard method. If there is no spark, the spark plugs themselves and the high-voltage wires are checked. If everything is in order, but there is no expected arc, the problem may be in the following nodes.

- Ignition module. A capricious and unpredictable detail on most VAZ family cars and budget foreign cars. The block design is practically beyond repair; upon diagnosis, it is replaced with a known good one. It is also important to have voltage on the module chip. If there is no electricity, the fuse and the corresponding relay are checked.

- DPKV - the sensor may transmit data with an error or completely fail. This is a key element of the ignition system; performance testing is performed with an oscilloscope. Also changes to a known good one.

- ECU. The injector control design may malfunction due to oxidation of the contact chips or internal problems.

- System errors. Accumulated failures of the on-board computer may prevent the engine from starting. The problem can be eliminated by diagnostics at a service station with specialized equipment.

- Mechanical failures. Broken wires, oxidized terminals or loose connections in 50% of cases lead to interruptions in the operation of the internal combustion engine.

How to solve a problem?

There are two ways to solve this problem:

- On the spot. If you don't have time to remove the spark plugs, you can try drying them directly in the engine. To do this, open the throttle valve 50 percent before starting. Fortunately, on the VAZ-2115 the accelerator pedal is mechanical, with a cable drive. This will allow more air to enter the combustion chamber. The candles are “blown out” automatically. After starting, the throttle valve can be closed. But this method is not always effective. And then the second method comes to the rescue.

- Self-drying. In this case, all four spark plugs are unscrewed. An important point - when removing armor wires, number each of them. Otherwise, the engine will not start at all, since the valve timing will be disrupted. You can quickly dry it with a home hairdryer, setting it to maximum blowing mode. If time permits, you can check the gaps between the electrodes of the spark plugs. When this parameter does not match the factory setting, the spark plug cannot produce a normal spark. We talk about this in more detail.

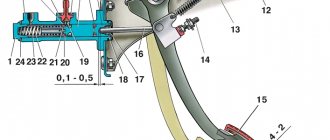

About spark plug gap

Over time, the gap between the electrodes increases. The normal parameter is from 0.7 mm to one millimeter. You can check this gap using a special feeler gauge.

The same is used for setting valve clearances on carburetor engines. So, if a parameter does not meet the norm, it should be adjusted. To do this, you should use a negative screwdriver. To reduce the gap, press the end of the plug onto the top electrode of the spark plug. With your other hand, hold the part itself. If you “overdid it”, it doesn’t matter – everything can be returned back. To do this, bend the electrode with the edge of a screwdriver (it bends quite easily) and check the distance again. It is worth noting that with a correctly set gap, you can not only ensure trouble-free engine starting, but also reduce fuel consumption by 5 percent. Also the car will run smoothly. After all, the mixture is ignited exactly at the moment when it is necessary. And the last thing is the resource of the candles themselves. If the gap is higher or lower than normal, the risk of breaking through the insulator increases significantly. As for the replacement schedule, it is about 40 thousand kilometers. It is recommended to replace the high-voltage wires along with the spark plugs.

Starter failure

If all other system components are in order, then the reason for the inability to start may lie in the absence of a starter. Typical problems:

- poor contact at the terminals;

- the starter shaft bearing has failed;

- The solenoid relay has stopped working.

It should be noted: the location of the power terminals on the starter suggests the presence of moisture. Therefore, often the contact simply oxidizes, which leads to problems in the operation of the device. That is why you need to carefully examine the contacts. Then clean them and check the voltage. If it is missing, there may be a break in the wiring.

When there is voltage, but the starter does not turn, it is often a problem with the bearings. To replace it, you will need a clean garage, as well as a special puller. This is the only way to dismantle it.

A little more often than a bearing, the solenoid relay fails. Sometimes it just jams - just tap it lightly with the key.

It is very simple to check the functionality of the retractor - just place the starter on the engine block and then touch the contact of the wiring relay connected to the positive terminal. If the starter starts spinning, it means the solenoid relay is in working condition. All of the problems listed above are typical and do not require any major repairs.

Other reasons for the inability to start the engine

Figuring out why the engine stalls is not difficult. In addition to typical problems, the following types of problems may be present:

- timing belt is broken;

- the engine “knocked”;

- the shaft is jammed.

A fairly common problem, especially on 16-valve engines, is a broken timing belt. In this case, the valves on the VAZ 2115 bend. Such breakdowns not only lead to the inability to start the engine. But they require a complete engine overhaul. The situation is similar if the engine knocks. If you can’t start the car even when it’s hot, you should check the air supply channel. Moreover, starting is not always possible the first time.

There are many nuances associated with setting the ignition and ensuring normal engine operation. You will need to carefully understand all the subtleties and nuances. Many problems associated with the inability to start the VAZ 2115 engine are associated with typical malfunctions and repairs take a minimum of time.

Coil

Modern cars are no longer equipped with distributors. There is an ignition module here. VAZ-2115 (16 valves) is no exception. Sometimes breakdowns happen. Because of this, the VAZ-2115 does not start. The reasons are a faulty ignition distributor.

This item cannot be repaired. And in order not to waste time on diagnostics (or if you don’t have a multimeter), it’s worth installing a known-good ignition module. The VAZ-2115 should start without difficulty. Sometimes the high-voltage wires themselves pierce. But in this case the car starts and starts. This can be heard by the characteristic sound of the engine.

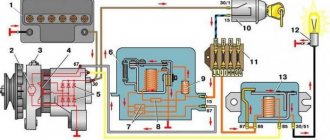

Relays and fuses VAZ-2115

It happens that the car does not start due to a banal failure of the fuses. In this case, the pump will not emit a characteristic hum when the ignition is turned on. The sound should come from under the rear seats. On VAZ-2115 cars the pump is submersible and is located directly in the fuel tank. If there is no hum in the first 3-5 seconds after turning on the ignition, it means that power is not supplied to the element.

We start looking for a break in the fuses. The cover indicates which one is responsible for the electric fuel pump. But not only fuses are checked. The VAZ-2115 is also equipped with a relay. This element should make characteristic clicks when the ignition is turned on. If the VAZ-2115 does not start and clicks are not heard, most likely the pump relay needs to be replaced. Sometimes cleaning contacts helps. For this purpose, special sprays in cans are used. For the future, it is worth purchasing a set of spare relays and fuses. Sometimes such a “childish” breakdown happens on the road. With new parts in stock, you can continue moving without hindrance.