“The spar is gone” - this phrase can often be heard from car service workers inspecting a car after an accident or other mechanical damage. Let's look at what a car spar is and find out where it can actually go.

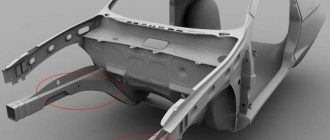

In the photo, the spar is the load-bearing part of any car.

A spar (from the French longeron, from longer - to go along) is a load-bearing part of a car. As a rule, it is the most powerful beam that holds all the other parts of the car. The spars are mainly made of metal profiles, often aluminum. In essence, it is a longitudinal pipe of the car frame, passing through the nose and rear of the car, and is the basis for the body and fastening of important parts: wheels, engine, etc.

Spars are an integral part of the car. You won't be able to see her in her usual position. But if you look at the bottom of the car from the inspection hole, you will not confuse it with anything.

Origin of the spar

First, it’s worth figuring out what it is - a car spar and how it came to be. Only after this we can move on and continue our acquaintance with this important part of the car. The spar is the strongest part that performs a load-bearing function. In a car this is a very strong box beam, metal profile or rectangular pipe. A large number of parts and mechanisms are attached to it.

The first cars had a frame, the longitudinal parts of which were called spars. To give the structure strength, lintels were added, making it look like a ladder. This technology is still used today. It can be seen on any truck. Passenger cars do not have a separate frame. The longitudinal spars became part of the body.

A car cannot exist without this part. You can't see it at all behind the wheels, but it's definitely there. You can see what the spar looks like; to do this you will need to lift the car on a lift. Spars come in different types; we will return to this issue later. If each of you understands what a spar is in a car, then you can move on to studying the functions that are assigned to this part.

The history of the creation of the spar is closely connected with the history of the development of the body frame structure. Initially, the frame was the main and only load-bearing (by the way, wooden) structure in the car. Over time, the car frame was improved and spar elements appeared in its composition.

Automobile body structure

In the 20s of the last century, Auburn engineers created a spar frame equipped with a cross member in the form of the letter X. This design consisted of two spars located parallel to each other and several transverse beams. In appearance, this design was similar to a staircase, for which they received the name “staircase”. These days, all trucks are equipped with a ladder frame.

Gradually, car creators began to integrate the spar frame into the body, or more precisely, into the floor of the car. So the side members became an integral part of the car body. Nowadays, spar frames are included in the design of all machines, and its presence does not depend on the type of supporting structure.

Which side members should be installed on the VAZ 2109?

The original number of the right spar is 21080-8403280-10, average price is 2714 rubles, the left one is 21080-8403281-00, average price is 2819 rubles.

We take out the battery and dismantle the front bumper. We also remove mats, sound insulation, doors and turn the car over.

A visual inspection of the bottom and side members is carried out. Places of maximum corrosion are identified, as well as places that can still be restored by straightening, priming and painting.

We cut off the rusted spars using a grinder.

Now, using a grinder and a brush, you need to clean everything down to the metal.

Then we treat it with orthophosphoric acid to completely remove the rust.

We clean the dust after the “anti-rust” to the metal.

Degrease the entire surface under the spar.

Prime with reactive primer.

Prime with regular primer.

We clean the welding points down to metal.

Primed spar with holes made for welding points. The connector between the spar and the bottom has already been welded, all welding spots on the spar have been cleaned to bare metal. Sealant applied.

The spar is adjusted to the connection points as accurately as possible. The spar is finally secured with clamps.

After this, the spar, without loosening the clamps, should be welded to the bottom of the body.

What is a spar? What consequences await the car if the spar “gets tired” or “goes away”? Can it burst? What does it look like? And, in the end, where is this element of the car located? We will answer all these questions in this article, and we will do it in a way that is clear to all drivers.

The spar is a rectangular tube, which can also be called a longitudinal beam of the body kit. They pass through the rear or front of the body. Body designs differ in many ways, which is why there are spars that pass right through between the bumpers.

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

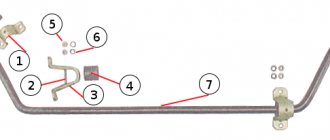

Spars can be either composite (looks like a set of iron parts) or solid (made by stamping or milling - looks like a solid part). In a standard design there are usually two of them: left and right. Each is divided into three parts: rear, front and middle spar. In addition, the front left, wing spar and rear are higher, relatively. Relative to each other, they are most often located parallel, but in some frames they are at a small angle.

Spars are an integral part of any car, regardless of body type. In the photo you can clearly see where they are. As for the material, it is most often made of titanium or aluminum alloys for the car body, as well as composite layers. The main section in the part is the channel (looks like a U-shaped section) - in the most loaded places the section increases.

Conclusion

The particular importance of the spar in the design necessitated the need to preserve and restore the high strength of the device. The condition of the load-bearing part must be monitored and necessary repair work carried out, since due to its importance it deserves maximum attention.

What is a spar? Only beginners can ask this question. An experienced motorist knows everything about this detail. It remains one of the main parts of the design, allowing the transport of large loads and reducing the risk of passengers during a car accident. Once you get acquainted with it, you will be able to find out where the elements are located and how manufacturers use them.

Functions performed by the structure

We have already found out where the spar is and even know what it is. But what it is needed for is not yet entirely clear. The spar is the most durable part of any car. Such a margin of safety is necessary to withstand the load exerted by the body, engine, luggage and driver with passengers.

This part also serves as a shock absorber for the front part of the body, absorbing impacts and preventing deformation. The body cannot be made very rigid and durable, since it will not be able to absorb the impact energy and most of it will be transferred to the passengers. This situation is unacceptable, because the body on the passenger side is minimally deformable and has the ability to absorb impact energy.

It is the side members that bear the greatest impact force. In this situation, they are often subject to deformation. But passenger safety increases significantly. Therefore, the sacrifice of the spar turns out to be justified.

Also, this part is subject to loads carried by surrounding working units, parts and mechanisms. Even the force from the wheelbase is absorbed by these robust structures.

Is it necessary to strengthen

Reinforcement of technically sound side members is required only in sports and when operating vehicles in particularly difficult conditions for which the bodies are not designed.

Sometimes reinforcement is carried out after an accident, when they are trying to avoid complex repairs with the replacement of load-bearing parts. In these cases, the geometry of the body is restored by drawing on a slipway, and since the deformed spar is no longer able to work normally in the future, external reinforcements are welded onto it.

The same technology is sometimes used to repair corrosion and fatigue cracks.

Types of existing load-bearing structures

The biggest difference is the direction of the load-bearing part and the location of the side members. The type of design differs depending on the role and tasks of the vehicle, as well as the decisions of the manufacturer.

Today there are a number of common types:

- completely horizontal placement with elements parallel to each other. Most often installed on vehicles that require high cross-country ability;

- with slight bends. The curvature is located throughout the bottom, the spars bend around the shape of the bottom, creating a single contour. Improve passenger comfort and effectively reduce vibrations;

- vertical position. The peculiarity of the type comes down to the possibility of creating a flat floor with a significant reduction, greater than that of traditional car models;

- angular views. Increases the passive safety of the vehicle.

The load-bearing part differs according to the transverse type, arranged in all cars. Their role is reduced to creating stiffening ribs, but structurally they are designed differently: inserted perpendicularly between the channels, in the shape of the letter K or X-shaped models. Cross members are almost always made of steel and then bent.

Spar on Infiniti FX35

The large group of different types of spars is based on the principle of their location. Different types of parts are suitable for different cars; there is no universal type.

- Parts in trucks are arranged horizontally parallel to each other.

- A horizontal position at a certain angle is typical for passenger SUVs.

- The curved, vertical arrangement of the load-bearing beams allows for a lower center of gravity. In this case, the floor in the cabin is located at a lower level.

- In a curved, horizontal position, the floor level in the cabin also decreases. Moreover, in the event of a side collision, passive safety will be at a higher level.

Between the beams there are cross members, we have already mentioned them. These crossbars are also divided into varieties depending on their shape:

- straight;

- in the form of the letter X;

- K-shaped.

The material for their manufacture is a curved metal profile. In truck-type vehicles, rivets are used to connect the crossbars to the main beam. When assembling passenger cars, a welding seam is used. To secure all the component elements of the body to the spar, brackets are used, which also differ in shape.

What is a spar, what does it look like, and where is it installed?

A spar is a structural unit of a car that looks like a rectangular pipe, that is, a metal profile with a rectangular cross-section.

The part passes through the front and rear of the body, acting as a support. Depending on the body design, an option with side members between the bumpers is possible.

This unit can be composite (assembled from several elements) or integral.

In the classic configuration, two spars are installed (left and right).

Example, left front side member of a VAZ 2110.

Each element is divided into three parts - middle, front and back. The main difference is the location.

Thus, the spar installed at the front and left is positioned at a level lower than the spar at the rear and the same unit, but only the wing.

The nodes are parallel to each other, but there may be cases where they are located at a minimum angle.

Spar on Nissan Bluebird HU14 SR20VE.

The starting material for production is aluminum or titanium. Sometimes component layers are used to add to the fortress structure. The cross section of the spar has the shape of the letter “P”. At the same time, in places of maximum load the cross-section is larger.

The main advantage of the part is its exceptional strength. These units are able to withstand maximum loads - the weight of the car, luggage, mass of units, and so on.

In addition, the side members cope with all the impacts that they receive when the wheels get into holes or in the event of an accident.

Structurally, these units form a U-shaped staircase frame laid on its side.

This type of design is an integral part of many SUVs and trucks.

As for passenger cars, the ladder principle is not applied in them. To visually see the detail, just look under the bottom of the vehicle.

Body structure of the VAZ 2108, location of the side members.

Purpose

In modern passenger cars, the part serves as reinforcement for the bottom of the body, trunk floor, and mudguards. For many trucks, the spar is needed as the main strength element of the body itself. The front spar serves as an additional shock absorber; it is installed in the deformation absorption zone.

Manufacturers of passenger cars reduce the thickness of the walls and make additional holes in those places where the load is minimal. Deformation of the side members during an impact leads to a decrease in the impact force of the passenger compartment, increasing the safety of the vehicle. In trucks, the front and rear side members take the impact.

Design features and types

Heavy-duty vehicles and SUVs use a frame-based load-bearing system. This is due to the increased load. In such structures, the spars are located parallel to each other along the entire length. Solid elements are connected to each other by special jumpers. Due to the unique shape of the frame, drivers often call this design a “ladder”.

Spars in a car frame

In modern passenger cars, the load-bearing part is the body itself. Therefore, the side members are already integrated into the body structure and are part of it. They can be either solid or separate and must be installed in the front and rear, although there are designs without rear load-bearing elements. The rear side members do not carry as much load as the front ones.

Solid side members can also be used in a monocoque body. This has its advantages. The structure becomes more rigid and reliable, but has a complex shape. This affects manufacturing technology.

Thus, spars can be divided into two types:

- composite;

- whole.

If the advantage of solid ones is rigidity, then composite ones are more practical. In a collision, the side members are most often damaged. They bend and break. It will be easier to replace the components with new ones.

Spars

In turn, much depends on the geometry of the elements. Additional bends increase the strength of the structure during a side or front impact. Curves also improve vehicle maneuverability and wheel steering angle.

Main types

The spars are installed in different positions, which depend on the type of car:

- Parallel and horizontal.

- Horizontally and at an angle.

- Curved elements arranged vertically.

- Curved power beams placed horizontally.

Horizontal parallel beams are installed on trucks, while on SUVs they are placed at an angle, due to which the steering axis of the wheels is larger. Elements curved vertically allow the car's center of gravity to be lowered. The vehicle's horizontally curved side member improves passive safety in the event of a side impact.

The low susceptibility of side members to destruction does not guarantee complete safety. Problems still exist, including:

- A significant problem with the classical design is the vehicle's susceptibility to fatigue. All metal loses most of its strength after 10 years, even without visual damage. In appearance, the spar may be durable, but in terms of technical characteristics it is significantly inferior to the new one;

- severe deformation of the side members when involved in an accident; in the future, the car loses performance even when this component is repaired. It is not uncommon for engine and suspension components to become dislodged after an accident;

- the complexity of the repair is due to the specifics of the design. Channels that have built-in accordion elements or have a variable cross-section are not publicly available. If the device breaks, it will be impossible to return to its original strength except by replacement. If you get into an accident, you must check for damage to the load-bearing part of the car, even if the condition is visually satisfactory.

Rotten spar

The method of repair is determined based on the extent and type of damage. The easiest way to replace the side members is in the frame structure; they can be removed with a minimum amount of additional work. If it is the basis of the load-bearing part of the body, it becomes difficult to replace, and sometimes it is impossible to change it. In older cars, the cost of work is such that replacing the side member becomes pointless.

After particularly severe accidents, pulling out the spar becomes impossible; the only way out is replacement. If any of the replacement stages are not followed - selection, welding, fastening, etc. - a repeated breakdown may soon occur.

Causes and consequences of deformation

Over time, the metal, under the influence of variable loads, succumbs to the effect of fatigue - cracks form on it. After ten years, the seemingly strong structure weakens and loses its former endurance. Neither nitriding nor chemical-thermal treatment helps. When a car gets into an accident, the side members are severely deformed, simultaneously worsening the overall technical characteristics of the car. It is possible that the engine, suspension and transmission parts may be displaced. And the entire body loses its inherent strength and geometry when the spar bursts. That is why, when inspecting a car on the secondary market, a specialist first checks these parts.

It is easier to restore the frame structure. On load-bearing structures, things are much worse: here the spar acts as part of the body, and in particularly unfortunate cases, changing it is pointless or simply impossible.

Bend over time

The spar can be repaired with a slight, not sharp bend. For this, a hydraulic stretching machine or winch is used. A sharp bend with an acute angle is already a loss of the basic shape. Such an element is almost impossible to restore: it is more advisable to replace part of the pipe or the entire beam.

Buckling of a straight bar is a known problem in engineering. The rectilinear shape loses stability over time.

If the side members are bent after an accident

The parts simply become wrinkled and lose their original shape. If the spar is not bent too much, it can be straightened on a slipway or caroliner. If it bursts from an impact, there is no point in repairing it. The only option left is overcooking, partial or complete. The old part is cut off with a grinder, then a new piece of pipe is installed. Anti-corrosion treatment of parts and painting are required.

Along with the side members, after an accident, such parts of the body as door connectors and fenders suffer, the position of the suspension and engine changes, the shape of the suspension is disrupted, and cracks form on the outer part of the body.

Crack or complete break

Small cracks and minor damage can be repaired. A welding machine will help in this case. It is necessary to carefully weld the cracks if the parts are not aluminum or titanium: such spars are difficult to weld.

A complete spar rupture is bad. The entire body structure suffers, especially the load-bearing type. More often than others, the front side members of the car are damaged beyond repair.

Characteristic

What is a spar? This word comes from the French longer, which translates as “to move along.” The spar is the main strength element of the body, which is located along its entire length. It is worth noting that this concept is found not only in the automotive industry. Spars are part of engineering structures such as bridges, carriages, ships and aircraft.

If we talk about a car, then this element lies along the entire length of the car. There are only two spars in the body. They are the ones that replace the frame. These elements are connected using jumpers. Suspension elements, an engine and other parts are also attached to the structure. Due to this structure, the car spar is called a ladder frame in motorist circles.

Repair and replacement of spar

In the event of an accident, specialists first inspect the spar to make sure that it has not moved out of place. No wonder. If this happens, then it is impossible to straighten, stretch or strengthen it with your own hands. The spar can be corrected only at a specialized body inspection and straightening stand - a caroliner, by disassembling half of the car.

As practice shows, it is very difficult to reassemble it. Replacing a spar with another is also not easy. But in the conditions of a regular car service it is impossible. In simple words, a cracked spar is a death sentence for a body that no longer meets reliability requirements. Editing, straightening and stretching of the car spar in a car service occurs when the spar is slightly deformed or bent.

Tasks of spars

The spar in a passenger car serves as a reinforcing part for the underbody, mudguards and luggage compartment floor. In large cars it acts as the main strength element of the body. In addition to its reinforcing task, the front spar acts as additional shock absorbers - it is located in the deformation absorption zone.

To ensure that vibration spreads evenly throughout the body, engineers create “deformable” zones in its front parts. In the longitudinal direction they have a weak force structure. Now passenger car manufacturers are trying to make it as thin as possible: they reduce the thickness of the section or walls, create special holes in the “safest” places where less load is applied.

Designers also use folds when stamping parts. They are needed so that during an accident the spar folds into an accordion and does not break. In a collision, the side members take the brunt of the impact, which is why they are often deformed. But such a sacrifice is justified: due to the absorption of kinetic energy, the force of the impact on the cabin is reduced. In trucks, both the rear and front side members suffer.

What are they for?

The parts are made of very hard metal and can withstand heavy weight. They absorb shock loads and vibrations received by the car when moving on various roads. Spars are needed to strengthen the elements of the bottom and floor of the trunk (passenger cars) or to completely take on all the loads (trucks, frame SUVs).

Another function of the side members is shock absorption. By taking on vibrations, the part distributes the load across all parts of the machine. Pipes effectively absorb deformation distortions. Therefore, they are made as rigid as possible, but not everywhere. In fact, a modern spar is a structurally very flexible unit with programmable deformation zones. Otherwise, it would not soften the shocks, absorbing them, but transmit them to the cabin.

Thus, the side members of the front part of the car are specially made with a greater ability to deform. Thanks to this, during a collision, the parts absorb the destructive shock wave, preventing it from going further.

Problems related to spars

Under the influence of loads, the side members still deform over time, especially the front one (the load from the engine and its systems) suffers. Just like the front ones, the rear ones can crack and get tired. The word “get tired” implies the initiation of a crack, which over time grows throughout the entire part. Of course, an accident can also leave a significant mark.

What does operating a car with damaged side members entail? Some parameters of the car are violated: slightly, but the position of the doors, connectors of body parts, and the position of the power plant changes. The suspension geometry also suffers. Due to all these shortcomings, the car's handling is reduced. Therefore, if the body is damaged, you need to take the car for diagnostics - this decision will be correct.

If the spar completely bursts, then the entire body structure will be completely destroyed. It is because of this that after an accident, experts look at the degree of deformation of these elements. The position in which the side members are in the car also plays an important role.

Rotten spar

It happens that the side members of a car are in such a state that the only option left is replacement. Changing parts entails a significant change in the properties of the entire body. After all, the shape, material and weight are calculated by the manufacturing company - in automotive centers you have to improvise. When the main parts of the spar are in good condition, a partial replacement is performed using arc gas welding.

When making repairs, you must insist that the new spar is no larger in size and weight than the old one. Some people prefer to harden a new one, but one must remember that such a decision may lead to a loss of shock-absorbing properties upon impact. Constant blows will lead to more serious consequences. Do not forget that in the event of an accident, the side members are checked first, and then everything else.

Repair features

In most cases, problems with the front side members are addressed; the rear side members are not deformed so often. Bent elements are “pulled out”. This is done using a special installation. The difficulty also lies in the fact that you have to disassemble most of the car. Remove the engine, suspension elements, bodywork, etc. Not every master takes on such complex repairs.

If the spar has burst, but the main part is in good condition, then repairs can be done with welding work. In this case, it is worth keeping in mind that even after high-quality welding, it will no longer be possible to achieve the previous state of these elements. The strength will decrease precisely at the seam location. In frame structures, replacing these elements is much easier.

In some bodies, the side members are attached not by welding, but by brackets. This also makes repairs easier since it is easier to replace the part. But if the elements are severely damaged or bent, then there is often no point in repairing them.

Some drivers try to strengthen the side members in advance by adding additional stiffeners. In this case, you need to understand that the part loses its shock-absorbing properties.

Spars are one of the most important parts not only of the body, but of the entire car. They may be hidden in the depths of the body, but do not forget about their significance. They play a big role in the safety and controllability of the car. If these important elements become deformed, you should definitely contact a car repair shop to avoid possible costly repairs in the future.

Possible faults

For the manufacture of spars, only special aluminum or titanium alloys are used. The strength of the structure is very important, since the elements are subject to constant loads.

Over time, such exposure can lead to their deformation. During operation, microcracks may appear on the metal. This effect is often called metal fatigue. Damage, bends and cracks can affect changes in body geometry and many other parameters of the car. For example, the wheel alignment angles will change, an incorrect gap will appear when closing the doors, various kinds of squeaks in the cabin, and so on.

Also, these important elements can be deformed during an accident. These are the most common cases. Bending of the side members threatens serious repairs, or even complete disposal of the body. Cracks and gaps appear, and the geometry of the body is disrupted. In this case, it is unsafe to operate the car. Even repairs do not always give the desired result. Due to geometry violations, tire wear will most likely increase and the factory steering settings will be disrupted.

Deformation zone of side members

On the other hand, side members also belong to passive safety elements. They have zones of programmed deformation. In the event of an accident, the part will bend exactly in this place, taking away part of the impact energy.

Advantages and disadvantages

The main advantage of this structural element is the creation of the proper level of rigidity with relative weight.

Due to the fact that the car is not burdened, its performance in terms of handling and other important characteristics increases significantly.

Very high passive safety is also ensured . However, when using this design, you may encounter several disadvantages, including:

- The mutual connection with the spar means that if the body is damaged, then all the parts that were attached to the spar are also damaged.

- Due to the design features, you should be prepared for the fact that the spars cannot be repaired, but simply require replacement in case of failure , so you should choose high-quality and reliable materials for its manufacture and be prepared for the fact that if the spar takes over impact, other parts will also be damaged.

Causes of damage

As we have already found out, the spar absorbs the bulk of the shock absorption when driving; manufacturers specially develop special designs for this part so that it absorbs all the kinetic energy and takes on the entire impact force in an accident. But even if the car has never been in an accident, the spar may crack over time from driving on our roads.

If you notice that the car is starting to pull sideways, or the doors are not closing well, the rubber is rubbing against the body - these are the first signs that the spar is cracked or misaligned. But don’t panic, how to pull out the spar is described in this article, and you can solve this problem yourself or turn to the services of a car repair shop. In today's article we will look at the method of drawing out a spar with our own hands using the example of a VAZ car.

Spar deformation

To damage or bend the spar, it is not necessary to make a head-on collision at “crazy speed”; this can also happen in a light collision, as a result of which the entire car body changes its geometry.

Preparatory work for replacing the VAZ 2109 spar

Since spar replacement and repair are carried out using the same technology, the set of tools will also be the same.

If you nevertheless decide to repair the side member on a VAZ 2109 yourself, first you will need to acquire the following tools for the job:

- welding unit (the most convenient and simplest option would be semi-automatic welding);

- grinder and discs, hard metal brush for the grinder;

- a set of new side members and connectors for the VAZ 2109;

- grinding tool;

- electric drill;

- metalworking tools;

- packaging of automotive mastic;

- 2 medium-sized paint brushes;

- can of primer;

- bottle of solvent.

Varieties of modern spars

To begin with, it should be noted that the installation of load-bearing structures in a car (the photos we offer will help you understand this) is carried out in a variety of positions. This mainly depends on the make and model of the machine and its technical characteristics. The following locations of spar structures can be distinguished:

- horizontal elements located parallel to each other - this design characteristic is typical for vehicles with increased cross-country ability

- curved elements that run along the bottom and follow its contour - in this case, the supporting structure increases the passive protection of people in the cabin;

- elements located vertically - in this way, designers achieve a “flat” floor, which is significantly lower compared to classic automobiles;

- elements located at an angle.

A design feature of almost all spars is the presence of diameters. These are peculiar stiffening ribs of body parts. At the same time, transverse elements can also be placed in different ways:

- perpendicular to the main elements of the spar structure;

- have an X-shaped pattern;

- K-shaped design.