What does code P0343 mean?

P0343 is triggered when the engine control module (ECU) receives a faulty signal from the camshaft position sensor (CPS).

A common cause is a faulty camshaft sensor or damaged wiring. The DPRV is installed on one of the camshafts. P0343 is a common trouble code that has been used by all automakers since approximately 2000.

Some engines have multiple camshaft position sensors. Since the camshaft must be in sync with the crankshaft sensor when starting, a common symptom is that the engine will be hard to start or not start at all.

The four-stroke crankshaft rotates two revolutions per cycle, and the camshafts rotate one revolution per cycle. Older cars usually do not have a camshaft sensor, but only a crankshaft sensor. This is because older cars don't need to know what RPM the crankshaft is at.

Each cylinder is supplied with ignition and fuel once every two revolutions of the crankshaft. To do this, the DPRV is used to determine whether the cylinder is in the intake or combustion cycle.

In older cars without a camshaft sensor, the spark plugs fire twice per revolution, this is called "wasted spark." Thus, to avoid firing the ignition coils twice per revolution when only one is required, a camshaft sensor is used.

Chevrolet Niva error codes: decoding and description of meanings

The popular Russian-made model is very widespread in the CIS countries due to its optimal cost and increased cross-country ability, which is critically important in the conditions of domestic operation. Motorists buy cars for off-road travel and small towns, where the quality of roads leaves much to be desired.

The disadvantages of the car include weak wiring - when the load increases to the design limit, on-board electronic systems often fail, which causes software failures. Chevy Niva error codes appear on the dashboard display or are detected using special equipment, but the common thing is that they all indicate a malfunction of a specific component.

Chevrolet Niva error diagnosis

The most reliable way to identify what is wrong with a car is to diagnose electrical appliances and equipment. The procedure allows you to accurately identify breakdowns and quickly repair your car.

There are two ways to detect a problem in a car.

The simplest procedure allows the motorist to independently identify the damaged area and repair the damage. Thanks to the successful firmware of the on-board computer, some errors are displayed on the standard display. In this case, nothing happens on its own - you will need to perform several steps manually:

- turn off the engine and turn off the ignition;

- find the daily mileage reset button on the dashboard and press it;

- at the same time turn the key in the starting cylinder;

- if everything is done correctly, all the indicators on the dashboard will light up, and the instrument arrows will make a full circle and return to their place;

- at the same time, the firmware version of the on-board computer will be reflected on the built-in display;

- The next press of the key will display a network error.

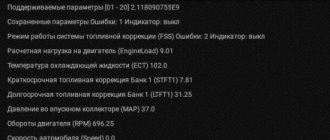

If the manipulations are correct, one of the indicated codes will appear on the display, and each Niva Chevrolet error number will be responsible for its own section of the highway:

- 0 – error 0 Niva Chevrolet indicates that there are no problems in the on-board circuits; most likely, the breakdown is purely mechanical in nature;

- 1 – standard error of the Niva Chevrolet ECU – the processor is not working correctly;

- 2 – for a Chevrolet Niva, error 2 indicates a lack of power to the gas tank float;

- 4 – malfunction of the battery or generator; a critical excess of the rated voltage of more than 16 volts was detected in the on-board circuits;

- 8 – has the opposite meaning; on a Chevrolet Niva, error 8 indicates an excessive voltage drop in the wiring due to a deep discharge of the battery or a malfunction of the generator;

- 12 – error 12 Chevrolet Niva reports a breakdown of the control indicator;

- 13 – signal transmission from the lambda probe is disrupted, you need to check the device and main power lines;

- 14 – on Niva Chevrolet, error 14 indicates a critical antifreeze temperature, the system requires cooling, otherwise the power unit may boil;

- 15 – the motor is too cold for normal operation, usually the error disappears after a good warm-up or replacement of the sensor;

- 19 – malfunction of the DPKV, the encoding indicates an incorrect speed of rotation of the unit;

- 21/22 – the throttle position differs from the calculated values up/down;

- 23/25 – the air mixture on the intake manifold is excessively cooled or overheated;

- 24 – open circuit of the speedometer, accompanied by a lack of response of the instrument needle to the driver’s manipulations;

- 27/28 – incorrect display of the actual amount of exhaust from the calculated value;

- 33/34 – Mass air flow sensor, the indicators of the device are overestimated or underestimated, relative to the actual state of the system;

- 35 – incorrect operation of the engine at idle, you need to check the correctness of the mixture formation settings;

- 41 – the phase distribution sensor or DPRV has detected an open circuit or the data received is erroneous;

- 42 – multiple misfires were detected, the system turned off the fuel supply to the damaged cylinders;

- 43 – the detonation channel sensor generates an error;

- 44/45 – fuel mixture is too rich/lean; you need to check the fuel lines for mechanical damage;

- 49 – the vacuum gauge is out of order or overloaded;

- 51 – ROM has failed, or there is a breakdown in the power cables;

- 52 – RAM is not working correctly, damaged, no power;

- 53 – the adsorber purge valve is faulty;

- 54 – octane corrector controller is de-energized or broken;

- 55 – the calculated load on the internal combustion engine differs from the established one;

- 61 – the oxygen quantity controller in the intake system transmits incorrect data to the computer.

Troubleshooting table for P0343

| Error | Description | Causes | Elimination |

| P0343 | The camshaft position sensor circuit is high. | Camshaft sensor malfunction. |

Damage to the 5V power wire from the control module (ECM).

Corrosion/poor connection in sensor connector.

Faulty ground wire to ECM.

Short circuit of the power and ground wires.

Low battery voltage / faulty alternator.

Repair any damage to the wiring between the camshaft sensor and the control unit.

Clean the sensor from oil.

Clean the sensor connector.

Replace the camshaft sensor.

How to Diagnose Trouble Code P0343

This is a guide on how a professional auto mechanic would diagnose a P0343 code. This may require some skill in vehicle wiring and the necessary tools. You will receive information on how to do everything correctly, without replacing faulty parts.

Always connect the car charger when troubleshooting. Low voltage can cause other error codes and even damage control units.

If you do not find any damage to the wires or the DPRV, then it may be a faulty engine control unit. But this happens really rarely. Before replacing the control unit, make sure you check everything else as they are quite expensive.

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

Error p0340 is defined as a malfunction of the camshaft position sensor circuit (in English - Camshaft Position Sensor A Circuit). It can occur for various reasons - when the camshaft sensor fails, there are faults in its wiring, problems in the operation of the engine control unit (ECU). The error itself is not critical, and if it occurs, the machine can be used. However, some inconveniences arise - increased fuel consumption, reduced power, etc. Eliminating the reasons why error code p0340 was generated is not difficult, and most car owners can handle it.

Error 0422

The efficiency of the Priora 16 neutralizer has fallen below the normal level - this is what error p0422 reports to the owner of the Lada Priora 16 valves. As practice shows, codes 0422 pop up quite rarely. If code 0422 appears on the on-board computer screen, then you need to perform the following steps:

- We examine the catalytic collector. Its body and filling must be in good condition;

- If damage is found, the catalytic collector should be replaced with a serviceable one;

- If the catalytic converter is not the cause of the message, then the remaining actions to eliminate p0422 must be entrusted to specialists from the service center.

To get rid of 0422 you will need to reflash the cathode collector. If you have the equipment to set the settings, you can do the work yourself.

Operation of the DPRV sensor

First of all, you need to decide what a crankshaft position sensor (abbreviated as CPS) is, what it is needed for and where it is installed. The main function of this device is to determine the position of the camshaft at a specific moment in time. The relevant information is transmitted to the electronic engine control unit (ECU) so that it programmatically calculates the timing of fuel injection from each injector. This ensures the so-called phased injection. If its operation is disrupted, the control unit automatically goes into emergency mode, in which pair-parallel injection is provided instead of phased injection. This leads to excessive fuel consumption and loss of engine power.

To resolve the P0340 code, it is also important to know the location of the sensor on the engine. This is relevant from the point of view that in the event of such an error, additional diagnostics of the DPRV and/or its wiring are most often performed. So, on eight-valve engines, the sensor is usually located at the end of the cylinder head, closer to the first cylinder. On sixteen-valve engines, similarly, it is also installed on the cylinder head, in close proximity to the first cylinder. Its close location to the first cylinder is due to the fact that on gasoline engines the sensor records the position of the piston of this cylinder at the so-called top dead center. On diesel engines, the position of all pistons is recorded.

Signs of an error

There are a number of indirect signs by which you can determine that there are problems with the camshaft position sensor or its wiring. The situations described below may indicate other breakdowns, so if they occur, additional diagnostics with an error scanner (for example, the popular ELM 327 device or its equivalent) is needed. So, when a sensor error p0340 occurs:

It is worth noting that the listed changes in the behavior of the car are not so relevant for engines running on gasoline. The loss of power and increase in fuel consumption are not so great. The only inconvenience that can be noted is that the car starts worse, you have to turn the starter for a long time.

But as for cars equipped with gas-cylinder equipment, here the problems described above can manifest themselves “in full.” The loss of power and increase in consumption will be significant. Another trouble will await owners of cars that have modern gas equipment installed, in particular the fourth generation. So, this equipment has its own electronic control unit. And if a phase sensor error 0340 occurs (as the DPRV is sometimes called), there will be a constant disruption of the operating parameters. Because of this, gas-cylinder equipment, firstly, will need to be constantly reconfigured, and secondly, despite all the adjustments, it will still work in a non-optimal mode, consume more fuel and cause the driver problems with loss of power of the car, constantly stall and etc.

Errors 0343, 0340 and other symptoms of a malfunction

In addition to reporting these errors, a malfunction of the sensor can be indicated by increased fuel consumption, a sharp decrease in dynamics, the inability to perform engine self-diagnosis, and sometimes the engine may refuse to start.

However, the Check Engine icon may light up even if the sensor is completely out of order and the diagnostic system simply does not identify it . Therefore, there is a danger of using a faulty sensor for some time, and this will not lead to anything good.

That is why it is worth checking the sensor at the first appearance of suspicious symptoms. The point is also that the injection system is guided by this sensor when the timing of fuel supply is calculated, and a failure in this system threatens not only increased fuel consumption, but also a drop in power and instability of the engine. The price of the sensor, regardless of the number of valves in the engine, rarely exceeds 600 rubles and depends on the manufacturer.

Judging by the reviews of the owners, the original Bosch devices performed best.

How to check the phase sensor on a VAZ-2114 with a multimeter

It is clear that hardly anyone keeps a professional laboratory oscilloscope in the garage. Only on the balcony. Therefore, we will make do with a less complex device that every motorist should have - a multimeter . The testing technology is simple and straightforward, but depending on the type of engine, it differs somewhat. We check the sensor on an eight-valve engine:

- To check, it will be necessary to measure the voltage in the on-board network and make sure that it is normal when the ignition is turned on.

We measure the voltage in the on-board network

- Now we connect the probes to contact E on the sensor and to contact B. The voltage should not change, which means that voltage is supplied to the sensor.

Using a multimeter we measure the voltage at the contacts of the phase sensor

- After this, we bring a metal object to the sensitive element of the sensor, look at the multimeter display, the voltage should drop to 0.4 V. Any error indicates the sensor has failed.

We bring a metal object to the sensor and measure the voltage

For a 16-valve engine, the test is the same, only you need to measure the voltage between the negative terminal of the sensor and terminal B. The voltage drop should also be 0.4 V when a metal object is in the sensor field and 0.9 V when the object is removed.

The on-board computer may show two errors related to our sensor:

- error 0340 , which indicates the physical absence of the sensor, which means that there is no voltage supplied to it or the sensitive element has failed;

- If error 0343 , there is a high probability that the sensor pulse level is too high, which may be due to lack of contact at the terminals or damage to the signal wiring.

Replacing a faulty sensor is carried out quickly, without noise and dust; just turn off the power to the car and unscrew the fixing bolt.

Then you should check the cleanliness of the contacts on the block and install a new device. Immediately after replacing the sensor, the error messages should disappear. Good luck with all the repairs and stable phases!

Reasons for the error

There are only three main causes of engine error p0340:

Sometimes the cause of error p0340 is incorrect installation of the sensor. However, this is a rather rare case, since it only has one seat. Perhaps the fastening is not strong enough (small tightening torque, which is why the sensor can vibrate when driving) or there is a large gap between the working (sensitive) part of the sensor and the so-called rapper - a tooth on the indicator wheel located on the camshaft.

How to get rid of error p0340

Methods for getting rid of malfunctions that caused the formation of error p0340 (malfunction in the camshaft position sensor circuit) depend on the causes of their occurrence, as well as the specific car model - for example, Nissan, Ford, Chevrolet, Opel, Toyota. , VAZ (in particular, VAZ 2114). However, the general verification algorithm will be as follows:

Scheme for checking the PRV sensor

Finally, it is worth noting that when identifying malfunctions of the camshaft sensor, it makes sense to check the operation of the crankshaft sensor, since these shafts work synchronously, and if there is no signal from the camshaft sensor, then the ECU uses signals from the crankshaft sensor. It is necessary to check whether there are any errors in the memory of the electronic engine control unit regarding the DPKV, and also, if possible, inspect its mechanical condition and wiring (similar to the DPKV).

Chevrolet Niva error reset

The standard procedure for resetting the controller occurs only after all faults have been completely corrected, otherwise annoying encryption will appear again. The procedure is performed in two available ways.

- Disconnect the battery from the on-board network for 10-15 minutes. The controller will completely reboot and return to factory default settings.

- In the BC menu, enter the “errors” service, press the daily mileage reset button and wait for the sound signal from the car, and horizontal lines should appear on the display.