Nissan primera p12 won't start, no errors

The Nissan Primera is a reliable car, but despite this, the risk of being unable to start the engine still exists.

The reasons for this problem can be very different. Some problems can be easily fixed with your own hands, but solving some problems may require a diagnostic scanner or other special tools.

Starting and problems in cold weather.

HOORAY. Congratulate me - it started.

I acted like this - I bought Benz 92, a syringe, and cut a tube in my garage. the candles were unscrewed. I poured a little gasoline into each pot, to clean it, so to speak, and to make it smell like gasoline. then I pumped out all this poop with a syringe and a tube (it was completely unsuccessful - it was problematic). Then the tube fell into the canister during the next intake of gasoline with a syringe, I screwed on the candles and started it a couple of times - some attempts to grab it appeared. I unscrewed the spark plugs - one was dry (she was probably wooing her), the rest were flooded. the pots became drier—you could only see gasoline in one. I screwed on the old candles (which I pre-heated a little at home) and when I got used to it, it started to catch on. Against my common sense, I press the gas and, lo and behold, it starts up and puffs. this and that - it worked. Of course it smoked from the silencer. Mom, don’t worry, the auntie watchman must have gone nuts, he warmed up the engine a little - it doesn’t work very well - it adjusts it from time to time. I unscrewed the spark plugs (old ones), screwed in the new ones (cleaned ones), the engine started up right away, the operating mode was smooth. on Tonchik's advice, I went to a gas station (Shell) and filled up with 10 liters of 98. and went to roll it in and warm up the whole thing after it had settled. And now about the sad thing - starting in this manner resulted in a burning Check Engine light - I think the error appeared after starting with the gas pressed and adjusting - the task is to determine whether it is an old error or a current one, I read here that you need to remove the terminal for at least a day, who I threw it off and why for a day, for more details please, otherwise I need to go to the service center. and also how catalysts or lambda probes relate to my experiments.

Security system and its influence on car starting

The Nissan Primera has a standard security system in the form of an immobilizer. The car owner has the opportunity to further protect the car by installing a purchased car alarm. If it is not installed correctly or one or more components malfunction, a situation may arise when the engine does not start.

Problems that arise with the security system are usually of a physical or software nature. The first involves sticking or breaking the contacts of a mechanical relay or other automation elements. Software failures manifest themselves as errors in the “brains” of the alarm system.

For diagnostic purposes, it is recommended to completely remove the installed security system. After this, carry out a test start of the engine. If it was successful, then the fault should be looked for among the car alarm units. It is important to check each module, as well as the correct connection.

A typical malfunction of the Nissan Primera, which affects engine starting, is souring of the antenna and immobilizer contacts. To fix the problem, car owners are advised to remove the chip from the module and fill everything with contact grease. If there are oxides on them, it is recommended to pre-clean them.

Starting and problems in cold weather.

THAT'S WHY . IF THERE IS A STORE NEARBY WHERE THEY SELL CANDLES AND FILTERS FOR FOREIGN CAR ALL.. RUN THERE (THEY 90% OF THE CASES) SELL NGK CANDLES. You need to buy them. lighting process. First of all, get yourself high-quality copper wires for “lighting” and carry them in the trunk. Having waited for the first opportunity to “light up” from someone else’s car or let the victim “light up”, proceed in the following order: 1. Make sure that the cars are close enough so that the wire length is enough, both batteries are 12-volt and both have a ground - one from the battery contacts must be closed to the car body. 2. Remove the insulation from the contacts and connect the red wire to the contacts with the plus sign on both batteries. 3. Connect one end of the black wire to the negative terminal of the car with a charged battery, and the other end to the body of the car with a dead battery. 4. Start the engine of the operating vehicle and leave it idling. 5. After a minute, start the car with a dead battery and wait until the engine warms up. Stop both engines and carefully disconnect the wires. Ready!

The second point is of course funny, but on the whole everything is correct. I will emphasize the main points: 1. First you connect “+”, then “-“. Disconnect first “-”, then “+”. 2. Never disconnect/connect wires while the engine is running on any of the machines. Otherwise, there is a high risk of damaging the electronics.

95 is usually full of additives, which is not very good in winter. At the station where they started me, bad gasoline is considered one of the main reasons for poor starting in the cold. They gave the following example: that on one of the cars they had to remove the fuel tank from which they then took out the “porridge” mixture of gasoline and ice.

To prevent this, alcohol is poured into the tank.

150-200 gr. for a full tank. The frequency of filling depends on: 1. On the rate of condensate accumulation in the tank (the more often the tank is full, the less). 2. On the degree of presence of water in the gasoline itself from the gas station (depending on how diluted it was)

)

Last edited by ROW111; 01/24/2010 at 10:22 am.

Battery problems

If the Nissan Primera does not start, it is recommended that you first pay attention to the battery. When it is discharged, starting the power unit is impossible. This is due to the fact that when the starter motor is connected, the on-board voltage will drop below the permissible level. As a result, instead of successfully starting the engine, the car owner will hear the crackling sound of the retractor relay coming from the engine compartment of the Nissan Primera P12.

Most often, problems with a used or discharged battery occur in winter. This is due to the fact that motor oil thickens in cold weather. This makes it harder for the starter to crank the engine, so it consumes increased starting current. The battery has poorer performance in the cold season than in the summer heat. Its starting current and energy output are reduced. The superposition of these factors on top of each other leads to complications in starting the engine and even the impossibility of starting the engine.

To solve the problem with a discharged battery, it is recommended to use one of the following methods:

- start the power plant “by lighting” from another vehicle;

- recharge the battery with a nominal or increased current using a charger;

- start the power unit using ROM.

If the battery runs out once, you can solve the problem by recharging the battery. If the battery discharges constantly and quickly, then it needs to be diagnosed. Based on its results, a decision is made on the advisability of repairing or replacing the power source. Experienced car owners recommend that if the battery has a significant service life, replace it with a new one without trying to restore it.

If the diagnostics show that the battery is fully operational, but the problem with its rapid discharge still exists, you need to check the on-board network. During inspection, a short circuit or significant leakage current is usually detected. If they are identified, you should promptly begin troubleshooting. Otherwise, there is a high risk of the Nissan Primera catching fire.

The presence of mechanical damage to the battery case leads to loss of electrolyte and a decrease in the starting current output. To monitor the condition of the battery, it is important to visually inspect the battery. If through cracks and other damage are detected, it is recommended to install a new power source to replace the old one.

Starting and problems in cold weather.

Read possible solutions for non-starting in cold weather here ROW111

Preventative measures to improve the launch of 2.0 QR20DE in winter from Moroz

-A.

We need a set of measures or change the car. What would I do, as the owner of a car with a QR20DE (I was one, but not for long, I didn’t drive in the winter) 1. Rewire the ignition coils, connect them to direct plus (via a relay and fuse) and minus. 2. Check the capacitor, if it is 0.47Mf, replace it with 2.2Mf 3. Spark plugs are iridium (LFR5AIX-11) or platinum (PLFR5A-11) 4. High-quality gasoline is required 5. Calcium battery with high starting current 6. Oil not thicker than 5w40, but it depends on where you live. 7. Put on the BN switch, turn off the car by turning off the pump. . These measures will make it possible to confidently start the car down to at least -25.

PS Ideally, for this internal combustion engine you need to install Webasto

2.0 won’t start, or dancing with a tambourine - recommendations from Joss

-A

So. As promised, I am posting the recommendations that I sent yesterday in a personal message to serginio404 Initial data. We have - QR20 frozen two days ago at -20. Semi-synthetic oil 10W-40 crankshaft is difficult to turn, spark plugs are flooded. There is a 2 kW fan heater, 10 meters from the outlet, the car has been sitting outside for three days. Sergey, the procedure is approximately this. DISCONNECTING THE FUEL PUMP (fuse or connector under the rear seat) 1. Place the fan heater on the pan (bottom of the engine) to warm up your 10W-40. since the car is on the street, it is better to cover the engine compartment with a blanket or film, whatever you have at hand. Close the hood, just make sure it doesn’t catch fire (I don’t know what kind of fan heater you have) 2. Unscrew the spark plugs, dry them, and clean them. 3. Spin for 5-10 seconds so that the gasoline flies out of the pots. 4. Use a syringe to fill each pot with 5 grams of motor oil. 5. After 5 - 10 minutes, turn again for 5 seconds so that the cylinder mirrors are covered with oil and compression appears. CONNECT THE PETROL PUMP 6. Tighten the spark plugs and God bless you, start it. 7. After you start it, change the oil to a thinner one (I drive synthetic AMALIE 10W-40 in the summer, AMALIE 5-W30 in the winter), and NGK iridium or platinum spark plugs.

The winter before last I had a situation exactly like yours now, the only difference is that I didn’t have a 220 nearby and had to tow it 3 km into the heat. Do not worry, everything will be fine. Alexander. Result. The engine started in -23 attempts on the fifth, sixth (according to Sergei) I think that this method is applicable in extreme conditions, it is better, of course, to warm the car up.

Tags: condenser, conder, frost

Last edited by Moroz; 12/17/2012 at 12:34 pm.

Source

Nissan Primera won't start in cold weather

But who notices this? Everything is attributed to the cold, starter, battery, engine, and then they pulled it into a warm box and everything started working... Yes, until the next cooling.

There will be many letters and few pictures. For those who don’t like to read, I’m sorry... Every year with the onset of cold weather, history repeats itself. Dozens of posts appear about cars that refuse to start in the cold, and after the first unsuccessful attempt, it is almost impossible to revive the car.

These records have gained notoriety for this car brand.

Nissan Primera won't start

Is it really that bad? Let's try to figure it out: Firstly, starting the engine in cold weather, and even in quite a bit of frost, predetermines increased requirements for all vehicle systems. We will not consider cars in perfect condition in terms of the engine, lubrication, fuel, electronic and cooling systems.

As a rule, such cars do not have starting problems. This is affected by the owner’s attitude, timely maintenance and preparation for the winter season.

The Nissan example won't start in the cold - excellent, we're just proud of it and move on to the group that - well, it's always a problem.

Nissan Primera P12 QG16. Doesn't start when cold.

Most often, oddly enough, this group includes cars made in Japan, Prouli, Yapiks with a 2 engine. These conclusions are based on the results of forums and communities on this model and mass requests with the question - it won’t start in the cold.

Starting and problems in cold weather.

Theme Options

I climbed the forums of Renoshnikov (Megan2 mainly), Ford (FF2), and Lancer lovers: with the onset of frosts below -20, the first complain about deformations on the roof, the second about the doors, and the third about the fact that they often do not start.

I wonder if Nissan Primera owners have similar problems. I inspected mine and found no paint or metal defects. starts up great.

Where is the capacitor located? If you look at the wires from the spark plugs, they merge into one common bundle, we go further along the harness from the spark plugs, there will be a thickening in it, rewound with insulation, that’s where it is located. You need to carefully cut the insulation and get to it.

it's right in the harness. behind the engine. go from the coils along the harness and you will find it!

And this is what he looks like. this is the number of the new capacitor with increased power

About non-factory Examples P12 - taken from the forum at www.******.ru from an author named Diagnostician. A completely reasonable explanation. Plus, incorrect adjustment of the throttle valve and temperature sensors are also discussed, but in any case, all ideas come down to incorrect formation of the mixture. Here's the explanation:

“As I already wrote, the problem is fuel. Now more details. Nissan, when releasing its cars, claimed that it was ready for EURO-5. This means that there are strict exhaust standards not only for a warmed-up car, but also during warm-up mode. Conducting experiments with their gasoline, they decided that for a cold start it is not necessary to pour gasoline into the cylinders in buckets, but you can pour a little, if it doesn’t start, add more, add more, and so on until there is enough enrichment for starting. This method is used on most modern cars that meet European toxicity standards. The enrichment of the mixture increases automatically when the starter cranks. The longer you turn the starter, the greater the enrichment. Let's assume that the initial enrichment is 15 msec. injection is designed for normal fuel, with volatility for a given temperature of 50%. If we have fuel with a volatility of 30%, then the mixture at first turns out to be lean. One more point: during startup, the injectors are not poured one by one, but all at once. This leads to the fact that out of 4 nozzle sprays, only one is picked up by the air flow and directed through the open valve into the cylinder. The remaining 3 are smeared on the walls of the inlet channel of the head and flow down onto the valve. Seeing the failure, the control unit begins to increase the injection time by 20, 25, 30 ms. There comes a moment when the enrichment is already sufficient for starting even on bad gasoline, but by this time so much liquid fuel has already accumulated in the cylinder that it simply floods the spark plug. Further scrolling will not help. The process of non-starting is aggravated by deposits on the intake and exhaust valves, in the combustion chamber and on the spark plugs from the same bad gasoline. As autocat wrote, the gasoline pan in the pan is up to the neck, i.e. the owner abused the engine and starter for a long time and persistently, trying to start it. I myself have seen more than once engines with two or three levels of oil from gasoline.

Tags: condenser, conder, frost

Yesterday I replaced the capacitor with my own hands, the replacement took only 2 minutes. I’m posting a photo of how I changed it and where?

The capacitor itself is where it is located, already removed from the wiring harness. the place where it is located (thickening in the wiring harness)

Nothing complicated! All that remains is to insulate it back.

It has been noticed from the experience of car owners. replacing the effect capacitor gives 0

I found it in the picture. finally. This infection (capacitor) is located on a left-hand drive car - on the box.

part under the letter N

In Japanese it is here:

Last edited by ROW111; 02/18/2011 at 12:58 pm.

Why won't Almera start?

- The starter has failed;

- there are malfunctions in the fuel system;

- no spark;

- the crankshaft position sensor is faulty;

- The mass air flow sensor (MAF) is not functioning or is not working properly;

Problem number one: broken starter. How to determine that it is the one that is faulty? If you open the hood and listen, then when you try to start the car, the Nissan Almera stater will make sounds characteristic of a running electric motor. If they are not there, then obviously the problem is somehow related to the starter. Stopping the starter can be caused by an alarm. Problems with it should only be resolved under the guidance of an auto electrician.

Problems with the fuel system can be of several types:

- The fuel pump has failed;

- fuel pipes or filter are clogged;

- injectors are not working properly;

- Condensation has formed in the tank.

Most often, it is the fuel pump that fails, since it works almost continuously, especially if the car is used daily. The second most common problem is clogged fuel pipes or filter, and this problem occurs due to low-quality fuel. In most cases, the injectors operate normally, but their failure is also possible due to bad gasoline. The presence of condensation in the tank will prevent the fuel from burning completely.

The lack of a spark can be due to two reasons at once. The most obvious is problems with the spark plugs, that is, large soot, an unnatural gap, damaged insulation or excess fuel. Diagnosing them is very simple: just unscrew the spark plug and conduct an external inspection. If there is soot on the tip, the gap does not correspond to the factory value, a crack is noticeable in the ceramic insulation, or the tip is wet, then the spark plug must be replaced. Also, to determine the “flooding”, you should inspect the spark plug channels. If fuel is visible at their bottom, you should inspect the mass air flow sensor and injectors.

Soot on Almera spark plugs is one of the problems due to which engine starting and operation become unstable

Another possible problem is faulty coils. Checking them is also very simple: just screw in a working, previously tested spark plug and try to start the Almera engine. If there is no spark, then the coils require attention. Important: before carrying out any mechanical work on electrical appliances, you should turn off the power to the car, that is, remove the terminals from the battery.

Diagnosing problems with the crankshaft position sensor is very simple: when you try to start, the Check Engine light will light up on the dashboard. This theory can only be confirmed or refuted at a service station, where there should be a special device for testing DPKV. If the car starts and stalls, the speed fluctuates or the power drops when the load increases, you should pay attention to the sensor.

The mass air flow sensor, or MAF, is a device that measures the air consumption of the engine. Problems with it can cause increased fuel consumption, detonation, or the inability to start the engine. Why? If the sensor is faulty, the system thinks that the car is consuming a lot of air. In proportion to it, the injectors increase the volume of supplied fuel. Accordingly, fuel consumption increases, detonation may occur, or the spark plugs are simply flooded.

How to start a Nissan Almera in cold weather - DIY car repair

› Almera

Nissan Almera has gone through several generations during its production. Of course, different power plants were used. Next, we will dwell in detail on modifications of engines of all generations of Almera.

GA14DE, GA16DE, QG15DE, QG18DE, QG16DE, K4M

Nissan Almera N15 engines

The first generation Nissan Almera was equipped with two types of gasoline engines:

On the second modification it was possible to choose a manual or automatic transmission. The GA14DE engine was combined with a manual transmission only.

GA14DE

The GA14DE is rusty in places, but the engine is over 20 years old

The GA14DE 1.4 liter power plant was produced with a cast iron cylinder block and an aluminum valve cover. The use of dual camshafts (D-DOHC) and a power supply system with multipoint injection were envisaged. The engine resource is approximately four hundred thousand kilometers.

Technical characteristics of the GA14DE engine:

- exact volume (cubic cm) – 1392;

- power (hp) – 87;

- torque (N/m) – 116;

- compression ratio – 9.5;

- number of cylinders – 4;

- valves per cylinder – 4;

- timing gear drive – chain;

- fuel - gasoline.

3-door hatchback before update

Let's look at gasoline consumption per hundred kilometers using the example of a Nissan Almera N15 with a five-speed manual transmission:

- 7 l – mixed cycle of operation;

- 9.2 l – movement within city limits;

- 5.8 l – driving on the highway.

Weaknesses and advantages of the 1.4 Almera N15 engine

The Nissan Almera N15 engine of the GA14DE modification has the following advantages:

- The service life of the chain drive of the gas distribution mechanism is more than 250 thousand kilometers.

- Low fuel consumption.

- Good characteristics.

- Long engine life, plus there is the possibility of major repairs.

THIS IS INTERESTING: Removing the Chevrolet Niva bumper

The disadvantages include:

- Over time, the engine begins to stall periodically. The disadvantage manifests itself due to clogging of filters, meshes, jets and other channels.

- Floating speeds are recorded due to failure of the idle air valve sensor or mass air flow.

- Excessive consumption of engine oil on high mileage units. The problem is associated with stuck oil rings, faulty caps and leaky gaskets.

GA16DE

The GA16DE engine used on the Nissan Almera N15 has the following technical characteristics:

- cylinder block material – cast iron;

- power (hp) – 90-115;

- exact volume (cubic cm) – 1597;

- torque (N/m) – 123-150;

- compression ratio – 9.5;

- injection - carburetor or injection;

- number of cylinders – 4;

- number of valves per cylinder – 2 or 4;

- timing drive – chain;

- fuel - gasoline;

- resource (thousand km) – more than 300.

Specific performance indicators for power, torque, injection and the number of valves per cylinder depend on the modification of the GA16 engine.

Fuel consumption

Almera N15 with 5-speed manual transmission - average gasoline consumption is 7.3, and within a populated area and on the highway - 9.3 and 6.1 l/100 km.

Nissan Almera N15 with 4-automatic transmission consumes gasoline:

- 8.2 l – in a mixed cycle;

- 11 l – in the city;

- 6.7 l - outside the city.

5-door hatchback after update

Advantages and disadvantages

The main advantages of the GA16DE engine when used on the Almera N15:

- reliability;

- unpretentious operation at subzero temperatures;

- availability of spare parts and consumables;

- Finding a contract engine is easy.

The disadvantages of the power plant include:

- Irrational ratio of volume and power.

- Increased fuel consumption during city driving.

- Periodic failure of the DMVR and IAC, which is accompanied by floating speed.

- After a run of 200 thousand km, there is an increase in engine oil consumption and timing chain stretching.

- Wear of the crankcase ventilation gasket leads to oil leakage.

Engines Nissan Almera N16

The second generation Nissan Almera (N16) used a one and a half liter QG15DE engine with a manual transmission, as well as a 1.8 liter QG18DE engine in combination with a manual transmission or automatic transmission.

Engine QG15DE

QG15DE was produced from 2000 to 2006 and had the following technical characteristics:

- exact volume (cubic cm) – 1498;

- cylinder block - made of cast iron;

- power (hp) – 90-109;

- torque (N/m) – 128-143 (like the previous indicator depends on the modification of the motor);

- compression ratio – 9.9;

- food – injector;

- number of cylinders – 4;

- number of valves per cylinder – 4;

- timing drive – chain;

- resource (thousand km) – more than 250.

QG15DE at implement belt side

Fuel consumption per 100 km of Nissan Almera N16 with QG15DE engine and five-speed manual transmission:

- 6.6 l – medium;

- 8.6 l – in the city;

- 5.5 l - outside the city.

Weaknesses of the QG15DE motor

When operating the QG15DE engine on a second generation Almere, you may encounter the following disadvantages:

- Timing chain stretches; breakage occurs less often.

- Clogged throttle valve or fuel pump mesh, which leads to difficulties starting the power unit.

- Periodically, the ignition coils fail and the engine begins to stall.

- Loosening the tension of the generator drive belt. The disadvantage is manifested by a voltage drop when the headlights are turned on, as well as belt whistling.

- Malfunctions of the injection system.

- Low catalyst life.

- The engine cooling circuit uses low-quality elements that fail over time.

QG15DE exhaust side

QG18DE

The QG18DE engine, produced from 1998 to 2006, is characterized by the following indicators:

- cylinder block material – cast iron;

- power (hp) – 115-128;

- torque (N/m) – 158-175;

- exact volume (cubic cm) – 1769;

- compression ratio – 9.5;

- food – injector;

- number of cylinders – 4;

- number of valves per cylinder – 4;

- timing drive – chain;

- the fuel used is AI-95 gasoline;

- resource (thousand km) – in the range from 250 to 300.

THIS IS INTERESTING: Replacing ball joints on a Chevrolet Niva

In the foreground is the intake manifold.

Fuel consumption per hundred kilometers driven by the QG18DE engine is presented using the example of a Nissan Almera N16 with a five-speed manual:

- 7.6 l – medium;

- 10.4 l – city;

- 6 l – track.

Design Features

The QG18DE engine has undergone significant changes in design compared to previous modifications that were used on the Nissan Almera. The piston stroke increased to 88 mm, with a cylinder diameter of 80 mm.

QG18DE at implement belt side

Hydraulic compensators are excluded, which is accompanied by the need to adjust the thermal clearances of the valves.

The emission of harmful substances into the atmosphere has been significantly improved thanks to the installation of dampers in the intake manifold.

Powerplant Almera Classic

The third generation Nissan Almera was equipped with a QG16DE engine with the following technical characteristics:

- exact volume (cubic cm) – 1597;

- power (hp) – 109 and 118;

- torque (N/m) – 114 and 165;

- compression ratio – 9.8;

- cylinder block - made of cast iron;

- number of cylinders – 4;

- number of valves per cylinder – 4;

- gas distribution mechanism drive – chain;

- resource (thousand km) – more than 350.

The power unit number QG16DE is stamped on the right side of the cylinder block and is highly susceptible to corrosion. To ensure its readability, apply a protective heat-resistant layer of varnish.

We will consider gasoline consumption on the following trim levels of the Nissan Almera Classic B10:

- With a five-speed manual transmission – 6.8 in the combined cycle, and in urban and suburban mode – 9.2 and 5.3 l/100 km;

- With a 4-automatic transmission - the average is 7.6, and on the highway and in the city - 6 and 10.4 l/100 km, respectively.

Weak spots

In principle, the QG16DE power unit of the Nissan Almera Classic is reliable. Disadvantages that appear with high mileage:

- Stretching the timing chain after overcoming the 150,000 km mark.

- Worn alternator belt and roller.

- Malfunctions of the electronic control unit.

- Failure of the catalyst.

Almera Classic power plant maintenance

The QG16DE engine maintenance process involves observing the following intervals for replacing consumables based on mileage:

- 15000 – oil and oil filter, spark plugs;

- 200000 – timing chain;

- 70000-80000 – attachment belts;

- 60,000 or after two years - antifreeze, the first replacement should be made after three years of operation or at 90,000 km.

Every fifteen thousand kilometers, you should check the condition of the thermal clearances of the valves. The air filter should also be changed annually.

Engine Almera G15

The fourth generation Nissan Almera uses the Renault K4M engine. It features a reinforced piston group. This is achieved by using a steel insert on the pistons where the oil scraper rings are installed.

The pins that fix the pistons are installed with a gap in the piston bosses, and they are pressed into the upper connecting rod heads with an interference fit. The connecting rods are made of forged steel, the cylinder block is made of cast iron, and the cylinder head is made of aluminum.

The design also provides for the presence of two lightweight camshafts.

Disadvantages of the Almera G15 engine

During operation of the K4M engine, the following disadvantages and weaknesses may appear:

- failure of the phase regulator, pump, crankshaft pulley, ignition coils;

- destruction of the crankshaft oil seal, cylinder head gasket;

- periodic contamination of the throttle valve.

K4M engine maintenance

Maintenance of the K4M engine involves replacing consumables after driving the following kilometers:

- 15000 – engine oil, oil and air filter

- 30000 – spark plugs

- 60,000 – replacement of timing belt and attachments

- 90,000 - the first replacement, then the antifreeze is changed every 60,000.

1 - crankshaft pulley, 2 - timing belt, 3 - tension roller, 4 - exhaust camshaft pulley, 5 - intake camshaft pulley, 6 - support roller, 7 - coolant pump pulley

How to check?

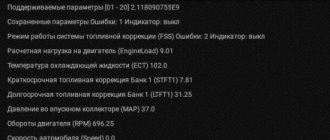

One of the main reasons to diagnose a Nissan car is the illuminated Check Engine icon on the instrument cluster. To read error codes, either a special scanner is used, connected to a connector in the vehicle’s on-board network, or a special self-diagnosis system. Deciphering Nissan error codes will allow you to identify the failed unit and carry out repairs.

On some Nissans, for example, the Sunny model, owners are unable to enter self-diagnosis mode. To read errors on them, an ELM scanner is used, which is inserted into the diagnostic connector. Error data is transmitted to a regular laptop or smartphone.

Auto Selection 24 RF shows in this video the diagnostics of a Nissan Murano.

Reading errors in self-diagnosis mode

Launching the diagnostic mode on the Nissan Primera P12 is done as follows:

- Turn on the ignition and wait 3 seconds.

- Press and release the gas pedal 5 times within 5 seconds.

- 7 seconds after the last press, fully press the gas pedal again and hold it for 10 seconds.

- If everything is done correctly, the Check Engine icon will start flashing on the Nissan Primera P12 instrument cluster.

- Release the gas pedal.

- The blinking icon indicates error codes in four-digit format. The first digit of the code is shown in long flashes, followed by the digits of the second character, etc., which are shown in short flashes. There is a 2 second break between the display of numbers. The number of flashes is equal to the value of the number in the error code, except for the number 0 - it is indicated by ten flashes. If there are several errors, they will be displayed sequentially.

- You can reset errors by pressing the gas pedal for 10 seconds while remaining in diagnostic mode. The Check Engine icon will show code 0000.

- Turn off the ignition.

For example, error code 1514 (open in the engine idle speed control signal circuit) will be displayed as:

- 1 - one long flash, then a pause of almost 2 seconds.

- 5 - five short flashes with an interval of 1 second, after which there will be a pause for 2 seconds.

- 1 - one short flash and a pause for 2 seconds.

- 4 - four short flashes every 1 second each.

Error codes are read in the same way on the following Nissan models:

- Tiida;

- Almera H16 and Almera Classic;

- Laptop;

- Ixtrail;

- Qashqai;

- Teana;

- Murano;

- Navara.

The video (author Nikolai Nikolaevich) shows the procedure for reading errors on a 2007 Nissan Tiida.

On the earlier Nissan Primera P11, the procedure for reading errors is different:

- Simultaneously press and hold the daily mileage reset and clock settings buttons.

- Turn on the ignition and release the buttons.

- Self-diagnosis will start, during which the speedometer, tachometer and fuel level needles will simultaneously move from the minimum reading to the maximum and back.

- The error code is displayed on the odometer screen by pressing any button on the combination - the first press shows the software version, the second will display the error codes directly on the screen.

It should be remembered that engine errors on P11 are not read this way. Another procedure is used for this:

- Turn on the ignition.

- Open the cover of the fuse box in the driver's left foot area.

- Place a jumper in the diagnostic connector between the IGN and CHK contacts. On pre-restyling P11s, it is necessary to close the rightmost contacts in the top row. On restyled P11 144, the leftmost and rightmost contacts in the bottom row of the block are closed.

- After two seconds, remove the jumper.

- By flashing the Check Engine light, you can determine the error code. Long flashes give the first character of the code, short ones - the second. The number of flashes corresponds to the meaning of the symbol. On the restyled P11 144, the error codes will already be four-digit.

- Turn off the ignition.

On a right-hand drive Nissan Winroad, equipped with a mechanically driven gas pedal, errors are also displayed by closing the pins in the diagnostic contact. The connector has a slightly different appearance.

Close pins 1 and 8

The video from Alexey Nikitin demonstrates self-diagnosis on a 1999 Vinroad with a 1.8 liter gasoline engine.

Nissan Premiere not: ambulance

Hello! I have a Nissan Primera P12. The problem is that it won't start when the engine is cold. Thank you in advance for your cooperation! (Gulnar)

Hello, Gulnar. The problem of the inability to start the engine when cold is relevant for many Nissan drivers. We will provide some recommendations for resolving this issue, we hope they will help you.

Why doesn't the car start when cold?

What to do in such cases:

- First of all, it is necessary to diagnose the injectors; failed elements must be replaced. If the injector does not hold, that is, the valve does not cut off the fuel properly, then while the vehicle is stationary (a day or two), the pressure in the ramp is maintained using a regulator. And a certain amount of fuel can go into the intake. That is, when you try to start the engine, an overflow immediately occurs in the intake. If you bleed the injectors, the problem can be solved. That is, the next time you are faced with the impossibility of starting the engine, try blowing out the injectors. If this helps, then those elements that are poisoning need to be changed.

- Check the fuse contacts in the block. It happens that over time the vehicle is used, the contact is broken.

- Sometimes the reason lies in a stretched timing chain. It is necessary to carry out diagnostics and compare the results obtained with those prescribed by the manufacturer.

- In some cases, the engine cannot be started due to a failed throttle sensor. It also needs to be checked and replaced if necessary.

Diagnostic connector for a Primera car

If these recommendations did not help you, then computer diagnostics will help you identify the problem. You will need a computer and a tester to test. The tester is connected to the diagnostic output located under the steering wheel. A check program is launched on the computer, which analyzes the performance of all nodes and displays errors on the screen indicating certain malfunctions.

You can check without a computer:

- To do this, insert the ignition key and turn it to the “On” position for three seconds.

- After this, you need to depress the gas pedal five times within five seconds.

- Wait 7 seconds, then press the gas all the way down once and hold your foot in this position for 10 seconds. The MI indicator on the instrument panel will flash.

- You can take your foot off the gas and the Check Engine light will start flashing. You need to count the flashes - they will be long and short, the error code itself will be four digits. If the light blinks ten times in a row, then no errors have been detected in the operation of the car.

Video “Self-diagnosis Nissan Primera P12”

Check out the process of self-diagnosis of a car at home (the author of the video is Anton AUTO).

Was this article helpful?This article was helpfulPlease share the information with your friends

Source: https://avtozam.com/help/nissan-primera-ne-zavoditsja-na-holodnuju/

Other reasons why the starter may not respond when the ignition is turned on

In some cases, there have been malfunctions in the operation of automobile anti-theft systems (car alarms, immobilizers). Such systems simply block the supply of electric current to the starter after the security mode is removed. At the same time, the diagnostics shows the full functionality of the battery, power contacts and other elements of electrical equipment that are involved when starting the engine from the starter. For an accurate determination, it is necessary to directly supply power from the battery to the starter, that is, bypassing other systems. If the starter works, then there is a high probability of failure of the car's anti-theft system or immobilizer.

The next item to check is the solenoid relay. If it breaks, the starter can:

- be completely silent, that is, do not make any sounds after turning the key to the “start” position;

- hum and crank, but do not turn the engine;

- click repeatedly or once without cranking the crankshaft;

Bendix and retractor

The above symptoms will indicate that the fault is localized to the solenoid relay or the bendix does not engage the flywheel. Note that in the case of Bendix, a more characteristic sign is that the starter crunches and does not turn the engine. Another common sign of a bad starter is that the starter buzzes but does not turn the engine.

After starting, the engine stalls immediately: why does this happen?

During the operation of a car, a common situation is that after turning the ignition key, the car starts, the engine starts to work and stalls after a few seconds. As a rule, 3-5 seconds pass from the moment of starting to stopping the internal combustion engine. Before the engine stops completely, engine vibrations are also noticeable, the power unit shakes and operates very unstable.

This happens as a result of a decrease in speed, the resonance effect of a rotating crankshaft, etc. When you try to start the engine again, the engine may no longer start, or the situation described above may repeat again.

The reasons for this problem vary. The main thing is that if the car starts and stalls, this indicates that in-depth diagnostics are needed. Next we will talk about what to do in such a situation, as well as how to find the reason why the engine stalls after starting.

The engine starts and stalls: troubleshooting

So, if a similar problem appears, then it is necessary to take into account a number of features. First of all, the operation of the internal combustion engine after startup will be influenced by the following factors:

At the same time, CPG malfunctions, low compression, significantly misaligned timing and other nuances are taken into account in this case, but do not come to the fore. The fact is that if there are serious problems, the power unit will most likely not start even for a short time.

With that said, you should first start by checking the main possible causes:

- Quite often, malfunctions in the operation of the alarm system and the anti-theft system can cause the engine to fail to operate after starting. In other words, the immobilizer does not turn off and continues to block the start of the internal combustion engine, which is its main function to prevent vehicle theft. If the alarm blocks the engine, then you need to check the operation of all elements, try to reset the error, turn off the anti-theft system, etc.

- Problems with the IAC and idle air valve often arise due to contamination of these elements. You should also pay attention to the cleanliness of the throttle valve. As for the crankshaft sensor, incorrect data that it transmits to the ECU can cause the engine to stall immediately after starting.

- Poor quality fuels and lubricants can also cause problems. As a rule, problems begin in cases where low-grade fuel was filled or the engine uses motor oil that does not meet the recommendations/has lost its properties.

- A faulty fuel pump, air leaks in the fuel line, the formation of air pockets and dirty fuel filters do not allow creating the required pressure in the power system or supplying fuel in the required volume.

- The air filter and its contamination leads to the fact that the working mixture is significantly over-rich. In other words, the engine does not have enough air to burn fuel, and the spark plugs flood.

- Problems with ECM sensors (EGR sensor, oxygen sensor, DPKV, etc.) can lead to both unstable engine operation at idle and a complete engine stop after starting.

We also recommend reading the article about why the engine stalls when braking. From this article you will learn about the reasons why the power unit begins to operate unstably or the engine stalls after pressing the brake.

Now let's look at the most common problems and how to fix them, looking at them in detail.

- First of all, the culprit may be the low level of fuel in the gas tank and its quality. If gasoline or diesel fuel runs out, then the engine will start using the remainder in the power system, but further operation will be impossible.

As for quality, unscrupulous sellers can use both various additives and ordinary water to dilute fuel. To check this, part of the fuel is poured into a transparent container, after which it is necessary to allow the liquid to settle.

Water is heavier than gasoline and settles to the bottom. If this is the case, then the problem has been identified. To solve this, it will often be enough to dilute the existing fuel with high-quality fuel, after which the engine can usually be started.

However, this doesn't always work. It is possible that the supply of low-quality fuel in the tank will need to be completely drained, after which the power system will be thoroughly cleaned and flushed.

If the malfunction occurs on a diesel engine, then problems with fuel can lead to more serious consequences. For example, if a diesel engine starts and stalls in winter, then the cause may be waxed and frozen diesel fuel. In this case, diesel fuel needs to be heated, filters cleaned, etc.

It is much worse if gasoline accidentally gets into the tank of a diesel car. In such a situation, there is a high risk of serious damage and failure of expensive diesel engine fuel equipment (fuel pump, injectors).

- The next reason why the engine starts, runs and stalls may be the battery. The fact is that many systems and actuators require sufficient battery charge for normal operation.

Starting and problems in cold weather.

Question: My car does not start at -25/30 degrees. Celsius. What to do?

Answer: The temperature is below minus 25/-30 degrees. Celsius already refers to the extreme level, which requires a special, technically competent, more responsible and balanced approach on the part of the owner/user of the car, as a technically complex product, to starting the engine and operating the car as a whole. Such measures include, in particular: · turning on the low beam headlights for a few seconds before the first attempt to start the engine to warm up the battery electrolyte for some time. · pressing the clutch pedal fully and holding it in the pressed position while starting the engine with the starter to eliminate resistance to cranking and increase the load on the starter and battery exerted by the transmission. After starting the engine, release the clutch pedal slowly. · use of engine oil with a viscosity of at least 5WЗ0 to ensure the least resistance · before the start of the cold season, replace spark plugs, even if they have not expired, to ensure reliable sparking in extreme conditions. · periodic, preferably before the start of the cold season and, especially for cars that have been in operation for a long time, washing of injectors using materials and procedures recommended and approved by NISSAN, battery maintenance (charging with special equipment) · if the engine starts with great difficulty at very low temperatures or high ambient temperatures, to make starting the engine easier, press and hold the accelerator pedal while the starter is operating.

· a recommendation to insulate the car radiator (if the design allows and there are manufacturer recommendations), which the owner can do independently. This is necessary so that the owner remembers this work, always monitors the operating temperature of the engine, and when the ambient temperature rises, he can remove the insulation himself. Such insulation allows you to increase the temperature of the internal combustion engine, the engine compartment and the battery in particular, and the latter, in turn, allows the charging system to charge it more efficiently · operation of the vehicle should be accompanied by a reduced speed, especially when warming up, to reduce dynamic loads on the vehicle’s suspension and shock absorbers in in particular, as well as for warming up tires to improve traffic safety and for warming up the oil available in the components and assemblies of the transmission and suspension (gearbox, axles) · preferential use of low gears when driving, which, together with an insulated radiator, will help reduce cooling of the engine compartment and increase the operating temperature of the engine and battery · once started, it is highly not recommended to turn off the engine until it has completely warmed up to operating temperature · Thus, in theory, the engine should start up to a temperature of -30 C. However, there is no official data from the NISSAN manufacturer on the operation of the car at low temperatures do not exist. However, the fact that each model has its own “Vehicle type approval” indicates the compliance of this vehicle with the requirements and standards adopted in the Russian Federation for vehicles.

Yesterday I plugged the preheater into my primo (tr-12, 2001, CVT, 2l), in Omsk today it was -26 in the morning, plugged it in for 30 minutes in the morning, and everything was fine, it started up like in the summer! Before that, I couldn’t start at -15, so I installed iridium spark plugs and bought a new Akum and pressed the gas to the floor. In short, I tried everything. I installed the engine heating myself. Any car market sells Japanese heating (although I doubt it), in short, the main thing is that there is a built-in pump and a thermostat, I recommend a power of about 2 kW, anything can be written there, I took a multimeter with me and measured the resistance of 3 pieces that they offered me (everywhere it was written 2.5 kW) in one only it was 27 ohms, which approximately corresponds to 2 kW. Next, we open the hood, remove the air vent (to provide access), and re-cut the pipe that goes to the stove (if you look at the entrance to the stove, it will be to the right), connect the end of the pipe from the engine to the heating inlet, and the end from the stove to the inlet (but first you need to fill the heating with antifreeze). That's it, in the morning before starting, turn on the heating at 220V for 30-45 minutes and start the car like in the summer. Price: 2500 rubles for a heater, 20 rubles for 2 collars, 100 rubles for 2 hours of warm boxing. Before that, I suffered and installed iridium spark plugs and took a new Akum and poured thinner oil and gasoline 98 and “cold start”. In general, I solved the problem this way. Here in Omsk it even gets down to -40 (now I’m not afraid).

Last edited by ROW111; 01/25/2010 at 19:02.