in our VKontakte group

DIAGNOSE YOUR CAR YOURSELF!

When the ignition is turned on, the malfunction indicator lamp lights up continuously. When the engine starts cold, the warning lamp turns off and blinks once. If there is any malfunction in the system, the warning lamp lights up.

Conditions for the DTC to Occur

The ignition switch is in the on position.

Conditions for setting the DTC.

The ECM detects a persistent short to ground or an open in the signal circuit.

Action Taken When the DTC Sets

The malfunction indicator lamp lights up. The controller records the operating conditions at the time the fault is detected. This information is stored in a status record buffer and fault logs. An archive of diagnostic trouble codes is saved.

Conditions for Clearing DTC/Malfunction Indication

The malfunction indicator lamp turns off after three consecutive test cycles have completed without failure. The historical DTC clears after 40 heat cycles without failure. The DTC can be cleared by a scan tool.

Diagnostic guidelines

An intermittent fault may be caused by a loose connection, chafed insulation, or broken wiring under the insulation. Any circuit suspected of causing an intermittent fault should be carefully tested for the following conditions. Removed terminals Terminal connections Faulty locks Deformed Damaged terminals Loose connection between terminals and wires Physical damage to wiring harnesses

Good day! The check light is on, error 0650 VAZ 2114 Error 0650, lamp circuit malfunction, has anyone had this? what did you do? Error 0650.

Similar articles

One comment on “Error 0650. Check light Error 0650 VAZ 2114 Error 0650 lamp circuit malfunction”

I got a check because of a light bulb. Try changing the light bulb

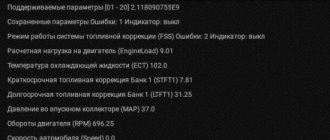

I figured out the errors, maybe it will be useful for someone (the symptoms were the following - waste of fuel, about 23 l/100 km in winter, 2.0 L engine). After diagnosing elm, the following came out:

P0650: Malfunction Indicator Lamp (ML) Control Circuit

P0038: HO2S Heater Control Circuit High (Bank 1 Sensor 2)

(the second lambda as it turned out)

I’ll tell you right away the decoding of all this, and more specifically, what to change and adjust I searched for a long time and with little success, and the benzene oil went on as usual. finally found this: “The heated oxygen sensor (HO2S) operating range is 350 to 850°C (662 to 1562°F). By using a HO2S sensor heater, the time required to activate the fuel control is significantly reduced. The current through the heater is controlled by the PCM via a pulse width modulation control circuit. The cold HO2S sensor circuit has low resistance and carries high current. On the other hand, as the temperature of the sensor resistor increases, the current gradually decreases.”

What does this mean? as explained by friends comrades + their thoughts = 1. P0038: HO2S Heater Control Circuit High (Bank 1 Sensor 2) P0038 HO2S heater control circuit high short circuit to positive electrical heating circuit

— bank 1 sensor 2 is the 2nd lambda (clean, wash, didn’t, bought a new one) spare part code

39210 23750.

2.

P0650: Malfunction Indicator Lamp (ML) Control Circuit P0650 Malfunction in the malfunction indicator lamp (MIL) circuit;

the malfunction was due to a malfunction lambdas, voltage was supplied to the lambda, the voltage was silent, the voltage became stronger (by the way, there is such a feature that wires can come off and short-circuit to the body, so check the wiring before replacing the lambda). Well, that’s all, I’m moving on to testing it in practice))) photo of the new lambda 2, located after the catalyst, otherwise some services can make a complex replacement, the replacement is simple and inexpensive; you don’t need to unscrew anything too much. Good luck to everyone!

Causes of error P0650

The most common causes of the P0650 code are:

- Short circuit or break in electrical wires related to the CAN bus, or damage to the corresponding connectors

- Control module ground wire loose or damaged

- Malfunction of the malfunction indicator light bulb or LED

- Malfunction indicator lamp control circuit malfunction

- CAN bus fault

- In rare cases, a faulty powertrain control module (PCM)

What are the symptoms of a P0650 code?

The main symptoms of this error are:

- Storing P0650 Code in Computer Memory

- The Check Engine light illuminates, indicating a malfunction, on the vehicle's dashboard

- The Check Engine light comes on in the absence of any faults

- The Check Engine light does not light up when there is a malfunction

- Absence of any symptoms other than the P0650 error code being stored in the computer's memory

How does a mechanic diagnose a P0650 code?

When diagnosing this error, the mechanic will do the following:

- Check for P0650 with an Advanced OBD-II Scanner

- Start the vehicle and check to see if the malfunction indicator light comes on for a few seconds and goes off shortly thereafter

- Determines whether the malfunction indicator light has burned out

- Checks whether the malfunction indicator lamp is properly connected

- Visually inspect electrical wires and connectors for shorts, looseness, and damage.

- If necessary, repair or replace all shorted, broken, damaged or corroded components.

- Determines whether the malfunction indicator lamp fuse has blown

- If no problem is found, check the powertrain control module (PCM).

How to Troubleshoot or Reset Trouble Code P0353

Some suggested steps to troubleshoot and fix error code P0353:

- Make sure the electrical connection at the coil connector is good.

- If there is a problem with the motor, turn it off and disconnect the cables related to coil No. 3. Then start the engine with the cables disconnected and use a voltmeter. It should show a range from 5 to 20 Hz, if this range is not present, replace the ignition coil.

- If there is no signal from the PCM to the ignition coil circuit, leave the coil disconnected and check the drive circuit at the ignition coil connector. Significant voltage means a short circuit. You need to find it and make the necessary repairs.

- If there is no voltage in the driver circuit, disconnect the connector from the PCM. And perform a driver continuity test between the powertrain control module (PCM) and the coil. If there is no break, this indicates a short to ground. Fix the problem.

- If there is a break, check the resistance between ground and the ignition coil connector. The result must be endless resistance. If not, repair the short to ground in the coil driver circuit.

Diagnosis and problem solving

Try wiggling and testing the wiring at coil #3 and along the harness to the PCM. If manipulation of the wiring causes misfire, correct the wiring problem. Check the reliability of the contact in the coil connector. Make sure the bundle of wires is not rubbing against anything. Repair if necessary.

If the engine is currently experiencing rough operation, stop the engine and disconnect the #3 coil wire connector. Then start the engine and check the driver signal on coil #3.

Use a voltmeter on the AC current scale in hertz. See if there is a reading between 5 and 20 Hz or so, which indicates the driver is working. If readings vary, replace ignition coil No. 3.

If there is no frequency signal from the PCM in the ignition coil driver circuit, leave the coil disconnected. Check the DC voltage in the driver circuit at the ignition coil connector. If there is significant voltage on this wire, then there is a short somewhere. Find the short circuit and repair it.

If there is no voltage in the driver circuit, turn off the ignition. Disconnect the PCM connector and check the continuity between the PCM and the coil. If there is no continuity, repair the open circuit or short circuit.

If there is a break, check the resistance between ground and the ignition coil connector. There must be endless resistance. Other indicators indicate a short, repair the short to ground in the coil driver circuit.

If you find that the engine is misfiring, the coil fires correctly, but the P0353 code keeps popping up. There is a possibility that the PCM coil monitoring system may be faulty.

What repairs can fix the P0650 code?

To resolve the P0650 code, you may need to:

- Replacing the malfunction indicator light bulb or LED

- Proper connection of the malfunction indicator light

- Repair or replacement of electrical wires or connectors

- Replacing fuses

- Properly connecting or replacing the control module ground wire

- In rare cases, replacing the powertrain control module (PCM)

- Clearing present trouble codes from the computer's memory and test driving the vehicle to see if the P0650 code appears again and determine if the problem is resolved

Additional comments for troubleshooting P0650

It should be noted that in some vehicles the Check Engine light may not come on immediately, but only after detecting the error multiple times. For more detailed information, please refer to the vehicle's owner's manual.

Diagnosing and repairing the P0650 code can take a lot of time and effort, so if you encounter this code, it is recommended that you seek help from a qualified technician who has the necessary diagnostic equipment.

Need help with error code P0650?

The company - CarChek, offers a service - on-site computer diagnostics; specialists from our company will come to your home or office to diagnose and identify problems with your car. Find out the cost and sign up for on-site computer diagnostics or contact a consultant by phone

Causes of error P0562

Low voltage occurs for the following reasons:

- Poor battery charging;

- Poor old electrical wiring;

- Oxidation on contacts, their weak connection;

- The generator is not working well.

Low voltage can already arise from the battery if it is simply discharged or has exhausted its service life. In the first case, the battery must be charged, and in the second, replaced with a new one. When connecting, inspect all connections to ensure they are not oxidized. One of the causes of the P0562 error due to a low battery is low air temperature. In other words, it is very common for the battery to run low in the winter. Another reason is electrical appliances left overnight. In old cars, electrical wiring wears out, breaks down, and breaks occur. Oxidation forms on the same old wires, especially when the car is left overnight in the yard and not covered with an awning in rainy weather. And finally, the generator. Worn or damaged terminals on the generator cause loss of power and voltage. A stretched alternator drive belt causes the current to not be fully generated. Worn brushes can cause the generator to not work or produce electricity. Or they will produce, but to a small extent, and error code P0562 will be displayed on the computer display.

Malfunction indicator lamp, circuit low voltage

- The ignition switch is in the on position.

- The ECM detects a persistent short to ground or an open in the signal circuit.

- The malfunction indicator lamp lights up.

- The controller records the operating conditions at the time the fault is detected. This information is stored in a status record buffer and fault logs.

- An archive of diagnostic trouble codes is saved.

- The malfunction indicator lamp turns off after three consecutive test cycles have completed without failure.

- The historical DTC clears after 40 heat cycles without failure.

- The DTC can be cleared by a scan tool.

Technical description and interpretation of error P0353

This diagnostic trouble code (DTC) is a generic powertrain code. The P0353 code is considered a common code because it applies to all makes and models of vehicles. Although the specific repair steps may vary slightly depending on the model.

The COP (coil-on-plug) ignition system is used in most modern engines. There is a separate coil for each cylinder, controlled by the PCM (powertrain control module).

This eliminates the need for spark plug wires by placing the coil directly above the spark plug. Each coil is allocated two wires. One of them is power, usually coming from an electrical distribution center. The other wire is the coil driver circuit from the PCM.

The PCM grounds/disconnects this circuit to activate or deactivate the coil. The coil driver circuit is monitored by the PCM for faults.

If an open or short is detected in the number 3 coil driver circuit, a P0353 code may occur. Additionally, depending on the vehicle, the PCM may also disable the cylinder fuel injector.

VAZ (LADA) errors via OBDI protocol. Self-diagnosis.

1 — Malfunction of the engine control unit.

2 — The voltage in the on-board network is too high.

3 — Malfunction in the electrical circuit of the fuel level sensor.

4 — Malfunction in the electrical circuit of the antifreeze controller.

5 — Error in external temperature controller.

6 — Overheating of the engine (power unit)

7 — Emergency oil pressure in the engine.

8 — The voltage in the vehicle's electrical network is too low.

9 — Low battery level (battery is discharged)

12 — Malfunction in the electrical circuit of the malfunction indicator located on the instrument panel.

13 — No data (loss of communication) from the oxygen sensor (lambda probe)

14 — High signal level of the coolant temperature sensor (antifreeze).

15 — Malfunction in the electrical circuit of the coolant temperature controller.

16 — Increased voltage in the vehicle’s electrical network

17 — Low voltage in the on-board network

19 — Malfunction in the electrical circuit of the crankshaft position sensor.

21 — Malfunction in the throttle position regulator.

22 — Low signal level of the throttle position sensor

23 — High signal level of the intake air temperature sensor

24 — Malfunction in the electrical circuit of the vehicle speed sensor.

25 — Low signal level of the intake air temperature sensor

27 — Incorrect signal from the exhaust gas system sensor

28 — Incorrect signal from the exhaust gas system sensor

33 — Malfunction in the electrical circuit of the air flow meter

34 — Malfunction in the electrical circuit of the air flow meter

35 — The ECU has detected a deviation in idle speed

41 — Incorrect signal coming from the phase regulator

42 — Malfunction in the electrical circuit of the electronic ignition system

43 — Incorrect signal coming from the knock sensor

44 — The mixture in the engine cylinders is too lean or rich

45 — The mixture in the engine cylinders is too lean or rich

49 — Vacuum leak

51 — Malfunction of one of the memory modules of the control unit - RAM or PROM

52 — Malfunction of one of the memory modules of the control unit - RAM or PROM

53 — Incorrect signal coming from the exhaust gas sensor

54 — No signal from the octane corrector regulator

55 — Poor air-fuel mixture at low load on the car engine

61 — Malfunction in the electrical circuit of the oxygen sensor (lambda probe)

E - Determining an error in a data packet stored in EEPROM

Error No. 8 on-board computer

Hello, dear guests, just yesterday I took up this problem. The fact is that I decided to work closely on Chek, in a fit of inspiration and the upcoming weekend, I checked the car for his personal mistakes. Well, you probably know how this is done, so I asked the machine what was bothering you, dear, and she told me, “The voltage in the vehicle network is too low.”

At first I didn’t believe it, because... I look at the generator and it shines like new, I look and don’t understand how this can happen (after all, I don’t know the instruments to check). After surfing the net yesterday I found a solution to this problem, but since it’s been like this since the 25th, because basically everyone wrote, “charge the battery,” but that may have been true, but I have a new battery, not even a year has passed. Damn I'm fucked. In short, pasans - All the problems of error No. 8 turned out to be in the generator brushes.

The uninitiated may ask, “WHAT THE FUCK IS THIS?”

I answer for those with a picture

“These brushes are not mine and the wear on my old ones is minimal, but the force of the springs is already less and most likely the contact was too small and therefore gave such an error”

Don’t worry about changing them - 15 minutes and you’re done (it will be difficult to install, because unsharpened ones can jump off the rollers and therefore need to be installed with a fair amount of skill)