One of the most important parts of your car's electrical system is the spark plugs. These parts ignite the fuel, and if the spark plugs stop working properly, the engine will experience certain problems. The spark plugs themselves do not break so often; most likely, other factors are to blame for the lack of a spark. However, sometimes a candle that has already exhausted its service life cannot properly perform its working functions. Therefore, it is advisable for every driver to know how to check spark plugs on the road without special tools and diagnostic equipment. The best way to check spark plugs is through timely maintenance and regular servicing of the machine.

The first symptoms of faulty spark plugs and lack of spark

The reasons for the failure of spark plugs in a car can be very different. But the symptoms are similar in most cases. The main indicator of the failure of one spark plug is that the engine begins to stall. When such an unpleasant aspect occurs, the power of the unit decreases, consumption increases, and the car shakes a little at idle. All this allows us to conclude that one of the cylinders is not working, in particular because there is no spark at the spark plug. The following symptoms of non-functioning spark plugs are also distinguished:

the car does not start, when trying to start the engine the starter turns smoothly, there is no progress in the ignition; after starting, 2 or 3 cylinders work for some time, then the fourth one is connected - this is an indicator of failure of the spark plug; the car constantly became difficult to start, the engine starts only on the third try; the car has lost power and responsiveness; pressing the gas pedal does not produce the desired effect; the car stalled during the trip, starting it is difficult or even impossible; From time to time, during startup, strong pops are heard in the exhaust pipe - this is the fuel that has been pumped up but not burned.

When all the spark plugs do not work, this situation should alert the car owner. Most likely, the reason is not the spark plugs. But if one spark plug refuses to work, you should look at the spark plug itself, as well as at the wire that connects it to the coil. This will help you find out what exactly caused the problem in your car. And if testing sensors, switches and coils in the field is not an easy task, then testing spark plugs is quite possible.

How to check spark plugs without special equipment?

On the road, we often don't have any equipment to test spark plugs. Therefore, you have to make do with traditional methods to check all the subtleties of the car. In particular, in the case of candles, you can use one of the proven testing methods. First, you should unscrew the spark plug and take a closer look at it, obtaining information about its condition. If the spark plug is wet, it floods with gasoline and does not work. A dry spark plug means there is no fuel getting to it or everything is working properly. A black candle wick also indicates a problem. You can check for spark as follows:

unscrew the spark plug and put a high-voltage wire on it so that you can give a spark; grab the rubber part of the wire with your hand, but under no circumstances grab the metal parts of the spark plug; place the candle wick at a distance of about 0.5 centimeters from the engine body - any metal part; Have another person turn the ignition key and try to start the engine within four seconds; if a spark appears and penetrates the engine body, it means that everything with the spark plugs is in perfect order, you need to look for other problems; if there is no spark, the spark plug does not work, and other not very pleasant problems are also possible.

If there is a spark, then the engine starting problem is related to the fuel system. If there is no spark, the culprit of your problems is the vehicle's electrical system. These will not necessarily be spark plugs, because the electrical system of a car contains quite a few different elements that can damage the spark plug assembly. You need to check everything to fully ensure that the equipment is working properly. By the way, the easiest way to check whether the spark plugs are working is to replace them with ones that are known to work.

What else could cause the spark plugs to not spark?

If there is no spark, many drivers confidently say that they need to change the spark plugs. But this is not always true. In particular, there are other modules that can affect spark production, so you need to check all the features of the vehicle's electrical system. If we are talking about the fact that the ignition system does not produce a spark, it is necessary to pay special attention to those modules that are responsible for this spark. Among them, you will have to check and suspect a malfunction of the following important machine modules:

high-voltage wires - often this element is the reason for the lack of a spark, the wire can pierce; ignition coils or distributors on older cars are frequent candidates for replacement and repair; the switch is a part that rarely raises doubts about its operation; it breaks down not so often, but very unexpectedly; ignition switch - one of the contacts may come off and not give normal commands to the car engine; an on-board computer that controls the actions of the vehicle's electrical system, including the ignition.

If one of these elements fails, the symptoms will also be similar to a simple spark plug failure. But replacing the spark plugs will not have any effect. If the switch or on-board computer breaks down, you will have to contact specialists and carry out quite expensive repairs. You cannot solve such problems on your own. It is also difficult to replace ignition coils in the field. However, this list of problems is not exhaustive.

Checking spark plug spark outdoors

It is important to know!

Every motorist should have a universal device for removing scratches on a car of any color. The effect is visible within 10 minutes, and the action of RENUMAX will pleasantly surprise you with its simplicity and effectiveness. Read more >>>

We unscrew the spark plug, put a high-voltage wire on it and install its base to ground (for example, the engine). We check for the presence of a spark when the starter is cranked.

It’s even better if you supplement this method with the following technique: close the gap between the electrode with a dielectric (for example, plastic). If the ignition system is working properly, the spark will jump between the central electrode and the skirt. If it is not there, then there is a crack in the spark plug insulator.

Attention! While the starter is operating, do not touch the spark plugs and tips of high-voltage wires.

Method No. 2: Spark piezoelectric probe (for example, Test-M) or lighter.

If you don’t have a ready-made device at hand, you can use an element from a piezo lighter instead. The principle of testing is similar: we connect the device to the upper contact of the spark plug and to the body. The button is pressed, if a spark jumps, then the spark plug is working; if it drips or is missing, then it is broken. Details in the video:

Method number 3: Use a multimeter. You should check the electrical circuit of the central electrode by setting the device to 20 kOhm.

If there is “contact” between the central electrode and the tip (shows resistance), then the reason for the lack of a spark may be damage to the insulator. Video example:

This is interesting: Which motor oils are better to choose?

Each type of candle must have its own resistance. This verification method is less accurate.

These methods work, but they cannot determine the serviceability of the spark plug 100%. For example, a spark plug installed in an engine has a bad spark, but when checked it will look like it is fully working. Why? In open air, the voltage required to form a spark is much less than in a cylinder. In the combustion chamber of an engine, a spark appears in the presence of a compressed air-combustible mixture.

Checking with a multimeter

A universal tester or multimeter helps to quickly check the performance of spark plugs. This device is familiar to many car owners who have had to repair their vehicle. The main purpose of using a multimeter is to detect the presence or absence of a short circuit inside the spark plug.

The multimeter is very easy to use; no special experience or skills are required to use it. For diagnostics, unscrew the conductor, connect one terminal to the spark plug thread, and the second to the central output. When voltage is applied, a spark should appear, which will indicate that the part is working, otherwise it must be replaced. Checking spark plugs with a multimeter is the most common diagnostic option at home. If in testing mode the multimeter shows infinite or very high resistance, then the spark plug is considered non-working.

To check the resistance of the spark plug's built-in resistor, set the multimeter switch to 20 kOhm. One probe of the multimeter touches the central electrode, the other touches the contact terminal. The resistance of all candles should be approximately the same with a slight spread. For spark plugs of injection engines, the resistor resistance is about 4 kOhm.

How to check the operation of spark plugs under pressure

Method number 4: On the engine. At idle, disconnect the high-voltage wire from each spark plug in turn. The spark plug that affects engine performance the least is the faulty one. This method is not safe, because... there is a possibility of electric shock when the wires are disconnected. And again, not a 100% method, because... The culprit for the power unit tripping may not be the spark plug, but the elements of the ignition system (ignition module, high-voltage wire, etc.).

Or make a pressure chamber like this.

Method number 6: Replacing the spark plug. Don’t forget that you can determine if a part is faulty by replacing it with a known good one.

These are perhaps the most popular verification methods. How do you know if there is a spark? Let us remind you that the condition of the engine can be determined by the soot of the spark plugs. In addition, a weak spark can be strengthened by modifying the MH.

In order to get rid of constant fines from cameras, many of our readers successfully use Special Nano Film for license plates. A legal and 100% reliable way to protect yourself from fines. Having familiarized ourselves and carefully studied this method, we decided to offer it to you.

In order to get rid of constant fines from cameras, many of our readers successfully use Special Nano Film for license plates. A legal and 100% reliable way to protect yourself from fines. Having familiarized ourselves and carefully studied this method, we decided to offer it to you.

Tip 1: How to check the spark

- How to check the spark

- How to strengthen the spark

- How to restore spark on a VAZ 2109

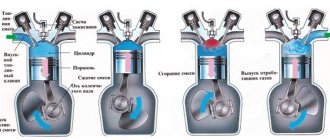

First you need to determine the reason for the refusal. Typically, to start an engine you need fuel, air, and a spark that will ignite the air-fuel mixture in the engine cylinders. If the air filter is ok and the fuel/air mixture is entering the intake manifold, it's time to check the ignition system. You can and should check the spark yourself, without putting this process on the back burner, or rather, before a visit to the service station.

The check is as follows: using a spark plug wrench, you need to unscrew the spark plugs from the cylinder head and carefully inspect them. The first thing you need to pay attention to is the gap between the central and side electrodes of the spark plug. It should correspond to values from 0.7 to 0.9 mm. If the gap is larger, it is necessary to bend the side electrode; if it is smaller, bend it. We also pay attention to the condition of the spark plugs: carbon deposits can also tell us about the operating mode of the engine. To check the spark, carbon deposits must be removed using fine sandpaper.

To carry out the test yourself, you can tie all the spark plugs with wire in a row and ground the free end of the wire to the “ground” of the car, put the tips of high-voltage wires on the spark plugs. After this, using the starter, we begin to crank the engine and observe the formation of a spark between the electrodes of the spark plug. Its appearance and color can also tell a lot. If the spark is weak on all spark plugs or absent altogether, then most likely the electronic switch has failed. If there is a spark, but it is different on all or on individual spark plugs, the problem may be the following:

- breakdown of the high-voltage wire from the distributor to the spark plug;

- the distributor runner (distributor) has a defect or wear;

- the spark plug is faulty;

- unstable contact at the wire tip.

If you were able to check the spark on the spark plugs yourself and, as a result of the test, establish that it is absent, you can at the same time test the operation of the ignition coil. To do this, you need to set a gap of 2-4 mm on one spark plug and crank the engine with the starter. If there is no spark at this spark plug either, then the ignition coil is faulty. In cars with a carburetor engine, it is enough to replace it, while in cars with an injection system, it is also necessary to check the electronic switch, which may fail.

The main reasons why there is no spark

- problem with spark plugs (flooded or faulty);

- breakdown of high-voltage wires or loss of contact;

- the reason is the crankshaft sensor (requires checking with a multimeter);

- malfunction in the ignition module;

- failure of the ignition coil;

- problem in the switch;

- Distributor malfunction (burned contacts, loss of clearance);

- poor ground wire contact;

- failure or malfunction of the ECU;

Pistol check

In addition to checking with a multimeter and a special tester, there is also an original method called “gun test”. Its essence is to examine performance under pressure on a special stand. The algorithm is as follows: insert the conductor into the groove, put on the tip, and after fixing, press the trigger of the gun. A green indicator will indicate 100% performance, a yellow indicator will indicate insufficient conductivity, and a red indicator will indicate a faulty spark plug. Despite the invention of such a device, it does not provide 100% confidence in diagnosis, since the pressure in the gun is somewhat different from the pressure inside the cylinder.

This is interesting: What dangers await a car in winter?

No spark injector

It is recommended to use a spark gap to understand at what stage there is no spark on the spark plugs (no spark from the distributor, no spark from the coil, or directly from the spark plug itself). If there is no spark in all cylinders at the same time, there may be several culprits:

- controller;

- entire module;

- coil or center wire.

If there is no spark from the ignition coil, then the reason may be hidden in many places. First of all, you need to check the high voltage wire, which must be in perfect condition and without damage to the insulation. Otherwise, the wire needs to be replaced.

No spark, check spark plugs

If the problem is not solved, then check the spark plugs. The spark plug contacts must be clean. The fact that there is no spark may be caused by dirty spark plug contacts. It is best to replace the spark plugs, but you can also clean the contacts. But before changing the spark plugs, check whether the discharge reaches the spark plugs themselves. To do this, remove the spark plug wire and bring it to the car body at a distance of 0.5 cm. Turn the starter several times and see if there is a spark between the wire and the body. The spark should be white with a slight blue tint. If it is absent or present, but with a different shade, we can say that the spark plugs are fine, and the problem is in the heart of the car’s ignition system – the coil.

How to check spark on ignition coil

To see if the coil is working at all, pull the wire from the breaker distributor that comes from the coil. The same test is carried out with it as with the spark plug wires, namely, they bring the wire to a distance of 0.5 cm and turn the starter. Now, regardless of the result, we can accurately talk about the cause of the breakdown.

In the first case, you need to check the contacts in the distributor-breaker for oxidation, insulation damage, and also check the serviceability of the rotor. If there is no spark due to it, the rotor must be replaced.

Checking the ignition coil

If, after checking, you realize that there is a spark in the car, but it does not start, then the ignition switch may need to be replaced.

How to check the spark on a spark plug

Even modern cars with injection engines and an abundance of on-board electronics are not immune from periodic problems. Quite often there are interruptions in the engine idling, or difficulties in starting the engine are noted, regardless of the ambient temperature. If you hear the noise of the fuel pump when you try to start, the first thing you should do is check the functionality of the entire ignition system, without relying on the on-board computer and sensors.

This is interesting: What to do if the brakes fail?

First of all, as practice shows, you will need to check the spark plug spark, since its “disappearance” is the most common cause of poor starting and unstable engine operation. It is necessary to understand that when checking it yourself, it is important to take special care, since in addition to the possibility of receiving an extremely unpleasant electric shock, you can damage the ignition module or controller. Therefore, it is advisable to carry out the test using a special spark gap, which you can make yourself.

Cleaning candles yourself

In many cases, diagnosing a spark plug comes down to cleaning it. After all, a candle covered with soot and dirt begins to work worse and worse.

Self-cleaning takes place using the following methods:

- Manual method . No auxiliary devices are required here. It is extremely important to be careful, otherwise the electrode may be damaged. Also, sharp objects are not needed in this case. Will do: a metal brush, a toothbrush, fine-grained sandpaper.

- Application of sand . You need a container with it and a drill. A candle is placed in the last one. Its end with the electrode is placed in sand. Let's start the drill. We look at the quality of turnover (insignificant).

- Using a sandblasting machine . This method effectively removes deposits and carbon deposits. Different types of sand are used here. The operation takes place with the effect of compressed air.

- Chemical cleaning . This method helps to quickly eliminate deposits. Here, agents such as acetone, the drug (Fairy or its analogues) and vinegar are used. A composition for cleaning the carburetor or a rust remover is also suitable. Some craftsmen use Coca-Cola for cleaning. Any of these products is applied in a layer of approximately 3 mm. This lasts for about 4 minutes. Then rinse with drinking liquid. Matches or wooden sticks are used to clean the outer part.

- Application of silite . Candles are placed in a jar. This product is poured into it. After which the container is placed under hot water. This results in a chemical reaction. There is an hour wait. You can then clean the electrode with a standard toothbrush.

- Using vinegar . The candle is placed in a jar with it. Stay time – 1 hour. Then a little electrolyte is added to this composition. Next, the candle is cleaned. You can use a toothpick.

Do not diagnose spark plugs by removing the caps with the engine running. Risk of electric shock. You can also burn the coil or commutator.

How to check spark on ignition coil

The ignition coil is not one of those units that constantly breaks down and causes other troubles, but in some cases problems are still noted. The most common cause of problems is winding damage. The subsequent breakdown of the insulation layer leads to a short circuit. The coil can also be damaged as a result of overloads caused by faulty spark plugs, or defects in the high-voltage wires themselves.

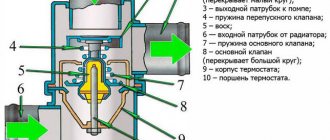

Before checking the spark on the ignition coil, it is advisable to drive the car into a dry garage. All work can be done independently, without the use of special equipment. The algorithm for such a check is standard.

- After cleaning the distributor cover from dirt, it is removed.

- By turning the crankshaft on the engine, it is necessary to achieve the closure of the distributor contacts.

- After turning on the ignition, the high-voltage wire coming from the distributor is brought to the ground of the vehicle. Particular attention should be paid to the distance - it should be 5 mm.

- To ensure the accuracy of the coil test, from time to time you will need to manually open the contacts of the distributor.

- You can say that the coil is working properly if a bright blue spark appears. If it is weak, uncertain, appears only periodically or is completely absent, the coil must be replaced, since its repair, as a rule, is simply impossible. When installing a new one, the polarity must be strictly observed, otherwise the new coil will also fail. At specialized service stations, coils are checked on a special stand, which allows testing the performance of the device in various operating modes. A very simple way to quickly check is shown in the video:

Diagnostic methods

How do you check the spark plugs yourself in your car? The SZ, which is one of the main components of the system as a whole, requires periodic diagnostics and regular maintenance, especially if engine maintenance is carried out. Basically, SZ are accessible for diagnostics, so dismantling them and checking them is not a problem. After removing them, it is advisable not to mix them up, so put them in order.

So how can you check the spark plugs yourself? There are several options that allow you to make the most productive diagnosis of SZ. To perform the verification procedure, you first need to disconnect the high-voltage cables from the SZ that go to the distributor. If you need to identify a specific non-working SZ, you need to remove it and listen to how the motor functions. If, when removing the spark plug, the engine sound remains the same, then the fault lies precisely there.

Spark test

Dismantling the SZ before diagnostics

Spark diagnostics is one of the most popular and used testing options. How to check a spark on a spark plug at home? To begin, clean the SZ from carbon deposits and contaminants. Then, using a feeler gauge—a device for adjusting the gap—adjust the distance between the electrodes. Then, after working with the probe, a wire is put on the spark plug, after which it is applied to the metal part of the car engine.

This is done in order to create the necessary electrical contact. If you don't know how to check a spark plug this way, just turn on the starter and try to start the engine. If the spark is blue and appears immediately when you try to start the internal combustion engine, then this indicates the serviceability of the engine protection system. If the spark is red or absent, then the spark plug needs to be changed.

Checking with a multimeter

You can use a special device for testing - it is called a tester or multimeter. It should be noted that the tester is not a test stand; stands are usually used at service stations and are not used for diagnostics at home. Using the tester probes, you can measure the device for an internal short circuit.

In general, a multimeter is a fairly simple device to use and has a simple design. To diagnose a short circuit, place one tester probe on the output of the SZ, and the other probe on its base. If at the moment of connection you see a spark, then everything is fine with the candles, you can use it further (the author of the video is Dmitry Maznitsyn).

Pistol check

There is another option for checking the performance of devices at home. To do this, you will need a special spark plug test gun. Such a device appeared quite a long time ago, but it became widespread among domestic motorists relatively recently.

In this case, the spark plugs are checked under pressure, the procedure is carried out as follows:

- The SZ is installed in a special connector of the device, after which the cap is put on it.

- When the spark plug is fixed, you need to press the so-called trigger on the device, after which the car enthusiast needs to be very careful.

- If, after pressing the trigger, you notice a spark and the lamp on the gun lights up, this indicates that the part is working.

It should be noted that this verification option is not widely used among our motorists because it cannot provide complete confidence in the performance of the SZ. This is because the procedure is carried out under pressure, and the pressure in the gun is significantly different from that used in the automotive system. But on the other hand, the method of checking with a pistol will allow the driver to be completely confident that the SZ is not working if this was revealed during the diagnosis (the author of the video is Nail Poroshin).

How to check if there is a spark at the spark plugs

If the ignition distributor is working properly and produces a good spark, the reason may be the lack of the same spark directly in the spark plugs. Especially if there are no problems with the supply of the fuel mixture and the air filter is not clogged. Checking the ignition spark on the spark plug itself will not be a complicated or lengthy procedure, and can be done on your own in a very short time. When checking the spark plugs on your own, you will need to first inspect the wires leading to them from the distributor to detect any insulation damage.

Then, using a special wrench, you will need to unscrew all the spark plugs and assess the degree of carbon deposits - the excess should be cleaned off before checking the spark. Be sure to check the current distance between the spark plug electrodes. It should not exceed 0.7-0.9 mm. If the current value is incorrect, there are two ways to go. The first has been widely used since Soviet times, when the gap was regulated by simply bending the electrode. Of course, the method has outlived its usefulness, but as a temporary one it has the right to exist. It is best to replace the spark plugs with new and modern ones, for example, iridium ones, which, along with excellent performance characteristics, can reduce fuel consumption.

After removing the candles, you need to tie them in one row using steel wire. One end of the wire must be left long in order to ground it to the ground of the body of the vehicle being tested. After the starter starts cranking the engine, you must carefully monitor the “behavior” of the spark plugs. A weak, dull spark, or its absence, is almost guaranteed to indicate a failure of the electronic switch. If the spark is different, dim, then this may indicate a number of problems at once:

- damage to the wire going to the spark plug;

- an existing defect or deterioration of the runner of the distributor itself;

- poor contact of the spark plug wire;

- defectiveness of the candle itself.

Thus, a seemingly serious question for novice car enthusiasts, “how to check the spark on an injection engine,” can be resolved quite easily in practice.

Ignition of the chainsaw

Electronic ignition for chainsaws and boat engines is not getting any more reliable. On the contrary, every year manufacturers produce electronic ignition units of worse and worse quality, while simultaneously increasing the price. From a commercial point of view, this makes sense: users are forced to constantly buy bad goods and change blocks that do not withstand even one season. To boycott defectors, it is necessary to develop a simple method for quickly and cheaply repairing electronic ignition units, as well as increasing their reliability. In [1] a very successful way to “revive” a chainsaw is described, but why run three wires outside the engine? After all, the housing (“ground”) can be “taken” anywhere, which means that it is enough to remove only two wires from the engine. The most valuable and unsurpassed textbook for repairing electronic ignition of chainsaws today is publication [2]. In our forest region, forestry departments are littered with faulty magnetos of chainsaws, and quite a few of them have accumulated in the hands of rural residents. Villagers replace the high-voltage magneto transformer with ignition coils from motorcycles and automobiles, but more often the electronics filled with compound fail to function. The operating principle of a chainsaw magneto (for example, MB1) is simple (see Fig. 1).

A rotating disk with four magnets induces an emf in the coil, which charges the capacitor. One of the magnets, having a polarity opposite to the polarity of the other magnets of the disk, acts on the coil in the thyristor control circuit. When the thyristor is turned on, the capacitor is discharged onto the primary winding of the pulse transformer. High voltage from the secondary winding of the transformer is supplied to the spark plug. Some magnetos use a half-wave rectifier instead of a diode bridge, and the thyristor control input is protected by a more advanced resistor-diode (or zener) current-voltage limiter. The same or similar schemes have imported chainsaws, lawn mowers, micro-thermal power plants (gasoline generators) and boat engines, as well as small motor vehicles (motor scooters, mopeds). The test bench can be made electronic [2] or purely mechanical based on a “native” magnetic rotor driven by an electric motor or manually. To quickly localize the fault, you can make a special electronic circuit and connect it to the coils being tested instead of the “native” one. Electrician V.V. Dubrovny tests coils by comparing heating dynamics by connecting them to a 220 V network through a light bulb, but I do not have such experience. This is how I remove the magneto electrical circuit filled with compound. First, I unscrew the board fastening screw (see Fig. 2, the fastening screw is blackened).

Then I unsolder the three wires going to the coils and solder them securely together. Having unsoldered the capacitor, I dismantled all the coils. I heat the magneto on an electric stove and, pulling the wires while the compound is loosened, I remove the board. In this case, the board hangs on the extended terminal of the capacitor. If it turns out that the capacitor is faulty, then it must also be removed, but this has not happened in my practice. A special contact petal is secured with a bolt securing the board, to which the “minus” of the diode bridge is soldered. The bridge diodes must withstand a voltage of 100 V. In half-wave circuits, the diodes must be rated for 200 V. A feature of the modernization I propose is the ability to quickly repair the electronic ignition in “field” conditions without disassembling the engine and using a soldering iron. Experience shows that the most vulnerable element of the circuit in Fig. 1 is the thyristor. I propose to install it outside the engine housing and make it quick-release. To do this, two wires are removed from the engine (through the “Stop” button or the hole in the explosive wire), and a washer or nut is soldered to the control terminal of the thyristor. A piece of wire is soldered to the cathode of the thyristor, which is subsequently pressed with a mounting bolt. The thyristor anode already has a bolted connection. All electronics, except for the diode bridge, are placed in some kind of box, which is mounted on the engine in a convenient place (see Fig. 3).

I use high-voltage RC filter caps from picture tubes of black-and-white TVs, to which I tape “ears” from old picture tubes with electrical tape. Repair shops are full of these parts. A thyristor and other radio components are placed inside such caps. Now, if the magneto breaks down, it is enough to replace the thyristor and you can continue working. This is very important, since the magneto usually fails in the forest or (for outboard motors) in the middle of the river. Details. Thyristor KU201 or KU202 with the letter index K, L, M, N. If you use KU202R1, then all the electronics can be placed in place of the old one and filled with quickly hardening foam or other compound. Diodes are suitable for KD209, KD105, KD243, 1N4004, 1N4007, etc. A 1 kOhm resistor of any type.

1. Ponomarenko R. How to revive a chainsaw // Electrician. 2000, No. 8, p. 19. 2. Paley V.M. Stand for testing electronic ignition units of chainsaws //Electric. 2001, No. 7, pp. 9-11.

How to check spark strength on the ignition module

Most car owners understand that when the engine starts to stall or has trouble starting, the problem is often a lack of spark. Therefore, checking the spark on the injector is a manipulation that should not cause any difficulty for the driver, who often has to deal with the need for repairs in the field. Naturally, you should always have a set of several new, or simply working, candles with you.

Since the lack of a spark is the most common cause of the engine stalling or difficult to start, as well as unstable idling, checking the spark on the spark plugs is carried out by motorists first. In order not to turn out all the spark plugs at once, you can check them one by one - removing one by one from the cylinder head, putting caps on them with a wire from the coil and grounding each spark plug to ground. Rotating the starter should produce a nice, bright spark. If it is missing, you can replace the wire (it is advisable to carry a spare one with you) or use one that is known to be working.

When removing high-voltage wires from the module, it makes sense to number them first - this will avoid confusion in the future. Problems caused by the spark plug or wires become obvious in this way. If a spark does not appear on the spark plug, the problem lies in the module itself. In order to accurately determine this, the “replacement” method will help - the working module can be temporarily “borrowed” from another car of the same model. If replacement fixes the problem, you can safely go to the auto store for a new one.