Five main ways to soften your car's suspension

When purchasing a car, the driver expects that he will be able to spend time in it comfortably, going to work, out of town, or just to the store for shopping. As you know, the quality of roads in Russia leaves much to be desired, but not all car manufacturers pay attention to this. Some companies specially adapt the suspension to Russian realities, making it softer so that you can comfortably overcome unevenness, potholes, off-road conditions and other sections of low-quality roads.

At the same time, a stiff suspension is also not uncommon for the Russian car market. It can often be found even on premium segment cars that are designed for fast driving. In most cases, the suspension of sports cars is rigid, this is especially true of “old Germans”. Some car manufacturers equip their models with suspension tuning systems so that drivers can adapt it to their own needs, but such functionality is provided in fairly expensive cars.

You can drive on Russian roads in a car with a rigid suspension, but the driver and passengers will feel literally every bump in the road. During long trips in cars with a rigid suspension system on bad roads, the driver gets tired very quickly, and over time his spine begins to hurt. If you purchased a car with a hard suspension, you can try to soften it. This article provides the main ways to make a car's suspension softer.

ADJUST OR REPLACE TIRES

The easiest way to soften the suspension is to work with tires that partially absorb road imperfections. There can be two options - tuning the tires or replacing them.

The first method does not require any costs from the driver, but it is less effective and more dangerous. By intentionally lowering the tire pressure, you can achieve a softer response to road irregularities on the suspension side, since less rolling will be applied to it. It is worth remembering the consequences of low tire pressure:

Deterioration of vehicle controllability;

Increased fuel consumption;

Acceleration of tire surface wear;

Increased braking distance.

While some economic losses that arise due to a forced reduction in tire pressure can be tolerated, from a safety point of view, such a solution to the problem with a rigid suspension does not look the best.

The second way is to buy softer tires. To choose them, before sending them to the store, it is recommended to read reviews of various tire models and determine which ones are the softest. If we look at the overall picture of the tire market, we can conclude that the softest tire options are presented by Michelin and Pirelli.

CUT OR REPLACE SHOCK ABSORBER SPRINGS

One of the primary roles in the operation of the suspension is played by shock absorber springs. If they are rigid and large, this increases the rolling radius of the car when overcoming obstacles; accordingly, to reduce the unpleasant sensations from the operation of a rigid suspension, they can be made smaller or a softer version can be purchased.

Specialists at a service center or in a garage can cut off part of the shock absorber springs for a fee. This will not make the suspension softer, but will somewhat reduce the rolling radius, and it will become easier to overcome obstacles (but not in all cases). At the same time, the driver runs the risk of getting a lot of problems associated with lowering the car:

Working out irregularities on cut springs can lead to rapid failure of shock absorbers;

Lowering a vehicle reduces its carrying capacity;

Overcoming potholes at high speed can lead to damage to important elements of the car: the chassis system, engine, and so on.

Another way to solve the problem of a hard car suspension is to buy softer springs. There are a variety of shock absorber springs available on the market, and salespeople at major auto stores will be able to advise on the best options for softening the suspension.

INSTALLING SOFT SHOCK ABSORBERS

Shock absorbers in a car are designed to dampen vibrations, and the softness of the suspension and its other characteristics directly depend on them. With faulty shock absorbers, a car accelerates poorly, brakes slowly, and has problems with maneuverability, smoothness and other parameters. The main task of shock absorbers is to maintain constant contact of the car wheel with the road. Some shock absorbers are made too hard, which leads to related problems.

You can make the suspension softer by replacing the shock absorbers. The most successful options for this are oil or gas-oil shock absorbers. If you want to get maximum softness of the suspension, it is better to choose a completely oil version.

REPLACING THE SUSPENSION TO PNEUMATIC

The most expensive solution to the problem is to completely replace the car suspension with a pneumatic one. Owners of cars with this type of suspension have the opportunity to adjust the driving characteristics of the car by selecting the pressure in the cushions on which the suspension rests. Its installation will not only increase the smoothness of the ride, but also, if necessary, change the ground clearance over a wide range.

The main disadvantage of switching to air suspension is the need to spend tens of thousands of rubles on modifying the car. Depending on the car model, the cost of air suspension and its installation will vary. Also among the important disadvantages it is worth noting the poor off-road performance of a car with air suspension (especially of low quality).

INSTALLING ALLOY WHEELS

Alloy wheels, also known as cast wheels, are a relatively inexpensive way to improve the comfort of driving a car with a rigid suspension. Alloy wheels differ from steel wheels in their light weight and good appearance. If we take average values, we can say that alloy wheels are about 40% lighter than steel ones. Due to this, it is possible to reduce the load on the suspension and increase the controllability of the car.

The main disadvantage of installing alloy wheels is the high chance of damage. Unlike steel wheels, cast wheels do not bend when colliding with an obstacle, but rather crack. This leads to the fact that it is much more difficult to restore light-alloy wheels after damage, and in a cracked state they lose their properties.

How to strengthen springs on a car with your own hands

A modern car with improved aerodynamic shapes is becoming faster and faster. Increasingly, ground clearance is being reduced to reduce air resistance. The road surface, on the contrary, forces a car enthusiast who bought a new car and drove for some time on domestic roads, constantly hitting potholes or potholes with the bottom, to think about increasing the ground clearance.

Spacers to increase ground clearance

A trifle and big consequences

Repair specialists know very well that there is no single point for determining road clearance.

The first point that can affect the increase in ground clearance is the front bumper. The situation is familiar to everyone when parking in the city near a high curb: accidentally hitting it, grinding and crunching. 2–3 centimeters could have saved the situation.

The front bumper of almost all modern cars has a kind of “skirt” with a width of 2 to 3 cm. It can be made of plastic or rubber. It was these centimeters that were needed in case of parking. The plastic part is cheap and easy to replace if broken. It is better to remove the rubber one for the winter.

Don't forget about the second point under the oil pan. The clearance of 12–17 cm is very small. In spring, “snowdrops” appear - deep holes filled with water. As people say, if you pick a snowdrop, you leave the pallet behind. Such a case is extremely unpleasant both when it occurs and during repair.

Machine with increased clearance

There are many options to choose from

Each driver independently decides how to lift the car.

The easiest option is to replace the stock tires with tires with a higher profile. This is the fastest and, according to many, the most painless solution for the car's chassis. However, at a significant cost, such a solution is not very effective.

A slightly greater effect is achieved by increasing the diameter of the disks. It is worth paying attention that you should not install wheels and tires with a larger diameter than those provided by the vehicle manufacturer. Exceeding the values entails increased load and rapid wear of wheel bearings, struts, shock absorbers, and so on.

The second option is to replace worn out shock absorbers. Is it possible to increase the car's ground clearance with such a replacement? The answer is rather negative, because when the car is stationary, its body hangs on springs, and accordingly, shock absorbers have no effect on lifting. They are triggered while moving, when swaying or leaving a curb, when a car with broken shock absorbers hits its nose. A properly functioning shock absorber solves this problem. Thus, shock absorbers do not affect the increase in ground clearance.

Replacing worn out shock absorbers

The third option is to raise the rear of the car using rubber spacers , which are installed on the spring instead of the standard ones made by the manufacturer. Such spacers are able to support the weight of the car and are not subject to deformation.

Is it possible to use this method to increase ground clearance without experiencing discomfort while driving, without deforming the body and without causing oxidation and corrosion? The clear answer is yes! In addition, this option is considered one of the safest both for driving and for the design of your car.

The fourth option is to install spacers between the lower mounts of the rear shock absorbers and the eyes of the rear beam. We are talking about the so-called “houses”. This method is convenient because it allows you to select the clearance height due to special holes in the spacers themselves. Moreover, this solution is fast and inexpensive. We should not forget that after such a procedure it will be necessary to additionally adjust the headlights, brake force regulator, and the angle of the front wheel steering axis.

Video showing installation of spacers:

The fifth option is one of the worst ways to increase car clearance at home. The old springs are removed and reinforced homemade springs or those that do not correspond to this car model are installed instead.

The body hangs on springs, the shock absorber travel is either reduced or absent, which leads to breakdown. In addition, the ride becomes uncomfortable, the suspension does not perform its function due to the lack of proper performance of the shock absorbers, which increases the braking distance and worsens the car's handling.

The sixth option is simple, not expensive, but unreliable. An interturn insert is installed in the spring. Consequences - a decrease in the compression ratio of the spring with all the ensuing consequences described in the fifth option

The seventh option is to increase the car's ground clearance by installing polyurethane spacers between the car body and the strut support. Due to the increase in rigidity, this method has an increased impact on body wear when driving on uneven roads.

What are spring spacers?

Spacers are special devices that reduce the compression and expansion of car suspension springs and raise the body. They are installed when the springs of the car sag and stop working as before, i.e. breaks through the pillars on a bad road. Or when a heavy load is often transported by car. In order not to buy new springs, rubber spacers are installed as a temporary option, which are not expensive and can temporarily restore the vehicle's ground clearance.

For whom is it suitable and what cars?

Spacers can be installed on cars and SUVs. For the latter, you need to install reinforced interturn inserts or a large number in the spring (at least three). Because the springs of crossovers or jeeps are much more powerful, because... the car weighs more. Many SUVs have torsion bar suspension or springs - then auto buffers will not work, another solution is needed.

Most car enthusiasts install interturn inserts to slightly improve ground clearance and drive safely on primer roads. Then there should be no negative consequences.

Material for spacers

- rubber;

- polyurethane;

- ABS plastic;

- aluminum.

The table shows the strengths and weaknesses of each material:

| Spacer material | Polyurethane | Rubber | Aluminum |

| How does it affect the suspension? | Long-term use leads to damage | Helps absorb vibrations smoothly | Do not have a significant impact |

| Operating period | Long | Rapid wear | Average |

| Difficulty of installation | Very simple | Simple | Average |

| What harm does | Possible damage to suspension | Minor | Minor |

| Possibility of deformation | Easily deformed | Deformation occurs during long-term use | Strong mechanical loads are required for deformation |

How to install spacers yourself

Installation principle for front and rear suspension:

- Place the machine on a flat surface. To make it easier to install the rubber inserts, we raise the car on a lift/jack. You can do without removing the wheel if access is free. But it is necessary to jack up the car to relax the springs.

- Before work, it is advisable to clean the spring from dirt.

- An interturn spacer is mounted into the spring. We put at least two pieces on each spring. Install at the top and bottom (or in the middle). If they are tight, then treat the rubber inserts with silicone grease (not oil, as it corrodes the rubber). You can install one at the bottom, the other at the top, or connect them in the middle. The main thing is to hold tight.

- Interturn inserts are installed on one side. Remember where the deep cut is located - this side should be on top. Once it is inserted into the spring, turn it slightly along the course of the spring so that it is securely fastened. As a result, the spacer should hold tightly after lowering the car from the jack.

The process of installing interturn spacers (auto buffers) is shown more clearly in the video:

Methods for restoring springs

Two methods of restoring such springs are considered: thermomechanical and electromechanical. In general, the procedure for restoring components is not particularly pleasant; it will require strength, patience, and special equipment. The following tools are needed: a vice, an electric transformer, a lathe, an oil bath, AC-8 oil.

We will attach the racks with sliding rollers to the guide frame. We connect the components to the machine supports. Now we carefully press the mandrel, and first install the spring on it.

Using similar methods it is possible to restore tired springs. By the way, springs provide comfort and create ground clearance. For cross-country ability, some car owners place spacers between the springs. As a result, the ground clearance adds several centimeters.

What are the dangers of installing the “wrong” suspension springs?

The chassis springs of any vehicle perform a number of functions, improving its control and smoothness when driving over uneven roads. When choosing this suspension element, you need to focus on the shape, steel thickness, rigidity, overall diameter, length. In addition, the manufacturer's brand is of great importance.

To avoid mistakes and make selection easier, springs must be marked by color and stiffness. Based on this data, you can choose the best option.

Wrong type

Among the abundance of designs, you should choose products that best match the original elements in shape, height, and rigidity:

- The number of turns and height may vary. The main thing is the complete coincidence of the seat and outer diameter. The easiest way to choose the right springs is with the help of branded catalogs offering their products for various cars.

- The durability of springs depends on the absence of technological defects. In addition, this parameter is directly affected by violation of recommendations for their selection and the use of unsuitable shock absorbers.

- Color markings may vary from manufacturer to manufacturer. The diameter of the spring rod may also vary. When choosing this suspension element, it is important to focus on the manufacturer, the type of product, which is determined using markings, and rigidity.

Changing the suspension design using artisanal methods has an extremely negative effect on the operation of the springs.

For example, installing elements from station wagons on sedans in case of sagging of the car body is justified. On the other hand, if this is done to increase load capacity, then this is an unjustified step, since reinforced structures can damage the body over time.

An unsuitable type can lead to loss of controllability, deterioration of road stability, damage to the body and shock absorbers.

In addition, the wrong type of products installed on a car often leads to failures of the ABS and ESP electronic systems. This can even lead to ECU failure.

Incorrect springs change ground clearance and wheel alignment angles. As a result, parts, chassis components, and tires wear out much faster.

lifebm › Blog › Understanding how your suspension works - its stiffness.

Good performance of your car's suspension is subjective. There is also a lot of magic here. When combined, these two things will never let others know exactly what suspension settings you need. But this is not so bad; a million more parameters add additional confusion. Such as differences in road surfaces, driving weather conditions, driving style, curb weight, and a number of others that also influence. As a result, your suspension will seem soft, but to your mother, on the contrary, it will seem extremely hard.

Debunking the “tougher is better” myth.

Stiffer springs are better

So let's get started. High-speed maneuvers are not interested in your opinion, your feelings are deceptive, so find a safe area. I'll tell you about negative camber, stretched tires, destroyed ground clearance and excessive spring stiffness - all this makes the car uncontrollable.

SPRING STIFFNESS COEFFICIENT

When thinking about the correct stiffness of your suspension, springs are the first thing that comes to mind. It is the springs that are its most important element. They prevent the car from touching the road and control the traction of the tires to the surface when driving over bumps. The springs limit body roll when cornering, resist “squatting” on the rear axle when you press the gas, and prevent you from nose-diving when braking. The height of the car depends on the springs. If we ignore the other components of the suspension, springs have the greatest influence on the handling of the car. Note that an uncontrolled increase in spring stiffness negatively affects many other parameters.

We can't talk about spring stiffness without talking about spring rate. Simply put, it is the amount of weight required to compress the spring one inch. This is a universal measure, applicable in principle to various springs - from the suspension spring to the valve spring. It is written something like this: 500 lbs/in, and the higher the value, the tougher it is.

Linear and progressive stiffness. Now let's complicate the theory a little. Know that there are two types of stiffness coefficient. The first type is linear, and it doesn't matter how compressed the spring is, how much weight is pressing on it, or how uniform the coilovers are tuned. The predictable nature of these springs makes them ideal for flat surfaces such as prepared tracks, which differ sharply from rough terrain due to the absence of bumps and potholes. For springs with progressive stiffness, the coefficient changes its value, for example, it increases with increasing pressure on the spring and depends on the settings of the coilovers. Dynamically variable stiffness is ideal for street riding, as street surfaces are more uneven than on a race track. Thus, the spring rate varies from hard to soft depending on how much the spring is compressed.

When they are tough, they are very tough. No matter what springs you put on your S13, your goal will likely be to lower the ride height and, with it, the center of gravity. This means that the compression ratio of the springs will be stiffer than what Nissan intended when it selected the stiffness coefficient taking into account the fact that it would protect the shock absorbers from breakdowns. If the springs are too stiff, ride quality will suffer. The performance of tires on bumpy, uneven surfaces will be sacrificed for rigidity. Also, overly stiff springs contribute to oversteer. In other words, if it is too stiff, the handling will become worse than it was before.

Classes

When choosing a product, first of all you need to pay attention to the reliability of the manufacturer and workmanship. The spring itself needs to be checked for paint chips that may have appeared during transportation.

The whole variety of springs can be divided into three classes: “A”, “B”, “C”:

- The premium category “A” includes products from Sachs, Kayaba, Bilstein, which are installed on the most expensive cars. These products are characterized by the highest quality, but their cost sometimes goes through the roof.

- The middle class “B” includes suspension elements at a relatively low price, which are characterized by acceptable quality.

- Budget option “C” is represented by Tekhtime, PROFIT, Maxgear. Their products do not differ in any quality, but are very cheap.

These companies do not have their own production facilities, so they purchase finished Chinese products for next to nothing.

It is dangerous to use such elements in the suspension of a moving car, since at any moment they can fail, subjecting the shock absorbers to extreme loads.

Installation errors and possible consequences

When installing springs, it is important to follow certain rules:

- Products of the same class must be installed on both sides of the same suspension axis, for example, elements “A” or “B”.

- The front axle can be equipped with class “A” springs, and the rear axle with class “B” springs. It should be remembered that the opposite installation is unacceptable.

If one of the elements fails, then it should be replaced only in pairs, regardless of the condition of the other product.

It is important to remember that the colors of the springs must be the same on both sides of the car. If you ignore this rule, the car body will be skewed in one direction. This will significantly worsen the handling and stability of the car on the road.

In addition, all parts and components of the chassis will wear out much faster.

It is not recommended to install special “spacers” between the spring coils, as this will significantly worsen the controllability of the machine and increase safety risks.

Thus, when choosing the optimal springs for a particular vehicle, it is important to strictly adhere to the manufacturer's recommendations. You should not skimp on these suspension elements, since safety depends on them. These products can only be purchased and installed in pairs.

How to increase ground clearance (clearance)

Increasing ground clearance is most often done by off-road driving enthusiasts, hunters and other people who like to go out of town. Roads in the city are significantly different from country roads. That is why increasing the clearance for cars unsuitable for these roads is one of the most important procedures.

- First method. An increase in ground clearance is achieved by installing wheels with a larger diameter. This is especially true for cars with basic equipment.

Among the disadvantages of this method are the appearance of a speedometer error and the limitation of the diameter by the wheel arches. This means that if you install a wheel that is too large in diameter, it will hit the arches on sharp turns.

- Second method . Installing spacers under the fastenings of suspension parts to the body, for example, springs, also allows you to increase ground clearance. Complete with spacers, you should purchase shock absorber extensions, or new extended shock absorbers, since when entering a deep hole, the shock absorber may fly out of the cup.

It will be useful: How to check a pawned car?

The disadvantage of this method is that the rear spacers are much thicker than the front ones and the increase in ground clearance occurs unevenly. In this regard, the brake force regulator, or “sorcerer” as it is called, receives incorrect information. However, the “sorcerer” has the ability to regulate.

- Third method. It is reminiscent of the second method and consists of replacing standard springs with springs with a large number of turns. In this way, a significant increase in ground clearance can be achieved. However, as in the second method, it is necessary to lengthen or replace the shock absorbers for the same reasons.

Compared to spacers, new springs will last much longer and more reliably, however, in addition to the same disadvantages, they have a high cost.

- Fourth method. Reinforced springs. This option is used for vehicles that are operated at full load. They can be pickup trucks and station wagons, which have the ability to transport large cargo. Reinforced springs do not increase the vehicle's ground clearance, but their use eliminates "sagging" under full load, while maintaining normal ground clearance and protects the underbody from damage due to uneven road surfaces.

Among the advantages of this system, one can note an increase in the service life of the entire chassis, however, the comfort of a trip without a load is reduced, since the rear part will “spring” on small bumps.

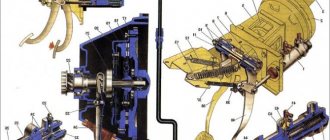

Do-it-yourself suspension spring replacement

Do-it-yourself suspension spring replacement

Due to compression and stretching, the spring dampens unevenness, potholes on the road, as well as vibrations of the car body. Since the springs take the heaviest impacts, they often burst, although this is very difficult to detect until it is removed. Experienced drivers can guess the problem by bumps in potholes, car pulls, or noise in the chassis. Replacing a suspension spring with your own hands is not difficult if you follow the preliminary steps. With the appropriate equipment, it is accessible even to beginners.

Let's consider the stages of removing and replacing the front and rear suspension springs of a car. The procedure is similar for almost any car brand.

Replacing the front spring

The springs are replaced in pairs, as are the brake discs. This is due to the fact that they must be equal in height so as not to cause distortions in the front of the car.

Tools

• key head 21;

• hex key, 7;

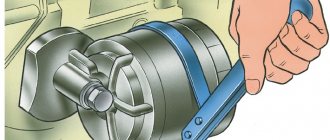

Ties are the main element of the spring replacement procedure

We assume that the front shock absorber and spring assembly has already been pulled out of its socket. Removing the shock absorber is a painstaking procedure that involves dismantling the front plastic panel, wheel, and headlight.

Before starting replacement, the shock absorber assembly should look like this:

What are we doing

1. Place ties on both sides of the spring and secure them.

2. Tighten the ties, the spring compresses. There is no need to rush, we do everything carefully and alternately.

3. Unscrew the nut securing the shock absorber support using a 21mm wrench and a hexagon.

4. Remove the support.

5. When disassembled, the upper mount consists of four components: the nut, the lower shock absorber mount, the bearing and the spring support cup.

6. These elements are replaceable, they can be damaged, just like the spring. For example, the support cup may rust over time.

7. Easily remove the old spring with boot from the shock absorber rod. We don't touch the ties.

8. Lubricate the supporting hemisphere of the body with silicone or other thick lubricant in order to eliminate squeaking when driving.

9. Change the spring and assemble the shock absorber and support.

10. Remove the ties, freeing the natural movement of the spring.

11. Install the shock absorber assembly into its socket.

The procedure takes 25-30 minutes, and completely removing and installing the shock absorber and replacing the suspension spring with your own hands will take about 2 hours.

spring reinforcement

- Please log in to reply.

#1 boss

- Users

- 110 messages

- Registration 14-December 10

- Top

- Complaint

#2 2-eschnik

- From: Ukraine, Kiev

- Auto: 2102

They advised to insert spring halves into the rear springs. The used one is empty and rides on standard ones. When loaded, the inserted spring starts working. What do you think and how to secure the insert?

no matter how hard you try, the halves will hit the bumps - glasses or cups (depending on which one turns out to be weaker) will quickly dream of a fluffy animal (((:

You can install springs 02-04, or springs (there is a topic nearby). But it is better not to carry such loads on a Zhiguli that they require reinforcements. In any case, extreme loads will kill the car.

It's cheaper to hire a truck than to invest in a Lada.

Added after 6 minutes There is an option for APA tuning: in Soviet times, people from the Caucasus brought tangerines - they put tennis balls in the springs.

Type semi-pneuma))) obviously the car is a consumable ((

If you want to tell me something, try using your mouth. type(c)BG

- Top

- Complaint

#3 PASSERBY

- Top

- Complaint

#4 VETERAN

- From: Galicia

- Auto: Nyklasnishe

insert used spring halves into the rear springs

- Like this: Jet

- Top

- Complaint

#5 WAZ

- Top

- Complaint

#6 Mets

There are air springs that are inserted into the middle of the stock spring. You can pump it up either with a compressor or a pump.

Message modified: Metz, August 01, 2011 - 16:34.

- Top

- Complaint

#7 optimus prime

- From: Ukraine

- Auto: 21063

- Top

- Complaint

#8 ShuriK777

- Top

- Complaint

#9 optimus prime

- From: Ukraine

- Auto: 21063

- Top

- Complaint

#10 W_R_X

- Top

- Complaint

#11 optimus prime

- From: Ukraine

- Auto: 21063

I once had double ones

- Top

- Complaint

#12 golden88

- From: Vinnitsa

- Car: VW Passat B5+

Anyone who says that twin springs are crap has never driven like that or assembled them crookedly.

I personally spent a year away. I installed it for a stiffer suspension because... There was a mess and the tires were grinding into the arch. My springs were new + I cut one normal one in half and put one half in mine. It turned out to be 2/3 double and 1/3 single. The impressions are good - it’s not hard to drive and when they sat down from behind the car did not sit on the arches. The plasticine ass disappeared during loading.

- Top

- Complaint

#13 W_R_X

- Top

- Complaint

#14 ORION

- Top

- Complaint

#15 optimus prime

- From: Ukraine

- Auto: 21063

- Top

- Complaint

#16 Dizeli-t

- Top

- Complaint

#17 Knjaaz

- Top

- Complaint

How to compress a spring in the field

Some craftsmen use seat belts in the absence of ties. To work you need 2 seat belts, 2 levers (fittings, strong sticks, pipes).

Spring compression procedure

1. Thread the straps on both sides of the spring and tie with a secure knot.

2. We take the above materials as levers.

3. The spring is placed on its side.

4. We insert the lever under each belt and tighten it. We fix it with wire.

5. We begin to alternately twist the levers to compress the spring.

6. The spring is compressed, continue the following procedures.

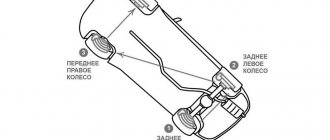

DIY rear suspension spring replacement

Rear springs come in two types: assembled with a shock absorber and without it (for example, on Renault Logan). They should also be changed in pairs on the same axis. As with the front springs, it is assumed that the preliminary steps have been completed and the spring is available for removal.

Without shock absorber

1. Raise the rear of the car on a jack.

2. Install the ties on the spring and compress to the desired position.

3. Using a flat-head screwdriver, remove the spring from its socket.

4. Remove the ties, as well as the upper and lower elastic bands.

5. Change the spring and perform the reverse assembly process.

With shock absorber

1. Unscrew the lower bolts of the shock absorber.

2. Jack up the rear of the car (under the rear axle stocking).

3. As you rise, watch the brake hose and the spring, which gradually comes out of its socket.

4. If the lifting height is sufficient, remove the spring and spacers.

5. Replace the spring and shock absorber assembly.

6. When returning it, it is important that the spring fits exactly into the lower recess of the cup.

7. Lower the car body.

8. Tighten the lower bolts of the shock absorber.

If the replacement is carried out correctly, the clearance increases by 6-7 cm.

How to strengthen the rear suspension - ways to strengthen the suspension

Many car enthusiasts are increasingly thinking about how to strengthen the rear suspension of their car. After all, looking at our roads, it becomes obvious that this is a necessity, and not just a whim of car owners. In order to protect your car from the consequences of bad roads, you can independently strengthen the rear suspension of the car. Moreover, the convenient thing is that this can be done even without any special or rare tools. A very good option for strengthening the rear suspension is a spring package that can be changed. You can add a leaf, or several, thereby strengthening the suspension. In order to find a new package of springs with a small number of leaves, you will have to search for a very long time, and in the end it is not a fact that you will find them. Therefore, you can do it yourself.

Springs

If you want to add multiple springs, you can do so by measuring the thickness of the spring package on your vehicle. As a rule, if you add even one leaf, this is quite enough to significantly strengthen the rear suspension. However, you must take into account that it is necessary to choose the right spring leaf. In addition, you will have to find a central bolt that is suitable in diameter and length.

Assembly of the spring package

If you are going to strengthen your rear suspension, then you will simply need additional parts, such as a clamp, as well as a spacer for each new leaf. They are used to tighten the spring package. Among other things, you will need some kind of spacer for the spring where it rests on the axle. If you're adding multiple sheets, you'll likely need new stepladders, nuts, and more.

Rear suspension device of UAZ 31512

Before you begin assembling the spring package, it would be better to lubricate the spring leaves together with some kind of thick lubricant. Solid oil or graphite lubricant is suitable for this.

Strengthening springs for Muscovites

Strengthening with an additional radical leaf

Installation of an additional root sheet

By installing the root leaf, you will receive a spring package similar to the one installed on station wagons. It is worth noting that the rigidity of the car will not increase much, but if you load it decently so that the root leaf rests on the root leaf, then you will feel that the additional leaf perfectly fulfills its purpose.

Building the package

You can add a sheet in different ways. An example is a root leaf whose ears are cut off and standard anti-creaking plates are used. In the plates you will need to cut off the round doll that secures the spring. You can glue it to the spring leaf using some kind of glue. It should be noted that if you create such a design, it will be used reliably and for quite a long time. You can also use the fifth sheet of the 6 sheet set, but it's worth noting that it's not easy to find.

Long bolt tie

Reinforcement with standard sheet

You can install an additional third leaf of a standard spring in place of the first or second leaf in the package. To do this you will need to insert stops into the holes of the anti-squeak plates. To do this, you can use some homemade bump stops. For example, fluoroplastic is suitable for this; by making bumpers from it, you will reduce their susceptibility to wear from friction forces. This method is good because it gradually makes the suspension stiffer as the load on it increases.

Spring bumper

Additional second sheet

You can also strengthen the rear suspension by installing an additional second leaf from the kit. The effect you achieve will be approximately the same as if you added an additional third sheet. But it won't be felt as much. If you want to modify the spring mounting, you can install new, longer shackles for the rear mounting of the spring package. It should be noted that their influence on the suspension is not entirely clear, because this changes the load vector on the springs, which can have a different effect.

Longer earrings

You can also install additional springs, it is worth purchasing a kit for this. It is quite easy to install, and if you want, you can easily dismantle it. Also, many car enthusiasts use a stabilizer to strengthen the rear suspension, and the operation will not affect the ground clearance or load capacity, but will significantly strengthen the suspension. It is worth noting that their installation will require strengthening the body spars at the point where the stabilizer is attached to it.

Rear stabilizer installation

Be careful, because in the process of strengthening the suspension you will certainly raise the body. If you increase the ride height by more than 5 centimeters, it can have a big impact on handling. The car can wear out when cornering, and this can also contribute to rapid wear of various suspension parts. This is due to the fact that when you strengthen the suspension, you will certainly raise the car, which in turn shifts the car's center of gravity. Therefore, if you decide to strengthen the suspension of your car, be sure to make sure that it is configured correctly.

In conclusion, we can say that the process of strengthening the rear suspension with additional springs is quite simple. But be careful and try not to change the geometry of the suspension structure, because this can have serious consequences for the body, as well as the car’s handling while driving.

Materials for production

To make a spring, you will need:

- ordinary door spring;

- gas burner or blowtorch;

- pliers;

- hand vice;

- container with machine oil;

- Bulgarian;

- bolt of the required diameter and length;

- slotted screwdriver.

Step 1. Making the blank

To make the required spring, we use a door spring, which is easy to buy in a supermarket or market.

Cut off a piece of the spring using a grinder.

To make the spring wire soft, it is necessary to anneal the steel. To do this, you need to heat it until it turns red and leave it to cool in the air. Heating a piece of spring can be done in various ways:

- Having built a microforge for the spring from pieces of vermiculite, we use a microburner.

- Using a blowtorch.

- Using a gas burner and forge.

We stop heating when the spring turns dark red (approximately 800 degrees Celsius). We leave it to cool in the air.

Step 2. Form a spring

After cooling, remove carbon deposits from the spring with a brush and unwind it.

We take a bolt with a diameter equal to the inner diameter of the spring that we want to make and, fixing the tip of the wire with a hand vice, we wind the wire tightly around it.

In the same way, springs of various shapes and purposes can be made.

For uniformity, use a slotted screwdriver to make the required distance between the turns.

After trimming, the result is a spring like this.

Step 3. Making the spring stronger and more elastic

We harden the spring, for which we heat it to a dark red color and immerse it in a vessel with machine oil.

To eliminate the fragility of the spring, we conduct a high tempering of the steel at a temperature of about 400-500 degrees Celsius, achieving a light gray tarnish color.

When this temperature is reached, stop heating and cool in air.

How to make a spring with your own hands at home

How to make a spring with your own hands [KNOW-HOW]

Spring restoration

Restoration by thermochemical method requires more time, skills and abilities. So, at the very beginning, you need to put the spring in a vice and compress it so tightly that the coils touch each other. Then you need to apply electric current through it, 200-400 A will be enough, working in this mode will be enough for 20-20 seconds. If you are not sure that the current is sufficient to heat the spring, then you can verify this visually - the metal should turn red.

And now, our spring has heated up to the desired temperature, now we should stop supplying the current and begin to slowly open the vice. As soon as it has extended to the limit, it is necessary to fix its end ends, and then try to stretch it a little more. Remember: the described procedure should take you at least a minute. After the operation, the spring should be hardened by placing it in a bath of oil; for this purpose we recommend using oil from the AC-8 series.

With these simple methods you can try to bring tired springs back to life, giving the car its former softness and elasticity. However, springs not only provide comfort, as mentioned above, but also play an important role in determining ground clearance. So, if you need to make your car more passable, you can install spacers between the springs, thereby adding a few centimeters to the ground clearance. If you prefer bulges (excuse the expression, but low cars are considered just that), then you can achieve your goal with the help of simple manipulations with these same springs. However, in any case, no matter what you do with the springs, no matter what tasks you set for yourself and your iron horse, remember: any intervention in the design of the car entails negative consequences. Thus, having decided to change the ground clearance, change the springs or do something else in this vein, know: after such procedures, in order to avoid troubles during trips, you will have to visit the service station more often to diagnose the suspension, although you can do it yourself . In any case, before making such important decisions, think several times whether the game is worth the candle!