Reasons why the injection VAZ 2114 does not start

The design of any modern car, the VAZ 2114 is no exception, is such that the successful production of a car depends on a number of positions. Previously, this was enough for the mechanical pump to supply fuel to the carburetor, and for the spark plugs to produce a spark. Today there are a lot of problems that prevent the engine from starting. An electronic injector requires the participation of several sensors, and the matter is not limited to them. In this article we will tell you why not and how to deal with it.

This article is sponsored by the Crafts website. This is a creative portal that contains the best master classes on needlework, practical tips on the house, knitting, embroidery, decoupage. Handmade gifts for loved ones will give memories for many years and will captivate with their individuality and exclusivity. Here are the best ideas with instructions for making applications and crafts that will become unique souvenirs, decorations for your home, apartment, or suburban area.

In general, all causes of malfunction can be divided into two large categories:

- Fuel system problems. This group includes any breakdowns as a result of which fuel is not supplied to the engine at all, is supplied incorrectly, or mixture quality errors occur.

- Electrical problems. Ignition of the fuel mixture is ensured by sending an electrical signal to the spark plugs. If problems arise here (and there are a huge number of electrical elements), the car will not start.

The most terrible malfunctions can be included in a separate category - for example, a “knocking” VAZ 2114 engine, a broken timing belt and, as a result, bending of the valves. In these situations, expensive repairs cannot be avoided.

If it doesn't help

Let's start checking the spark plugs. You need to unscrew them and visually inspect them, as well as “smell” them. If they smell strongly of gasoline, it means they were filled during a cold start of the engine. We clean it of oil and carbon deposits and put it back. We wait for some time and repeat starting the frozen car.

You can also check the spark plugs to see if they work or not. Method for injection and carburetor cars without individual ignition coils. You will need: an assistant, a spark plug wrench. We unscrew the spark plug and insert its pointed part into the high-voltage wire. We bring the other side of the spark plug (it is advisable to first clean it from oil and carbon deposits) to a metal part of the car, for example to the engine. I do not recommend bringing the spark plug to the outside of the car due to possible damage to the paintwork.

Common situations

Next, we will look at several typical situations that arise for many VAZ 2110 owners who complain about the inability to start the engine of their car.

Situation

What do we have to do

The starter turns, the spark plugs fill. Replacing spark plugs leads to flooding again

The car can only be started 2-3 times

At negative air temperatures, the car does not start, although the starter turns. The battery is low, the oil warning light is on

After changing the ignition switch, the engine started, but after assembling the steering unit, the engine ran for a couple of minutes, slowly died out and will not start again.

Check the serviceability of the fuel pump:

The engine started with difficulty, a lamp with an exclamation mark appeared on the panel, and soon the engine stalled

This lamp indicates that there is still voltage going to the starter, although the engine has started. Most likely, the decoupling from the engine did not occur, and the starter failed. To fix the problem, you need to install a new starter.

Each of these reasons has its own methods of prevention and measures to prevent their recurrence. Therefore, be careful and respond in a timely manner to the signals that the car itself sends to you. Thanks to them, you can detect a malfunction in a timely manner and find ways to solve the problem on your own.

Fuel system diagnostics

This is the first stage of measures to eliminate our problem. If your car is manufactured by a domestic manufacturer, then when you try to start the engine you should hear a characteristic “buzzing” noise coming from under the rear seats of the car. If this sound, which determines the activation of the fuel pump, is absent, you need to check the fuses, the main relay of the engine management system, as well as the relay of the pump itself. In VAZ 2107, 08 and 09 cars (as well as their modifications), the fuses are located under the glove compartment. On cars of the VAZ 2110 family they are located on the passenger side behind the side cover of the heating console. Pavel V., a novice car enthusiast, sent us his “cry from the heart”: “...the VAZ 2110 will not start, the fuses are fine, what should I do?” We answer - check the serviceability of the relay, fortunately this is done quite simply - just touch it with your palm and you should feel a characteristic click. If these devices are working properly, we will need to check if fuel pressure is present at the rail. Naturally, it is better to check the pressure using a pressure gauge (the operating fuel pressure in the system is 2.8 atm), but in its absence, this can be done “by eye”. For VAZ cars, you will need to press the spool, which is located at the end of the ramp, under the protective cap, and for GAZ models, disconnect the supply tube. When you press the spool or contact the “output” of the tube, you should feel pressure in the system. Your injection engine does not start, although the pressure corresponds to the optimal value? Turn on the fuel pump and watch how gasoline enters the system - the stream should be smooth, with constant pressure. Note that if the device operates normally, but the pressure in the system is insufficient, then the cause of this malfunction may be “clogged” fuel filters or pipelines, a faulty pump, or simply a lack of fuel. So, we are convinced that the fuel pump is working, the pressure in the system is close to normal - all that remains is to check the serviceability of the ignition system, as well as the condition of the spark plugs.

The VAZ 2107 engine does not pick up speed and does not pull

It happens that the VAZ engine does not pull. This is most often due to low pressure in the rail. The engine starts normally, also idles stable, but does not pick up speed. The thing is that in such modes the fuel pump requires increased performance, which it cannot provide.

If the VAZ engine does not run hot, then it is worth checking the air flow meter, as well as the spark plugs. The article already mentioned a red spark, but when cold, they can be normal, but under the influence of temperature they become “broken.”

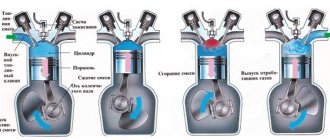

Specifics of the injection engine

Cars with the mentioned type of power unit came off the assembly line only in the last years of mass production of “sevens”. Engines with such an injection system are more advanced compared to carburetor engines, but at the same time they are noticeably more complex. However, the reluctance to launch here can be explained by very few factors.

The most basic reason is an empty gas tank. If there is sufficient quantity of fuel, then it should be assumed that its supply is somehow disrupted.

The second option is the absence of a spark or its insufficient strength.

It wouldn't hurt to find out what the pressure is in the fuel line. In a VAZ on which the injector is installed, too low sometimes prevents normal starting. Measurements are made with a pressure gauge, for which there is a special fitting.

If your car has an on-board computer, it will allow you to quickly determine the cause of the malfunction. So, often problems with startup lead to an error being displayed. In this case, most likely, the VAZ injector does not want to start due to the fact that the fuel is not ignited properly in the cylinders. Inspecting the spark plugs will help here. Make sure they spark.

Proceed like this:

- unscrew one together with the wire;

- apply to the mass of the car;

- turn on the ignition.

Possible faults

No matter how trivial it may sound, if the injector does not start, it means something has gone wrong. The success and speed of repair depends on how quickly and efficiently the problematic link in the car’s design can be identified. To better understand the essence of repair activities, it would be a good idea to pay attention to potential breakdowns. The basic list of the latter is as follows:

- Malfunctions of the injector itself. In the event of a breakdown of this kind, as a rule, the car does not start either cold or hot. On top of that, the injector indicator on the dashboard or on-board computer constantly lights up, signaling its malfunction. It is much less common for the engine to work when the indicator is on, but in this case the car starts poorly and is extremely unstable. It is worth noting that the injectors in the injector most often become clogged or the ECU burns out, so it is advisable to check these components first;

- Ignition system failures. Here the list of possible faults is quite large. Often the candles that suffer are simply flooded. In the event of such a breakdown, the car starts and immediately stalls, but in the long term it stops even “grasping.” Other components of the ignition system (coil, module, distributor, crankshaft sensor, etc.) are noticeably less likely to suffer;

- Incorrect operation of the fuel system. In this aspect, injection engines most often suffer on three fronts:

- Fuel filters are clogged (the car “picks up”, but does not start; if the engine starts, it is extremely unstable);

- The fuel pump is faulty (its characteristic operating sound is absent when you turn the ignition key, the injector itself simply does not start both cold and hot, the starter turns).

- There is insufficient pressure in the fuel system (the engine starts up reluctantly both cold and hot, but if it starts working, it functions unstable);

- Engine problems. Perhaps the widest range of possible malfunctions. Often the reason lies in weak compression or incorrectly adjusted valves. In any case, with a “motor” starting problem, high-quality engine diagnostics are required, otherwise it will be very difficult to determine the cause of the malfunction.

Necessary equipment

In order to find and eliminate the main, most common faults associated with our problem, you will need the following “simple” equipment: 1. Test lamp. Make it yourself by soldering wires to a light bulb from the instrument lighting system. When “checking” an injection engine, do not use lamps with a power of more than 2.5–3 W, this may damage the controller. 2. Discharger. It will be required to check the presence of a “spark” - a discharge on the spark plugs. “Recipes” for making it yourself can be found on the Internet, there is no difficulty there. 3. Multimeter. You will have to buy this device in a store; its cost does not exceed 500 rubles. It was these simple devices that helped our reader Sergei S., who wrote that his “... the VAZ 2107 injector does not start, the starter turns, but the engine does not start...”. It turns out that the cause of the malfunction was... Okay, let’s not get ahead of ourselves, let’s, as they say, “in order.”

Common problems and how to fix them

Before jumping into troubleshooting information, you should understand that there are two things you absolutely need to do. The first thing is to read the technical instruction manual that you receive when purchasing the engine. The second is compliance with the engine preventive maintenance schedule. These two points will help you avoid engine failure due to your own fault and not lose the warranty service provided by the manufacturer.

It is very difficult and time-consuming to describe all the faults, so we will talk about the most common ones. Engine problems can range from simple glitches to more complex problems. While some problems require the expertise of mechanics, others can be easily resolved by following the correct troubleshooting steps. Here are the most common problems you may encounter. Reasons for engines of different power.

Engine won't start

The fuel tank is empty (one of the most common reasons).

Fill the fuel tank with the correct type of fuel. If the engine has overheated and is still hot, allow it to cool before refilling the fuel tank.

The fuel tank has old fuel or water.

Fuel that has been in the tank for more than 30 days must be drained and replaced with clean, fresh gasoline. It is advisable to install a filter separator.

The ignition circuit is open (one of the most common reasons).

Insert the switch clip (key sling) firmly into place. Alternatively, try pulling the clip out and putting it back in place. If you started the engine without a clip, you will need to dry the spark plugs.

The engine is in gear.

The motor must be set to neutral. Place the engine lever in neutral and try again.

Charge the battery (especially for electric motors) to give the engine enough power to start. Also, check the motor's electrical connections for any signs of damage, corrosion, or exposed wiring.

Damaged spark plugs or ignition systems.

Unscrew the spark plugs and check. Spark plug is dirty or incorrect type - clean or replace with the correct type. The spark plug cap does not fit well - check and correct the cap. Poor connection or damaged ignition wiring - Check wiring for fraying or breaks, tighten any loose connections, and replace frayed or broken wires. Check sparking - make sure that the spark plug is threaded to the cylinder block and turn the starter. It’s a big plus if you have an extra spark plug in stock, designed specifically for a boat motor. If the spark is bad, then the cause most likely lies in the ignition coil. However, before definitively diagnosing the presence of a problem in the coils, you need to make sure that everything is in order with the wiring contacts, because the reason could just as well lie here. In more extreme cases of damage to the ignition system, it may need to be replaced.

Boat motor overheating

Outboard motors need a continuous amount of water flowing through the engine. When this is not the case, overheating occurs, i.e. the running engine stalls. The motor runs idle for a few seconds to allow water to enter. This can be felt by the burnt smell, and noticed by a change in color and shedding of enamel from the PLM parts.

To fix this, turn off the engine and check if there is a blockage in the water flow. This may be due to foreign objects such as algae blocking water intake. Try starting the engine again after it has cooled down.

Another possible cause of overheating is a faulty water pump impeller. The impeller of a water pump is a round disc with blades that circulate water through the outboard motor. When this part is broken, it cuts off the water supply to the engine and causes the engine to overheat.

Replace the broken pump impeller.

Remember, low-power PLMs, as a rule, do not have an engine overheat alarm. The impeller asks for replacement from time to time, mainly for temporary reasons (even if the engine has not been working for two years, it is still better to replace it). The channels of the cooling system, once per navigation, require cleaning from clogging and salt deposits. And during operation, do not forget to check the pump every 100 hours.

Severe outboard vibration

The running engine vibrates strongly. This can be caused by various factors. The most common cause is a damaged or loose propeller, and of course incorrect installation.