How to properly configure a VAZ-2109 carburetor

The majority of VAZ cars of the Samara family, and in particular the VAZ-2109, came off the assembly line with a carburetor power system, and only later a small series received injectors. The carburetor system has a simple design and is quite reliable, but its main component, the carburetor, requires periodic adjustment. The VAZ-2109 and other models of the family were equipped with Solex carburetors, characterized by a relatively simple adjustment technology that every car enthusiast can perform.

There are two main carburetor settings - the fuel level in the float chambers and the engine speed at idle (idle). These adjustments are carried out when the engine is unstable at idle and when certain symptoms of improper operation of the power system appear:

- The engine does not start well.

- The dynamics of speed gain have decreased.

- Dips appeared during intensive acceleration.

These problems indicate that the fuel level in the chamber is not normal.

Briefly about the key components of the G8 carburetor

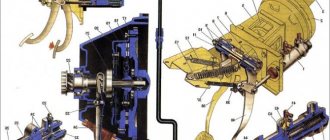

The Solex 1107010 carburetor, which is installed on the Lada 2108, is an emulsion device with two chambers. It has a cable-actuated throttle body (manual). The lower chamber of the carburetor contains dampers and a float compartment. It also has a housing with special diffusers. The upper chamber has a cover covering the body and fuel fittings. This cover is equipped with studs (they secure the air filter) and a flange.

The Solex 1107010 design provides for a number of key components:

- accelerator pump;

- float device;

- throttle control system;

- forced idle economizer system;

- two chambers and their dosing mechanisms;

- starting device (manually controlled);

- econostat;

- idle system.

In addition, the carburetor has many other mechanisms and individual parts that ensure its stable operation.

Setting the fuel level

Adjusting the amount of fuel in the chambers of Solex carburetors is a simple procedure and does not require specialized equipment. Although in the factory this adjustment is performed using a special template, which simplifies and speeds up the work. But at home you can do without this template.

To carry out adjustment work yourself you need:

- screwdrivers (phillips, flat);

- ruler (preferably a caliper);

- round rod with a diameter of 2 mm (wire or drill will do).

With such equipment you can quickly complete all work.

Briefly about the key components of the G8 carburetor

The Solex 1107010 carburetor, which is installed on the Lada 2108, is an emulsion device with two chambers. It has a cable drive (mechanics). The lower chamber of the carburetor contains dampers and a float compartment. It also has a housing with special diffusers. The upper chamber has a lid covering the body and fuel fittings. This cover is equipped with studs (they secure the air filter) and a flange.

The Solex 1107010 design provides for a number of key components:

- accelerator pump;

- float device;

- throttle control system;

- forced idle economizer system;

- two chambers and their dosing mechanisms;

- starting device (manually controlled);

- econostat;

- idle system.

In addition, the carburetor has many other mechanisms and individual parts that ensure its stable operation.

Recommended Method

Level control technology includes a number of stages:

- We dismantle the housing of the air filter element. To do this, unscrew the fastening nut of the housing cover, unclip the latches, remove the cover, take out the filter and tighten the 4 nuts that secure the housing to the carburetor.

- Raise the body and disconnect the rubber pipes. We move the body to the side.

- Loosen the clamps securing the fuel pipes going to the carburetor and disconnect them.

- Remove the wire suitable for the idle speed solenoid valve;

- Disconnect the drive cable of the air damper (the “choke” handle);

- Unscrew the 5 screws securing the carburetor cover;

- Having removed the cover, we immediately determine the fuel level in the chambers by lowering a ruler or caliper into one of them until it stops (using its depth gauge). If the measurement shows a level of 25-26 mm, it corresponds to the norm and no adjustment is required;

If the amount of fuel in the chamber is lower or higher than normal, we perform a visual inspection and a series of measurements on the floats, and if necessary, we correct their position.

To carry out adjustment work, place the removed carburetor cover on a flat horizontal surface with the floats facing up.

First, we look at the position of the elements from above. The outer side surfaces of the floats are parallel to the special imprints on the gasket. Deviations can cause the floats to touch adjacent elements and surfaces, causing the fuel level to be incorrect. If necessary, adjust the position of the floats by bending their mounting arms.

The next step is to measure the gap between the floats and the gasket. A rod with a diameter of 2 mm is useful here - this is how much the specified gap should be.

If it does not correspond, we bend the tongue of the floats, with which they act on the locking needle. After this adjustment, we check the total height of the floats, which is normally 34 mm. If this is not the case, check the gap again, adjust it if necessary and measure the height again.

The last stage of setup is determining the working stroke of the floats. To do this, place a caliper near the float, mark the distance from its lower corner to the surface of the cover, then lift the float with your hand and mark where the lower corner is.

A working stroke of 15 mm is considered normal; if it differs, it is adjusted by bending the tongue.

Alternative way

There is a simpler method for determining the correct position of the floats, which does not require measurements.

Place the carburetor cover on a flat table and look at the stampings made on the side surfaces. When the floats are in a normally adjusted position, these strips are parallel to the lid.

Then we lift the floats up and look at their bottom, which after lifting should be parallel to the surface of the lid. If necessary, adjust the position of the floats by bending the tongue.

After adjustment work, we assemble the carburetor.

Idle speed adjustment

The second setting of the VAZ-2109 carburetor is idle speed, it can be partial or full. The first is for minor speed adjustments, the second is for adjusting the amount of air (setting CO emissions in the exhaust gases).

Partial adjustment is performed using the air-fuel mixture “amount” screw. This screw sets the opening angle of the throttle valves, which ensures that the air-fuel mixture enters the cylinders when the accelerator pedal is released. The “quantity” screw rests on the throttle valve control lever and when screwed in, it pushes the lever, causing the valves to open slightly.

Partial idle adjustment is performed with a warm engine and creating a load on the vehicle's on-board network by turning on the high beam headlights and the interior heater at full power.

The adjustment is carried out with the engine running by screwing in/unscrewing the “quantity” screw until the optimal idle speed is established, which for the VAZ-2109 is 800-900 rpm (this can be tracked using a standard or plug-in tachometer).

If it is not possible to set the required speed or the motor operates unstably at it, a complete adjustment is made, which is made by two screws - “quantity” and “quality”.

The algorithm for this adjustment consists of the following stages:

- Warm up the engine and then turn it off;

- We find the quality screw (it may be closed with a plug that will have to be removed), screw it in until it stops, and then unscrew it 3-4 full turns;

- We start the engine, turn on electrical consumers (lighting and stove) to create a load in the on-board network;

- By rotating the “quantity” screw, we achieve 700-800 rpm on the tachometer;

- By turning the “quality” screw, we set the maximum possible speed (they will increase to a certain level, and then stop. The moment the speed increase stops is considered the maximum);

- We set the “quantity” screw to 900 rpm;

- Using the “quality” screw we lower them to 800 rpm;

- We slowly tighten the “quality” screw until interruptions appear in the operation of the power plant, after which we unscrew it back 1 turn;

- We adjust the speed with the “quantity” screw, bringing it to a normal value - 800-900 rpm;

After the adjustment operations, we check that they were carried out correctly. This is done by sharply pressing the gas pedal and then quickly releasing it. With a properly configured carburetor, the engine should respond quickly to pressure, without any failures or hesitations. And after releasing the pedal, the speed will drop to the idle level, without sags or instability of the engine.

Video: HOW TO CORRECTLY ADJUST THE FUEL LEVEL

Didn't find the information you are looking for? on our forum.

Engine running on choke

Now we need to take a closer look at its structure. Both the adjustment of the VAZ 2108 carburetor and its repair are carried out according to a certain algorithm. The fuel mixture enters the cavity, which is located in the trigger mechanism. In this case, the diaphragm, which is located in this device, overcomes the influence of the spring. And the air damper opens slightly. When you return the choke lever to its original position, the starting gaps decrease. They are not adjustable in any way; they depend on the size of the drive lever, as well as the shape of its cutouts. Changing them yourself is quite problematic. While the choke lever is depressed, the accelerator pedal will only control the drive located on the throttle valve of the primary chamber. And in this case, the idle speed adjustment of the VAZ 2108 carburetor cannot be carried out - the air damper must be completely open. As for the secondary camera, it is blocked. Thanks to this, it is possible to avoid jerks while driving a car whose engine is not warmed up.