Maybe someone is interested! Fuel injectors standard installed on VAZ vehicles

Recently, AvtoVAZ has significantly expanded the range of injectors installed on the assembly line. Currently, 4 types of Siemens Deka injectors are “seen” on VAZs: “thin” 20734 (orange) / 20735 (blue) and “thick” 6393 (beige) / 20734 (yellow). The situation with the same number of injectors of different design is incomprehensible, but it is a fact.

BOSCH injectors with catalog numbers 0 280 158 502 and 0 280 158 022 are also installed.

Bosch 0 280 158 022

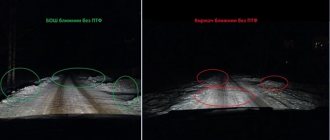

“Thin” Siemens differ in the location of the nozzles, in 20734 all 4 nozzles are located in the same plane in a cone-shaped recess, and in 20735 they are spaced apart in pairs in two different planes (see photo). Such injectors are called “double-flare”, each torch pours fuel onto “its own” inlet valve, and not onto the partition between them.

“Thick” Siemens Deka nozzles are available in two types: 6393 (beige) and 20734 (yellow). It is unclear what caused the use of the same code (20734) for structurally different injectors. I don’t want to think that there weren’t enough numbers or imagination :). There is an assumption that the “thin” nozzles for some reason did not suit Siemens-Deka and they were replaced with ordinary ones.

No clear relationship has been found at this time between engine type and installed injectors. At this time, statistics are being collected on installed injectors on different engines. At the moment, the generalized table looks like this:

A month ago, trouble happened - the car began to stall at idle, the speed began to pick up worse, and traction appeared only after 2,500 thousand revolutions. Using a simple method of checking the spark on the spark plugs and turning them off one by one, I found out that the 3rd cylinder was not working. The compression in it is about 11. That is. the problem was with the fuel supply. Suspicion fell on the injectors. I tried to check the injectors myself - when voltage is applied to the contacts, a working injector should make a quiet clicking sound. I also measured the resistance of the injector windings - everything was normal. I went for diagnostics, connected it, checked it, looked at the graphs, used an oscilloscope and came up with a verdict: the injector on the 3rd cylinder is not working, the rest are on the way. By the way, I have SIEMENS

DEKA VAZ

6238

And then the question arose:

Option 1.

Clean the old ones.

the pleasure costs fifteen hundred. But there is no guarantee that they will not be covered soon. Option 2.

Install BOSH, the ones that fit my 8 - these are BOSCH 0 280 150

996

are not currently produced and they are very difficult to find and the price is very high, and their replacement, which is now on the market - this is BOSCH 0 280 158 110 requires firmware adjustments .

Because I didn’t intend to flash it - this option is due to the price and difficulty in finding spare parts. didn't fit. The advantage of Bosch injectors is that they have 4 nozzles and should work better (Siemens has 2 nozzles) Option 3.

Install the same

Siemens 6238

gray ones.

I started looking for injectors and called several stores. Some people didn’t even know about Siemens injectors and hadn’t even heard about BOSCH replacements. Not anywhere, not even in the Ladovsky store near the VAZ Auto Show - there was only one type of injectors and on another fuel rail assembly (I have an aluminum square one), which also did not suit me. In the end, I found a Siemens kit, the price is for all 4 pieces. 2150 rub. Replacement work cost 600 rubles, and at the same time we changed the fuel line gaskets.

FakeHeader

Comments 18

What kind of brain do you have?)

And on 8k there was a BOSCH one, it seems, with a chip that had to be soldered and programmed for firmware)

Guys, tell me who changed the force to BOSCH 0 280 158 110? Is it necessary to flash it? VAZ 2109i 2001

If you change the forces and their performance differs from the parameters specified in the firmware, then inevitably you need to adjust the firmware, which is complete crap, because from the section and parameters “VAZ injector” and that’s it. That's why they shove it at people who don't understand and install it. For example, there were Siemens deck 6238 - 4 pcs. with a performance of 1.6537 and one piss began to leak, or worse, flow through the housing or the winding resistance was zero, which is not uncommon. So, a man goes to the store and buys a VAZ injector, and the seller pushes him, for example, Avtelov’s 6393! They look completely identical, only the color is different, but the performance is different! The poor fellow sticks her into the ramp and gets sausage. Then he starts to get his mind blown in the store that the force is dead, and they tell him that we don’t sell dead meat, only fresh stuff. In this performance category, Siemens deck 6238 and Bosch 0280150996 green are identical. But the Boshevsky ones are structurally different and fit a different ramp. Something like this. It’s the same with DMRV 037 and 116. The firmware for them has different calibrations, which need to be changed to the type of DMRV and registered in the firmware. Install spark plugs with resistance that is not suitable for short circuit? And what ? Can you tell me for a moment that it runs and starts? Yes, I agree that perhaps they have less resistance and therefore a stronger spark, but then the question is, how long will the coil last or what is worse than the coil? Even, I didn’t sign for jokes))))) Here is a table of interchangeability of VAZ engines, where the asterisks indicate identity in performance, but this does not mean that they are structurally identical. The plant always swims against the current ((((

Which injectors are better to install on a VAZ-2114

The first, but not the last sign of injector failure is increased fuel consumption.

In addition, detonation, failures when changing engine operating modes, and unstable idling may occur.

For 2021, AvtoVAZ is installing several types of injectors and many of them are interchangeable. Today there are several main types - three types of Bosch injectors and three types of Siemens injectors. First, let's look at Bosch injectors.

BOSCH injectors

Their use depends on the engine size and the number of valves. There is no particular variety in VAZ-2114 engines, so there are only the following options:

- Injector BOSCH 0280 158 022. The nozzle is marked black, has a productivity of 1.9644 mg/sec, and operates at a standard pressure of 3.8 atmospheres. Installed on a 1600 cc engine with 16 valves. Works with January 7.2 controller.

BOSCH nozzle: productivity 1.9644 mg/sec

BOSCH nozzle: productivity 1.922 mg/sec

The new injector may have a thicker O-ring and, accordingly, a longer nozzle. The injectors are completely interchangeable. These injectors can only work with the January 5.1 controller.

In addition, you need to know which engine control controller is installed on the car, since January 5.1 and January 7.2 may require injectors of different capacities.

Siemens Deka injectors

There is no certainty with Siemens injectors, since the plant can install injectors of different markings on the same engine. However, there is a clear difference between the injectors for eight-valve and 16-valve engines .

In the first case, the nozzle is single-flame, in the second - double-flame, that is, it sprays fuel onto each of the intake valves separately.

They are marked as VAZ20734 (orange markings) and 20735 (blue markings). On eight-valve engines, a Siemens 6393 nozzle with a thick torch can be used. Its productivity is 1.662 mg/sec, and its operating pressure is 3 atm . Each of these injectors can be installed on a VAZ-2114 engine.

Signs of injector failure

As you know, the main task of injectors is to supply fuel to form a fuel mixture in the combustion chamber. Accordingly, the most common breakdown that can occur is a blockage or its complete failure. A malfunction in the injector can be determined by several factors:

- at idle the engine is unstable;

- fuel consumption increases significantly;

- the engine does not start well, especially if it is cold;

- sometimes there is a lot of black smoke from the exhaust system (if the injector leaks, too much fuel may enter the combustion chamber);

- from time to time there are loud pops from the muffler;

- the car loses dynamism, power drops, jerks appear even when driving on a flat road, as well as when the load on the engine changes.

Of course, such signs may also indicate defects in other components of the car, but if they are detected, it is still recommended to check the injectors and, if necessary, repair them or replace them with new ones. Faulty injector operation will result in faster engine wear, which will lead to the need for major repairs.

When to change: self-diagnosis

The fuel system of an injection engine has a fairly extensive architecture and faults can only be identified after an accurate diagnosis of each of the system elements. For example, a drop in engine power may be the result of either a malfunction of the injectors, insufficient performance of the fuel pump or a clogged fuel filter.

In addition, jerks and dips, unstable idle and difficult starting, increased consumption, can occur when the injector is simply clogged.

You can check the injectors themselves directly on the engine without removing them. To do this, just start the engine and remove the wires from the connector one by one. If the stability of the engine changes at the same time, the engine starts to oscillate, then the injector is in order. If, when removing the wires from the connector, the stability of the motor does not change, the injector needs to be cleaned or replaced.

Replacement or flushing?

Some problems can be eliminated by cleaning and flushing. Others are “treated” only by replacement.

Table: problems with injectors

| Malfunction | Remedy |

| reduced performance | flushing, replacement if flushing fails |

| leakage | flushing, replacement if flushing fails |

| increased productivity | replacement |

| valve sticking | replacement |

| unstable valve sticking | flushing, replacement if flushing fails |

| overestimated or underestimated winding resistance | replacement |

In these cases, flushing is not a panacea. This method should be used taking into account the mileage and quality of service during operation.

During operation, the injector nozzles inevitably become coked and clogged with resinous deposits. The picture is aggravated by low-quality fuel, which can introduce additional pollutants.

For some time, fuel atomizers continue to operate without any visible changes, but sooner or later contaminants accumulate, changing the shape of the spray and reducing performance.

Injector life expectancy is limited even when using the cleanest fuel. Manufacturers recommend changing them every 100–120 thousand kilometers. Due to the fact that motorists use imperfect gasoline, and the one that can be bought at gas stations, the part has to be changed after 80-100 thousand km.

There is an opinion among motorists that “there is no need to interfere if everything works fine.” This opinion is justified, but only if the owner is ready to replace the nozzles with new ones approximately every 50 thousand kilometers.

The fact is that by getting rid of minor deposits as they accumulate, the owner extends the life of the consumable, since pollutants do not have time to cause irreparable damage.

Clogged injectors begin to interfere with normal operation after 30–50 thousand km.

Initially, negative processes manifest themselves only in increased fuel consumption. Owners do not always associate the increased “appetite” of the engine with injectors, since there are many reasons for this phenomenon.

In the range of 50–80 thousand km, pollution, having accumulated, can cause interruptions in engine operation, which is no longer undetectable. It becomes clear that “you have to get into the injectors,” but cleaning them at this stage may be useless. When a clogged part is used for a long time, the diameter of the nozzle often increases. Flushing will remove contaminants, but the original parameters will not be restored.

To extend the life of trouble-free operation and postpone replacement, you should regularly check the

pour injector cleaning fluid into the tank or use it in another way recommended by the manufacturer.

Motorists' opinions about the effectiveness and safety of injection chemicals are contradictory. Many people fear that flushing without removing it from the engine will clog the cylinders.

Indeed, if the car owner has not touched the injectors for a long time, it is impossible to do without removing the rack. The chemicals in the tank can cause harm instead of benefit. If you use cleaners regularly, without waiting for characteristic malfunctions to appear, there will be no harm to the engine from the chemicals.

Although injection chemistry has a beneficial effect on slightly dirty injectors, its use does not guarantee that the atomizers will comfortably “live” the entire period “allotted” to them by the manufacturer. You can unsuccessfully fill the tank with “left” gasoline at almost any gas station.

To minimize the accumulation of deposits, manufacturers recommend additional preventive flushing with special products every 30 thousand kilometers.

Table: advisability of flushing and replacement depending on mileage

| Mileage (thousand km) | Flushing | Replacement |

| up to 30 | preventive flushing with fuel additives every 3–5 thousand km | individual replacement of faulty parts |

| 30–80 | preventive flushing with a special agent every 30 thousand km | individual replacement |

| 80–120 | preventive flushing with a special agent every 30 thousand km | complete replacement of all injectors if at least one faulty one is detected |

Replacing injectors (full technology)

Before replacing injectors on a VAZ-2114 of any generation, it is necessary to relieve the pressure in the power system.

To do this, remove the rear seat cushion, open the hatch and remove the contact block from the fuel pump. Now it is de-energized and will not build up pressure.

We start the engine and wait a few minutes until all the fuel in the system is used up. The pressure has been relieved, now you can safely remove the old injectors and replace them with new ones. We proceed according to the following algorithm:

- We de-energize the car by removing the negative terminal from the battery.

Disconnect the negative terminal from the battery

Remove the hose from the pressure regulator

Disconnect the electrical connector of the throttle position sensor

Disconnect the connector from the idle air regulator

Disconnect the connector block from the injector wires

Unscrew the fuel rail mounting bolts

We dismantle the fuel rail with injectors

Squeeze the spring clip and disconnect the electrical connector of the injector.

Rock the injector and remove it from the fuel rail.

Installation of injectors is carried out in the reverse order. Before installation, it is advisable to check the integrity of the o-rings ; if they have lost their elasticity, it is better to replace them with new ones. The injectors are installed and ready for further use. Good luck to everyone!

Video about removing and cleaning injectors on a VAZ-2114

It may be leaking, you forgot to check it, if you inflate the ramp with forces up to 3 bar and the forces get wet from the side of the mesh, then your cleaning is a “dead poultice”, and therefore, without further disassembling, you put the ramp in place and go buy a new injector.

It may be leaking, you forgot to check it, if you inflate the ramp with forces up to 3 bar and the forces get wet from the side of the mesh, then your cleaning is a “dead poultice”, and therefore, without further disassembling, you put the ramp in place and go buy a new injector!

Replacing O-rings

To prevent fuel leakage, do not reuse the O-rings of the injector and injector body. They are replaced with new ones every time they are removed for any reason.

To remove the old ring, just pry it up with a screwdriver. When installing new ones, do not use hard tools; install the seals by hand. Before installing the injector, lubricate the rubber bands with engine oil.

An injection engine is not at all complicated, as owners of carburetor cars sometimes believe. Injectors are reliable parts that require only a little attention. Show it, and the engine will thank you.