What is its structure?

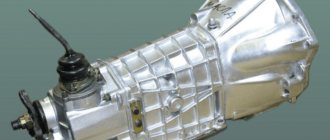

The main component of the crosspiece is a bearing, which is secured with bolts and allows it to rotate. The cross itself is a cross-shaped joint that controls the alignment of the axes of all rotating parts of the vehicle. It connects the plugs together. They are attached to each end of the cross. The movement of the hinge is carried out thanks to special needle bearings located on its spikes. These bearings are located in holes on the forks, and are secured on top with retaining rings (so that they cannot move).

Thus, the crosspiece of the VAZ 2107 is a very flexible connection between the car engine and the axle, which serves to move the connected parts and transmit torque to the wheel.

Purpose of VAZ 2107 cardan crosspieces

The need to use cardan crosses (CC) in the design of a car is due to changes in the position of the shafts relative to each other during movement. If the axes of these shafts were constantly on the same straight line, then crosspieces would not be needed. However, when moving, the distance between the axes changes in both vertical and horizontal planes.

The cardan joint is involved in the transmission of torque from the gearbox to the drive axles. Thanks to the KK, a flexible connection of the VAZ 2107 engine with the driving rear axle is ensured. The cardan design also includes hinges, intermediate supports and connecting devices. But it is the crosspieces that are responsible for transmitting torque at constantly changing angles between the shafts during movement.

The VAZ 2107 is a rear-wheel drive car, and its design provides a special role for the cardan. It transfers all engine work only to the rear wheels. Therefore, on the “seven” the cardan is located under the bottom and the floor in the cabin is raised in the middle.

Preparing for work

When buying a new crosspiece for a VAZ 2107, you don’t need to try to save money. Everyone knows that “the miser pays twice,” so it’s better to buy an original part right away than to change a couple of crosses in six months.

The body of the crosspiece is made of heat-treated steel. This is necessary to ensure the special hardness of the studs. Thus, the quality of the material plays a big role in the service life of the part. How long can a car run without replacing crosspieces? It is believed that approximately 500 thousand km!

The retaining rings and bearing also need replacement. Please note that the rubber of the bearing itself must be sufficiently elastic.

Replacing the driveshaft crosspiece of a VAZ 2107

If at the beginning of the vehicle movement you hear loud clicks, at high speed there are impacts from below, vibrations appear when you engage reverse gear, and upon inspection you see destruction or deformation, then it’s time to replace the driveshaft crosspiece of the VAZ 2107. This cross-shaped joint fixes the transmission axes , it is not difficult to replace it on a new car, but over time it becomes covered with rust and the task becomes extremely difficult. The cross consists of seal collars, four cups, retaining rings and bearings. It transmits torque to the drive axle from the gearbox. Below we will describe how to repair this hinge with your own hands.

How to remove the crosspiece, step-by-step instructions

Self-replacement of the driveshaft crosspiece

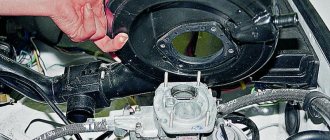

The first thing that needs to be done is to mark how the forks of the crosspieces are located, since at the manufacturing plant they are required to undergo balancing and when reinstalled, the driveshaft will emit vibrations. First, remove the retaining rings. It is best to do this using special sharp pliers. In specialized workshops, bearings are pressed out using a hydraulic or manual press, but during self-repair, this issue can be resolved using a drift from a soft material and a hammer. Next, remove a pair of bearings from the fork. We carry out a similar operation with another pair of crosspiece bearings. You should also clean the mounting holes and grooves for the retaining rings. You can use sandpaper (fine or medium grain). In addition, you may have to use a file to remove small burrs that sometimes occur when knocking out bearings.

Fault diagnosis

When you hear something wrong with the car’s movement and suspect a problem with the driveshaft, you should immediately investigate and identify the causes of the problem. To do this, you don’t have to go to the station; you can do this work yourself. Beginners should not do it themselves, but those who understand at least a little can fix the problem themselves. So:

- We drive the car into the pit and go down;

- With one hand we hold the flange that leads to the gearbox gear, and at the same time, with the other hand we take the shaft;

- We turn them in different directions and listen. If there is play in the connection, then this means that the surfaces are worn out and the VAZ 2107 cardan crosspieces need to be replaced;

However, one more thing should be said: if one bearing is faulty, you may not notice any play. Then you just need to visually look at the entire mechanism:

- Take a 13mm wrench and disconnect the driveshaft from the flange. After this, we look at the state of the entire node.

Attention: When disassembling, apply alignment marks. After completing the work, you can then carry out the assembly without any problems.

Spare part selection

In order to repair this unit less often, you need to purchase good quality spare parts. The correct choice of crosspiece determines how often it will need to be replaced. Choice of cross:

- It is advisable to make purchases in specialized stores and markets where there are quality certificates and traders value their reputation. It is better to never buy anything from random sellers who trade in spontaneous markets from time to time. In addition, a normal retail outlet provides a guarantee that allows you to return the product within 14 days if there is something wrong with it.

- The spare part should be from a well-known brand that has been proven over the years, and not of some dubious quality.

- The crosspiece should be purchased equipped with a grease fitting (grease fitting), through which you can always renew the lubricant in the bearings using a supercharger (“syringe”) - both manual and electric. This part will last longer.

And another effective way to check. The crosspiece taken out of the package should be placed on a piece of glass - a glass counter is quite suitable, or on the same side-view mirror (removed, of course). Holding your fingers opposite the axis of the cross, you need to try to swing them on this surface. Next, you need to do the same with other axes. Then turn the part and do the same operation again. During the inspection process there should be no knocks on the glass surface, which will indicate the absence of deformation of the part.

You should buy two parts at once, because after replacing one, the replacement of the other will very soon follow. Many people immediately change the bearing of the suspension device, so as not to have to repeat what they have done before, that is, disassemble everything, wasting time and their own nerves.

This is interesting: Uber tariffs for drivers

Features of the mechanism

The driveshaft transmits the torque generated by the car's engine to the rear axle, causing the wheels to rotate.

It is located under the bottom of the VAZ-2107 car, which is why you can find a raised floor in the cabin. The cardan on the VAZ 2107 consists of two main parts, which are connected to each other using a cross. This design of the device is necessary because the rear suspension constantly “plays” when driving due to shock absorption. The device is a hollow tube, which is the “arm” connecting the engine to the wheels. Despite the simplicity of the product, the shaft, like other car parts, fails and requires repair or replacement.

Main cardan malfunctions

The main malfunction of the driveshaft is that elements such as the spider and the outboard bearing fail. It is these parts that are the most loaded. The crosspiece and bearing fail for a simple reason - lack of lubrication. Over time, it is necessary to periodically diagnose these elements with the obligatory addition of lubricants. In rare cases, a cardan malfunction may be associated with a defective crosspiece, which requires its replacement.

The malfunctions of the mechanism in question are as follows:

- failure of crosspieces;

- destruction of the outboard bearing;

- violation of the configuration (imbalance) of the shaft;

- breakage of flanges, splines and couplings, which happens under heavy loads;

- excess moisture and dirt inside the crosspieces.

At the slightest sign of malfunction, it is necessary to diagnose the mechanism and eliminate all resulting damage. The malfunction can be identified by the following signs:

- the appearance of a knocking sound when the clutch is engaged, which may indicate wear of the splines or damage to the elastic coupling;

- the occurrence of a grinding noise when the car is moving indicates a lack of lubrication;

- the appearance of vibration when the car is moving, which indicates a violation of the alignment of the product;

- knocking noise during sudden acceleration or braking, which indicates wear of the crosspieces.

We will discuss how to replace the VAZ 2107 driveshaft in the next paragraph.

The process of removing and replacing the cardan

The mechanism is removed for the purpose of carrying out repair work or replacing it with a new product.

Often the driveshaft itself is an unpretentious device, but it is important to periodically check the condition of the bearing, splines and crosses. These are the weak points that need to be periodically looked at and monitored for their condition.

Work on dismantling the cardan is carried out in the following order:

First, you need to secure the car by placing stops under the front wheels, and place the gearshift lever in the “neutral” position. Next, jack up the rear of the car, while suspending one of the drive wheels. We proceed to disconnect the device from the mount to the differential. To do this, you need to unscrew the 4 fastening nuts and then remove the bolts. After unscrewing the fastener, you can separate the product from the differential flange.

It remains to unscrew the two nuts securing the cross member on which the suspension bearing is mounted. After unscrewing, you can dismantle the cardan from the VAZ 2107. Using a wooden hammer, you need to knock out (if necessary) the shaft from the engagement of the splines with the elastic coupling. After the shaft is repaired or replaced, you can install it in place. The installation process is inversely proportional to removal

When installing the product, it is important to ensure that the shaft is positioned correctly.

The driveshaft on cars of the VAZ family is a fairly reliable unit. However, it also needs periodic maintenance. All driveline faults should be repaired as soon as possible. Otherwise, more serious and costly problems may arise.

Signs that replacement is needed

How and why to syringe the driveshaft crosspieces? blog and news

The reason for replacement is the play of the hinge joint. Its occurrence is signaled by the appearance of various extraneous sounds when the cardan rotates. This may include squeaks, knocks and metallic ringing. The car vibrates when starting from a stop and at high speeds.

When you hear such sounds, you will know that it is time to check the driveshaft. For such a check, you need access to the machine from below, that is, you need a lift, pit or overpass. We check this way:

- Roll the car onto a pit (lift, overpass)

- Move the gear lever to neutral position.

- Get under the car.

- Hold the cross with one hand, and with the other turn the cardan back and forth.

- You will feel the existing play immediately.

- There are 2 crosspieces in the cardan design, check both.

Which crosspiece to choose

When choosing a crosspiece, pay attention to the presence of a grease nipple on it. By lubricating, you will extend its service life.

Selecting the cardan shaft cross

It wouldn’t hurt to conduct a small test of the part even in a store. To do this you will need a small piece of glass or a small mirror. We take the part under test out of the packaging and place it on the glass. Holding the opposite ends, try to shake the part, then do the same with the others. Then we turn the cross over and repeat the operation. If a knock is heard during the procedure, then there are serious doubts about the quality of the cross.

For me, the best option for installation is the Tolyati cross.

If you are changing the universal joint crosspiece, then it makes sense to change the second one too, so that you can deal with it soon. And also replace the outboard bearing.