Disassembling the front brake caliper Chevrolet Niva

Tools:

- Flat file

- Small hammer

- Hammer with plastic tip

- Vice with soft metal jaws

- Pliers

- Punch

Parts and consumables:

- Aerosol lubricant type WD-40

- Front caliper

Note:

The front brake cylinder block is replaced when brake fluid leaks through the O-rings, as well as when the pistons jam due to corrosion.

1. Remove the caliper from the vehicle as described here.

2. Clamping the brake caliper in a vice with soft metal jaw linings, use a drift to remove the cylinder block retainer.

3. At the same time, we recess the cylinder block retainer with a rod with a diameter of 3-4 mm and, hitting the cylinder block with a hammer with a plastic tip, we begin to move the block along the caliper guides.

4. After moving the cylinder block by 1.5-2.0 mm, remove the rod. Using a hammer with a plastic tip or a mallet, knock out the cylinder block from the caliper guides. Cylinder block and brake caliper.

5. We remove the retainer and its spring from the socket of the brake cylinder block.

6. The retainer fits into the caliper hole and limits the movement of the cylinder block.

7. We assemble and install the front brake mechanism in the reverse order. To facilitate assembly, use a file to remove the chamfers from the guides of the cylinder block.

8. Having sunk the latch into the block socket, insert the block into the grooves of the caliper. Using a hammer with a plastic tip, hammer the cylinder block until the retainer fits into the caliper hole.

9. Install the caliper on the car.

10. Bleed the hydraulic brakes as described here.

The article is missing:

- Photo of the instrument

- Photos of parts and consumables

- High-quality photos of repairs

Source: Chevrolet niva device, operation, maintenance and repair. Publishing house "Behind the Wheel".

brake lubricants

The topic of the article is brake lube. We receive a lot of questions on this topic, and about all cars. Therefore, I will talk in relation to all cars, sometimes focusing on the Niva and Shniva. As I said earlier, replacing pads and servicing calipers are two “big differences”. And if replacing the pads can be done in a couple of hours on both sides, then routine work on the calipers can take a whole working day. This includes cleaning the unit, lubricating the guides, and checking and replacing rubber elements.

Lubricant for seals, pistons and boots

I would probably call this group of lubricants assembly pastes. They lubricate everything that is structurally located under the boot. In the old days, when Lenin was still vertical, mechanics used camphor or castor oil. It was both a good lubricant for rubber and protection against water. But the time has come for modern lubricants. For these purposes, you can use two lubricants, identical in their functions, but different in price and manufacturer.

Toyota brake lubricant

Color glamor pink J. I put the manufacturer in quotation marks because Toyota does not make oils and lubricants, like other automakers, but uses the facilities of other chemical companies. There are plenty of them in Japan, and if I give several company names, they won’t tell anyone anything. (IDEMITSU KOSAN, JX Nippon Oil & Energy, SHOWA SHELL SEKIYU). The most disgusting thing for a Russian person is that this lubricant can only be bought under the Toyota brand and half the price will be for the name. It has the most magical effect on rubber. As an example - brake cylinder boots in the field. After processing, it seems that the boot is made not of bad rubber, but of silicone, it becomes so soft. Moreover, this effect does not disappear in either cold or heat. I provide this lubricant for clients only upon request. Firstly, because I order it exclusively in Japan, and secondly, because the item is quite expensive. The cost of a tube is about 1000 rubles.

Brake Lubricant, Caliper Guides

Under no circumstances should you use “lithols and solid oils”. These lubricants are thermally stable up to 80-90 degrees, then they either coke or leak. The temperature at the calipers can be significantly higher. Also, these lubricants must be moisture-resistant and “salt-resistant,” and only “semi-synthetic” base fillers can do this. Another important characteristic of these lubricants is their neutrality towards rubber, plastic and non-ferrous metals. And just for the Niva family, this point is very important, since the cylinders are made of “aluminum alloy”. In our case, these lubricants are applied to the ends of the pads, the caliper axles, and the bracket, in the place where the “horseshoe” is adjacent to it.

Bosch and ATE grease

There are two manufacturers in the title. The explanation is simple: inside the tubes there is the same lubricant. This lubricant is not recommended for use when the guides are in rubber boots. But in our case, the structure is completely bare. Practice has shown that even in the conditions of St. Petersburg humidity and salt, it remains alive until the next replacement of the pads.

Brake Lubricant, TRW

As in the first case, Bosch lubricant, there is an alternative. This is a German product, manufactured by TRW. It has one significant advantage. It is absolutely neutral to rubber, plastic and paints. That is, it can and should be used where there are rubber boots on the guides. And this is 95% of modern designs of disc calipers from all manufacturers.

Types of lubricants

It’s worth pointing out right away that manufacturers divide lubricants into two types - paste and spray. Before we move on to listing their types and brands, it is necessary to decide what characteristics the caliper lubricant should have. With an aggressive driving style or driving along mountain serpentines, the caliper temperature can reach +300°C, and in urban conditions it can heat up to +150°C...200°C. In addition, the caliper is affected by moisture, dirt, and reagents that are sprinkled on the roads. Therefore, the lubricant for calipers and its guides should be:

- non-aggressive towards rubber and plastic parts of the machine;

- do not lose their properties when exposed to water, brake fluid or other substances that can wash or dissolve it;

- high-temperature lubricant, that is, not to lose its temperature properties at +180°C or more;

- should not lose its physical properties in severe frosts (from -35°C and below).

Commonly used cheap lubricants do not provide the described conditions. We are talking about graphite paste, lithol, nigrol and their other analogues. That is, for the normal operation of the brake system, and in particular the caliper, it is necessary to use modern developments.

Currently, manufacturers produce the following groups of lubricants for calipers:

First group

— mineral or synthetic pastes using metals. They are of the high temperature extreme pressure type. Their operating range is very wide, and is approximately -185°C...+1100°C (each lubricant has its own operating range). The substance is based on synthetic or mineral oil, to which thickeners have been added, as well as metal particles (copper or molybdenum). These include the following subtypes:

- complex pastes, which include copper, aluminum and graphite powder;

- copper, containing copper and graphite powder;

- pastes without metal particles, instead of which magnesium silicate and ceramics are used;

- lubricants based on copper or molybdenum disulfide.

Examples of specific brands of lubricants of this type:

- complex pastes - HUSKEY 2000 Lubricating Paste and Anti-Seize Compound for High Temperature, Loctite No. 8060/8150/8151, Wurth AL 1100;

- copper pastes - HUSKEY 341 Copper Anti-Seize, LIQUI MOLY Kupfer-Paste, Mannol Kupfer-Paste Super-Hafteffekt, Marly Cooper Compound, Molykote Cu-7439 Plus Paste, Motip Koperspray, Permatex Copper Anti-Seize Lubricant, Pingo Kupfer-Paste, Valvoline Cooper Spray, Wurth SU 800;

- metal-free pastes - HUSKEY 400 Anti-Seize, TEXTAR Cera Tec, LIQUI MOLY Bremsen-Anti-Quietsch-Paste;

- pastes with molybdenum disulfide - HUSKEY Moly Paste, Assembly Lubricant & Anti-Seize Compound, Loctite No. 8012/8154/8155.

Pastes belonging to this group can be applied to GUIDE PINS of brake calipers and any highly loaded friction surfaces, except for the working surfaces of brake pads!

Second group

— Pastes based on mineral oil. They contain bentonite, which acts as a thickener. In addition, metal particles and fatty acids are added here. The main advantage of mineral-based lubricants is stable operation in the temperature range from -45°C...+180°C. That is, the paste does not flow out and does not lose its properties. Thus, it is excellent for lubricating the guide calipers of vehicles operated under gentle conditions. An example of this type of lubricant is Teroson VR500. Third group

— lubricants based on synthetic oil. These are the most universal compositions, since they are suitable not only for lubricating calipers, but also other elements of the car’s braking system. Lubricants are made from purified synthetic oil, as well as additives that have anti-corrosion, anti-oxidation, and anti-wear qualities. The composition also includes a thickener. Lubricants based on synthetic oil have excellent characteristics. They do not dissolve in water, brake fluid, alkalis and acids, do not evaporate, and also have dielectric properties. The operating temperature range is approximately -40° to +300°C. Examples of lubricants are Molykote AS-880N Grease, Permatex Ultra Disk Brake Caliper Lube, SLIPKOTE 220-R Silicone Disc Brake Caliper Grease and Noise Suppressor, SLIPKOTE 927 Disc Brake Caliper Grease.

The scope of their use is wide. They are used to lubricate sliding and rolling bearings, as well as other parts operating under conditions of high temperature and significant pressure.

One of the most popular types of pastes and sprays for calipers and guides are copper greases, which are a type of lubricant that uses metal. Let's look at it briefly.

2021 Addition

The Frenkit repair kit is in great demand . And very often the question comes up in letters: is there ATE mounting paste available in smaller packaging? Unfortunately, no, brake lubricant, ATE, is a service product and is sold in “professional packaging”, that is, this tube is enough to process and assemble approximately 20 front cylinders of a Niva. For a person who owns one car, and even a private mechanic, this is a very large portion. Use it once, and the tube lies restless. But since one of the goals of my sites is to improve the culture of repair work, I packaged this lubricant in 30 grams. This amount is quite enough to process and assemble 4 front cylinders. In the price list, this item is indicated by the word “packaging 30 grams.”

Why do you need lubrication?

During operation, the calipers are constantly exposed to:

- With dust and dirt

- With low and high temperatures

- With various road reagents

This system is a fragile structure in which the calipers move smoothly along the guides; the entire system is protected by anthers that prevent moisture, dust, and dirt from entering them. If you do not service them on time, or do not service them properly, then the entire system may fail; this MC-1600 lubricant is perfect for these purposes.

This lubricant was developed and created in a special scientific center called VMP-AUTO, and was presented as the first domestic universal lubricant for guides, which has no analogues, which would be comparable to it in its characteristics and properties. This product was also tested by such a leading service in Russia as Volk Brake Performance, as a result of which it was decided to use it in their services when repairing calipers.

Top 5 caliper lubricants

In first place are Molykote lubricants manufactured by Dow Corning. Despite the relatively high cost, the product is popular among car enthusiasts and professionals. In addition, the company has taken care of the accessibility of its products and produces them in small portions, packaged in tubes, bags, cans, and cans.

Molykote D-708 spray is an anti-friction coating containing polytetrafluoroethylene with an epoxy binder. Suitable for metal-to-metal and metal-to-plastic applications. Operates in a temperature range from -180 to 240°C. Upon application, the solvent evaporates and the binder hardens, forming a thin film that serves as a matrix for the fluoroplastic dispersion. As a result, the formed film acts as a protective and anti-friction coating on the part.

Heat-resistant paste Molykote Cu-7439 with a base of semi-synthetic oil and filler - copper dispersion. The composition contains additives to prevent sticking of metal elements. It is characterized by excellent load-bearing capacity, no dropping point, reduced evaporation, excellent adhesion and resistance to washout.

Molykote PG-54 silicone grease is intended for use in the temperature range -50...+180°C. Includes solid fillers for metal-plastic/rubber work. It is characterized by increased resistance to oxidation, leaching, aggressive influences, and also provides a low coefficient of friction.

Universal lubricants include the Efele brand product. Efele MG-212 lithium grease containing molybdenum disulfide is designed to work under conditions of high loads and temperatures. The load-bearing capacity of the material is comparable to lubricants for shock loads. Excellent resistance to water wash-off and suitable for parts exposed to dust and dirt. This option is an economical solution for processing the caliper under moderate vehicle use conditions (normal driving in urban conditions).

Weicon AL-M 400 universal long-acting lubricant is characterized by similar performance properties. It contains aluminum and molybdenum dispersion. The product is highly resistant to high pressure and is designed to protect exposed parts and guides.

Lubricant properties

It has received such recognition due to such excellent properties as:

- It does not lose its properties and functions at temperatures from -50 to 1000 degrees.

- Thanks to its excellent anti-corrosion properties, it prevents the formation of rust on calipers

- Protects all rubber components from deformation

- Resistant to water for long life

- Protects the entire brake system from dust and dirt

- Does not interact with substances such as DOT-3, DOT-4 and DOT 5.1

Types of lubricants

Classifying lubricants by type, they are divided into paste and spray. The car caliper can heat up to almost +300 C when driving outside the city in mountainous areas with heavy use of the brakes. In urban conditions, the caliper heats up to approximately +200 C. The calipers are not protected from external abrasive substances and moisture. In this connection, the lubricant for them must have good characteristics that ensure reliable operation of the devices.

Properties and characteristics of the lubricant:

- do not have acidity, that is, do not corrode metal and rubber;

- if water or brake fluid gets on it, it should not spread;

- withstand high temperatures, approximately +200 C;

- withstand severe frosts, up to approximately -35 C

- should not lose its properties.

Many people use cheap lubricants that do not have such effective physical and chemical characteristics.

Cheap lubricants include: litol (litol 24, litol 24RK, cyatim 201), graphite lubricant, nigrol, grease. Hence, smart drivers conclude that for reliable operation of the braking system it is better to use special lubricants for calipers and guides.

Classification by brand, that is, by manufacturers of fuels and lubricants:

- the first group of SMEs (mineral or synthetic pastes);

- the second group of PMM (mineral oil-based pastes);

- the third group is SSM (lubricant based on synthetic oil).

A feature of the first group, mineral and synthetic pastes using metals, is that they can withstand very high temperature conditions, about +180 ... +1000 C. Each type of lubricant has its own temperature range.

To make lubricants of the first group, mineral oil or synthetics are used, as well as thickeners, and also particles of the metal molybdenum or copper.

The first group of lubricants is divided into subgroups:

- Complex paste. The composition of the complex includes copper, aluminum and graphite powder.

- Copper. Copper paste contains copper and graphite powder.

- Paste without metal particles. Metal-free paste includes magnesium silicate and ceramic.

- Grease with copper or molybdenum disulfide.

As an example, I will give some brands of lubricants in this group:

Brands of the first subgroup (complex paste): Huskey 2000 Lubricating Paste and Anti-Seize Compound for High Temperature, Loctite No. 8060/8150/8151, Wurth AL 1100.

Brands of the second subgroup: HUSKEY (Husky) 341 Copper Anti-Seize, LIQUI MOLY Kupfer-Paste, Mannol Kupfer-Paste Super-Hafteffekt, Marly Cooper Compound, Molykote Cu-7439 Plus Paste, Motip Koperspray, Permatex Copper Anti-Seize Lubricant, Pingo Kupfer-Paste, Valvoline Cooper Spray, Wurth SU 800.

Brands of metal-free pastes: Husky number 400 Anti-Seize, TEXTAR Cera Tec, LIQUI MOLY Bremsen-Anti-Quietsch-Paste.

Brands of the fourth subgroup with molybdenum disulfide: HUSKEY Moly Paste, Assembly Lubricant & Anti-Seize Compound, Loctite No. 8012/8154/8155.

All pastes of the first group are applied to brake caliper pin guides and all surfaces with high friction friction. Who doesn't know, the surfaces of the brake pads are not lubricated.

The second group includes pastes based on mineral oil. This paste contains the thickener bentonite, metal particles and fatty acids. The operating temperature range of such a lubricant is -45 C ... +180 C. It follows from this that if you use this type of lubricant, then the car must be operated so as not to drive on steep slopes and frequent braking. This is, for example, the Teroson VR500/Teroson VR500 brand.

The third group of synthetic oil lubricants. It has excellent physical and chemical characteristics. Due to the fact that such a paste contains purified synthetics, a thickener and additives that protect against corrosion, oxidation and wear, this lubricant does not spread or evaporate, it is also not soluble in water and brake fluid, it is a dielectric, that is, it almost does not conduct electricity. Operating temperature -40 C… +300 C.

This group includes the following brands of manufacturers: Molykote AS-880N Grease, Permatex Ultra Disk Brake Caliper Lube, SLIPKOTE 220-R Silicone Disc Brake Caliper Grease and Noise Suppressor, SLIPKOTE 927 Disc Brake Caliper Grease.

What advantages does it have?

Any lubricant has its own advantages, this SV has the following:

- Prevents pads and other system elements from sticking

- Helps extend the life of all rubber components by protecting them from deformation and rapid degradation

- Facilitates the piston stroke and also ensures normal operation of cylinders that are already worn out.

- Reduces or completely eliminates squeaking brake pads

- Has excellent anti-corrosion properties, which reduces the appearance of rust

- Protects all elements from dirt, moisture and dust, this is especially true for those who use the Chevrolet Niva in extreme conditions

- It can be used at high power

- Due to the fact that this lubricant is universal, it can be used for any caliper elements.

- To completely treat all the pads, five grams is enough, which helps save money by at least one thousand rubles

- Helps increase pad life

What could be the disadvantages of universal formulations?

Avid car enthusiasts strive to “stuff” their garage with various devices and tools, so that they can then carry out the necessary repairs and maintenance themselves. The issue with lubrication is similar.

Such people purchase inexpensive graphite or copper lubricants, and then begin to use the product for any reason. Not everyone knows that if you apply copper grease to the pads, they will jam very quickly. To provide complete protection to the brake system, an ideal lubricant must have the following characteristics:

- successfully withstand high temperatures;

- do not dissolve in the brake fluid when lubricating the caliper pistons;

- maintain all declared properties even after exposure to moisture and auto chemicals from the road;

- do not harm rubber and plastic parts.

Multipurpose lubricants exist and work in a specific area. For the most part, such compounds are used in personal garage boxes. Professionals prefer to purchase TRW for calipers and guides.

How to properly lubricate a caliper

Let's take a step-by-step look at how to properly carry out the process of lubricating calipers

- The first thing you need to do is take a jack and install it under the car, then lift it with the jack so that you can remove the front wheels, and then the brake pads

- After the wheels and pads are removed, unscrew the special fixing screw at the top, while the pipe with the brake fluid does not need to be touched. Remove the bracket from the caliper; it is secured with screws.

- By gently pressing the brake pedal and removing the piston, pressing creates pressure that pushes the piston out. After it has been removed, close the fuel line to prevent dirt from getting there.

- When the caliper is disassembled, it needs to be cleaned, wiping off all dirt

- When everything is prepared and cleaned, you can begin to lubricate all elements of the system. It is advisable to replace the entire repair kit before this, this will help extend the service life of the entire system as a whole.

- We reassemble the caliper in reverse order.

Army and weapons

Let's continue. When replacing the silent blocks, I also changed the pads. The previous owner had rubber gaskets placed between the caliper and the bracket to prevent them from rattling. In my opinion, this is not a very good idea... since in this place the caliper is mobile and the rubber will interfere... IMHO of course, but this my opinion. On the second caliper, the inner pad was worn down to zero and the outer one was like new... Perhaps this was due to the fact that the caliper itself did not move but pressed only one pad with the cylinders. Maybe the rubber bands and the soured bracket played their roles. After reading a little, I decided to install these springs (from the VAZ 2108 gear retainers). There are 4 pieces in the set - accordingly, we need 2 sets.

.I bought the front pads from Nippon. Why? And it’s simple... along with the wheels, a person gave a set of rear pads to this particular company as a gift)) Plus, the store said that the pads were not bad. I also bought a set of axles for the calipers and, in the process, 1 bracket. And some grease for the calipers)

Let's start... jack up, remove the wheel, unsplint the axles on the calipers, knock out the top one and remove the top bracket. We take out the caliper and the old pads, simultaneously press in the cylinders on the caliper. And now the interesting thing... since when replacing the pads it is not necessary to remove the bottom bracket, the axle is in it it soured tightly on both sides and it was a problem to knock it out... the most interesting thing is that it soured in the bracket itself... I was able to knock one out, but when I tried to knock out the second bracket it burst ((I had to buy it.

We put it back together. I cleaned the holes for the axles everywhere and lubricated them with caliper grease. We insert new springs, install the bottom bracket and hammer in the axle. We install the pads.

I lubricated it everywhere where movement occurs. Well, except of course for the working surfaces of the pads))) We put the caliper itself in place and then it started)) We must simultaneously press the caliper, install a bracket with new springs and drive in the axle. By the way

-It’s better to sharpen the axis a little. In general, it’s a simple matter if you install standard springs. In general, with the help of a mounting tool, a hammer, sleight of hand and half an hour of swearing, it was accomplished and everything is in place.

We pin the axles, install the wheel and make the other side. When we go, don’t forget to press the brake a couple of times and check that there are no surprises. What can I say... there is no strumming... there is no creaking of the pads... I've been riding for more than a week and the car brakes amazingly. We'll see what happens with the uniform wear of the pads at this pressure of the brackets under the new springs. There was a desire to switch to other calipers (Gazelle or eight), but it gone. We really need to replace the brake discs, they were new from the previous owner, but they were bad (there was and still is a slight runout on the brake pedal). And there is one problem. There are reinforced hubs with a double-row bearing from Mazda... and lo and behold... to wave brake disc designed for 80t. km. It is necessary to change the bearing, designed for 100 tons. km.)))we'll decide)

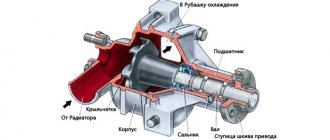

Rice. 8.6. Front wheel brake mechanism: 1 – cylinder block; 2 – brake pads;

3 – caliper clamping lever; 4 – protective casing; 5 – axis of the clamping lever; 6 – pad guide; 7 – brake caliper; 8 – brake

disk; 9 – fittings for removing air; 10 – brake hoses

The front wheel brake mechanism (Fig. 8.6) is a disc with a floating three-piston caliper. Cylinder block 1 is fixed in the caliper on two guides and secured with a spring retainer.

Brake pads 2 with steel bases having a figured shape, ensuring their tight fit to the pad guide. When installing the pads, spring-loaded levers 3 press the caliper 7 to the ends of the pads, which ensures constant pressing of the pads to the guide grooves.

Disassembling the front brake caliper Chevrolet Niva

Tools:

- Flat file

- Small hammer

- Hammer with plastic tip

- Vice with soft metal jaws

- Pliers

- Punch

Parts and consumables:

- Aerosol lubricant type WD-40

- Front caliper

Note:

The front brake cylinder block is replaced when brake fluid leaks through the O-rings, as well as when the pistons jam due to corrosion.

1. Remove the caliper from the vehicle as described.

2. Clamping the brake caliper in a vice with soft metal jaw linings, use a drift to remove the cylinder block retainer.

3. At the same time, we recess the cylinder block retainer with a rod with a diameter of 3-4 mm and, hitting the cylinder block with a hammer with a plastic tip, we begin to move the block along the caliper guides.

4. After moving the cylinder block by 1.5-2.0 mm, remove the rod. Using a hammer with a plastic tip or a mallet, knock out the cylinder block from the caliper guides. Cylinder block and brake caliper.

5. We remove the retainer and its spring from the socket of the brake cylinder block.

6. The retainer fits into the caliper hole and limits the movement of the cylinder block.

7. We assemble and install the front brake mechanism in the reverse order. To facilitate assembly, use a file to remove the chamfers from the guides of the cylinder block.

8. Having sunk the latch into the block socket, insert the block into the grooves of the caliper. Using a hammer with a plastic tip, hammer the cylinder block until the retainer fits into the caliper hole.

9. Install the caliper on the car.

10. Bleed the hydraulic brakes as described.